Abstract

In the present work, microwave method has been employed for synthesis of cerium oxide nanoparticles (CeO2 NPs) and it was used for preconcentration of trace levels of Cu(ІІ) in different real samples followed by flame atomic absorption spectrometry. The results of X-ray diffraction spectroscopy (XRD) and transmission electron microscopy (TEM) show that CeO2 NPs were successfully synthesized in the size of 10–20 nm. By using a batch method, CeO2 NPs have been used as efficient, easy to synthesize and efficient adsorbent for highly rapid solid phase extraction of Cu(ІІ) in different real samples for the first time. The effects of different parameters affecting the extraction efficiency such as pH, extraction time, type and concentration of desorbent solvent and desorbent time were completely investigated and optimum conditions selected. Under the optimum conditions, the calibration curve was linear in the range of 10–300 ng cm−3 Cu(ІІ) with correlation coefficient of 0.998. The relative standard (RSD, %) based on six replicate analysis of 50 ng cm−3 Cu(ІІ) was 3.3%. In order to check the accuracy of the proposed method certified reference material, CRM-TMDW and GBW07605 tea reference material, with the known amounts of 20 ng cm−3 Cu(ІІ) and 17.3 ± 0.3 µg g−1 Cu, respectively, were analyzed and the obtained results (19.5 ± 1.0 ng cm−3 Cu(ІІ) for CRM-TMDW and 17.0 ± 0.7 µg g−1 Cu) show very good agreement with the CRM certified values (Student t-test, 95% confidence limit, n = 5). Finally the proposed method was successfully applied for determination of trace levels of Cu(ІІ) in different water (tap, spring and river) and food samples (black tea, lentil, sesame, cabbage, wheat and liver).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copper (Cu) is one of the first metals ever extracted and used by humans; it has made vital contributions to sustaining and improving society since the dawn of civilization. Cu has widespread application in different industries such as pharmaceuticals [1], manufacturing of batteries [2], electronic equipment, alloys and cables [3]. It is an essential trace element in both humans and animals. Cu is a co-factor of many redox enzymes [4] and has myriad of biological processes such as antioxidant defense, neuropeptide synthesis and immune function [5]. Dietary Cu deficiency can result in adverse consequences throughout the life span. Also, Cu deficiency may result in impaired development of the cardiovascular system, bone malformation, ongoing neurologic and immunologic abnormalities into infancy and beyond [6]. Though an essential micronutrient for man, Cu is toxic at high levels and could cause severe damage to the organs of body; therefore, determination of accurate levels of Cu in different real samples is an important demand.

Flame atomic absorption spectrometry is one of the most common, simple to use, low cost and relatively selective (due to the use of hollow cathode lamp) analytical techniques for determination of heavy metals. Despite the advantages mentioned above, this technique has low detection limit for determination of many heavy metals. Therefore, in order improve the detection limit and also reduce the interferences of many heavy metals, applications of sample preparation techniques are highly recommended [7]. Different preconcentration methods such as dispersive liquid phase microextraction [7, 8], cloud point extraction [9,10,11], hollow fiber liquid phase microextraction [12] and solid phase extraction techniques [13,14,15] have been used for preconcentration of trace levels of Cu in different real samples.

The main drawbacks of liquid phase microextraction techniques are the use of organic and hazardous solvents for the extraction of analyte which they are very toxic for environmental and human health and also difficulty to automation. While, solid phase extraction (SPE) is one of the most common sample preparation techniques which has been used for preconcentration of toxic and potentially toxic metals due to its simplicity, rapidity, high enrichment factor and ability for automation [16]. Different adsorbents such as carbon naotubes [17], natural wastes [18], modified active carbon [19, 20], modified silica membrane [21], modified silica-gel [22] and modified magnetic nanoparticles [23] were used for solid phase extraction of Cu(ІІ). In recent years cerium oxide nanoparticles (CeO2 NPs) have gained much attention due to their important applications as automobile exhaust catalysts, oxide ion conductors in solid oxide fuel cells, electrode materials for gas sensors, ultraviolet absorbents and glass-polishing materials [24]. Also, due to its high surface area, ease of synthesize and available active sites; it is a good candidate for solid phase extraction of toxic and potentially toxic metals [25].

In this paper solid phase extraction technique has been used for preconcentration of trace levels of Cu(ІІ) in different real samples followed by flame atomic absorption spectrometry (FAAS). CeO2 NPs were synthesized by microwave method and characterized by XRD analysis and TEM images. By using a batch method, CeO2 NPs were used as adsorbent for preconcentration of trace levels of Cu(ІІ) in real samples. Based on our knowledge, CeO2 NPs have not been used for preconcentration of Cu(ІІ) in solid phase extraction. Different parameters affecting the extraction efficiency such as pH, amounts of CeO2 NPs, extraction time and type and concentration of desorbent solvent were completely investigated and optimum conditions selected. Based on the obtained results, the proposed solid phase extraction has advantages such as simplicity, sensitivity, rapidity, high efficiency and also without using any hazardous organic solvents for determination of Cu(ІІ) in different water and food samples.

Experimental

Instrument

A Shimadzu AA-670 (Shimadzu, Japan) flame atomic absorption spectrometer equipped with a 100 mm burner head, deuterium background correction and an air acetylene flame was utilized. A copper hollow cathode lamp (Shimadzu, Japan) operated at a current of 12 mA and a wavelength of 324.8 nm with a spectral bandwidth of 0.7 nm was used. The pH values in the aqueous phase were measured with Metrohm 827 pH lab (Switzerland) glass-electrode pH meter. Phase separation was assisted using Centurion Scientific Centrifuge (model Andreas Hettich D72, Tuttlingen, Germany). A Leo912AB transmission electron microscopy (TEM) was used to determine the shape and size of the synthesized CeO2 NPs. The X-ray analysis was performed by X-Plorer instrument (Made in Italy).

Reagents

All reagents were of analytical reagent grade and deionized water was used throughout the analysis. A stock solution of 1 × 103 µg cm−3 Cu(II) was prepared by dissolving appropriate amounts of copper nitrate hexa-hydrate (Merck, Darmstadt, Germany) in 1% (v/v) nitric acid. Working standard solutions were prepared freshly at various concentrations by diluting the stock standard solution with deionized water. HCO2H (formic acid, 95.0–97.0%, Merck, Darmstadt, Germany), CH3CO2H (acetic acid, 99.5%, Merck, Darmstadt, Germany), (NO2)OH (nitric acid, 65.0%, Merck, Darmstadt, Germany) and HCl (hydrochloric acid, 37.0%, Merck, Darmstadt, Germany) were used to make 0.0010, 0.0020 and 0.0040 mol cm−3 desorbent solutions. Concentrated (NO2)OH (65.0%) was used for sample digestion and purchased from Merck, Darmstadt, Germany. Cerium nitrate hexa-hydrate (Sigma Aldrich, USA) was used to synthesize CeO2 NPs. Sodium hydroxide (0.0001 mol cm−3) and nitric acid (0.0001 mol cm−3) were used to adjust the pH values.

Synthesis of cerium oxide nanoparticles

CeO2 NPs have been synthesized as previously reported by our team [25]; briefly; 3.65 mmol Ce(NO3)3.6H2O was dissolved in 20.0 mL deionized water and proper amounts of 0.0002 mol cm−3 NaOH solution was rapidly added to it. In this step, the white Ce(OH)3 precipitate was produced. The solution was stirred for 30 min at room temperature (25 ± 2 °C). The oxidation transfer of Ce(III) to Ce(IV) takes place because of the dissolved oxygen from air. The reaction was carried on for 30 min in air in a domestic microwave oven. The microwave oven (10 × 102 W) followed a working cycle of 10 s on and 5 s off (30% power) and a yellowish precipitate started to appear. After cooling to room temperature, the resulting precipitate was centrifuged (10 min with 10 × 103 G) and washed with ethanol and deionized water several times. Finally, the products were dried in a vacuum oven at 65 °C overnight.

Preconcentration procedure

An aliquot of 10 mL of sample solution containing 100 ng cm−3 Cu(ІІ) was adjusted at pH 8.0–9.0; by addition of 0.010 g of CeO2 NPs, the sample solution was stirred for 5 min at the rate of 400g. Then, it was transferred into conical centrifuge tube and centrifuged for 10 min at 3.0×103g. By decanting of the sample solution, 400 µL of 0.0020 mol cm−3 (NO2)OH was added to CeO2 NPs and it was vortexed for 2 min at 2.8 × 103g. Finally, it was centrifuged for another 5 min and aspirated into the FAAS for quantification of Cu.

Preparation of real samples

Water samples

Different water samples including tap water (from Ferdowsi University of Mashhad, Mashhad, Iran), spring (Nowchah, Mashhad, Iran), Dejleh and Forat River (Kadhimiya Iraq) were obtained from their local sources and acidified with 0.0001 mol cm−3 (NO2)OH. An aliquot of 10 mL of each sample was adjusted at pH 8.0–9.0 and analyzed for its Cu(ІІ) content according to the microextraction procedure.

Food samples

Sampling

As the amounts of Cu content in foodstuff is different, it is necessary to determine its value in dietary source of people to consider it with caution or to find the better replace for it [26]. For this purpose, most common foodstuff in Iran including black tea, red lentil, sesame, white and red cabbage and wheat were chosen and analyzed for their Cu content. Lentil is a legume crop, and it has been used as food throughout the world. Lentil consists of the important constituent of dietary source of protein, oligosaccharides, bioactive peptide, dietary fibers, minerals, antioxidants, vitamins, and non-nutritive bioactive phytochemicals. Tea is the one of the most popular beverages in the world. Among other components, tea leaves consist of tanning agents, alkaloids, amino acids, pigments, and trace amounts of mineral compounds such as copper, manganese and zinc. Trace elements present in tea leaves play an important role in human metabolism [26].

Wheat is one of the most consumed cereal grains worldwide and makes up a substantial part of the human diet. Wheat supplies a significant portion of the nutrients required for growth, maintenance of health and well-being. Therefore, determination of necessary minerals such as copper and iron is highly demanded. Sesame seed is a reservoir of nutritional components with numerous beneficial effects along with health promotion in humans. Sesame seed is high in protein, vitamin B1, dietary fiber as well as an excellent source of phosphorous, iron, magnesium calcium, manganese, copper and zinc [27].

Black tea (from a known brand in Northern of Iran), red lentil (from a known brand in Iran), wheat and sesame samples (from a known brand in Mashhad, Iran) were randomly supplied from different supermarkets. Sampling for each one was performed by weighting (800–900 g) of the samples (N = 5) followed by mixing and crashing of them to obtain uniform powdered sample.

White and red cabbage samples were prepared randomly from Neyshbur (Iran) farm lands in summer season (N = 8). After washing of samples by deionized water to remove any impurities, sampling was performed from different layers of each cabbage. The prepared samples were dried at 70 °C for 12 h and grind in a high speed rotator mill to obtain uniform sample. The plant material prepared in such a way was stored in labeled, tightly sealed polyethylene containers. Liver samples (N = 3, Sheep liver) were prepared from butcher shop in Mashhad, Iran. Sampling was performed from different parts of each liver sample (each part has a weight of 30–50 g), and after mixing them in cryogenic grinding, the prepared sample was stored in polyethylene container before analysis [28].

Black tea, red lentil, sesame and wheat samples

1.00 g powdered of each sample was weighted and transferred into the crucible followed by heating at 500 °C for 2 h. Then, 2.0 mL concentrated (NO2)OH was added to the sample and heated at 70 °C for another 15 min. Finally, it was diluted to 25.0 mL with deionized water and then, aliquot of 1.0 mL of each sample solution was adjusted at pH 8.0–9.0 and after dilution to 10.0 mL with deionized water; it was analyzed for its Cu(ІІ) content according to the preconcentration procedure.

White and red cabbage samples

1.00 g of each sample was weighted and digested as explained above.

Liver sample

1.00 g of liver sample was weighted and dried at 90 °C for 3 h. The dried sample was heated at 500 °C for 3 h. Then, 2.0 mL concentrated (NO2)OH was added to the sample and heated at 70 °C for another 15 min. Finally, by dilution of sample solution to 25.0 mL with deionized water, an aliquot of 1.0 mL of sample solution was adjusted at pH 8.0–9.0 and after dilution to 10.0 mL, it was analyzed for its Cu(ІІ) content according to the preconcentration procedure.

Certified reference tea sample (GBW07605)

1.00 g of GBW07606 certified reference material was weighted and digested as a tea sample explained above. Then, aliquot of 1.0 mL of digested sample solution was adjusted at pH 8.0–9.0 and after dilution to 10.0 mL with deionized water; it was analyzed for its Cu(ІІ) content according to the preconcentration procedure.

Results and discussions

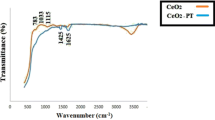

Characterization of CeO2 nanoparticles

The XRD spectrum and TEM images of the synthesized CeO2 NPs are shown in Figs. 1 and 2, respectively. As the results in Fig. 1 show, the characteristic peaks at 111, 200, 220, 311, 222, 400 and 331 are located at 2θ, 29.1, 33.0, 47.2, 56.3, 59.5, 69.5 and 77.1 indicating that the crystalline phase of the synthesized CeO2 NPs is body centered cubic phase.

The average CeO2 NPs crystalline size, D, can be calculated by the Scherrer’s equation (Eq. 1) using the (111) CeO2 peak located at 2θ = 29.1 and k factor of 0.89.

where λ is the X-ray wavelength (1.54 Å) and θ is the diffraction angle for the (111) plane. The average crystallite size for sample was calculated to be 14.7 nm. Also, the images of TEM microscopy of CeO2 NPs are shown in Fig. 2a, b. as it can be seen the uniform cubic CeO2 NPs with average size of 10–20 nm have been synthesized successfully by microwave method.

Effect of amounts of CeO2 NPs

In order to check the effect of amounts of CeO2 NPs on the signal/noise ratio of Cu(ІІ), different amounts of CeO2 NPs in the range of 0.005–0.040 g were added to the samples solution and subjected to the preconcentration procedure. The results are shown in Fig. 3. Based on the results, the maximum extraction was achieved for 0.010 g of CeO2 NPs and it decreased gradually afterwards. Therefore, 0.010 g of CeO2 NPs was selected as the optimum value. The increase of Signal/Noise ratio by increasing of the amounts of CeO2 NPs could be related to the increase of its effective surface to adsorb Cu(ІІ), however, the decrease in signal/noise ratio at higher amounts of CeO2 NPs could be describe by the aggregation of CeO2 NPs and therefore decreasing of its surface area and available sites.

Effect of extraction time

In solid phase extraction, extraction time is one of the important parameter affecting the extraction efficiency. The effect of extraction time on the signal/noise ratio of Cu(ІІ) was studied in the range of 2–30 min at a constant stirring rate of 400 G. The results are shown in Fig. 4. Based on the results; 5 min was an optimum time for extraction of Cu(ІІ) and further extraction times have no considerable effect of the signal/noise ratio of Cu(ІІ). Therefore, it can be concluded that the adsorption of Cu(ІІ) on the surface of CeO2 NPs is happened very quickly.

Effect of type and concentration of desorbent solvent

In order to choose the most effective eluent for quantitative stripping of Cu(ІІ) ion retained by the adsorbent, different concentrations (0.0010, 0.0020 and 0.0040 mol cm−3) of (NO2)OH, HCl and CH3CO2H and HCO2H were examined. According to the results (Fig. 5), 0.0020 and 0.0040 mol cm−3 (NO2)OH efficiently desorbed Cu(ІІ) from CeO2 NPs and show similar effects on desorption of Cu(ІІ). Therefore, 0.0020 mol cm−3 (NO2)OH was selected as the optimum desorbent solvent. As it can be seen, organic acids have lower efficiency for desorption of Cu(ІІ) which could be related to their lower acidic strength in compared to inorganic acids. Also, the effect of desorption time on the signal/noise ratio of Cu(ІІ) was studied by vortexing of CeO2 NPs in the range of 1–10 min at 2.8 × 103 G. According to the results, 2 min vortex time at 2.8 × 103 G provided the maximum signal/noise ratio for determination of Cu(II) ion.

Effect of pH

pH is an important parameter affecting the extraction efficiency in solid phase extraction [25]. The effect of pH on the signal/noise ratio of Cu(ІІ) was studied in the range of 2.0–11.0. The results are shown in Fig. 6. Based on the results, Signal/Noise ratio reaches to its maximum value at pH 8.0–9.0 and it decrease gradually at higher pH values. Therefore, pH 8.0–9.0 was selected as the optimum value. It can be concluded that at basic pH values the hydroxyl groups on the surface of CeO2 NPs are deprotonated and the surface of CeO2 NPs have negative charges which easily adsorbed Cu(ІІ) ions. However, at low pH values, the functional groups on the surface of CeO2 NPs have been protonated which electrostatically repulse the positive charged Cu(ІІ). Therefore, pH 8.0–9.0 was selected as the optimum pH value.

Effect of ionic strength

The ionic strength of the sample solution could change the extraction efficiency by salt in and salt out effects. In order to check the effect of ionic strength on the signal/noise ratio of Cu(ІІ), different concentrations of KNO3 and KCl were tested in the range of 0–1.0% g cm−3. The results (Fig. 7) show that KCl and KNO3 have approximately no effect on the Signal/Noise ratio of Cu(ІІ) up to 0.5 and 0.8% g cm−3, respectively, which can be conclude that this technique can be used for determination of Cu(ІІ) in saline samples.

Effect of interfering ions

As FAAS has relatively high selectivity to heavy metals, many interferences origin from the preconcentration step. The effect of different cation and anions on the extraction efficiency of Cu(ІІ) was studied and presented in Table 1. Ions consider as interfere when their presence caused a variation in the Signal/Noise ratio of the sample greater than ± 5.0%. Based on the results, the proposed method could be applied for determination of Cu(ІІ) in different real samples.

Analytical figure of merit

Under the optimum condition, the calibration curve after preconcentration was linear in the range of 10–300 ng cm−3 Cu(ІІ) with a correlation coefficient of 0.998. The equation of calibration curve after preconcentration step is expressed in Eq. 2:

Where A is the absorbance of Cu and \({{\text{C}}_{{\text{C}}{{\text{u}}^{2+}}}}\) is the concentration of copper ion in ng cm−3. The relative standard deviation based on six replicate analysis of 50 ng cm−3 Cu(ІІ) was 3.3% and the detection limit (n = 6) was 3.2 ng cm−3. The preconcentration factor (PF) was calculated based on the volume of sample solution (10.0 mL) to the final solution aspirated into the FAAS (0.4 mL) which equal to 25. The enhancement factor (EF) was 19, defined as the slope of the calibration curve after preconcentration step to that of before preconcentration step. Equation 3 shows the calibration curve before preconcentration step.

\({{\text{C}}_{{\text{C}}{{\text{u}}^{2+}}}}\) is the concentration of copper ion in the range of 1–6 µg cm−3 [29,30,31].

Analysis of real samples

In order to check the applicability of the proposed method, different real samples (including different water, food and liver samples) were analyzed for determination of Cu(ІІ) and the results were shown in Tables 2 and 3. Spike tests also performed on the samples in order to check the validity of the obtained results. Based on the results; very good recoveries were obtained for determination of Cu(ІІ) in different real samples. In order to check the accuracy of the proposed method, CRM-TMDW certified reference material with certified value of 20 ng cm−3 Cu(ІІ) was analyzed. The obtained value was 19.5 ± 1.0 ng cm−3 Cu(ІІ) which shows high accuracy of the proposed method for determination of Cu(ІІ). According to the student t-test which expressed in Eq. 4:

where X is sample mean, µ is the population mean, N is the size of sample and S is the standard deviation; the calculated t value (tcal) is 1.12. By considering ttable = 2.13 for 95% confidence limit and df = 4 (degree of freedom) it can be concluded that ttable > tca. Therefore, the obtained result is consistent with the population.

Also, GBW07605 tea reference material with the certified value of 17.3 ± 0.3 µg g−1 Cu was analyzed to test the accuracy of the obtained results in food samples. The obtained value for Cu in GBW07605 was 17.0 ± 0.7 µg g−1 Cu. The calculated t value is 0.96. Therefore, according to the ttable = 2.13 for 95% confidence limit and df = 4, the obtained result is consistent with the population.

Conclusion

Solid phase extraction technique is one of the most common used sample preparation techniques with many advantages such as wide range of adsorbents, simplicity, relatively rapidity, ability for automation and high enrichment factor. Metal oxide nanoparticles are used widely in solid phase extraction techniques. Cerium oxide nanoparticles (CeO2 NPs) have many applications in different industrial fields and due to its high surface area, ease of synthesizes and available active sites, it is a good candidate for solid phase extraction of toxic and potentially toxic metals. In this research, CeO2 NPs were synthesized by microwave method as a rapid and simple synthesize route followed by its application for solid phase extraction of Cu(ІІ). The average crystalline size of the synthesized CeO2 NPs which obtained by XRD analysis were 14.7 nm. The obtained results show that this method is rapid, simple and efficient for preconcentration and determination of trace levels of Cu(ІІ). Also, the analyses of CRM and real samples show that the proposed method has very good validity and sensitivity for determination of Cu(ІІ) in different real samples.

References

I. Iakovidis, I. Delimaris, S.M. Piperakis, Mol. Biol. Int. 2011, Article ID 594529, 1–13 (2011)

M. Morcrette, P. Rozier, L. Dupont, E. Mugnier, L. Sannier, J. Galy, J.M. Tarascon, Nat. Mater. 2, 755–761 (2003)

G. Joseph, K.J.A. Kundig, Copper: Its Trade, Manufacture, Use, and Environmental Status (ASM International, Materials Park, 1999), pp. 331–377

E.D. Harris, J. Nutr. 122(3S), 636–640 (1992)

S.H. Nile, S.W. Park, Nutrition 30(2), 134–144 (2014)

J.Y. Uriu-Adams, C.L. Keen, Mol. Aspects Med. 26(4–5), 268–298 (2005)

Z. Al Othman, Y. Emre Unsal, M. Habila, A. Shabaka, M. Tuzen, M. Soylak, Anal. Lett. 48(11), 1738–1750 (2015)

S. Bahar, R. Zakerian, J. Braz. Chem. Soc. 23(6), 1166–1173 (2012)

P. Liang, J. Yang, J. Food Compos. Anal. 23(1), 95–99(2010).

S.A.M. Fathi, M.R. Yaftian, J. Colloid Interface Sci. 334(2), 167–170 (2009)

M. Ghaedi, A. Shokrollahi, F. Ahmadi, H.R. Rajabi, M. Soylak, J. Hazard. Mater. 150(3), 533–540 (2008)

Z. Es’haghi, R. Azmoodeh, Arab. J. Chem. 3(1), 21–26 (2010)

M.A. Habila, Z.A. ALOthman, E. Yilmaz, M. Soylak, Int. J. Environ. Anal. Chem. 98(2), 171–181 (2018)

R. Saxena, P.L. Meena, RSC Adv. 4(39), 20216–20225 (2014)

V. Yilmaz, Z. Arsalan, O. Hazer, H. Yilmaz, Microchim. J. 114, 65–72 (2014)

M. Tuzen, K.O. Saygi, M. Soylak, J. Hazard. Mater. 152(2), 632–639 (2008)

M. Soylak, O. Ercan, J. Hazard. Mater. 168(2–3), 1527–1531 (2009)

R.S.D. Castro, L. Caetano, G. Ferreira, P.M. Padiha, M.J. Saeki, L.F. Zara, M.A.U. Martines, G.R. Castro, Ind. Eng. Chem. Res. 50(6), 3446–3451 (2011)

M. Ghaedi, F. Ahmadi, Z. Tavakoli, M. Montazerozohori, A. Khanmohammadi, M. Soylak, J. Hazard. Mater. 152(3), 1248–1255 (2008)

M. Ghaedi, F. Ahmadi, M. Soylak, J. Hazard. Mater. 147(1–2), 226–231 (2007)

M.H. Mashhadizadeh, M. Pesteh, M. Talakesh, I. Sheikhshoaie, M. Mazloum Ardakani, M.A. Karimi, Spectrochim. Acta Part B 63(8), 885–888 (2008)

F. Xie, X. Lin, X. Wu, Z. Xie, Talanta 74(4), 836–843 (2008)

M.H. Mashhadizadeh, Z. Karimi, J. Hazard. Mater. 190(1–3), 1023–1029 (2011)

L. He, Y. Su, J. Lanhong, S. Shi, J. Rare Earth 33(8), 791–799 (2015)

S. Mohajer, M. Chamsaz, E.K. Goharshadi, S. Samiee, Sep. Sci. Technol. 52, 1652–1659 (2017)

M. Bost, S. Houdart, M. Oberli, E. Kalonji, J.F. Huneau, I. Margaritis, J. Trace Elem. Med. Biol. 35, 107–115 (2016)

N. Pathak, A.K. Rai, R. Kumari, K.V. Bhat, Pharmacogn. Rev. 8(16), 147–155 (2014)

B. Kratochvil, D. Wallace, J.K. Taylor, Anal. Chem. 56(5), 113–129 (1984)

F. Javedani-Asleh, M. Eftekhari, M. Chamsaz, Spectrosc. Lett. 49, 420–425 (2016)

M. Chamsaz, A. Atarodi, M. Eftekhari, S. Asadpour, M. Adibi, J. Adv. Res. 4(1), 35–41 (2013)

M. Eftekhari, M. Gheibi, M. Akrami, F. Iranzad, New J. Chem. 42, 1159–1168 (2018)

Acknowledgements

This work was financially supported by the Ferdowsi University of Mashhad, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Majeed, H.J., Eftekhari, M., Gheibi, M. et al. Synthesis and application of cerium oxide nanoparticles for preconcentration of trace levels of copper in water and foods followed by flame atomic absorption spectrometry. Food Measure 13, 339–346 (2019). https://doi.org/10.1007/s11694-018-9949-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9949-3