Abstract

An efficient, green, novel and rapid vortex-assisted dispersive solid-phase extraction (VADSPE) technique was used for the preconcentration and determination of trace levels of Cu2+ followed by flame atomic absorption spectrometry. Graphene oxide (GO) was synthesized from graphite and then modified by pectic acid (poly-d-galacturonic acid, PA) to synthesize the pectic acid–graphene oxide (PA-GO) nanocomposite. The Fourier transform infrared spectrophotometry, field emission scanning electron microcopy, energy-dispersive X-ray spectroscopy and X-ray diffraction analysis were used to characterize the synthesized GO-PA nanocomposite. By using VADSPE technique, PA-GO was used as an adsorbent for preconcentration of Cu2+. The main parameters affecting the extraction recovery, including pH of the sample solution, amounts of adsorbent, extraction time, type and concentration of desorbent solvent and desorption time were completely investigated and optimized. Under the optimum conditions, the results show that the proposed method has the linearity range of 10–300 µg L−1 with a correlation coefficient of 0.9950. The limit of detection based on six replicate analyses of the blank sample was 2.22 µg L−1, and the relative standard deviation was 2.7% for the five replicate analysis of 50 µg L−1 Cu2+. The validity of the proposed method was checked by the analysis of two certified reference materials including CRM-TMDW and GBW07605 tea samples, and then, the proposed method was successfully applied for the determination of trace levels of Cu2+ in different water and food samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copper (Cu) is an essential element for the human body. It is the constituent of the respiratory enzyme, cytochrome C oxidase and also necessary for neuropeptide synthesis and immune function [1]. However, its high concentration in the human body could damage the liver and kidney [2]. Up to now, different analytical tools were used for the determination of Cu including atomic absorption spectrometry [3, 4], electrochemical methods [5, 6], inductively coupled plasma optical emission spectrometry [7, 8] and UV–Vis spectrophotometry [9, 10]. Flame atomic absorption spectrometry (FAAS) is the most common analytical technique with advantages such as simplicity, non-expensively and selectivity [11, 12]. However, the matrix effect is the main parameter affecting the accuracy of the results, especially at trace levels. Therefore, to obtain the maximum sensitivity for the determination of analyte, the application of the sample preparation step is inevitable. Up to now, different preconcentration techniques including solid-phase extraction [13,14,15,16,17], vortex-assisted liquid-phase extraction [18], ultrasonic-assisted liquid-phase microextraction [19], dispersive liquid–liquid microextraction [20] and cloud point extraction [21] were used for preconcentration of Cu2+. Among them, solid-phase extraction is more favorable due to the advantages such as a variety of adsorbents, easy to use, able to automation and high preconcentration factor [22]. Graphene oxide (GO) with unique properties such as high surface area, high mechanical and electrical properties could be easily prepared from graphite [23]. Also, the existence of hydroxyl, epoxy and carboxylic groups on the surface of GO provides conditions to modify its surface with different functional groups for many approaches such as adsorption of environmental pollutants [24,25,26]. Pectic acid (PA) known as the poly-d-galacturonic acid is an organic acid existing in fruits and vegetables. Its structure in Fig. 1 shows functional groups (carboxylic groups, hydroxyl and ether), which act as donor electron groups to interact with cationic materials such as heavy metals. Therefore, it could be considered as a good candidate for modification of GO nanosheets.

The aim of the proposed work is to synthesize the GO from graphite using Hummer method and then modify its surface with pectic acid to synthesize the GO-PA nanocomposite. The X-ray diffraction spectroscopy (XRD), Fourier transform infrared spectrophotometry (FTIR), energy-dispersive X-ray spectroscopy (EDX) and field emission scanning electron microscopy (FESEM) were used to characterize the synthesized GO-PA nanocomposite. Then, by using the vortex-assisted dispersive solid-phase extraction (VADSPE) technique, GO-PA was used as an adsorbent for preconcentration of trace levels of Cu2+ followed by FAAS detection. Based on our knowledge, up to now, no paper reported the modification of GO with PA and its use for the preconcentration of heavy metals. The parameters affecting the extraction recovery including pH of the sample solution, amounts of adsorbent, extraction time, type and concentration of desorbent solvent and desorption time were studied and optimized. Finally, the proposed method was applied for the determination of trace levels of Cu2+ in different water and food samples.

Experimental

Reagents

Deionized water was used to make solutions. Pectic acid from apple (PA, CAS number: 9046-40-6) was purchased from Sigma-Aldrich, Missouri, USA. A solution of 1000 mg L−1 Cu2+ was prepared from Cu(NO3)2·3H2O (Merck, Darmstadt, Germany), and working solutions were prepared daily by dilution of the stock solution in deionized water. Graphite (Merck, Darmstadt, Germany) was used for synthesizing the GO, and the reagents including H2SO4 (98%, Merck, Germany), NaNO3 (99.0–100.5%, Merck, Germany), KMnO4 (99.0–100.5%, Merck, Germany) and H2O2 (30%, Sigma-Aldrich, USA) were used for the oxidation of graphite to the graphite oxide.

Instrument

PerkinElmer HGA 700 flame atomic absorption spectrometry (acetylene as fuel and air as an oxidant) was used for the measurement of Cu equipped with hollow cathode lamp (Cu, 324.8 nm) operated at 12 mA and 0.7 nm monochromator bandpass. A Metrohm 827 pH meter (Switzerland) was used for the measurement of pH values, and a centrifuge (Andreas Hettich D72, Germany) was used for the separation of adsorbent from the sample solution. An AVATAR 370 (USA) FTIR instrument was used to record the FTIR spectrums of GO and GO-PA nanocomposite. The XRD spectrums of the synthesized GO and GO-PA were obtained from the D8-Advance Bruker CuKα1 (λ = 0.15406 nm) instrument. Also, field emission scanning electron microscope (FESEM, TESCAN BRNO-Mira3 LMU, Czech Republic) was used to study the morphology of the synthesized GO-PA nanocomposite.

Synthesis of GO

Graphene oxide was synthesized according to the Hummer method as our research team reported in our previous research paper [23]: One gram of graphite powder was weighted and transferred into the beaker. Then, an aliquot of 23 mL concentrated H2SO4 was added slowly to it. The mixture was stirred in an ice bath for 30 min followed by the addition of 0.5 g NaNO3 and stirring for 30 min at 15–20 °C. To oxidize the graphite, 3 g KMnO4 was added within 1 h into the mixture and stirred for 90 min, and then, it was heated to 35 °C followed by stirring at this temperature for 120 min. Finally, after addition of 100 mL deionized water, an aliquot of 5 mL H2O2 was added into the mixture, which causes to change its color to green. The synthesized graphite oxide was centrifuged at 3500 rpm for 10 min, washed with deionized water (to obtain the pH of 6–7 for the supernatant) and then ultrasonicated for 1 h to obtain GO nanosheets.

Synthesis of GO-PA nanocomposite

To synthesize, 0.4 g of GO was dispersed in 100 mL of 0.1 mol L−1 Tris buffer solution adjusted at the pH of 8. Then, 50 mL of 0.4% (w/v) PA in deionized water was added into the mixture followed by stirring for 5 h. The synthesized GO-PA nanocomposite was centrifuged at 3500 rpm, washed with deionized water three times and dried at 50 °C for 12 h.

Preparation of real samples

Water samples

Different water samples, including tap (Mashhad, Iran), river (Kashaf Rood and Golmakan Mashhad, Iran) and spring water (Nowchah, Mashhad, Iran), were analyzed freshly as follows:

An aliquot of 10 mL of each sample solution was adjusted at the optimum pH value of 5.5 and analyzed for its Cu2+ content according to the preconcentration procedure.

Food samples

Sampling

Different food samples with the abundant use in Mashhad, Iran, including, black tea, red lentil, wheat and sesame, were selected. For the sampling, 500 g of the most usable brand from each sample was purchased randomly from five local supermarkets, and after mixing them and crashing to obtain a uniform sample, about 2 g of each sample was digested and analyzed for its copper content as follows:

The weighed sample was transferred into the crucible followed by heating at 400 °C for 3 h. After it was cooled, an aliquot of 2.5 mL concentrated HNO3 was added into the residue and heated at 60–70 °C for 10 min. Then, it was diluted to 25 mL with deionized water, and finally, an aliquot of 1 mL from each sample was adjusted at the pH of 5.5 and analyzed for its Cu content according to the preconcentration procedure.

Preconcentration procedure

To the 10 mL of a sample solution containing 50 µg L−1 Cu2+ adjusted at the optimum pH value of 5.5, an aliquot of 1 mL deionized water containing 5 mg GO-PA nanocomposite was injected. The resulting mixture was vortexed for 10 min at 2800 rpm and then centrifuged at 3500 rpm for 5 min. The supernatant was removed completely by a 2-mL syringe, and then, 400 µL of 1.0 mol L−1 HNO3 as a desorbent solution was added to the mixture and vortexed for 5 min. Finally, by centrifuging the mixture for another 5 min, the supernatant was aspirated into the FAAS for Cu quantification. Extraction recovery was calculated according to Eq. 1, where Cds and Css are the concentrations of analyte in the desorbent solution and sample solution, respectively, and also, Vds is the volume of desorbent solution (mL) and Vss is the volume of sample solution (mL).

Results and discussion

Characterization of adsorbent

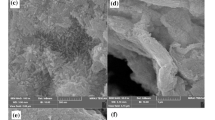

The synthesized GO-PA nanocomposite was characterized by FTIR spectrophotometry, FESEM images, EDX analysis and XRD spectroscopy. The FTIR spectrums of GO and the synthesized GO-PA nanocomposite are shown in Fig. 2. As it was reported by our research group [23], the peaks at 3400 cm−1, 1220 cm−1, 1050 cm−1, 1730 cm−1 and 1650 cm−1 are related to the stretching vibrations of O–H, epoxy, C–O, carbonyl (C=O) and C=C groups, respectively. However, as it could be seen, the intensity of epoxy ring in the GO-PA nanocomposite decreases, which could be described by the SN2 reaction between the nucleophilic groups on the PA molecules and the epoxy rings of GO. This reaction causes the chemical bonding of PA on the GO nanosheets. The FESEM images of the synthesized GO and GO-PA nanocomposite are shown in Fig. 3. Based on the results, the roughness of GO nanosheets changed after it was modified by PA molecules. Also, the EDX analysis of GO and GO-PA nanocomposite (Fig. 4) shows 52.87% C for GO; however, in the case of GO-PA, the elemental analysis shows 59.11% C. Finally, XRD analysis was performed on the GO and GO-PA nanocomposite (Fig. 5). The XRD pattern of the GO shows the main diffraction peak at 2θ = 10.9°, which corresponds to the 0 0 2 plane. However, after its modification with PA molecules, the peaks around 2θ = 15°–20° and 2θ = 30°–40° appeared in the spectrum related to the crystallinity of pectic acid [27, 28]. The obtained results clearly show that the modification of GO with PA molecules was performed successfully.

Effect of pH

Due to the effect of pH of sample solution on the ionization or protonation of the functional groups on the adsorbent, this parameter could be considered as the critical parameter on the extraction recovery of Cu2+. By using GO-PA nanocomposite as an adsorbent, there are two main mechanisms for the adsorption of Cu2+: (1) electrostatic attraction of Cu2+ on the negatively charged sites on the GO-PA adsorbent (carboxylic groups on PA molecules) and (2) ion–dipolar interaction between Cu2+ and hydroxyl groups. The effect of pH on the extraction recovery of Cu2+ was studied in the range of 2–9, and the results are presented in Fig. 6. As it could be seen, by increasing the pH of the sample solution, the extraction recovery of Cu2+ increases and reaches its maximum value at the pH of 5–6. However, higher pH values cause to decrease in the extraction recovery, which could be due to the formation of copper hydroxide in the sample solution. Also, in acidic solution (pH values lower than 3), the decrease in the extraction recovery of Cu2+ could be due to the protonation of the hydroxyl groups of GO-PA adsorbent, and therefore, the repulsion between Cu2+ and the positively charged GO-PA nanocomposite causes decrease in the extraction recovery. Therefore, for further experiments, a pH value of 5.5 was selected as the optimum value.

Effect of the amounts in GO-PA nanocomposite

In this research, VADSPE was used as the extraction technique for the solid-phase extraction of Cu2+. Therefore, to the 1 mL of deionized water, different amounts of GO-PA, 2–8 mg GO-PA, were added, and the mixtures were ultrasonicated for 2 min. Then, by injection of them into the sample solutions, the resulting mixtures were vortexed at 2800 rpm for 10 min. The results in Fig. 7 show the variation of the extraction recovery of Cu2+ by changing of the amounts of GO-PA adsorbent. As it could be seen, the maximum extraction recovery was obtained in the range of 5–7 mg adsorbent. Therefore, for further experiments, 1 mL of deionized water containing 5 mg GO-PA nanocomposite was selected as the optimum value.

Effect of extraction time

The agitation of sample solution was performed by using a vortex agitator system operated at 2800 rpm. The produced vortex stream causes increase in the diffusion of the analyte onto the adsorbent, and therefore, the preconcentration of analyte takes place at a short time. The effect of vortex time on the extraction recovery of analyte was studied in the range of 5–20 min. The results in Fig. 8 show that 10-min extraction time provides the maximum extraction recovery for the determination of Cu2+. Therefore, for further experiments, 10-min vortex time was considered as the optimum value.

Effect of type and concentration of the desorbent solution

To desorb the Cu2+ from the adsorbent, different desorbent solutions including HCl, HNO3, CH3COOH and HCOOH with the concentrations of 0.5, 1.0 and 2.0 mol L−1 were added to the adsorbent, and the resulting mixtures were vortexed at 2800 rpm for 5 min. The results show that solutions of 1.0 and 2.0 mol L−1 HNO3 provide the maximum extraction efficiency for the determination of Cu2+. Therefore, a solution of 1.0 mol L−1 HNO3 was selected as the optimum desorbing solvent.

Effect of ionic strength

The effect of the ionic strength of the sample solution was checked by the addition of the solutions of NaCl and NaNO3 in the range of 0–1% (w/v). The results show that the extraction recovery of analyte remains constant up to 0.3% NaCl and 0.5% NaNO3. Therefore, the proposed VADSPE technique could be successfully applied for the determination of Cu2+ in the solutions containing sodium chloride and sodium nitrate salts.

Effect of interfering ions

As FAAS technique has inherent selectivity for measurement of heavy metals, it could be expected that the interferences start from the preconcentration step. Herein, the effects of different cation and anions on the extraction recovery of Cu2+ were studied in the presence of fix amounts of analyte, and the obtained results are presented in Table 1. Based on the results, the proposed method has very good tolerance limit toward other ions, which makes it a good adsorbent for solid-phase extraction of Cu2+.

Analytical figure of merit

The calibration curve for the determination of Cu2+ was determined in the range of 10–300 µg L−1 with a correlation coefficient of 0.9950. Its equation was A = 0.0015CCu2+ + 0.0053, where CCu2+ is the concentration of Cu2+ in µg L−1, and A is the absorbance of the analyte. The limit of detection (LOD) for the six-time replication of the blank sample was 2.22 µg L−1 (3Sb/m, where Sb is the standard deviation of the blank and m is the slope of the calibration curve after preconcentration step), and the relative standard deviation (RSD, %) for five replicate analyses of the sample solution containing 50 µg L−1 Cu2+ was 2.7%. The preconcentration factor (Eq. 2) was equal to 25, which can be calculated from the ratio of the volume of sample solution (Vss, 10 mL) to the volume of desorbent solvent injected into the FAAS (Vds, 0.4 mL).

Also, the enhancement factor was 21.6, which can be obtained from the ratio of the slope of the calibration curve after preconcentration step (slope = 0.0015) to that before the preconcentration step (A = 0.0695CCu2+ − 0.0072).

Analysis of real samples

The accuracy of the proposed method was checked by the analysis of two certified reference materials including CRM-TMDW (certified value of 20 µg L−1) and GBW07605 tea sample (certified value of 17.3 ± 0.3 µg g−1 Cu2+). By using the VADSPE technique and to analyze the CRM samples, the obtained values are 19.2 ± 1.23 µg L−1 and 16.8 ± 1.02 µg g−1 Cu2+ for CRM-TMDW and GBW07605 tea sample, respectively. Student’s t test, which is expressed in Eq. 3 (where X is the sample mean, µ is the population mean, N is the size of sample and S is the standard deviation), was performed on the obtained results, and the calculated t values (tcal) are 1.45 and 1.10 for CRM-TMDW and GBW07605 tea samples, respectively (N = 5) which show that the calculated t values are lower than the ttable = 2.13 (df = 4, 95% confidence limit).

Therefore, the obtained results for the analysis of CRM samples are in consistent with the certified values. Also, the applicability of the proposed method was checked by the analysis of different real samples, including water and food samples. The results are presented in Tables 2 and 3. Spike tests were also performed on the samples to check the validity of the obtained results. As it could be seen, the proposed method could be successfully applied for the determination of Cu2+ in different water and food samples.

Comparison with other methods

The proposed VADSPE technique was compared by other analytical methods for the determination of Cu2+, and the results are presented in Table 4. As it could be seen, the wide linearity range, short analysis time, green aspect of adsorbent, high efficiency and good precision are the main advantages of the proposed method.

Conclusion

The proposed paper describes the use of vortex-assisted dispersive solid-phase extraction technique (VADSPE) for preconcentration of trace levels of Cu2+ followed by its determination using flame atomic absorption spectrometry. Pectic acid-coated graphene oxide nanocomposite (PA-GO) was used as a novel adsorbent and characterized by FTIR spectrophotometry, FESEM, EDX and XRD analysis. By optimization of the parameters affecting the extraction recovery of Cu2+, the linearity range and the analytical figures of merit were determined. Based on the results, wide linear range (10–300 µg L−1), novelty and green aspect of the synthesized adsorbent, high rapidity (10-min extraction time), simplicity and high efficiency are the main advantages of this SPE method. The validity of the proposed method was successfully checked by the analysis of two certified reference materials including CRM-TMDW and GBW07605 tea samples. Also, the analysis of different real samples shows that the proposed method could be successfully applied for the determination of trace levels of Cu2+ in different real samples.

References

Bost M, Houdart S, Oberli M, Kalonji E, Huneau JF, Margaritis I (2016) Dietary copper and human health: current evidence and unresolved issues. J Trace Elem Med Biol 35:107–115

Uriu-Adams JY, Keen CL (2005) Copper, oxidative stress, and human health. Mol Asp Med 26:268–298

Jihad Majeed H, Eftekhari M, Gheibi M, Chamsaz M (2019) Synthesis and application of cerium oxide nanoparticles for preconcentration of trace levels of copper in water and foods followed by flame atomic absorption spectrometry. J Food Meas Charact 13:339–346

Zou J, Ma X, Dang Y, Chen Y (2014) Trace determination of cadmium(II) and copper(II) in environmental water samples by solid-phase extraction using a novel ionic liquid-modified composite sorbent combined with flame atomic absorption spectrometry. J Anal Atom Spectrom 29:1692–1697

Frag EY, Abdel Hameed RM (2019) Preparation, characterization and electrochemical application of CuNiO nanoparticles supported on graphite for potentiometric determination of copper ions in spiked water samples. Microchim J 144:110–116

Zamani Mohammadabadi S, Zanganeh AR (2018) Electrochemically generated recognition sites in self-doped polyaniline modified electrodes for voltammetric and potentiometric determination of copper(II) Ion. Electroanalysis 30:415–425

Zhang Y, Zhong C, Zhang Q, Chen B, He M, Hu B (2015) Graphene oxide–TiO2 composite as a novel adsorbent for the preconcentration of heavy metals and rare earth elements in environmental samples followed by on-line inductively coupled plasma optical emission spectrometry detection. RSC Adv 5:5996–6005

Otero-Romaní J, Moreda-Piñeiro A, Bermejo-Barrera A, Bermejo-Barrera P (2005) Evaluation of commercial C18 cartridges for trace elements solid phase extraction from seawater followed by inductively coupled plasma-optical emission spectrometry determination. Anal Chim Acta 536:213–218

Wen X, Yang Q, Yan Z, Deng Q (2011) Determination of cadmium and copper in water and food samples by dispersive liquid–liquid microextraction combined with UV–Vis spectrophotometry. Microchim J 97:249–254

Horstkotte B, Alexovič M, Maya F, Duarte CM, Andruch V, Cerdá V (2012) Automatic determination of copper by in-syringe dispersive liquid–liquid microextraction of its bathocuproine-complex using long path-length spectrophotometric detection. Talanta 99:349–356

Chamsaz M, Eftekhari M, Eftekhari A, Yekkebashi A (2013) 2-Nitroso-1-naphthol as a selective reagent for preconcentration of cobalt by vortex assisted combined with solidification of organic droplet and its determination by flame atomic absorption spectrometry. Environ Monit Assess 185:9067–9075

Khodarahmi M, Eftekhari M, Gheibi M, Chamsaz M (2018) Preconcentration of trace levels of cadmium (II) ion using Descurainia sophia seeds as a green adsorbent for solid phase extraction followed by its determination by flame atomic absorption spectrometry. J Food Meas Charact 12:1485–1492

Mohammadnezhad G, Moshiri P, Dinari M, Steiniger F (2019) In situ synthesis of nanocomposite materials based on modified-mesoporous silica MCM-41 and methyl methacrylate for copper (II) adsorption from aqueous solution. J Iran Chem Soc 16:1491–1500

Kobylinskaya NG, Khainakova EA, Diaz-Garcia ME, Zaitsev VN (2017) Nanocomposites based on magnetite modified by chelate groups for a solid-phase concentration of heavy-metal ions from aqueous solutions. Prot Met Phys Chem Surf 53:675–684

Khayatian G, Moradi M, Hassanpoor S (2018) MnO2/3MgO Nanocomposite for preconcentration and determination of trace copper and lead in food and water by flame atomic absorption spectrometry. J Anal Chem 73:470–478

Soylak M, Doğan M (1996) Column preconcentration of trace amounts of copper on activated carbon from natural water samples. Anal Lett 29:635–643

Tuzen M, Soylak M, Citak D, Ferreira HS, Korn MGA, Bezerra MA (2009) A preconcentration system for determination of copper and nickel in water and food samples employing flame atomic absorption spectrometry. J Hazard Mater 162:1041–1045

Soylak M, Kiranartligiller E (2017) A simple vortex-assisted dispersive liquid–liquid microextraction system for copper(II) to preconcentration and separation from natural water and table salt samples. Arab J Sci Eng 42:175–181

Jalbani N, Soylak M (2015) Ligandless ultrasonic-assisted and ionic liquid-based dispersive liquid–liquid microextraction of copper, nickel and lead in different food samples. Food Chem 167:433–437

Karadaş C, Kara D (2017) Dispersive liquid–liquid microextraction based on solidification of floating organic drop for preconcentration and determination of trace amounts of copper by flame atomic absorption spectrometry. Food Chem 220:242–248

Yang S, Fang X, Duan L, Yang S, Lei Z, Wen X (2015) Comparison of ultrasound-assisted cloud point extraction and ultrasound-assisted dispersive liquid liquid microextraction for copper coupled with spectrophotometric determination. Spectrochim Acta A Mol Biomol Spect 148:72–77

Hemmati M, Rajabi M, Asghari A (2018) Magnetic nanoparticle based solid-phase extraction of heavy metal ions: a review on recent advances. Microchim Acta 185:160–191

Eftekhari M, Gheibi M, Akrami M, Iranzad F (2018) Solid-phase extraction of ultra-trace levels of lead using tannic acid-coated graphene oxide as an efficient adsorbent followed by electrothermal atomic absorption spectrometry; response surface methodology-central composite design. New J Chem 42:1159–1168

Ghahramani A, Gheibi M, Eftekhari M (2018) Polyaniline-coated reduced graphene oxide as an efficient adsorbent for the removal of malachite green from water samples. Polym Bull. https://doi.org/10.1007/s00289-018-2651-0

Yuan Y, Zhang G, Li Y, Zhang G, Zhang F, Fan X (2013) Poly(amidoamine) modified graphene oxide as an efficient adsorbent for heavy metal ions. Polym Chem 4:2164–2167

Arshad F, Selvaraj M, Zain J, Banat F, Haija MA (2019) Polyethylenimine modified graphene oxide hydrogel composite as an efficient adsorbent for heavy metal ions. Sep Purif Technol 209:870–880

Bagliotti Meneguin A, Stringhetti Ferreira Cury B, Cesar Evangelista R (2014) Films from resistant starch-pectin dispersions intended for colonic drug delivery. Carbohydr Polym 99:140–149

Minhas MU, Ahmad M, Anwar J, Khan S (2018) Synthesis and characterization of biodegradable hydrogels for oral delivery of 5-fluorouracil targeted to colon: screening with preliminary in vivo studies. Adv Polym Tech 37:221–229

Ayala-Cabrera JF, Trujillo-Rodríguez MJ, Pino V, Hernández-Torres OM, Afonso AM, Sirieix-Plénet J (2016) Ionic liquids versus ionic liquid-based surfactants in dispersive liquid–liquid microextraction for determining copper in water by flame atomic absorption spectrometry. Int J Environ Anal Chem 96:101–118

Mohammadi SZ, Seyedi F (2016) Preconcentration of cadmium and copper ions on magnetic core–shell nanoparticles for determination by flame atomic absorption. Toxicol Environ Chem 98:705–713

Yavuz E, Tokalıoğlu S, Sahan H, Patat S (2016) Nanosized spongelike Mn3O4 as an adsorbent for preconcentration by vortex assisted solid phase extraction of copper and lead in various food and herb samples. Food Chem 194:463–469

Durukan I, Şahin CA, Bektaş S (2011) Determination of copper traces in water samples by flow injection-flame atomic absorption spectrometry using a novel solidified floating organic drop microextraction method. Microchem J 98:215–219

Es’haghi Z, Azmoodeh R (2010) Hollow fiber supported liquid membrane microextraction of Cu2+ followed by flame atomic absorption spectroscopy determination. Arab J Chem 3:21–26

Acknowledgements

The authors wish to thank the University of Neyshabur (Grant No. 1278) for the financial support of this project. Also, we have appreciated the Iran Laboratory, Mashhad, Iran, for the assistance to complete this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eftekhari, A., Shakerian, M., Majeed, H.J. et al. Pectic acid–graphene oxide nanocomposite as an adsorbent in vortex-assisted dispersive solid-phase extraction for preconcentration of copper ion followed by flame atomic absorption spectrometry. Polym. Bull. 77, 2821–2836 (2020). https://doi.org/10.1007/s00289-019-02884-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02884-y