Abstract

In this paper, poly (2-hydroxyethyl methacrylate) (pHEMA) and poly (2-hydroxyethyl methacrylate)-starch (pHEMA-S) composites were prepared from 2-hydroxyethyl methacrylate and different ratio starch. The pHEMA-S showed high thermal stability and biodegradability. The biodegradability of pHEMA-S composites was in the range of 14–22 % for 4 weeks depending on the starch ratio of pHEMA-S. Then, L-ASNase was immobilized onto pHEMA-S composites. The immobilized L-ASNase was investigated with optimum temperature, pH and kinetic parameters. Immobilization improved the pH stability and thermal stability of the enzyme. The K m values were 1.58 and 0.56 mM for free and immobilized enzyme, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

L-asparaginase (l-asparagine amidohydrolase, EC 3.5.1.1; L-ASNase) is used as a therapeutic agent for many types of cancer including children’s leukemia [1–3]. L-ASNase has a molecular weight of 138–140 kDa, which comprises of four same subunits with one active center each and catalyzes the hydrolysis of l-asparagine to produce l-aspartic acid and ammonia [4]. Bacteria, algae, plants, fungi, ferments and actinomycetes have been used in the production of L-ASNase for the last 35 years [5, 6]. The most important bacteria sources of commercial use featuring L-ASNase are Escherichia coli (E. coli) and Erwinia caratovira [7].

L-ASNase is an indispensable chemotherapeutic drug in the treatment of acute lymphoblastic leukemia (ALL) disease, especially [8]. Although, normal cells do not need to l-asparagine in the blood to grow, l-asparagine is an essential amino acid for cancer cells. Thus, scavenging of l-asparagine by L-ASNase in the blood slows the growth of cancer cells and leads to death. L-ASNase has been extensively used as chemotherapeutic agent in the treatment of acute and chronic lymphoblastic leukemia, Hodgkin’s disease, acute myelocytic leukemia, acute myelomonocytic leukemia, lymphosarcoma, reticulosarcoma and melanosarcoma [9]. However, this enzyme causes a variety of side effects such as fever, skin rashes and even can lead to life-threatening allergic reactions [10]. Due to decrease in the immunological effects caused by this enzyme, extending its action time and increase drug effect in blood, native L-ASNase is generally immobilized physically or chemically on various biocompatible polymers. It has been reported that the immobilized enzyme did not only reduce the immunity and toxicity but also greatly improved the resistance against proteolysis [4]. Natural and synthetic polymers such as albumin [11], dextran [12], chitin [13], CM-cellulose [9], polyethylene glycol (PEG) [14], polyvinyl alcohol (PVA) [15] are usually used for enzyme immobilization. The PEG which is the most widely used carrier, is linear, non-toxic and non-immunogenic [16]. Studies have shown that immobilized L-ASNase compared to native L-asparaginase has a longer half-life in blood as well as faces with less of an immune response. Due to formation of neutralizing antibodies, the half-life of circulating L-ASNase can be shortened to 2.5 h [17]. The half-life of L-ASNase in the blood has been prolonged more than 5 days via immobilization. The basic hypothesis in the L-ASNase immobilization on biocompatible polymers as physical or chemical is to create an increase in half-life and stability of this enzyme in the blood against immune response [18].

As early as 1960, poly (2-hydroxyethylmethacrylate) (pHEMA) hydrogels had been successfully applied as biomedical materials in plastic surgery, ophthalmology, and drug delivery [19, 20]. The pHEMA has been preferred as a scaffold material because of excellent mechanical properties and high hydrophilicity [21]. Application of pHEMA as a drug immobilization matrix has been limited due to its low biodegradability [22–24]. In our work, pHEMA-starch composites as an enzyme immobilization matrix were synthesized to improve the biodegradability. We hypothesized that pHEMA-starch composite as model matrix can provide more advantages both of biocompatibility and biodegradability in comparison with pure pHEMA polymers.

In this study, biodegradable pHEMA-starch composites were synthesized by emulsion polymerization using 2-hydroxyethyl methacrylate (HEMA) and different ratios of starch. The pHEMA-starch composites were characterized by Fourier transform infrared (FT-IR), thermal techniques (TGA, DSC, DTA), dynamic contact angle, SEM and energy-dispersive X-ray analysis. L-ASNase was immobilized onto pHEMA-starch composites. Then, activity and immobilization of L-ASNase on pHEMA-starch composites were investigated with optimum temperature and pH, kinetic parameters and storage stability.

Materials and methods

Materials

L-ASNase (from E. coli), l-asparagine, bovine serum albumin (BSA), sodium dodecyl sulfate were obtained from the Sigma-Aldrich Chemical Company (St. Louis, USA) and used as received. 2-Hydroxyethyl methacrylate (HEMA), phosphate-buffer solution (PBS) and acetone were obtained from Aldrich (Switzerland) and stored at 4 °C until used. Starch and tris base were purchased from Merck AG (Darmstadt, Germany). Trichloroacetic acid (TCA), potassium persulfate (KPS), Nessler’s reagent was purchased Riedel–deHaen AG (Seelze, Germany). All other chemicals of analytical grade were used as received.

Experimental

Infrared spectra of the pHEMA-starch composites were recorded on a Mattson 1000 model Fourier transform infrared (FT-IR) spectrometer by dispersing the sample in KBr pellets. These pellets were analyzed for transmittance in the range of 4000–400 cm−1. The thermal stability of pHEMA-starch composites was determined by a thermogravimetric analyzer (TGA-50, Shimadzu) with a heating rate of 10 K min−1 in dry air. The sample weight was 10 mg. The differential thermal analysis (DTA) curves of PHEMA-starch composites were investigated using differential thermal analysis (Shimadzu DTA-50) with a heating rate of 10 K min−1 in dry air. The sample weight was 5 mg. The glass transition temperature (Tg) of pHEMA-starch composites was determined by differential scanning calorimeter (Shimadzu DSC-60).

Surface structure, porosity type and morphology of the prepared pHEMA-starch composites were observed by scanning electron microscopy (SEM). The SEM images were acquired on LEO Evo-40 VPX scanning electron microscope in the secondary electron imaging mode. Emission current was 10 μA, accelerating voltage was 2 kV, and the working distance was 3 mm for the analysis. Carbon tape (Spectro tabs, 12 mm O.D.) attached to the aluminum specimen stubs was used for the sample preparation; pressured air was applied to remove the loosely attached particles. Chemical composition analysis by EDX was performed with an EDX; Rönteck Xflash detector analyzer is associated to a scanning electron microscope (SEM, Leo-Evo 40xVP). Incident electron beam energies from 3 to 30 keV have been utilized. In all cases, the beam was at normal incidence to the sample surface and the measurement time was 100 s. All the EDX spectra were corrected using the ZAF correction, which takes into account the influence of the matrix material on the obtained spectra.

Water contact angles were measured with an SEO Phoenix 300. The activity of free and immobilized enzyme was determined spectrophotometrically using Shimadzu UV–Visible 1601 at 480 nm.

Synthesis of pHEMA

The pHEMA was synthesized by emulsion polymerization method of 2-hydroxyethylmethacrylate monomer [25]. 2-Hydroxyethylmethacrylate (HEMA, 10 mL) and surfactant sodium dodecyl sulfate (SDS, 0.04 g) were added into 100-mL Schlenk flask and stirred for 30 min with a magnetic stirrer. An aqueous solution of potassium persulfate (KPS, 0.5 g) was subsequently added to the medium. Then, the mixture was heated to 80 °C in a water bath with a magnetic stirrer. The polymerization was maintained for 3–4 h at 80–90 °C. After cooling the mixture at room temperature, the pHEMA hydrogel was obtained and the polymer was gathered by filtration, washed several times with acetone/water (90:10, v/v) to remove any unreacted monomer and dried in a vacuum oven (yield was about 90 %).

Synthesis of pHEMA-starch composites

HEMA and crosslinker starch with various ratios were added into 100 mL of water containing 0.04 g of SDS and stirred for 30 min with a magnetic stirrer. An aqueous solution of KPS (0.5 g) was subsequently added to the medium. The solution was placed in a 100-mL flask and the solution temperature was heated in a water bath with a magnetic stirrer heating until 80 °C. The polymerization was maintained for 3–4 h at 80–90 °C, after which the pHEMA-starch composites were obtained. Four different batches of composites were prepared using four different starch concentrations (1, 3, 5 and 10 %), respectively. The particles were denoted as pHEMA-S-1 %, pHEMA-S-3 %, pHEMA-S-5 %, and pHEMA-S-10 %, respectively.

Biodegradation assay of pHEMA-starch composites

Biodegradation medium was prepared in 50 mM phosphate-buffer solution of pH 7.4. 0.1 g of samples was weighed and each sample was placed in an individual vial containing 10 ml PBS, and incubated at 37 °C. Three samples of each formulation were removed from buffer after 1, 2 and 4 weeks. After washing samples with distilled water and drying under vacuum at room temperature for 2 days, samples were reweighed to determine the weight loss percent using the following formula: Weight loss (%) = \(\left( {m_{\text{o}} - \frac{{m_{\text{d}} }}{{m_{\text{o}} }}} \right) \times 100\) where m o and m d are the masses of hydrogel and composites before and after biodegradation.

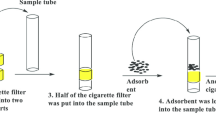

Immobilization of L-ASNase enzyme on pHEMA-starch composites

Pure pHEMA and composite samples (0.1 g) were put into Eppendorf tubes, respectively. 100 IU of L-asparaginase was diluted with 0.75 mL distilled water and the diluted solution was added into tubes. The samples were stirred for 30 min with orbital shaker at 4 °C and then, the samples were centrifuged for 5 min at 5000 rpm. After centrifugation, unbound L-ASPNase was removed by washing the solid with distilled water. Then, samples were dried in a vacuum oven at 35 °C. Determination of enzyme activity taking 5 mg of dried sample was performed.

Determination of L-asparaginase activity

The activity analysis for both free and immobilized L-ASNase was performed according to Mashburn and Wriston method [26]. This method is based on the measurement of released ammonia during catalysis of l-asparagine. The reaction mixture, consisting of 1 mL of 10 mM l-asparagine (prepared with 0.05 M Tris–HCl pH 8.6) and 5 mg of samples, was incubated for 30 min at 37 °C then centrifuged to separate the samples from the solution. The reaction was stopped by the addition of 0.1 mL of 1.5 M trichloroacetic acid solution and the mixture (0.25 ml of the samples, 0.5 ml of distilled water and 0.25 mL of Nessler’s reagent) was kept at room temperature for 10 min. L-ASNase assays were measured using a UV–visible spectrophotometer at 480 nm. The activity values of samples were average values of three-repeated measurements. One unit of the L-asparaginase (IU) is defined as that amount of enzyme capable of producing 1 µmol of ammonia per minute at 37 °C. The ammonia concentration produced in the reaction was determined on the basis of a standard curve.

Determination of optimum parameters for the immobilized L-ASNase

The pure polymer and composite structure corresponding immobilized enzyme activity values are given in Table 1. Owing to its hydrophilic nature, biodegradation and high enzyme activity, pHEMA-S-5 % composite was chosen as optimum model matrix for immobilization. pHEMA-S-5 % composite was used for optimization of immobilization parameters. The highest activity was expressed as 100 % and all activity values were given in comparison to 100 %.

Determination of the optimal pH for the immobilized L-ASNase

To determination effect of pH on free and immobilized enzyme activity, the activities of free and immobilized L-ASNase were determined at different pH values. Two buffer systems, including sodium citrate buffer (0.1 M, pH 4.0–6.0), Tris–HCl buffer (0.1 M, pH 7.0–10.0), were used for measuring the optimum pH of enzyme activity. The highest activity was expressed as 100 % and all activity values were given in comparison to 100 %.

Determination of the optimal temperature for the immobilized L-ASNase

To determine the effect of temperature on free and immobilized enzyme activity, the activities of free and immobilized enzymes are examined by altering the reaction temperatures involved, 25, 30, 35, 40, 45, 50, 55, and 60 °C at pH 8.6. The highest activity was expressed as 100 % and all activity values were given in comparison to 100 %.

Calculation of K m, V max, and protein estimation of the immobilized L-ASNase

K m and V max values for both free and immobilized enzymes were calculated by representing the enzyme activity values at different l-asparagine concentrations (0.1–50 mM) in a Lineweaver–Burk equation. Protein concentration was estimated with Bradford method using bovine serum albumin as a standard [27].

Storage stability of immobilized L-ASNase

To determine the storage stability of both free and immobilized enzyme, it was incubated at 4 °C and room temperature for 15 days. Depending to time, changes in the activity of free and immobilized enzymes (5 mg samples) were measured as described in “Materials and methods”.

Results and discussion

Enzymatic catalysis has been pursued extensively in a wide range of important biochemical and biotechnology processes for their unparalleled selectivity, and mild reaction conditions [28–30]. However, enzymes are usually costly and easy to inactivate in their free forms. Immobilization is the key to optimizing the in-service performance of an enzyme in biotechnology processes. In recent years, considerable efforts have been put into the studies of using polymer particles for enzyme immobilization [31, 32]. Still, polymers are not sufficiently biocompatible for high enzymatic activity. In particular, many polymers are also not hydrophilic for biomedical applications in body. Thus, in this study, to improve the biodegradability, biocompatibility and enzyme immobilization properties of the pHEMA, the starch as a more hydrophilic natural reinforcement material, was used. The chemical structure, thermal stability and the morphology of the prepared starch reinforcement composites were investigated and the L-ASNase immobilization properties have been examined.

Characterization of pHEMA and pHEMA-starch composites

pHEMA-starch composites were synthesized by emulsion polymerization in the presence of HEMA and different ratios of starch (1, 3, 5 and 10 %). The FT-IR spectra obtained for pHEMA and pHEMA-starch composites are shown in Fig. 1. The –OH stretching vibration band was observed at 3438 cm−1 and the asymmetric CH2 stretching was confirmed at 2960 cm−1. The ester stretching band of the carboxyl group (C=O) was observed at 1727 cm−1; the characteristic absorption band of C–O–C was observed at 1276 cm−1; the asymmetric stretching vibration of C–O was observed at 1161 cm−1; the distortion vibration bands of methyl and methylene were observed at 1454, 947 cm−1, respectively [33, 34]. The characteristic absorption band of the vinyl group was not observed, which indicated that the HEMA monomer was successfully converted to the pHEMA polymer through the emulsion polymerization reaction. Compared to the pure pHEMA polymer, infrared spectra of the pHEMA-starch composites are similar to pure pHEMA. This is a typical characteristic absorption band of -OH in the starch unit, whose relative intensity increased along with the starch amount.

A differential scanning calorimeter (DSC) was used to study the thermal behavior of the pure pHEMA and pHEMA-starch composites. A thermogravimetric analyzer (TGA) and differential thermal analyzer (DTA) were also used to determine the thermal stability of the pure pHEMA and pHEMA-starch composites in the 20–800 °C range.

Thermal stabilities of the synthesized pHEMA and pHEMA-starch composites were determined by thermogravimetric analysis (TGA) (Fig. 2). Two distinct mass loss peaks can be seen in Fig. 2. The initial weight loss up to 120 °C is attributed to the moisture retained in the sample. The decomposition temperatures of pure pHEMA are in the range of 220–400 °C. However, because the thermal stability of the starch is low, decomposition temperatures of pHEMA-starch composites are shifting to even lower values. Especially, approximately 10 % mass loss in pHEMA-S-10 % composites confirms the presence of starch in the structure of pHEMA-starch composites at between 50 and 200 °C.

DTA schematic representations of pHEMA and pHEMA-starch composites are given in Fig. 3. In these thermograms, a decomposition peak of pHEMA is between 230 and 450 °C. Structures containing starch shows also two main decomposition peaks. The first peak is degradation of starch in the structure; the second peak is a decomposition peak of the polymeric structure. With increase in level of starch, first main peak shifts to lower temperature value. This proves that the structure of starch has entered.

All the samples were characterized via differential scanning calorimeter (DSC) for the glass transition temperature (Tg). As seen in Fig. 4, this curve indicated that Tg temperature of pure pHEMA is 111 °C [35]. With the structure of the starch, these values increase. Tg values of the starch-containing structures are 119, 125, 149 and 165 °C, respectively. Because of hydrogen bonds between pHEMA and starch, the chains are more stocked and the value of free volume decreases. With the decrease of the value of the free volume, Tg values are shifting to higher values.

Presence of enzyme binding

L-ASNase was immobilized into pHEMA-starch composites by physical adsorption. For confirming the presence of L-asparaginase in composite structure, FT-IR, SEM and EDX techniques were used. The FT-IR spectra of pHEMA, pHEMA-S-5 % composite and pHEMA-S-5 %-L-ASNase are shown in Fig. 5. In the FT-IR spectrum of pHEMA-S-5 %-L-ASNase, the peak at 1638 cm−1 confirmed the formation of an amide bond. The C–O stretching band that appeared at 1322 cm−1 came from the carboxylic acid group of L-asparaginase in the structure of enzyme containing composite. The peak in this wavenumber of pHEMA-S-5 %-L-ASNase is sharper than the peak of the pHEMA and pHEMA-S-5 % composite because of the peptide bond formation in enzyme structure. In addition, peaks due to the presence of characteristic groups in the enzyme structure appear in the spectrum. The peak at 1553 cm−1 is due to the NH bending modes and the band at 1401 cm−1 is due to the CH2 group (scissoring) attached to the amide linkage.

To investigate the influence of L-ASNase incorporated into the pHEMA-starch composites on the morphology, pHEMA-S-5 % and pHEMA-S-5 %-L-ASNase were examined by scanning electron microscopy. Figure 6 represents the typical SEM images of pHEMA-S-5 % and pHEMA-S-5 %-L-ASNase with high and low magnification. It has been reported that the morphology of pHEMA-S-5 %-L-ASNase is found to be very fragmental in shape.

EDX spectra of the pHEMA-S-5 % and pHEMA-S-5 %-L-ASNase were collected and compared to control the content of enzyme in the polymeric matrix (Fig. 7). The presence of N and S can be clearly seen from the EDX spectra of pHEMA-S-5 %-L-ASNase. Thus, the EDX analysis confirmed that L-ASNase was successfully incorporated into pHEMA-starch composites structure.

Contact angle measurements of pHEMA-starch

Using a Wilhelmy plate technique, water contact angle data of the pHEMA and pHEMA-starch composite surfaces are reported in Table 2. We measured three times for each samples and calculated average of three measurements. Water contact angles for pHEMA in the literature described 69° [36]. As seen from the Table 2, we found that the contact angle for pHEMA is consistent with the literature. Depending on the levels of starch, the contact angle of composites was changed from 68° to 38°. The increasing level of the starch generated an increase of the hydrophilicity of composites. These results also prove that increase in the starch ratio can be benefit for more biodegradable pHEMA.

Biodegradation of pHEMA-starch

The biodegradation of pHEMA-starch composites were compared with pure pHEMA in a study for 1 month during interval of 1, 2 and 4 weeks. Degradation results are shown by calculating percentage weight loss in Fig. 8. pHEMA-S composites were observed to be biodegradable and weight loss of pHEMA-S composites were in the range of 14–22 % for 4 weeks. Generally, the weight loss of composites increased as parallel with starch content of pHEMA-S. Especially, weight loss of pHEMA-S-5 % and pHEMA-S-10 % was more than the others.

Effect of pH on the activity of immobilized L-ASNase

Due to the denaturation, effect of changes in pH on the enzyme structure becomes important [37]. The effect of pH on the activity of free and immobilized L-ASNase was determined in the pH range from 4.0 to 10.0. Figure 9 reveals that the maximum relative enzymatic activity of both free and immobilized enzyme was optimal in pH 8.5. For L-ASNase, the optimum pH values of free and immobilized L-ASNase are reported in the literature to be between 8.5 and 9.0 [38, 39]. Literature shows that after immobilization, the optimal range of pH value had no evident changes in comparison with free enzyme [4, 39]. After pH 8.5, the activity of the free enzyme falls considerably in comparison to that of the immobilized enzyme. However, immobilized enzymes maintained significant activity, even at pH 10.0. Immobilized L-ASNase showed resistance to the alkaline changes in medium as compared to the free enzyme. These results clearly demonstrated advantages and importance of enzyme immobilization.

Effect of temperature on immobilized L-ASNase

The thermal stabilities of the free and the immobilized L-ASNase were carried out by measuring the residual activity of the enzyme exposed to eight different temperatures (25–60 °C) in Tris–HCl buffer (50 mM, pH 8.6) for 30 min (Fig. 10). The optimum temperatures of the immobilized and free L-ASNase were 50 and 45 °C, respectively. Increase in optimum temperature was caused by changing physical and chemical properties of the immobilized enzyme. The immobilized formation of enzyme reduces the conformational flexibility, resulting in higher activation energy for the molecule to reorganize to a proper conformation for substrate binding. While, the residual activity ratio of free L-ASNase was 30 % at 55 °C, this ratio was of 95 % for immobilized L-ASNase. The free L-ASNase exactly lost activity at 60 °C. However, the residual activity of immobilized L-ASNase was still at 51 % at 60 °C. Finally, these results indicated the advantage of immobilization on pHEMA-S composite against high temperature.

Calculation of K m and V max of immobilized L-ASNase

Reaction kinetics was analyzed for free and immobilized L-ASNase in Tris–HCl buffer, pH 8.6, at 37 °C using different concentrations of l-asparagine. The kinetic parameters (K m and V max) of the free and immobilized L-ASNase are listed in Table 3. K m and V max are the affinity of the enzyme for its substrate and maximum enzyme activity, respectively. V max The values of K m and V max were found as 0.56, 1.58 mM and 3610, 5882 U/mg of protein for the immobilized and free L-ASNase, respectively. K m value of the immobilized L-ASNase on composites decreased approximately 2.8-fold. As parallel, V max value was also observed at 1.6-fold decrease. In general, K m value of immobilized enzyme is different from the free enzyme due to diffusional limitations, steric effects and ionic strength [40]. In our study, the decrease in K m value of immobilized enzyme proves that immobilized L-asparaginase–substrate interaction is the more suitable confirmation compared with free L-asparaginase–substrate interaction.

Storage stability of immobilized L-ASNase

The storage stabilities of both free and immobilized L-ASNase were investigated at dry condition at 4 °C and room temperature, respectively. The results are shown in Fig. 11. For 4 °C, the free and immobilized L-ASNase residual activities were obtained at above 80 and 60 % at the end of 15 days, respectively. The storage stability of L-asparaginase was also determined at 25 °C. Generally, the free enzyme in solution easily lost activity at room temperature [41]. In 15-day storage period at 25 °C, the residual activity of the free enzyme was completely lost after 7 days. However, immobilized L-ASNase protected 22 % of initial activity during the 15-day period. Therefore, the immobilization of L-asparaginase conferred extended storage life of the enzyme.

Conclusions

In the present work, L-ASNase was successfully immobilized onto biodegradable pHEMA-starch composites matrix, which was prepared by emulsion polymerization from 2-hydroxyethylmethacrylate and different ratios of starch in the presence of potassium persulfate as an initiator. The pure pHEMA and pHEMA-starch composites were characterized by Fourier transform infrared (FT-IR), thermal techniques (TGA, DSC, DTA), dynamic contact angle, SEM and EDX analyses. L-ASNase, a chemotherapeutic enzyme, was immobilized onto pHEMA-starch composites. Optimum conditions for L-ASNase activity were not affected by immobilization of L-ASNase. The optimum pH and temperature for free and immobilized enzyme were found as 8.5 and 45–50 °C, respectively. However, immobilized L-ASNase was more stable at high pH and temperatures. The kinetic parameters for free and immobilized L-ASNase were also determined using the Lineweaver–Burk equation. The K m values were 1.58 and 0.56 mM for free and immobilized enzyme, respectively. The V max values were 5882 and 3610 U/mg of protein for free and immobilized enzyme, respectively. The pHEMA-starch composites as model matrix for enzyme immobilization can provide more advantages both of biocompatibility and biodegradability in comparison with pure pHEMA.

References

Pieters R, Hunger SP, Boos J, Rizzari C, Silverman L, Baruchel A, Goekbuget N, Schrappe M, Pui CH (2011) L-asparaginase treatment in acute lymphoblastic leukemia: a focus on Erwinia asparaginase. Cancer 117:238–249

Avramis VI, Tiwari PN (2006) Asparaginase (native ASNase or pegylated ASNase) in the treatment of acute lymphoblastic leukemia. Int J Nanomedicine 1:241–254

Vına I, Karsakevich A, Bekers M (2001) Stabilization of anti-leukemic enzyme l-asparaginase by immobilization on polysaccharide levan. J Mol Catal B Enzym 11:551–558

Zhang YQ, Tao ML, Shen WD, Zhou YZ, Ding Y, Ma Y, Zhou WL (2004) Immobilization of L-asparaginase on the microparticles of the natural silk sericin protein and its characters. Biomaterials 25:3751–3759

Nabeel A, Nitin PP, Sanjiv KM (2012) L-asparaginase gene—a therapeutic approach towards drugs for cancer cell. Int J Biosci 2:1–11

Zuoa S, Xue D, Zhanga T, Jianga B, Mu W (2014) Biochemical characterization of an extremely thermostable L-asparaginase from Thermococcus gammatolerans. J J Mol Catal B Enzym 109:122–129

Marlborough DI, Miller DS, Cammack KA (1972) Physical properties and subunit structure of l-asparaginase isolated from Erwinia carotovora. Biochem J 126:361–379

Ahlke E, Nowak-Göttl U, Schulze-Westhoff P, Werber G, Börste H, Würthwein G, Jürgens H, Boos J (1997) Dose reduction of asparaginase under pharmacokinetic and pharmacodynamic control during induction therapy in children with acute lymphoblastic leukaemia. Br J Haematol 96:675–681

El-Sayed ST, Fyiad AA, Gamal-Eldeen AM (2012) Immobilization, properties and anti-tumor activity of L-asparaginase of Vicia faba and Phaseoulus vulgaris seeds. Aust J Basic Appl Sci 6:785–794

Kotzia GA, Labrou NE (2011) Engineering substrate specificity of E. carotovora l-asparaginase for the development of biosensor. J Mol Catal B Enzym 72:95–101

Poznansky MJ, Shandling M, Salkie MA, Elliott JF, Lau E (1982) Advantages in the use of L-asparaginase-albumin polymer as an antitumor agent. Cancer Res 42:1020–1025

Wileman TE, Foster RL, Elliott PNC (1986) Soluble asparaginase-dextran conjugates show increased circulatory persistence and lowered antigen reactivity. J Pharm Pharmacol 38:264–271

Maysa EM, Amira M, Gamal E, Sanaa T, Sayed EI (2010) Production immobilization and antitumour activity of Laspraginase of Bacillus sp R36. J Am Sci 6:157–165

Ashihara Y, Kono T, Yamazaki S, Inada Y (1978) Modification of E. coli L-asparaginase with polyethylene glycol: disappearance of binding ability to anti-asparaginase serum. Biochem Biophys Res Commun 83:385–391

Nambu M (1986) Process for producing immobilized L-asparaginase preparations for the therapy of leukemia. US Patent 4617271

Ettinger LJ, Ettinger AG, Avramis VI, Gaynon PS (1997) Acute lymphoblastic leukaemia: a guide to asparaginase and pegaspargase therapy. BioDrugs 7:30–39

Wolf M, Wirth M, Pittner F, Gabor F (2003) Stabilisation and determination of the biological activity of l-asparaginase in poly(d, l-lactide-co-glycolide) nanospheres. Int J Pharm 256:141–152

Asselin BL, Whitin JC, Coppola DJ, Rupp IP, Sallan SE, Cohen HJ (1993) Comparative pharmacokinetic studies of three asparaginase preparations. J Clin Oncol 11:1780–1786

Kök FN, Bozoglu F, Hasirci V (2001) Immobilization of acetylcholinesterase and choline oxidase in/on pHEMA membrane for biosensor construction. J Biomater Sci Polym Ed 12:1161–1176

Galante R, Paradiso P, Moutinho MG, Fernandes AI, Mata JLG, Matos APA, Colaço R, Saramago B, Serro AP (2015) About the effect of eye blinking on drug release from pHEMA-based hydrogels: an in vitro study. J Biomater Sci Polym Ed 26:235–251

Meng X, Stout DA, Sun L, Beingessner RL, Fenniri H, Webster TJ (2012) Novel injectable biomimetic hydrogels with carbon nanofibers and self assembled rosette nanotubes for myocardial applications. J Biomed Mater Res A 101:1095–1102

Alizadeh R, Karimi M, Mofrad RT, Asadpour-Zeynali K, Entezami AA (2015) Electroactive nanofibers of Poly (2-hydroxyethyl methacrylate-graft-aniline) copolymers and their blends with polycaprolactone. Polym Plast Technol Eng 54:21–32

Zhao J, Xiao C, Xu N, Feng Y (2011) Preparation and properties of oil-absorptive fiber based on polybutyl methacrylate-inter-polyhydroxyethyl methacrylate via wet spinning. Polym Plast Technol Eng 50:818–824

Rao SS, Rajiv S (2014) Comparison of nanocomposite film and electrospun nanocomposite fibers based on poly (2-hydroxy ethyl methacrylate) and microcrystalline cellulose as anticancer implants. Polym Plast Technol Eng 53:1690–1696

Chu HH, Ou ED (2000) Emulsion polymerization of 2-hydroxyethyl methacrylate and partition of monomer between particles and water phase. Polym Bull 44:337–344

Mashburn LT, Wriston JC Jr (1963) Tumor inhibitory effect of L-asparaginase. Biochem Biophys Res Commun 12:50–55

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Biochem 72:248–254

Paşahan A, Köytepe S, Ekinci E (2011) Phosphine—oxide containing polyimide membrane for the fabrication of amperometric glucose Sensor. Int J Polymer Mater 60:1079–1090

Babadostu A, Guldu OK, Demirkol DO, Medine EI, Unak P, Timur S (2015) Affinity based laccase immobilization on modified magnetic nanoparticles: biosensing platform for the monitoring of phenolic compounds. Int J Polymer Mater 64:260–266

Branzoi F, Branzoi V (2014) Enzymatic electrode obtained by immobilizing of urease into a nanocomposite film based on conducting polymers and different additives. Int J Polym Mater Polym Biomater 63:549–556

Wen Y, Li D, Xu J, Wang X, He H (2013) Electrosynthesis of Poly(thiophene-3-acetic Acid) film in ionic liquids for covalent immobilization of biologically active species. Int J Polymer Mater 62:437–443

Shukla S, Bajpai AK (2013) Plaster of Paris-reinforced nanocomposites of poly (2-hydroxyethyl Methacrylate-co-acrylamide) as alternative orthopedic material. Polym Plast Technol Eng 52:133–140

Zhang L, Zheng GJ, Guo YT, Zhou L, Du J, He H (2014) Preparation of novel biodegradable pHEMA hydrogel for a tissue engineering scaffold by microwave-assisted polymerization. Asian Pac J Trop Med 7:136–140

Tomic´ SL, Dimitrijevic´ SI, Marinkovic´ AD, Najman S, Filipovic JM (2009) Synthesis and characterization of poly(2-hydroxyethyl methacrylate/itaconic acid) copolymeric hydrogels. Polym Bull 63:837–851

Gumusderelioglu M, Cakmak S, Timucin HO, Cakmak AS (2013) Thermosensitive PHEMA microcarriers: ATRP synthesis, characterization, and usabilities in cell cultures. J Biomater Sci Polym 24:2110–2125

Morra M, Occhiello E, Garbassi F (1992) On the wettability of poly(2-hydroxyethylmethacrylate). J Colloid Interface Sci 149:84–91

Ak M, Yildiz HB, Toppare L (2014) Enzyme immobilization in a photosensitive conducting polymer bearing azobenzene in the main chain. Polym Bull 71:1827–1841

Ghosh S, Chaganti SR, Prakashamb RS (2012) Polyaniline nanofiber as a novel immobilization matrix for the anti-leukemia enzyme L-asparaginase. J Mol Catal B Enzym 74:132–137

Bahreini E, Aghaiypour K, Abbasalipourkabir R, Mokarram AR, Goodarzi MT, Saidijam M (2014) Preparation and nanoencapsulation of l-asparaginase II in chitosan-tripolyphosphate nanoparticles and in vitro release study. Nanoscale Res Lett 9:340–353

Lopez GP, Ratner BD, Rapoca RJ, Horbett TA (1993) Plasma deposition of ultrathin films of poly(2-hydroxyethyl methacrylate): surface analysis and protein adsorption measurements. J Macromol Sci 26:3247–3253

Zhang YQ, Wang YJ, Wang HY, Zhu L, Zhou ZZ (2011) Highly efficient processing of silk fibroin nanoparticle-l-asparaginase bioconjugates and their characterization as a drug delivery system. Soft Matter 7:9728–9736

Acknowledgments

This work was partially supported by The Inonu University Scientific Research Projects Unit (Grant No. BAP 2013/37).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ulu, A., Koytepe, S. & Ates, B. Synthesis and characterization of biodegradable pHEMA-starch composites for immobilization of L-asparaginase. Polym. Bull. 73, 1891–1907 (2016). https://doi.org/10.1007/s00289-015-1583-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1583-1