Abstract

The aim of this study is to evaluate the effect of different thermal pretreatments of the inoculum on the diversity of the microbial community producing hydrogen from sugarcane vinasse. High-throughput sequencing of the 16S and 18S rRNA genes was performed. The reactor samples were also selected for the isolation of strict anaerobes. Decreased microbial diversity was observed with increasing pretreatment temperatures, with Firmicutes predominating: 90% to 97%. The highest abundance of Staphylococcus (7.9%) was found in pretreatment at 120 °C / 20 min at pH 6. The fungal analysis revealed a high prevalence of Candida (47%), Agaricomycetes, Pezizomycotina and Aspergillus in assays with higher H2 production (90° C / 10 min at pH 6). Three species of Clostridium were isolated: C. bifermentans, C. saccharoperbutylacetonicum and C. saccharobutylicum. The isolates were tested separately and in co-cultures for the production of hydrogen. Hydrogen-producing capacity by co-culture of Clostridium species was increased by 18%. Knowing microorganisms and understanding the interaction between eukaryotes and prokaryotes is essential to obtain strategies for biotransformation of vinasse for the production of bioenergy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogen is a clean and renewable energy source that can be produced via anaerobic digestion during the treatment of several agro-industrial residues. Vinasse is a by-product derived from the production of ethanol generated in proportions of 12 to 15 L per liter of ethanol produced, with values of chemical oxygen demand (COD) reaching 100 g L−1, which requires finding suitable treatments before the disposal [1, 2]. Thus, the use of vinasse in anaerobic digestion for the production of hydrogen may be an ecologically correct alternative use of this residue.

The biological production of hydrogen can be performed by pure cultures or microbial consortia from inocula from various sources such as, anaerobic digestion sludge, sewage wastewater, soil samples among others [3]. In these environmental samples, microorganisms (prokaryotes and eukaryotes) are evolutionarily associated, acting on biodegradation and the production of several compounds. The variability of these microorganisms can be used as a source of inocula in various industrial processes, such as bioremediation, fermented foods, anaerobic waste treatment and biofuel production [4].

Several hydrogen-producing microorganisms are present in these environmental samples. Predominantly, strictly anaerobic belonging to the genus Clostridium and, facultative anaerobic microorganisms belonging to the Enterobacteriaceae family and other Proteobacteria, as well as several species of the genus Bacillus are reported in mesophilic conditions [4,5,6]. Eukaryotes (fungi) are also present and play an important role in environmental inocula. These groups of microorganisms can have different fermentative metabolic pathways and compete during the fermentation process. Hydrogen consumption can be linked to two microbiological processes, such as hydrogenotrophic methanogenesis and homoacetogenesis that use hydrogen and carbon dioxide to produce methane and acetic acid, which can cause instability in hydrogen production [7]. Thus, hydrogen production requires pretreatment of the inoculum to suppress the activity of hydrogen consuming bacteria.

The methods of thermal pretreatment of the inoculum have been widely described in the literature [8,9,10] for the elimination of bacteria that do not form spores, since hydrogen-producing bacteria can form protective spores and survive high pressure, such as the genus Clostridium. The thermal pretreatment conditions described in the literature range from 65° C to 121° C with a time of exposure between 20 min and 24 h [8, 11]. Studies describe [12, 13] an increase in hydrogen production using heat pretreatment of the inoculum compared to other pretreatments (aeration, chloroform, acid and base) [14]. However, the effect of thermal pretreatment on the composition of the hydrogen-producing microbial community is not yet well known.

The complex composition of the microbial community of hydrogen-producing reactors has been studied by scanning electron microscopy methods, to visualize the structure of the inoculum and, molecular tools through PCR followed by denaturing gradient gel electrophoresis (PCR-DGGE), real-time PCR (q-PCR), T-RFLP, fluorescence in situ hybridization (FISH), cloning and Sanger sequencing, among others [15]. Currently, high-throughput sequencing has been used to characterize microbial consortia of biotechnological interest, such as hydrogen and methane producers [16]. This method is an alternative since they have high reliability in identifying the composition of microbial communities [17].

Yang and Wang [18] evaluated the composition of the microbial community of fermentative processes for hydrogen production, carried out with inocula subjected to various pretreatment methods (heat shock, acid, base, aeration and gamma radiation) and observed that abundance of Clostridium and Enterococcus showed a considerable variation in the different pretreatments. Etchebehere et al. [17] evaluated the microbial community present in 20 reactors used for hydrogen production in four different countries and described remarkably unequal communities with a high predominance of phylum Firmicutes in most samples. In the samples with a high yield of hydrogen, the genera Clostridium, Kosmotoga, and Enterobacter were detected. However, in samples with low hydrogen production, Lactobacillus and microorganisms of the family Veillonelaceae were found. Knowledge of the microbiota that makes up the fermentation is the key to boost the process and increase the yield of hydrogen production as well as its stability.

Thus, this study aims to evaluate the effect on microbial communities after three methods of thermal pretreatment of the inoculum in the process of hydrogen-producing reactors from sugarcane vinasse. The isolation of strictly anaerobic microorganisms was also performed and tested for the production of hydrogen in pure culture or co-cultures.

Material and Methods

Samples

Samples were taken from batch reactors for hydrogen production from sugarcane vinasse using granular sludge from the vegetable oil industry effluent as inoculum, after different heat treatments, from a previous study [19]. This granular sludge inoculum was chosen because it represents an efficient anaerobic COD removal process. Samples of the initial inoculum before pretreatments and the final fermentation stage were taken and stored at 4 °C for subsequent isolation in culture or were stored at − 20 °C for subsequent DNA extraction. The assays were performed using undiluted vinasse without adding nutrients or another carbon source. The COD concentration of vinasse was 20.84 g/L and the initial pH was set to 5, 6 or 7 according to Standard Methods [20].

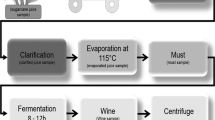

The identification of the microbial community producing hydrogen from batch reactors is a complementary work to the study by Magrini et al. [19] as shown in the flowchart in Fig. 1. Samples were taken from each of the tests pretreatment with better hydrogen yield (HY) (Figure S1, Table S1, Supplementary material), specifically: Sample 1 (S1) taken from the test with thermal pretreatment of the inoculum of 90 °C / 10 min at pH 6 (4.75 mmol H2 / g COD); Sample 2 (S2)—105 °C / 120 min at pH 5 (4.50 mmol H2 / g COD); Sample 3 (S3)—121 °C / 20 min at pH 6 (4.47 mmol H2 / g COD) [19].

Flowchart of the experimental process. The orange figures are the tests that were carried out in this study as a complement to the previous study by Magrini et al. [19] (figures in gray) (Color figure online)

Isolation and Identification of Microorganisms

The microorganisms from the samples of the final fermentation stage of samples S1, S2 and S3 were isolated. For the isolation of the strict anaerobic, serial dilutions (1:10) were carried out in PYG culture medium g / L (glucose 10, meat extract 5, yeast extract 5, peptone 5) supplemented with 13% agar (HiMedia) under anaerobic conditions. The isolation was performed with the Roll tube technique, as described by Castelló et al. [21]. Isolates were characterized according to the method described by Eder et al. [22], using universal primers for the partial ribosomal 16S rRNA gene: 16S-F 5’-CCTGGCTCAGGACGAACGCTGG-3’ and 16S-R 5’-CTGCGCTCGCTTTACGCCAAT-3’ [23]. The sequences obtained were deposited in NCBI GenBank with accession numbers MK027301; MK027302; MK027303.

High Throughput Sequencing of 16S and 18S rRNA Genes

The total DNA of initial inoculum and the samples S1, S2 and S3 were extracted with the PowerSoil DNeasy Kit (QIAGEN) according to the manufacturer's protocol.

The extracted DNA was amplified by PCR with the primers 515F (5'-GTGCCAGCMGCCGCGGTAA-3') and 806R (5'-GGACTACVSGGGTCTCAT-3') that amplify the V4 region of the 16S rRNA ribosomal gene [24]. For characterization of eukaryotes (including fungi), fragments of the 18S ribosomal gene were amplified using the primers Fw (5'-ATTAGGGTTCGATTCCGGAGAGG-3') and Rv (5'-CTGGAATTACCGCGGSTGCTG-3'), described by Nolte et al. [25]. The amplified fragments were visualized on 1% agarose gel (Figure S2).

PCR products were submitted to high throughput DNA sequencing on the Ion PGM System (Thermo Fisher) following the manufacturer’s instructions. The libraries construction was performed with the Ion Plus Fragment Library kit for short amplicons (≤ 350pb), from 100 ng of the amplification product. For the quantification and equalization of the libraries, the Ion Library Equalizer kit was used according to the manufacturer’s instructions. An adapter containing unique sequences (IonXpress Barcode kit) was added to each sample so that these could be identified and sequenced in one sequencing. All procedures were performed according to the manufacturer’s protocol.

For the PCR reaction emulsion and enrichment steps, the Hi-Q ion PGM View OT2 kit was used with the One Touch System Ion 2. For sequencing, an Ion chip 316 was used with the Ion PGM Hi-Q View Sequencing Kit according to the manufacturer's instructions. Fragments of the 16S and 18S ribosomal genes generated by the sequencing were submitted to quality control using the PRINSEQ program [26]. The replicate sequences were identified, sorted and filtered to exclude singletons using the USEARCH v8.0.1623 program [27]. The clusters of sequences were assembled using UCLUST algorithm on 97% minimum identity. Chimeras were removed using the RDP reference database [28]. The taxonomic attribution was obtained using QIIME v1.9 at 97% of similarity with GreenGenes 13.8 database [29, 30] for 16S and 18S rRNA fragments, respectively. The sequences were deposited at the National Center Biotechnology Information (NCBI) in BioProject PRJNA471891.

Microscopy

Images by scanning electron microscopy were obtained in equipment FEI Inspect F50 in secondary electron mode (SE) available at Microscopy and Microanalysis Laboratory Center (LabCEMM) PUCRS. Samples were fixed with 2.5% glutaraldehyde, washed with 0.2 M phosphate buffer, post-fixed with 2% osmium tetroxide, dehydrated with acetone and HMDS, and then coated with Au–Pd sputtering.

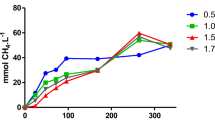

Production of Hydrogen by Isolates

The microorganisms were initially grown and incubated on an orbital shaker at 37 °C until the exponential phase. The amount of inoculum used was based on the absorbance of the cultures at 600 nm, adjusted to 1 O.D. (optical density). The co-cultures were constructed with an equal number of cells of each isolate microorganism according to Eder et al. [22]. The assay was performed in 60 mL glass vials containing 30 mL of vinasse undiluted at pH 6.0. The bottles were kept under agitation (Ethik Technology) at 140 rpm at 37 °C and in the absence of light. To guarantee the anaerobiosis conditions, nitrogen gas (N2) was injected for 10 min. All assays were performed in triplicate. The volume of hydrogen was determined by applying the ideal gas equation (PV = nRT), where P is the local atmospheric pressure (0.918 atm), V is the volume of H2 (liters), n is the number of moles of H2, R is the universal ideal gas constant (0.082 atm L/K.mol), and T is the temperature in the tests (K).

Chemical Analysis

The hydrogen concentration was measured by gas chromatography (Dani Master – Automatic Sample AS Chromatographer) equipped with a thermic conductivity detector (TCD) and chromatographic column CarboxenTM 1006 PLOT Capillary Column (30 m × 0.53 mm). Ultra-pure nitrogen gas was used as the carrier gas at 6 mL min−1 flow. The injector temperature was 100 °C, the detector temperature was 230 °C and the column temperature was 40 °C. For the preparation of the calibration curve, volumes of 10, 25, 50, 100, 150, 200 and 250 μL of pure hydrogen gas were injected.

Additional Statistical Analysis

Statistical analyses of Shannon and Simpson alpha diversity (observed OTU abundances) and Chao1 (species richness) were performed using the Past3 software [31]. To evaluate the connections between microbial community (8 most abundant genera or OTU) and chemical parameters (substrate consumption (% SC), COD removal (%), hydrogen yield (HY), final pH and volatile fatty acids (mg/L), the Canonical Correspondence Analysis (ACC) was also performed with the Past3 software.

Results and Discussion

Bacterial Community Analysis

More than 55 000 16S ribosomal gene fragment sequences were obtained for each sample analyzed. The analysis of the microbial community showed a considerable variation between the initial inoculum and samples after the thermal treatments followed the fermentation (Fig. 2). In the initial sample, a total of 25 phyla were identified, with a predominance of Proteobacteria (31.2%), Bacteroidetes (30.5%) and 15.7% of the operational taxonomic unit (OTU) Bacteria AC1. These results are similar to those found by Si et al. [32], where it was observed a high microbial diversity in this type of sample.

In the samples after fermentation, the predominance was of the Firmicutes phylum with 90.6% (S1), 95.2% (S2) and 97.2% (S3). It was observed that with the increase in temperature in the pretreatments, the predominance of Firmicutes increased, decreasing the microbial diversity in these inoculums (Fig. 2). The predominance of the phyla Firmicutes was also observed by other authors in reactors of hydrogen production. Etchebehere et al. [17] observed the prevalence of this phylum in 25 of the 29 samples of different bioreactors operated in Brazil, Chile, Mexico, and Uruguay. Si et al. [32], comparing the hydrogen production of granular inoculum in two types of reactors, found 99% of Firmicutes in the UASB (upflow anaerobic reactor) and 91% in the PBR reactor (fixed bed reactor).

In the initial inoculum, 13 genera and 11 OTUs were identified, showing a considerable microbial diversity in the crude granular inoculum (Fig. 3). By comparing the initial inoculum and the samples (S1, S2 and S3), it is possible to observe a variation of the microbial diversity before and after the pretreatments. The microorganisms present at the beginning of the fermentation (Fig. 3) are fundamental to the process since some genera such as Syntrophomonas, Bacillus, Mycoplana and Chryseobacterium act in the hydrolysis process of the organic matter transforming it into simpler compounds for bacterial assimilation [33,34,35].

In the samples S1, S2 and S3, there is a reduction of microbial diversity and a high predominance of the genus Clostridium and an OTU belonging to Clostridiaceae family, with relative abundances comprising 90% for each pretreatment (Fig. 3). It indicates that the three thermal pretreatments favor hydrogen-producing spore-forming microorganisms. Clostridium is a bacterium described as a producer of hydrogen due to its high growth rate, high yields in the process and the capacity to use several carbon sources as a substrate [36]. Different Clostridium species have already been used in fermentative trials for the production of hydrogen, such as Clostridium beijerinckii, Clostridium butyrene, Clostridium tyrobutyricum, Clostridium acetobutylicum and Clostridium saccharoperbutylacetonicum [37].

However, some Clostridium species also act as homoacetogenic bacteria, consume hydrogen to produce acetic acid [7], or even produce lactate and propionate by lowering hydrogen yield [38]. A significant abundance of the genus Clostridium was detected in the higher hydrogen production (S1) assay (Fig. S1), but the 16S ribosomal gene sequences obtained in the high-performance sequencing are about 250–300 nucleotides, which did not allow to classify sequences at the species level (Fig. 3).

In S3, the greatest abundance of the genus Staphylococcus (7.9%) (Fig. 3 and Table 1) was obtained, which besides acting on the oxygen consumption, also produces extracellular polymeric substances (EPS), which act to form the structures [39] playing a vital role in the integrity of the granules. Possibly the high temperature and the pressure of this pretreatment favored the aggregation of Staphylococcus species and consequently the production of EPS, which conferred resistance and stability of the granules in this assay.

Other genera such as Bacillus, Syntrophomonas, Geobacter, Syntrophus, Sulfurimonas were also detected mainly in S1 and the initial inoculum (Fig. 3 and Table 1) and unidentified in S2 and S3. These genera have an essential role in the microbial consortium, either in the substrate hydrolysis or the degradation of volatile fatty acids or even in the case of Sulfurimonas, they act in the sulfur oxidation in sulfate [33, 34, 40].

In addition to the microorganisms mentioned above, other genera were also found in relative abundance smaller than 1% of the total sequences for S1, S2, and S3, but higher in the initial inoculum (Table 1). Stenotrophomonas from the Proteobacteria phylum, act in the process of acetogenesis [41]. Arcobacter, Mycoplana, Chryseobacterium, and Flavobacterium assist in substrate hydrolysis, degradation of amino acids and complex organic compound [35, 42,43,44] are strict halotolerant and thiosulfate-reducing anaerobes [45]. However, Fusibacter genus is a strict anaerobe halotolerant and, reduces thiosulfate [45].

To measure the microbial diversity, the Shannon (H'), Simpson (D) and Chao 1 indices were applied, indicating similar diversity (71) for the microorganisms from the S2 and S3 samples, with a decrease in diversity in relation to S1 (100) and compared to the initial inoculum (Table 2). The canonical correspondence analysis (CCA) (Fig. 4) shows that there is a correlation between hydrogen production (S1) with the order Bacteroidales and SHA-114 OTUs. The hydrogen production (S1) was also correlated with the high initial acetic acid concentration (400 mg/L) (Figure S4, Supplementary material) and abundances of Geobacter. Currently, this genus has been widely described in anaerobic digestion of waste due to its ability to transfer extracellular electrons [46]. About 40% of the Geobacteraceae family can use hydrogen as an electron donor [47]. Further, Geobacter is capable of oxidizing acetate, which might explain the decrease of acetic acid during the assays S1 (400 to 80 mg/L). This genus is efficient in generating electric current and producing bioelectrochemical hydrogen through microbial electrolysis cells (MECs), improving hydrogen yield (HY) [48], which may be promising in the future work to improve efficiency in the production of hydrogen from sugarcane vinasse.

The fermentation process in S3 is related to the great abundance of Staphylococcus, which act in the production of EPS favoring the anaerobic environment due to the maintenance of the granule and, may also be involved in the production of hydrogen, as described in previous works [23]. S3 is also related to the presence of isovaleric acid that can be oxidized to form hydrogen, acetic acid, and propionic acid, which demonstrated a higher amount in this pretreatment while S2 is correlated to the production of valeric and isobutyric acids (Fig. S4), Clostridium and a OTU belonging to the Clostridiaceae family are related to the three assays.

Identification of Microorganisms and Hydrogen Production by the Isolates

Six strains of strictly anaerobic microorganisms from the assay S1, four strains from the S2 and S3 assays were isolated. Out of these isolates, three species were identified: Clostridium bifermentans isolated from S1, C. saccharoperbutylacetonicum isolated from S1, S2 and S3 samples and C. saccharobutylicum from S2 and S3 (Table 3). Only Clostridium species were isolated due to the Roll tube method used [49] to be exclusive for the selection of strict spore-forming anaerobic microorganisms and possibly the cultivation and anaerobiosis conditions favored the selection of these species. It was not possible to isolate other anaerobic species present in these samples (Fig. 3).

The species of C. bifermentans and C. saccharoperbutylacetonicum are already reported as producers of biohydrogen [50,51,52]. C. saccharobutylicum is cited in the literature as a producer of butanol and 1,3-propanediol [53, 54]. Clostridium species are very versatile because they can utilize a variety of carbohydrate sources, including cellulosic, hemicellulosic and starch materials [55, 56].

To test the interaction between these microorganisms, they were evaluated for the production of hydrogen alone and associated with co-cultures. Table 3 shows the H2 production results of selected isolates. C. bifermentans alone was the best producer of hydrogen in vinasse (435 mL H2). When associated with co-culture C. bifermentans and C. saccharoperbutylacetonicum, hydrogen production increased by 18% (530 mL H2). It corroborated with other studies describing the potential of C. bifermentans in the production of hydrogen from vinasse [57], glucose [58] or wastewater sludge [59]. The other Clostridium species had a low hydrogen production, with no statistically significant differences in both, alone and in co-cultures, using vinasse as substrate (Table 3).

However, the hydrogen production by isolates obtained (Table 3) was smaller than that of microbial consortia (Table S1). The bioassay S1 obtained a hydrogen production 48% higher (821 mLH2) than the isolate C. bifermentans (435 mL H2) and 35% higher than the co-culture C. bifermentans and C. saccharoperbutylacetonicum (530 mL H2). A similar result was also observed with the facultative anaerobic microorganisms Enterobacter muelleri, Enterobacter tabaci and Bacillus subtilis with a hydrogen production lower than the microbial consortium [19]. These results show that even though the consortium is dominated by Clostridium species (Fig. 3), microbial diversity and interaction with other facultative anaerobic microorganisms play a vital role in hydrogen production.

Obtaining isolated microorganisms is very important, as they can be used to study the causes of the instability of hydrogen production and the physiological capacity of microorganisms alone for certain substrates or residues. [4]. Isolates can be used for artificial construction or bio-augmentation of microbial consortia to increase hydrogen production and produce compounds of biotechnological interest in fermentation processes.

Analysis of the Fungal Community

Both the sludge and vinasse used in reactors for hydrogen production are environmental samples with complex microbiota, so in addition to the bacterial community described above, the fungal community was also evaluated in the fermentation trials. The fungi were evaluated in the initial inoculum and S1 sample, assay with higher hydrogen yield (4.75 mmol H2 / g COD) (Table 4). The unicellular fungus Candida was found in great abundance in the initial inoculum (24%) and increased 50% to the fermentation process (47%). Possibly the considerable increase of Candida can be due to the composition of the vinasse used as a substrate, which favored the growth of this microorganism, being a product of the sugar and alcohol industry. However, the presence of Candida in the microbial community may be an inhibiting factor in the production of biohydrogen during acidogenesis due to the production of antimicrobial compounds (usually proteins or low molecular weight glycoproteins < 20 kDa) [60]. In future works, efficient methods of pretreatment in the control of the yeast population in the tests of hydrogen production can be evaluated.

In the sample after fermentation (S1), they were also found in significant proportions class Agaricomycetes (5.2%) and Pezizomycotina subphylum (4.6%), which are common fungi in activated sludge [61]. They play an essential role in the fermentation process since they synthesize enzymes that digest polysaccharides [62], aiding the hydrolysis of the substrate, facilitating the absorption of hydrolytic bacteria into hydrogen and volatile fatty acids.

The filamentous fungus Aspergillus remained constant from start to end of fermentation (~ 4%). Some species of Aspergillus are sources of enzymes such as pectinases, proteases, and amyloglucosidases, which may aid in the hydrolysis process, forming a hydrolyzate rich in nutrients and facilitating the production of hydrogen [63].

There was an increase in the abundance of subphylum Mucoromycotina in the final sample (Table 4). This group of filamentous fungi participates in biodegradation under aerobic and anaerobic conditions and has carbohydrase activity, facilitating the biodegradation of complex compounds [64, 65] and are capable of growing on substrates such as vinasse [66].

The presence of fungi in the fermentation process is due to the fact that they are more resistant than bacteria, due to their persistence characteristics in environments with a large amount of organic matter [61]. However, Hernández et al. [67] noted that the loss of greater diversity was to fungi than to bacteria after heat treatment of the inoculum (105 °C for 24 h) and, bacterial communities recover more readily than fungal communities.

Some works suggest the bio-augmentation of activated sludge with fungi capable of degrading pollutants, mainly phenols or fungi specialized in degrading lignocellulosic substrates, capable of converting polysaccharides into simple sugars that can be subsequently fermented, improving the efficiency for subsequent hydrogen production [61, 68]. This hydrolysis process requires the synergistic action of pools of enzymes that in many cases, only mixed cultures composed of fungi and bacteria can produce [67].

Microbial Morphology in the Different Assays

In the scanning electron microscopy (SEM) images of the initial inoculum (a) before the pretreatments, an agglomerate of several microorganisms forming the granular structure of the sludge is observed at a resolution of 10 000 X (Fig. 5a).

The samples after the thermal treatments S1 (Fig. 5b) and S2 (Fig. 5c) were very similar morphologically, with the predominance of bacilli-like structures, possibly bacteria of the genus Clostridium, which was found in high abundance in the sequencing analysis. While in the S3 sample (Fig. 5d), the inoculum presents itself with a higher amount of bacilli and cocci, possibly Staphylococcus, that produce EPS and for this reason, the inoculum is more compacted than in the other pre-treatments.

In this study, the S1 sample which had the best performance in hydrogen production, indicating that under these conditions the strict anaerobic microorganisms (Clostridium) responsible for the efficiency of hydrogen production were favored, as well as the facultative anaerobic microorganisms (bacteria and fungi), which are extremely important in the maintenance of anaerobic and substrate hydrolysis.

Not only composition and microbial diversity are important, but also the abundance and interaction between the different microorganisms that drive the process. Also, we observed that Clostridium alone or associated with other species of this genus (Table 3) do not present the same performance as when related to other facultative microorganisms as observed in the microbial consortium [19], which indicates once again that the interaction with other microorganisms is fundamental for the fermentation success.

The production of hydrogen via microbial consortium is already described as a complex process, and this is increased when associated with agro-industrial residues, such as sugarcane vinasse. Besides the bacterial diversity of the inoculum and the substrate, we have the presence of fungi, which are also part of this microecosystems and play a key role in microbial ecology, assisting in the process of degradation and hydrolysis of vinasse used as substrate.

Conclusion

The thermal pretreatments and the initial pH values of the samples showed an influence on the composition of the microbial community and consequently on the fermentative metabolism of the reactors.

With the increase in temperature of the pretreatments, there was also an increase in the predominance of the Firmicutes phyla, with 90.6% (S1), 95.2% (S2) and 97.2% (S3) and consequently decreased microbial diversity.

In S1 sample, where there was a higher production of hydrogen, there was a great abundance of the genus Clostridium and the presence of Bacillus, Syntrophomonas, Geobacter, Arcobacter, Stenotrophomonas, besides the correlation with Bacteroidales. In addition to the fungi Agaricomycetes, Pezizomycotina, and Aspergillus described as necessary in the hydrolytic process of vinasse.

Clostridium bifermentans alone and the combination of the co-cultures C. bifermentans and C. saccharoperbutylacetonicum performed well in the production of hydrogen (435 and 529 mL, respectively), but a poor performance compared to assays with consortia microbial (821 mL H2). These results show that microbial diversity and the interaction with microorganisms (prokaryotes and eukaryotes) play a crucial role in the production of hydrogen.

The results obtained in this work show the influence of the pretreatments of inocula on the microbiota diversity in the vinasse bioconversion for the production of hydrogen. These results provide new insights to understand how different pretreatments can affect the functionality and interaction between the different organisms present in an ecosystem.

Data Availability

The data used to support the findings of this study are available upon request.

References

Sydney EB, Larroche C, Novak AC et al (2014) Economic process to produce biohydrogen and volatile fatty acids by a mixed culture using vinasse from sugarcane ethanol industry as nutrient source. Bioresour Technol 159:380–386. https://doi.org/10.1016/j.biortech.2014.02.042

Ramos LR, Silva EL (2018) Continuous hydrogen production from cofermentation of sugarcane vinasse and cheese whey in a thermophilic anaerobic fluidized bed reactor. Int J Hydrogen Energy 43:13081–13089. https://doi.org/10.1016/j.ijhydene.2018.05.070

Maintinguer SI, Sakamoto IK, Adorno MAT, Varesche MBA (2015) Bacterial diversity from environmental sample applied to bio-hydrogen production. Int J Hydrogen Energy 40:3180–3190. https://doi.org/10.1016/j.ijhydene.2014.12.118

Fuentes L, Braga L, Castelló E, Etchebehere C (2018) Work scheme to isolate the different micro-organisms found in hydrogen-producing reactors: a study of effectiveness by pyrosequencing analysis. J Appl Microbiol 125:96–110. https://doi.org/10.1111/jam.13763

Motte JC, Trably E, Hamelin JÔ et al (2014) Total solid content drives hydrogen production through microbial selection during thermophilic fermentation. Bioresour Technol 166:610–615. https://doi.org/10.1016/j.biortech.2014.05.078

Ferraz Júnior ADN, Etchebehere C, Zaiat M (2015) Mesophilic hydrogen production in acidogenic packed-bed reactors (APBR) using raw sugarcane vinasse as substrate: Influence of support materials. Anaerobe 34:94–105. https://doi.org/10.1016/j.anaerobe.2015.04.008

Saady NMC (2013) Homoacetogenesis during hydrogen production by mixed cultures dark fermentation: unresolved challenge. Int J Hydrogen Energy 38:13172–13191. https://doi.org/10.1016/j.ijhydene.2013.07.122

Ren NQ, Guo WQ, Wang XJ et al (2008) Effects of different pretreatment methods on fermentation types and dominant bacteria for hydrogen production. Int J Hydrogen Energy 33:4318–4324. https://doi.org/10.1016/j.ijhydene.2008.06.003

Kim DH, Han SK, Kim SH, Shin HS (2006) Effect of gas sparging on continuous fermentative hydrogen production. Int J Hydrogen Energy 31:2158–2169. https://doi.org/10.1016/j.ijhydene.2006.02.012

Khanal SK, Chen WH, Li L, Sung S (2004) Biological hydrogen production: Effects of pH and intermediate products. Int J Hydrogen Energy 29:1123–1131. https://doi.org/10.1016/j.ijhydene.2003.11.002

Wang J, Yin Y (2017) Principle and application of different pretreatment methods for enriching hydrogen-producing bacteria from mixed cultures. Int J Hydrogen Energy 42:4804–4823. https://doi.org/10.1016/j.ijhydene.2017.01.135

Bakonyi P, Borza B, Orlovits K et al (2014) Fermentative hydrogen production by conventionally and unconventionally heat pretreated seed cultures: a comparative assessment. Int J Hydrogen Energy 39:5589–5596. https://doi.org/10.1016/j.ijhydene.2014.01.110

Yang S, Phan H, Bustamante H et al (2017) Effects of shearing on biogas production and microbial community structure during anaerobic digestion with recuperative thickening. Bioresour Technol 234:439–447. https://doi.org/10.1016/j.biortech.2017.03.051

Wang J, Wan W (2008) Comparison of different pretreatment methods for enriching hydrogen-producing bacteria from digested sludge. Int J Hydrogen Energy 33:2934–2941. https://doi.org/10.1016/j.ijhydene.2008.03.048

Tolvanen KES, Karp MT (2011) Molecular methods for characterizing mixed microbial communities in hydrogen-fermenting systems. Int J Hydrogen Energy 36:5280–5288. https://doi.org/10.1016/j.ijhydene.2011.01.029

Faust K, Raes J (2012) Microbial interactions: from networks to models. Nat Rev Microbiol 10:538–550. https://doi.org/10.1038/nrmicro2832

Etchebehere C, Castelló E, Wenzel J et al (2016) Microbial communities from 20 different hydrogen-producing reactors studied by 454 pyrosequencing. Appl Microbiol Biotechnol 100:3371–3384. https://doi.org/10.1007/s00253-016-7325-y

Yang G, Wang J (2018) Kinetics and microbial community analysis for hydrogen production using raw grass inoculated with different pretreated mixed culture. Bioresour Technol 247:954–962. https://doi.org/10.1016/j.biortech.2017.09.041

Magrini FE, de Almeida GM, da Maia SD et al (2020) Effect of different heat treatments of inoculum on the production of hydrogen and volatile fatty acids by dark fermentation of sugarcane vinasse In Biomass Convers. Biorefinery. https://doi.org/10.1007/s13399-020-00687-0

APHA, AWWA, WEF (2017) Standard Methods for the Examination of Water and Wastewater. Washington, DC

Castelló E, Braga L, Fuentes L, Etchebehere C (2018) Possible causes for the instability in the H2 production from cheese whey in a CSTR. Int J Hydrogen Energy 43:2654–2665. https://doi.org/10.1016/j.ijhydene.2017.12.104

Eder AS, Magrini FE, Spengler A et al (2020) Comparison of hydrogen and volatile fatty acid production by Bacillus cereus, Enterococcus faecalis and Enterobacter aerogenes singly, in co-cultures or in the bioaugmentation of microbial consortium from sugarcane vinasse. Environ Technol Innov 18:100638. https://doi.org/10.1016/j.eti.2020.100638

Poleto L, Souza P, Magrini FE et al (2016) Selection and identification of microorganisms present in the treatment of wastewater and activated sludge to produce biohydrogen from glycerol. Int J Hydrogen Energy 41:4374–4381. https://doi.org/10.1016/j.ijhydene.2015.06.051

Bates ST, Berg-Lyons D, Caporaso JG et al (2011) Examining the global distribution of dominant archaeal populations in soil. ISME J 5:908–917. https://doi.org/10.1038/ismej.2010.171

Nolte V, Pandey RV, Jost S et al (2010) Contrasting seasonal niche separation between rare and abundant taxa conceals the extent of protist diversity. Mol Ecol 19:2908–2915. https://doi.org/10.1111/j.1365-294X.2010.04669.x

Schmieder R, Edwards R (2011) Quality control and preprocessing of metagenomic datasets. Bioinformatics 27:863–864. https://doi.org/10.1093/bioinformatics/btr026

Edgar RC (2010) Search and clustering orders of magnitude faster than BLAST. Bioinformatics 26:2460–2461. https://doi.org/10.1093/bioinformatics/btq461

Cole JR, Wang Q, Fish JA et al (2014) Ribosomal Database Project: Data and tools for high throughput rRNA analysis. Nucleic Acids Res 42:633–642. https://doi.org/10.1093/nar/gkt1244

DeSantis TZ, Hugenholtz P, Larsen N et al (2006) Greengenes, a chimera-checked 16S rRNA gene database and workbench compatible with ARB. Appl Environ Microbiol 72:5069–5072. https://doi.org/10.1128/AEM.03006-05

Caporaso JG, Kuczynski J, Stombaugh J et al (2010) correspondence QIIME allows analysis of high- throughput community sequencing data Intensity normalization improves color calling in SOLiD sequencing. Nat Publ Gr 7:335–336. https://doi.org/10.1038/nmeth0510-335

Hammer Ø, Harper DAT, Ryan PD (2009) PAST–Palaeontological statistics. Palaeontol Electron 4:1–9

Si B, Liu Z, Zhang Y et al (2016) Towards biohythane production from biomass: Influence of operational stage on anaerobic fermentation and microbial community. Int J Hydrogen Energy 41:4429–4438. https://doi.org/10.1016/j.ijhydene.2015.06.045

Gan Y, Qiu Q, Liu P et al (2012) Syntrophic oxidation of propionate in rice field soil at 15 and 30°C under methanogenic conditions. Appl Environ Microbiol 78:4923–4932. https://doi.org/10.1128/AEM.00688-12

Shah AT, Favaro L, Alibardi L et al (2016) Bacillus sp. strains to produce bio-hydrogen from the organic fraction of municipal solid waste. Appl Energy 176:116–124. https://doi.org/10.1016/j.apenergy.2016.05.054

Wang Y, Wang Q, Li M et al (2016) An alternative anaerobic treatment process for treatment of heavy oil refinery wastewater containing polar organics. Biochem Eng J 105:44–51. https://doi.org/10.1016/j.bej.2015.08.012

Lin PY, Whang LM, Wu YR et al (2007) Biological hydrogen production of the genus clostridium: metabolic study and mathematical model simulation. Int J Hydrogen Energy 32:1728–1735. https://doi.org/10.1016/j.ijhydene.2006.12.009

Abdeshahian P, Al-Shorgani NKN, Salih NKM et al (2014) The production of biohydrogen by a novel strain Clostridium sp. YM1 in dark fermentation process. Int J Hydrogen Energy 39:12524–12531. https://doi.org/10.1016/j.ijhydene.2014.05.081

Hawkes FR, Hussy I, Kyazze G et al (2007) Continuous dark fermentative hydrogen production by mesophilic microflora: Principles and progress. Int J Hydrogen Energy 32:172–184. https://doi.org/10.1016/j.ijhydene.2006.08.014

Hung CH, Cheng CH, Guan DW et al (2011) Interactions between Clostridium sp. and other facultative anaerobes in a self-formed granular sludge hydrogen-producing bioreactor. Int J Hydrogen Energy 36:8704–8711. https://doi.org/10.1016/j.ijhydene.2010.06.010

Zhang K, Ren NQ, Wang AJ (2015) Fermentative hydrogen production from corn stover hydrolyzate by two typical seed sludges: Effect of temperature. Int J Hydrogen Energy 40:3838–3848. https://doi.org/10.1016/j.ijhydene.2015.01.120

Dhar BR, Elbeshbishy E, Hafez H, Lee HS (2015) Hydrogen production from sugar beet juice using an integrated biohydrogen process of dark fermentation and microbial electrolysis cell. Bioresour Technol 198:223–230. https://doi.org/10.1016/j.biortech.2015.08.048

Ruiz V, Ilhan ZE, Kang DW et al (2014) The source of inoculum plays a defining role in the development of MEC microbial consortia fed with acetic and propionic acid mixtures. J Biotechnol 182–183:11–18. https://doi.org/10.1016/j.jbiotec.2014.04.016

Gao Y, Wang C, Zhang W et al (2017) Vertical and horizontal assemblage patterns of bacterial communities in a eutrophic river receiving domestic wastewater in southeast China. Environ Pollut 230:469–478. https://doi.org/10.1016/j.envpol.2017.06.081

Guo N, Ma X, Ren S et al (2019) Mechanisms of metabolic performance enhancement during electrically assisted anaerobic treatment of chloramphenicol wastewater. Water Res 156:199–207. https://doi.org/10.1016/j.watres.2019.03.032

Li D, Hendry P, Faiz M (2008) A survey of the microbial populations in some Australian coalbed methane reservoirs. Int J Coal Geol 76:14–24. https://doi.org/10.1016/j.coal.2008.04.007

Mei R, Nobu MK, Narihiro T et al (2018) Novel Geobacter species and diverse methanogens contribute to enhanced methane production in media-added methanogenic reactors. Water Res 147:403–412. https://doi.org/10.1016/j.watres.2018.10.026

Coppi MV, O’Neil RA, Lovley DR (2004) Identification of an uptake hydrogenase required for hydrogen-dependent reduction of Fe(III) and other electron acceptors by geobacter sulfurreducens. J Bacteriol 186:3022–3028. https://doi.org/10.1128/JB.186.10.3022-3028.2004

Wang L, Singh L, Liu H (2018) Revealing the impact of hydrogen production-consumption loop against efficient hydrogen recovery in single chamber microbial electrolysis cells (MECs). Int J Hydrogen Energy 43:13064–13071. https://doi.org/10.1016/j.ijhydene.2018.05.081

Hungate RE (1969) Chapter IV A roll tube method for cultivation of strict anaerobes. Methods Microbiol 3:117–132. https://doi.org/10.1016/S0580-9517(08)70503-8

Alalayah WM, Kalil MS, Kadhum AAH et al (2008) Hydrogen production using clostridium saccharoperbutylacetonicum N1–4 (ATCC 13564). Int J Hydrogen Energy 33:7392–7396. https://doi.org/10.1016/j.ijhydene.2008.09.066

Al-Shorgani NKN, Tibin EM, Ali E et al (2014) Biohydrogen production from agroindustrial wastes via Clostridium saccharoperbutylacetonicum N1–4 (ATCC 13564). Clean Technol Environ Policy 16:11–21. https://doi.org/10.1007/s10098-013-0586-6

Wong YM, Wu TY, Ling TC et al (2018) Evaluating new bio-hydrogen producers: clostridium perfringens strain JJC, clostridium bifermentans strain WYM and clostridium sp. strain Ade.TY. J Biosci Bioeng 125:590–598. https://doi.org/10.1016/j.jbiosc.2017.12.012

Gungormusler M, Gonen C, Ozdemir G, Azbar N (2010) 1,3-Propanediol production potential of Clostridium saccharobutylicum NRRL B-643. N Biotechnol 27:782–788. https://doi.org/10.1016/j.nbt.2010.07.010

Ujor V, Bharathidasan AK, Michel FC et al (2015) Butanol production from inulin-rich chicory and Taraxacum kok-saghyz extracts: determination of sugar utilization profile of Clostridium saccharobutylicum P262. Ind Crops Prod 76:739–748. https://doi.org/10.1016/j.indcrop.2015.07.045

Al-Shorgani NKN, Kalil MS, Yusoff WMW (2011) The effect of different carbon sources on biobutanol production using clostridium saccharoperbutylacetonicum Nl-4. Biotechnology 10:280–285. https://doi.org/10.3923/biotech.2011.280.285

Nizzy AM, Kannan S, Anand SB (2020) Identification of hydrogen gas producing anaerobic bacteria isolated from sago industrial effluent. Curr Microbiol 77:2544–2553. https://doi.org/10.1007/s00284-020-02092-2

Rabelo CABS, Soares LA, Sakamoto IK et al (2018) Optimization of hydrogen and organic acids productions with autochthonous and allochthonous bacteria from sugarcane bagasse in batch reactors. J Environ Manage 223:952–963. https://doi.org/10.1016/j.jenvman.2018.07.015

Singh S, Sudhakaran AK, Sarma PM et al (2010) Dark fermentative biohydrogen production by mesophilic bacterial consortia isolated from riverbed sediments. Int J Hydrogen Energy 35:10645–10652. https://doi.org/10.1016/j.ijhydene.2010.03.010

Wang CC, Chang CW, Chu CP et al (2003) Producing hydrogen from wastewater sludge by Clostridium bifermentans. J Biotechnol 102:83–92. https://doi.org/10.1016/S0168-1656(03)00007-5

Detman A, Chojnacka A, Mielecki D et al (2018) Inhibition of hydrogen-yielding dark fermentation by ascomycetous yeasts. Int J Hydrogen Energy 43:10967–10979. https://doi.org/10.1016/j.ijhydene.2018.05.004

Wang X, Wang Y, Zhang A et al (2019) Isolation of a highly efficient phenol-degrading fungus and the preparation of an effective microbial inoculum for activated sludge and its enhancement for hydrogen production. Int J Hydrogen Energy 44:16004–16014. https://doi.org/10.1016/j.ijhydene.2018.10.154

Zhao L, Cao GL, Wang AJ et al (2013) Simultaneous saccharification and fermentation of fungal pretreated cornstalk for hydrogen production using Thermoanaerobacterium thermosaccharolyticum W16. Bioresour Technol 145:103–107. https://doi.org/10.1016/j.biortech.2013.01.144

Han W, Ye M, Zhu AJ et al (2015) Batch dark fermentation from enzymatic hydrolyzed food waste for hydrogen production. Bioresour Technol 191:24–29. https://doi.org/10.1016/j.biortech.2015.04.120

Fisgativa H, Tremier A, Le Roux S et al (2017) Understanding the anaerobic biodegradability of food waste: Relationship between the typological, biochemical and microbial characteristics. J Environ Manage 188:95–107. https://doi.org/10.1016/j.jenvman.2016.11.058

Zambrano C, Kotogán A, Bencsik O et al (2018) Mobilization of phenolic antioxidants from grape, apple and pitahaya residues via solid state fungal fermentation and carbohydrase treatment. LWT - Food Sci Technol 89:457–465. https://doi.org/10.1016/j.lwt.2017.11.025

Ahmed PM, Pajot HF, De Figueroa LIC, Gusils CH (2018) Sustainable bioremediation of sugarcane vinasse using autochthonous macrofungi. J Environ Chem Eng 6:5177–5185. https://doi.org/10.1016/j.jece.2018.08.007

Hernández C, Alamilla-Ortiz ZL, Escalante AE et al (2019) Heat-shock treatment applied to inocula for H2 production decreases microbial diversities, interspecific interactions and performance using cellulose as substrate. Int J Hydrogen Energy 44:13126–13134. https://doi.org/10.1016/j.ijhydene.2019.03.124

Nkemka VN, Gilroyed B, Yanke J et al (2015) Bioaugmentation with an anaerobic fungus in a two-stage process for biohydrogen and biogas production using corn silage and cattail. Bioresour Technol 185:79–88. https://doi.org/10.1016/j.biortech.2015.02.100

Acknowledgements

The authors thank Petrobras for their financial support, the University of Caxias do Sul and the Pontifical Catholic University of Rio Grande do Sul, in particular, the Institute of Petroleum and Natural Resources (IPR/PUCRS) and the Laboratory of High Performance (LAD/PUCRS). Luiz Gustavo dos A. Borges thanks PEGA/PUCRS.

Funding

This work was funded by Petrobras/CENPES [0050.007.3626.12.9] and supported by the University of Caxias do Sul.

Author information

Authors and Affiliations

Contributions

FEV designed the study, analyzed the data and wrote the paper; GMA and DMS carried out the experiments; LGB, LM and AG performed bioinformatic analyses and modified the manuscript; SP wrote the paper and supervised the research. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Magrini, F.E., de Almeida, G.M., da Maia Soares, D. et al. Variation of the Prokaryotic and Eukaryotic Communities After Distinct Methods of Thermal Pretreatment of the Inoculum in Hydrogen-Production Reactors from Sugarcane Vinasse. Curr Microbiol 78, 2682–2694 (2021). https://doi.org/10.1007/s00284-021-02527-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-021-02527-4