Abstract

In this work, pH/temperature dual-sensitive polymers of P(NVCL-co-MAA) with the increased low critical solution temperature (LCST) values of about 37 °C that differed from that of ~ 32 °C of pure poly(N-vinyl caprolactam) (PNVCL) were synthesized via radical polymerization. Then the nanofibers of P(NVCL-co-MAA) and its cospinned nanofibers with nifedipine (NIF) as drug model were fabricated by electrospinning method. Structures and the interactions within the components were detected by FT-IR, NMR, and XPS methods. The dual-responsive properties and the controlling release of the drug were investigated by water contact angle tests and in vitro drug release tested by UV-vis spectrophotometer. SEM was conducted to demonstrate the morphology of the nanofibers and the obvious improved stabilized morphology of the modified system within the aqueous media. The maintained morphology within the media and the obvious elongated releasing period of over 150 min at 37 °C and with pH of 1.99 both proved the promising prospects of the fabricated nanofibers as excellent carrier in drug delivery system.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As one kind of temperature-sensitive polymer, poly (N-vinyl caprolactam) (PNVCL) has been widely researched in recent years [1]. It could be transformed into sponge-like phase changes above the low critical solution temperature (LCST, at about 32 °C) and would result in the dehydration of solution with the increase of the temperatures. Eventually, it would occur that the phase separation and the hydrophilic PNVCL could be transferred to the hydrophobic material [2, 3]. Therefore, the characters would further contribute it to the potential applications as drug carrier and/or with function of temperature switch [4]. In addition, the unreleasing behaviors of any toxic amine molecules while hydrolyzing and the biocompatibility make it available for the application in biomedical research [5, 6], such as drug delivering, enzyme capturing, and tissue engineering. However, the relative lower LSCT values of PNVCL than that of human physiological temperature (37 °C) restricts it to be used in delivering medicines in the human body. Moreover, the single temperature-sensitive property would usually make it unsatisfied to meet the demands in many practical applications. Hence, the materials with adjustable LCST values and especially with multiple responsive properties to pH values [7], to magnetic [8] or light [9] response, are all currently underway researched.

Various shapes of PNVCL-based materials with potential applications as drug carriers have been fabricated, including nanogel [10], microgel [5], and nanofibers [11]. Electrospun nanofibers present the advantages of larger specific surface area and high porosity, which is beneficial to drug loading. Electrospinning, on one hand, is fast developing to coaxial [12], modified coaxial [13], tri-axial [14], side-by-side [15], and other multifluid processes [16]. On the other hand, many efforts have been spent on the creation of nanofibers on a large scale [17]. However, the filament-forming polymer matrices are always limited with a selection from slightly over 100 types, and thus new electrospinnable polymers are always highly desired to support the unspinnable fluids for expanding the capability of electrospinning [18]. As one kind of typical and common used drug model to treat angina and high blood pressure, nifedipine (NIF) has relative short effect period and thus usually it needed frequent intakes, which would enlarge the blood pressure variability and increase mortality of coronary heart disease (CHD) patients [19]. Nevertheless, the drug-loaded-sensitive PNVCL nanofibers fabricated by electrospinning could avoid the sudden release of drugs effectively, and with the on-off release characters during the transformation of nanofibers from hydrophobic to hydrophilic state [11]. Moreover, many research have been reported that, by the copolymers of NVCL monomer with other monomers, the LCST could be modulated effectively [20, 21].

It is known that pH values in different parts of the body are different, such as the values of pH in the stomach and intestines are about 1–3 and 6–7, respectively [22]. And by introducing pH-sensitive monomers into PNVCL, pH/temperature dual-sensitive system could be fabricated [23, 24] and the physical properties would be varied with the changing of pH values of medium or the temperatures of the environments [7, 25]. The structures of pH-sensitive monomers usually contain acidic or basic groups that can be ionized and can respond to the changing pH of the environment, these monomers include methacrylic acid (MAA) [26, 27], acrylic acid (AA) [28, 29], and maleic acid (MA) [30]. Moreover, some research have indicated that PNVCL polymerized with some hydrophilic monomers could increase its LCST values obviously [31]. Therefore, through polymerizing with such monomers, the LCST and hydrophobicity of PNVCL could be adjusted, and the synthesized copolymers could have promising applications as pH/temperature dual-sensitive drug delivery systems.

Here, in order to obtain pH/temperature dual-sensitive characters and to further improve the water stability and increase the LCST values to that close to 37 °C, we synthesized the polymers of P(NVCL-co-MAA) via radical polymerization, and fabricated the P(NVCL-co-MAA) nanofibers and P(NVCL-co-MAA)/NIF drug-loaded nanofibers by electrospinning method. The structure, morphology, and pH/temperature dual-sensitive and drug release behaviors from nanofibers have all been investigated in details. The results showed that P(NVCL-co-MAA) nanofibers with temperature/pH-responsive properties could be a useful drug carrier and have potential applications in the fields of wound healing and peroral treatment.

Experimental section

Materials

All the reagents used in this work were commercially available and used directly without further purification. Methacrylic acid (MAA, AR), dimethylformamide (DMF, AR), and methanol (99.5%) were provided by Xilong Chemical Co., Ltd. (Guangdong, China). N-vinylcaprolactam (NVCL, 98%) and 2,2′-Azobis(2-methylpropionitrile) (AIBN, 98%) were purchased from Aladdin Chemical Co., Ltd. (Shanghai, China). Nifedipine (NIF, AR) was obtained from Jianyuan Chemical Co., Ltd. (Wuhan, China).

Synthesis of PNVCL and P(NVCL-co-MAA)

The copolymers of P(NVCL-co-MAA) were synthesized via radical polymerization with different mass ratio of NVCL/MAA (90/10, 75/25, 65/35, and 60/40). A fixed amount of NVCL (5 g/mL) and a different amount of MAA (0.67, 2.00, 3.23, and 4.00 g) were dissolved completely in methanol (30 mL) and reacted in a sealed three-necked flask. Under a dry nitrogen atmosphere, the solutions in flask were heating to the temperatures of up to 70 °C, then AIBN (60 mg) was added as initiator. After stringing for 5 h at 70 °C and removing methanol by evaporation, the obtained copolymers of P(NVCL-co-MAA) were recrystallized by n-hexane for three times and dried at 50 °C overnight.

To compare with the copolymer, NVCL (6 g) was dissolved in 30-mL methanol and placed into a three-necked flask, after delivering N2 into flask and heating to 70 °C, AIBN (60 mg) was added as initiator. The following process was the same as the synthesis of copolymer. The obtained PNVCL had a weight-average molecular weight (MW) range from 26,400 to 9580 g mol−1.

Fabrication of nanofibers of copolymers and copolymers with NIF

The above-obtained PNVCL and P(NVCL-co-MAA) were respectively dissolved in DMF to prepared 0.5 mg/L concentrations solutions, then stirred for 3 h at room temperature to form homogeneous spinning solutions. To prepare the polymer nanofibers, the spinning solutions were refilled with 2-mL syringes connected to needles with diameter of 2 mm, then the electrospinning processes were carried out at a feeding rate of 0.9 mL/h, a collecting distance of 15 cm, a voltage of 15 kv, and at room temperature. By the same way, the drug-loaded nanofibers were prepared by mixing NIF with P(PNVCL-co-MAA), in which the mass percentage concentration of NIF was 4.2% within the spinning solutions, and then the electrospinning proceeded under the same parameters.

Structural characterizations, morphology observations, and dual-responsive behavior detection

Infrared spectra of PNVCL and P(NVCL-co-MAA) with KBr pellets were recorded on a FT-IR spectrometer (FT-IR, Perkin Elmer) in the range from 450 to 4000 cm−1. The chemical structure of polymers was analyzed by 1H NMR (Bruker AV400 spectrometer) in CDCl3.

X-ray photoelectron spectra of nanofibers were recorded on an ESCALAB 250 Xi (XPS, USA) using a standard source Al kα X-ray (12.5 kv and 250 w). Scanning electron microscopy (SEM, Merlin Compact, GER) was used to observe the morphology of electrospun nanofibers.

The pH/temperature dual-sensitive properties of polymers and fabricated nanofibers were investigated by UV-vis spectrometer (760CRT, INEAA, CN) and water contact angles (CA, JC-200, Shanghai Solon Information Technology, CN) detection, respectively.

The stabilities of the nanofibers in aqueous media and in vitro drug release test of NIF from the nanofibers

To further evaluate the possibilities of the release behavior of NIF in nanofibers, the stabilities of the nanofibers in aqueous media were detected by immersion experiments. Briefly, tiny droplets of ultra-pure water were dropped onto the nanofibers. Then after drying at 50 °C overnight, the morphologies of the nanofibers were observed by SEM images.

In order to simulate the physiological environment, the phosphate buffer saline (PBS) solutions with pH values of 1.99 were used for the drug release test. Five milligrams of the P(NVCL-co-MAA)/NIF nanofibers was immersed in 10 mL of above PBS solutions and then put into a shaker. At 37 °C and with selected intervals, the concentration of NIF in PBS solutions was detected by a UV-vis spectrometer at a wavelength of 332 nm, and the regressed standard equation of NIF was described as follows:

where A and c (μg/mL) are the absorbance and the concentration of NIF, respectively.

Under the same experimental conditions and intervals, three samples of NIF solution were being taken and the averaged concentration of NIF was obtained by UV-vis testing. Finally, the accumulated amount of the releasing NIF was calculated by the following equation:

where Q is the amount of NIF released (%), c is the concentration of NIF in PBS solution (μg/mL), w is the mass percentage concentration of NIF in nanofibers (wt%), and m is the weight of P(PNVCL-co-MAA)/NIF nanofibers (mg).

Result and discussion

Structure analysis

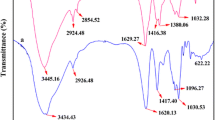

The chemical groups of synthesized P(NVCL-co-MAA) were investigated by FT-IR spectroscopy. As shown in Fig. 1a, compared with that of PVCL, for the spectrum of P(NVCL-co-MAA), a new peak appeared at 1729 cm−1 could be ascribed to the stretching vibration of -COOH that belonged to MAA [32]. While the spectrum of P(NVCL-co-MAA) also displayed the characteristic band of NVCL, the C=O with stretching vibration peak is at 1608 cm−1 [33], that indicated the successful polymerization of P(NVCL-co-MAA). Furthermore, after polymerization, the band of C=O occurred red-shifted compared with the spectrum of NVCL (1658 cm−1) (Fig. 1a), and there was no obvious absorption peak of -OH band in the spectrum of P(NVCL-co-MAA), suggesting the forming of intramolecular hydrogen bonds between the H atom of carboxyl (in NVCL) and O atom of carbonyls (in MAA) [11].

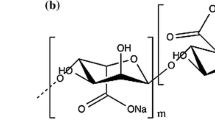

Moreover, drug-loaded nanofibers of PNVCL/NIF and P(NVCL-co-MAA)/NIF were fabricated by co-spinning of polymers with NIF. As FT-IR spectrum is shown in Fig. 1, after introducing NIF, PNVCL/NIF and P(NVCL-co-MAA)/NIF the characteristic peaks appeared at 1528 cm−1, associated with the stretching vibration of the benzene ring in NIF unite [34]. In addition, the NIF characteristic peaks in the co-spinned nanofibers weakened obviously, indicating the successful introduction of NIF into the electrospun nanofibers. Furthermore, comparing the spectrum of P(NVCL-co-MAA), the variety of the position and the intensity of C=O stretching vibration peak in P(NVCL-co-MAA)/NIF indicated the linkage of hydrogen bonds formed between the copolymer and NIF.

1H NMR spectrum was used to confirm the structure of P(NVCL-co-MAA) (Fig. 2). The δ at 1.74 ppm (peak f) resulted from methyl resonances of MAA units. In addition, the methylene resonances that connected with N on the C-C long chain directly appeared at 4.92 ppm (peak b) [11]. The δ at 3.22 and 2.48 ppm (peak c and d) were respectively ascribed to protons in methine (connected with N) and protons in methylene (connected with carbonyl) of the heterocyclic ring [35]. The protons in methylene group of C-C long chain and the protons in heterocyclic ring overlapped each other, and the δ was observed between 1.89 and 0.92 ppm (peak a and e) [36]. These results all suggested that P(NVCL-co-MAA) was prepared successfully. In addition, the mass ratio of NVCL and MAA in the co-polymers was calculated by the integration of the peak areas in 1H NMR spectrum, which was about 73:27 and different from the initial monomer ratio.

XPS analysis was used to investigate the surface element composition of P(NVCL-co-MAA) and P(NVCL-co-MAA)/NIF nanofibers, as shown in Fig. 3. Comparing the single peak of N 1 s in P(NVCL-co-MAA), there exhibited three peeks of N1s for P(NVCL-co-MAA)/NIF, the peaks at 397.7, 399.8, and 398.7 eV associated with nitrogen atom in heterocyclic ring [37], nitroso-group [38], and imino group [39], respectively. Moreover, after blending with NIF, the atomic concentration of N increased slightly from 3.3 to 3.72%, might probably owe to the existence of the NIF particles within the nanofibers, rather than the attachment to the outside of the nanofibers.

Morphology, water stability, and pH/temperature-responsive behavior

As shown in Fig. 4, the SEM observation was conducted to explore the morphology of nanofibers, and the fiber diameter distribution was calculated through SEM images using the Nano Measure software. The PNVCL nanofibers were smooth and uniform with average diameters of about 0.43 μm, while the P(NVCL-co-MAA) with 90/10, 75/25, and 60/40 weight ratios nanofiber showed un-smooth, bending characters, and with some droplets. In addition, the P(NVCL-co-MAA) with 65/35 weight ratio nanofiber’s morphology was uniform without the formation of droplets, in which a single independent fiber could be observed and the average diameter was about 1.76 μm. Hence, P(NVCL-co-MAA) (65/35 weight ratios) was used to fabricate the drug-loaded nanofibers.

Subsequently, to explore the hydrophilic characteristic of PNVCL and P(NVCL-co-MAA) that changes with temperature, contact angles tests were taken at 25 °C and 40 °C, and for the same fibrous membrane, the samples were tested for three times and then an average value was calculated. As shown in Fig. 5, when temperature changed from 25 to 40 °C, the contact angles on the surface of PNVCL and P(NVCL-co-MAA) nanofiber films increased obviously, which revealed that both of these polymers showed temperature-sensitive property. Moreover, the difference of the contact angles for the polymer with 90/10 weight ratios was the most obvious ones; therefore, the sample was used for further dual-responsive behaviors detection. Although as hydrophilic monomer for MAA, P(NVCL-co-MAA) was more hydrophobic with higher contact angles while testing compared with that of PNVCL, which might due to most of the carboxyl in MAA unite could form intramolecular hydrogen bond, this result was in good consistency with the analysis from FI-IR.

The transmittance at different temperatures of the PNVCL and P(NVCL-co-MAA) nanofibers was studied by ultraviolet spectra analysis and the target wavelength during detection determination was set as 500 nm (as shown in Fig. 6a). Hence, the LCST of P(NVCL-co-MAA) was 36.8 °C, higher than that of PNVCL (32 °C). By adjusting the pH values, the LCST of P(NVCL-co-MAA) could be changed theoretically owing to the existence of MAA. Then, the transmission spectrum curves of P(NVCL-co-MAA) at different pH values in PBS solutions were detected. As shown in Fig. 6b, the LCST values of copolymer were 36.4, 36.8, and 34.1 °C when pH was 1.99, 5.20, and 7.40, respectively. Consequently, it could be seen that introducing MAA could not only increase the LCST values of copolymer to the value of 37 °C, much more make the temperature close to the physiological temperature of human body, but also add the pH-responsive property into the fabricated system. Thus, copolymer of P(NVCL-co-MAA) was pH/temperature dual sensitive through changing the temperature or pH values.

The stabilities and the controlled drug release behavior detection

The stabilities of the nanofibers in aqueous media were one of the conditions that were applied in drug releasing. In this work, the morphography of nanofibers with and without the contacting of water were observed by SEM images. As shown in Fig. 7a and b, PNVCL and PNVCL/NIF nanofibers contacting with water were dissolved rapidly and thoroughly. Hence, the PNVCL/NIF nanofibers were uneasy to maintain in the morphology within the aqueous solution, and thus difficult to control in releasing the drug. Contrary to that of PNVCL and PNVCL/NIF nanofibers, the morphology of P(NVCL-co-MAA) and P(NVCL-co-MAA)/NIF nanofibers (Fig. 7c and d, respectively) kept the original morphology mostly after contacting with water. Therefore, polymerization with MAA could improve the hydrophobicity and the stability of PNVCL in the aqueous solution that provides the possibility of the nanofibers to be used within aqueous solution.

To further investigate the release behavior of NIF from P(NVCL-co-MAA)/NIF nanofibers, the changes of absorbance were detected within 150 min at 37 °C and with pH of 1.99, then the cumulative release of NIF doses were calculated. As seen from the release curve (Fig. 8a), the NIF release reached 33.4% within 10 min. With the increasing time, the rates of drug release decreased gradually. Until the time was that from 135 to 150 min, the cumulative drug release reached 68.9% without further obvious increasing. In conclusion, the drug-loaded P(NVCL-co-MAA)/NIF nanofibers kept fiber morphology stable at 37 °C and with pH of 1.99, and NIF sustained release at certain time, which effectively controlled the drug release and could keep for more than 150 min. Thus, P(NVCL-co-MAA)/NIF electrospun nanofibers with pH/temperature dual-sensitive property had potential application in drug-releasing system and could effectively control the drug release.

Conclusions

Here, we successfully synthesized the pH/temperature dual-sensitive copolymers of P(NVCL-co-MAA) via radical polymerization, then the nanofibers and drug-loaded nanofibers were fabricated by electrospinning. The introduction of MAA contributes to the system of P(NVCL-co-MAA) pH/temperature sensitive and with improved LCST values at about 37 °C. Moreover, the P(NVCL-co-MAA) nanofibers had a better water stability that differed from pure PNVCL nanofibers obviously. In addition, after blending with NIF, the morphology of P(NVCL-co-MAA)/NIF nanofibers was in smooth, uniform morphology and was of stability while contacting with water. The release behavior of NIF from P(NVCL-co-MAA)/NIF nanofibers showed an elongated and continuous releasing, and the cumulative drug release reached 68.9% at 150 min, which implied that the pH/temperature dual-sensitive P(NVCL-co-MAA) nanofibers could control the drug release effectively and had potential applications in drug carriers and delivery systems.

References

Siirila J, Hakkinen S, Tenhu H (2019) The emulsion polymerization induced self-assembly of a thermoresponsive polymer poly(N-vinylcaprolactam). Polym Chem 10:766–775

Lozinsky VI, Simenel IA, Kurskaya EA, Kulakova VK, Galaev IY, Mattiasson B, Grinberg VY, Grinberg NV, Khokhlov AR (2000) Synthesis of N-vinylcaprolactam polymers in water-containing media. Polymer 41:6507–6518

Halligan SC, Dalton MB, Murray KA, Dong Y, Wang W, Lyons JG, Geever LM (2017) Synthesis, characterisation and phase transition behaviour of temperature-responsive physically crosslinked poly(N-vinylcaprolactam) based polymers for biomedical applications. Mater Sci Eng C Mater 79:130–139

Mohammed MN, Bin YK, Shariffuddin JHBH (2018) Poly(N-vinyl caprolactam) thermoresponsive polymer in novel drug delivery systems: a review. Mater Express 8:21–34

Rao KM, Rao KSVK, Ha CS (2016) Stimuli responsive poly(vinyl caprolactam) gels for biomedical applications. Gels 2:1

Liu J, Debuigne A, Detrembleur C, Jerome C (2014) Poly(N-vinylcaprolactam): a thermoresponsive macromolecule with promising future in biomedical field. Adv Healthc Mater 3:1941–1968

Li H, Liu K, Williams GR, Wu J, Wu J, Wang H, Niu S, Zhu LM (2018) Dual temperature and pH responsive nanofiber formulations prepared by electrospinning. Colloid Surface B 171:142–149

Amantea BE, Piazza RD, Chacon JRV, Santos CC, Costa TP, Rocha CO, Brandt JV, Godoi DRM, Jafelicci M, Marques RFC (2019) Esterification influence in thermosensitive behavior of copolymers PNIPAm-co-PAA and PNVCL-co-PAA in magnetic nanoparticles surface. Colloid Surface A 575:18–26

Siirila J, Karesoja M, Pulkkinen P, Malho JM, Tenhu H (2019) Soft poly(N-vinylcaprolactam) nanogels surface-decorated with AuNPs response to temperature, light, and RF-field. Eur Polym J 115:59–69

Gonzalez AMA, Cortez LNA, Zizumbo LA, Licea CA (2014) Nanogels of poly(N-vinylcaprolactam) core and polyethyleneglycol shell by surfactant free emulsion polymerization. Soft Mater 12:315–325

Liu L, Bai S, Yang H, Li S, Quan J, Zhu L, Nie H (2016) Controlled release from thermo-sensitive PNVCL-co-MAA electrospun nanofibers: the effects of hydrophilicity/hydrophobicity of a drug. Mater Sci Eng C Mater 67:581–589

Wang M, Hai T, Feng ZB, Yu GD, Yang YY, Annie Bligh SW (2019) The relationships between the working fluids, process characteristics and products from the modified coaxial electrospinning of zein. Polymers 11:1287

Zhou HL, Shi ZR, Wan X, Fang HL, Yu DG, Chen XH, Liu P (2019) The relationships between process parameters and polymeric nanofibers fabricated using a modified coaxial electrospinning. Nanomaterials 9:843

Zhao K, Wang W, Yang YY, Wang K, Yu DG (2019) From Taylor cone to solid nanofiber in tri-axial electrospinning: size relationships. Results Phys 15:102770

Yu DG, Li JJ, Zhang M, Williams GR (2017) High-quality Janus nanofibers prepared using three-fluid electrospinning. Chem Commun 53:4542–4545

Yu DG, Wang ML, Li XY, Liu XK, Zhu LM, Bligh SWA (2019) Multifluid electrospinning for the generation of complex nanostructures. Wiley Interdiscip Rev Nanomed Nanobiotechnol. https://doi.org/10.1002/wnan.1601

Yu DG, Li JJ, Williams GR, Zhao M (2018) Electrospun amorphous solid dispersions of poorly water-soluble drugs: a review. J Control Release 292:91–110

Wang ML, Wang K, Yang YY, Liu YN, Yu DG (2020) Electrospun environment remediation nanofibers using unspinnable liquids as the sheath fluids: a review. Polymers 12:103

Souviron RA, Martinez MM (1992) Captopril + hydrochlorothiazide versus captopril + nifedipine in the treatment of arterial hypertension in diabetes mellitus type II. Rev Esp Cardiol 45:432–437

Durkut S, Elcin YM (2017) Synthesis and characterization of thermosensitive poly(N-vinylcaprolactam)-g-collagen. Artif Cell Nanomed B 45:1665–1674

Phetrong S, Sansuk C, Tangboriboonrat P, Paoprasert P (2017) Temperature-responsive crosslinked materials prepared from natural rubber and poly(N-vinylcaprolactam). Macromol Res 25:799–805

Liu L, Yao W, Rao Y, Lu X, Gao J (2017) pH-responsive carriers for oral drug delivery: challenges and opportunities of current platforms. Drug Deliv 24:569–581

Indulekha S, Arunkumar P, Bahadur D, Srivastava R (2017) Dual responsive magnetic composite nanogels for thermo-chemotherapy. Colloid Surface B 155:304–313

Rejinold NS, Baby T, Chennazhi KP, Jayakumar R (2015) Multi drug loaded thermo-responsive fibrinogen-graft-poly(N-vinyl caprolactam) nanogels for breast cancer drug delivery. J Biomed Nanotechnol 11:392–402

Wu Q, Tang X, Liu X, Hou Y, Li H, Yang C, Yi J, Song X, Zhang G (2016) Thermo/pH dual responsive mixed-shell polymeric micelles based on the complementary multiple hydrogen bonds for drug delivery. Chem Asian J 11:112–119

Wang K, Xu X, Wang Y, Guo G, Huang M, Luo F, Zhao X, Wei Y, Qian Z (2010) In vitro release behavior of bovine serum albumin from alginate/P(CE-MAA-MEG) composite hydrogel. Soft Mater 8:307–319

Yang J, Kim B (2013) Effect of pH-sensitive P(MAA-co-PEGMA) hydrogels on release and stability of albumin. Polym-Korea 37:262–268

Chen Y, Sun P (2019) pH-sensitive polyampholyte microgels of poly(acrylic acid-co-vinylamine) as injectable hydrogel for controlled drug release. Polymers 11

Dong Y, Jin Y, Wang J, Shu J, Zhang M (2017) Pd nanoparticles stabilized by a simple pH-sensitive P(acrylamide-co-acrylic acid) copolymer: a recyclable and highly active catalyst system in aqueous medium. Chem Eng J 324:303–312

Constantin M, Bucatariu S, Harabagiu V, Popescu I, Ascenzi P, Fundueanu G (2014) Poly(N-isopropylacrylamide-co-methacrylic acid) pH/thermo-responsive porous hydrogels as self-regulated drug delivery system. Eur J Pharm Sci 62:86–95

Meeussen F, Bauwens Y, Moerkerke R, Nies E, Berghmans H (2000) Molecular complex formation in the system poly(vinyl methyl ether)/water. Polymer 41:3737–3743

Tian ZF, Yu X, Ruan ZJ, Zhu M, Zhu YF, Hanagata N (2018) Magnetic mesoporous silica nanoparticles coated with thermo-responsive copolymer for potential chemo- and magnetic hyperthermia therapy. Microporous Mesoporous Mater 256:1–9

Hurtgen M, Liu J, Debuigne A, Jerome C, Detrembleur C (2012) Synthesis of thermo-responsive poly(N-vinylcaprolactam)-containing block copolymers by cobalt-mediated radical polymerization. J Polym Sci Polym Chem 50:400–408

Chan KLA, Kazarian SG (2004) FTIR spectroscopic imaging of dissolution of a solid dispersion of nifedipine in poly(ethylene glycol). Mol Pharm 1:331–335

Prabaharan M, Grailer JJ, Steeber DA, Gong SQ (2008) Stimuli-responsive chitosan-graft-poly(N-vinylcaprolactam) as a promising material for controlled hydrophobic drug delivery. Macromol Biosci 8:843–851

Lin X, Tang D, Yu Z, Feng Q (2014) Stimuli-responsive electrospun nanofibers from poly(N-isopropylacrylamide)-co-poly(acrylic acid) copolymer and polyurethane. J Mater Chem B 2:651–658

Liu W, Zhang L, Liu X, Liu X, Yang X, Miao S, Wang W, Wang A, Zhang T (2017) Discriminating catalytically active FeNx species of atomically dispersed Fe-N-C catalyst for selective oxidation of the C-H bond. J Am Chem Soc 139:10790–10798

Urzua J, Carbajo J, Yanez C, Marco JF, Squella JA (2016) Electrochemistry and XPS of 2,7-dinitro-9-fluorenone immobilized on multi-walled carbon nanotubes. J Solid State Electrochem 20:1131–1137

Han W, Muller C, Vogt D, Niemantsverdriet H, Thune PC (2006) Introducing a flat model of the silica-supported bis(imino)pyridyl iron(II) polyolefin catalyst. Macromol Rapid Commun 27:279–283

Acknowledgments

The authors are grateful for the Excellent Academic Leaders Foundation of Harbin, China (No. 2014RFXXJ017).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, X., Li, W., Sun, Z. et al. Electrospun P(NVCL-co-MAA) nanofibers and their pH/temperature dual-response drug release profiles. Colloid Polym Sci 298, 629–636 (2020). https://doi.org/10.1007/s00396-020-04647-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04647-y