Abstract

One of the biggest environmental impacts of mining is the generation of acid mine drainage (AMD). In the absence of proper post-mining management practices, AMD pollution can cause massive environmental damage. Current AMD management practices often fail to meet the expectations of cost, efficiency, and sustainability. The objective of this study was to utilize the metal-binding and acid-neutralizing capacity of an industrial by-product that is otherwise landfilled, namely drinking-water treatment residuals (WTRs), to treat AMD-water, thus offering a green remediation alternative. AMD-water was collected from Tab-Simco coal mine in Carbondale, Illinois. It was highly acidic (pH 2.27), and contaminated with metals, metalloids and sulfate at very high concentrations. A filter media, prepared using locally-generated aluminum (Al) and calcium (Ca)-based WTRs, was used to increase pH and to remove metals and \({\mathrm{SO}}_4^{2 - }\) from AMD-water. Laboratory-batch sorption studies at various WTRs (Al and Ca):AMD-water ratios were performed to optimize the filter media. WTRs:sand ratio of 1:6 provided optimal permeability, and 1:1 Al-WTRs:Ca-WTRs ratio was the optimal sorbent mix for removal of the metals of concern. A scaled-up study using a 55-gallon WTRs and sand-based filter was designed and tested. The results showed that the filter media removed more than 99% of the initial Fe (137 mg/L), Al (80 mg/L), Zn (11 mg/L), Pb (7 mg/L), As (4 mg/L), Mn (33 mg/L), and 44% of the initial \({\mathrm{SO}}_4^{2 - }\) (2481 mg/L) from Tab-Simco AMD-water. pH increased from 2.27 to 7.8. Desorption experiments showed that the metals were irreversibly bound to the WTRs and were not released back to the water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Production of acid mine drainage (AMD) is one of the most concerning environmental impacts associated with mining operations. Oxidation of pyrite (FeS2), in the presence of oxygen and water, can lead to the generation of a metal-rich and highly acidic solution, namely AMD. The overall pyrite oxidation reaction can be expressed as follows (Stumm and Morgan 1981):

pH of AMD is reported to be typically between 2.0 and 4.0, in which many metals are highly soluble (Neculita et al. 2007; RoyChowdhury et al. 2015). Studies have reported AMD-induced acidity and metal toxicity to have destroyed habitats of many aquatic species, such as trout, shrimp, and mosquito fish (Soucek et al. 2000; Hansen et al. 2002; Schmidt et al. 2002; Gerhardt et al. 2004; Martin and Goldblatt 2007; Jennings et al. 2008; Trout Unlimited 2011). Without proper management practices, abandoned mine sites could accelerate the AMD generation process. Currently, more than 557,000 abandoned mines exist in the United States (US Forest Service 2005), and AMD-impacted streams range between 15,000 and 23,000 km across the country (Kim et al. 1982; U.S. Forest Service 1993; USEPA 1994a; Jennings et al. 2008).

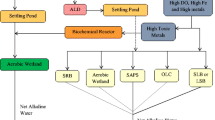

AMD treatment technologies are either prevention/source control techniques or remediation techniques. Prevention techniques focus on exclusion of oxygen or water or both from the system to control AMD production. Remediation techniques employ various methods to clean up AMD and AMD-impacted systems (Johnson and Hallberg 2005; RoyChowdhury et al. 2015). Existing AMD remediation technologies, such as aerobic wetlands, anaerobic wetlands, and sulfate-reducing bioreactors are costly, require constant maintenance, and cannot address AMD problems over a prolonged period of time (RoyChowdhury et al. 2015). Hence, there is an urgent need to develop technically and economically effective AMD remediation technologies, ideally that are also sustainable.

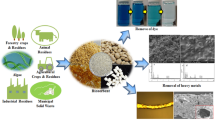

Drinking water treatment residuals (WTRs) are a by-product of water coagulation and flocculation process. The most frequently used coagulants include alum, iron salts, and lime, which generate aluminum-based water treatment residuals (Al-WTRs), iron-based water treatment residuals (Fe-WTRs), and calcium-based water treatment residuals (Ca-WTRs), respectively. More than 2 mega tons of WTRs are generated from various water treatment facilities in the United States every day (Prakash and Sengupta 2003), which, in the absence of proper recycling options, are mostly landfilled. Al- and Fe-WTRs are primarily made of amorphous oxides and hydroxides of aluminum and iron, which provide reaction sites for adsorption of heavy metals, such as Cu, Pb, and Zn (Sarkar et al. 2007; Makris 2004; Makris et al. 2004), while Ca-WTRs is a liming agent which can be used to increase solution pH (RoyChowdhury et al. 2018). WTRs have high affinity for a wide range of environmental contaminants, such as perchlorate, phosphate, chromate, and arsenate (Sarkar et al. 2007; Makris et al. 2004; Makris et al. 2006a, b, Makris et al. 2007, Hardy et al. 2008, Nagar et al. 2009). With very small particle size distribution and an extensive micro-porous network, WTRs ensure a high relative surface area for sorption (Sarkar et al. 2007; Makris 2004; Makris et al. 2004; Hardy et al. 2008). Toxicity Characteristic Leaching Protocol (TCLP) studies have consistently shown that the leaching of bound metals from WTRs are well under the USEPA-prescribed limit (Makris et al. 2006a, b; Sarkar et al. 2007; RoyChowdhury et al. 2018), which classifies WTRs as non-hazardous, allowing for reuse in various environmental applications. These unique characteristics of WTRs led us to hypothesize their potential reuse in pH elevation and removal of toxic metals from AMD-impacted water. Hence, the objectives of this study were (1) to develop a WTRs-based gravity flow filter media to lower the acidity and metal concentrations in AMD-water, (2) to optimize the efficiency of the proposed WTRs-based filter media via laboratory batch and column experiments, and (3) to design and evaluate a field-deployable drum filter using the optimized WTRs-based filter media.

Materials and Methods

Location of AMD-Site, Sample Collection and Characterization

The Tab-Simco mine, an abandoned coal mine located in Carbondale, Illinois, was selected as the proposed study area of this project. This site is reported to be heavily impacted by AMD contamination (RoyChowdhury et al. 2017; Smith 2002; Segid 2010). Detailed characterization of the Tab-Simco mine site and its AMD pollution status has been reported elsewhere (RoyChowdhury et al. 2017). In 2007, a sulfate-reducing bioreactor (SRB) was constructed at the Tab-Simco site, but the system failed in 2011 (Behum et al. 2013). The bioreactor is currently filled with AMD-water (Figures ESM1 and ESM2 in online resources), from which water samples were collected in October, 2014. Samples were collected and transported to New Jersey following the 1981 EPA/CE-81-1 protocol (Plumb 1981). Detailed methods for handling and analysis of these samples has been reported elsewhere (RoyChowdhury et al. 2017).

Water samples were tested for pH and electrical conductivity (using Oakton ion 510 series pH/conductivity meter, USA). pH and EC measurements were taken both on site and at the laboratory following standard protocols (Klute 1996; Rhoades 1996). Samples were then filtered using 0.45 µm syringe filter, and tested for RCRA 8 metals plus Fe, Al, Mn, Cu, and Ni using an ICP-MS (Thermo-scientific X-series: X0448, USA). Method detection limit for all analytes tested was 1 µg/L. Filtered water samples were also tested for total sulfate (\({\mathrm{SO}}_4^{2 - }\)) using a Dionex IC (IC 25 with EG 40, Dionex, USA). All analyses were performed in triplicates.

Collection and Characterization of WTRs

Al-WTRs was collected from the City of Carbondale Water Treatment Plant, IL, and Ca-WTRs was collected from Saline Valley Water Treatment Plant, IL. Al- and Ca-WTRs were transported to New Jersey following the 1981 EPA/CE-81-1 protocol (Plumb 1981). WTR samples were air-dried, ground, and sieved through a 1-mm sieve prior to use. pH and EC of Al-WTRs and Ca-WTRs were measured following standard protocols (Klute 1996; Rhoades 1996). Organic matter content of WTRs was calculated using loss on ignition (LOI) method (Klute 1996). Total C and N content of Al- and Ca-WTRs were analyzed following a dry combustion process using an Elementar Vario EL-III CHNS analyzer (USA). Total Fe and Al concentrations of Al- and Ca-WTRs were analyzed by ICP-MS following USEPA 3050B method (USEPA 1996). Oxalate-extractable Fe and Al concentrations were determined by ICP-MS following the ammonium oxalate extraction method (McKeague et al. 1971). Toxicity characteristics leaching protocol (TCLP) tests were performed on both WTRs using the USEPA 1311 method. Method detection limit for all analytes tested was 1 µg/L. All analyses were performed in triplicates.

Laboratory Batch Sorption Experiments

Metal sorption experiments with Al- and Ca-WTRs were performed as a function of solid:solution ratio and contact time. All experiments were carried out in triplicates in 50-mL polypropylene centrifuge tubes. For laboratory batch sorption experiments, reaction volume was set as 50 mL as 50-mL polypropylene centrifuge tubes are sturdy and easy to handle in such experimental setups. Detailed experimental setups are described in the following subsections. Only metals that exceeded USEPA permissible limit in Tab-Simco AMD-water were used in these experiments.

Effect of Solid:Solution Ratio

Six solid:solution (g:mL) ratios of WTRs to AMD-water were tested: 1:10, 1:25, 1:50, 1:100, 1:125, and 1:150. Solid:solution ratios were selected based on previous studies on WTRs involving various environmental contaminants (Makris et al. 2006a; Nagar et al. 2009; Punamiya et al. 2013; Sarkar et al. 2007). To achieve these solid:solution ratios, an appropriate mass of WTRs was introduced into 50 mL AMD-water in a 50 mL polypropylene centrifuge tube. In the tests to evaluate the effect of co-application of Al-WTRs and Ca-WTRs, mass ratios of 1:1, 1:2, and 2:1 Al-WTRs to Ca-WTRs were used. Co-application was tested for higher solid:solution ratios (1:100, 1:125, and 1:150), and in total, 21 different treatments were tested. It was hypothesized that co-application of Al- and Ca-WTRs would reduce the overall amount of WTRs required to treat AMD-water. pH was not controlled during the treatments; initial and final pH values were recorded. The tubes were shaken on a reciprocating shaker at 250 rpm for 24 h at room temperature, then centrifuged at 4000 × g for 15 min at room temperature and filtered using 0.45 µm syringe filters. Metals exceeding the USEPA permissible limit were analyzed, and the optimum solid:solution ratio was determined.

Effect of Contact Time

Once the optimal solid:solution ratio was determined, various contact time intervals were tested for metals sorption: 1, 2, 3, 5, 10, 15, 30 min, 1, 2, 6, 10, and 24 h, using the same reactor (50 mL centrifuge tubes) as described in the previous section. The retention times were selected based on previous WTR studies on different environmental contaminants (Hardy 2008; Makris et al. 2006a; Nagar et al. 2009; Punamiya et al. 2013; Sarkar et al. 2007).

Desorption studies were performed using spent WTRs after completion of the solid:solution ratio experiments. Supernatants were removed and residuals were collected, air-dried, and weighed. An appropriate volume of deionized (DI) water was added to the tubes to attain the initial solid:solution ratio. Samples were shaken at 250 rpm on a reciprocating shaker at room temperature. Samples were withdrawn at designated time intervals (1, 6, 12, 24, 40, and 48 h), filtered using 0.45 µm syringe filters and analyzed for metals.

Laboratory-Scale WTRs-Filter Column Studies

WTRs-filter columns were prepared using 30 cm × 2.54 cm clear PVC pipes. Each end of the pipe was fitted with a 2.54-cm dome-shaped cap. Each of these caps was drilled in order to install inlet/outlet tubing. Glass wool and filter membranes were used to seal the bottom to prevent leaching of the filter media. A Cole-Parmer Ismatec 4 channel peristaltic pump was used to feed AMD-water into the columns (Fig. 1, and ESM3 in online resource).

One of the major disadvantages of WTRs is their low porosity. To improve hydraulic conductivity of the filter media (10 cm height and 53 mL volume), WTRs were uniformly mixed with sand at ten mass ratios ranging from 1:1 to 1:10. Sand was thoroughly washed with DI water and dried prior to mixing. Based on the results of previous experiments, a 1:1 mixture of Al-WTRs to Ca-WTRs was used for this study. Hydraulic tests were conducted using DI water to select the optimal WTRs:sand ratio. The filtration rate was greatly influenced by the height of water table over the filter bed. Therefore, the flow rate was measured at ten different heights of water table above the filter media (1–10 cm). Based on the test results, an optimal WTRs:sand ratio was selected for follow-studies where AMD-water was passed through the WTRs-filter media, and filtrates were periodically collected until the number of bed volume (BV) reached 50. Collected samples were filtered (using 0.45 µm syringe filters) for measurement of RCRA 8 metals plus Fe, Al, Mn, Cu, Ni (using ICP-MS), and \({\mathrm{SO}}_4^{2 - }\) concentration (using IC). Method detection limit for all analytes tested in ICP-MS was 1 µg/L.

Field-Scale 208 L (55 gallon) Drum Filter Studies

Based on the previous laboratory-scale WTRs-filter column studies, a field-scale 208 L (55 gallon) drum filter was designed, with an outlet pipe at the bottom (Figure ESM4 in online resource). Ninety kg of filter media were packed into the drum. A membrane filter was installed inside the drum to prevent leaching of filter media. Two different types of “green” filter media (1 and 2) were prepared to test the effluent flow rate.

Filter media 1 was prepared by mixing sand and WTRs at 1:6 ratio while maintaining 1:1 ratio of Al-WTRs and Ca-WTRs. The filter media was initially saturated with water. After draining, 378 L (100 gallons) of AMD-water collected from the Tab-Simco SRB pond was fed into the filter. The AMD-water was filtered by gravity without any additional energy requirement. Filtered AMD-water was collected through the outlet at the bottom of the drum.

Filter media 2 was prepared to obtain an increased flow rate by adding clean carbon materials. A specific amount of carbon material was placed at the bottom and the sand-WTRs mixture was layered on top. AMD-water was filtered through the media as described above for filter media 1.

Effluent collected from the filter media 1 and 2 were analyzed for total RCRA 8 metals plus Fe, Al, Mn, Cu, Ni (using ICP-MS), and \({\mathrm{SO}}_4^{2 - }\) concentration (using IC). Method detection limit for all analytes tested in ICP-MS was 1 µg/L. Influent and effluent pHs were recorded.

Results and Discussion

Characterization of Tab-Simco AMD-Water

Table 1 presents the characterization data of Tab-Simco AMD-water. Water was highly acidic with a pH of 2.27 ± 0.2. EC of water was 3.9 ± 0.03 mS/cm. Presence of a wide range of metals was detected in the Tab-Simco AMD-water samples. Fe concentration water was 137 ± 5 mg/L, which far exceeded the USEPA permissible limit for Fe (1.0 mg/L) in surface water (USEPA 1994b; NCAC 2003). Among the RCRA8 metals, concentration of As (4.00 ± 0.01 mg/L), Pb (7.0 ± 1.2 mg/L), and Cr (1.0 ± 0.04 mg/L) were significantly higher than their respective USEPA permissible surface water limits (0.05, 0.25, 0.5 mg/L) (USEPA 1994b; NCAC 2003). Zn concentration (11.0 ± 0.9 mg/L) was also higher than its USEPA permissible limit (0.5 mg/L). Other metals with concentrations above USEPA permissible limits included Al (80 ± 15 mg/L), Cu (4 ± 0.05 mg/L), Cd (1 ± 0.01 mg/L), Mn (33 ± 0.36 mg/L), Ni (3 ± 0.25 mg/L), and \({\mathrm{SO}}_4^{2 - }\)(2481 ± 50 mg/L). USEPA permissible limits for Al, Cu, Cd, Mn, Ni, and \({\mathrm{SO}}_4^{2 - }\) are 0.05–0.2, 1, 0.005, 0.05, and 250 mg/L, respectively (USEPA 1994b; NCAC 2003). Tab Simco AMD-water was, therefore, highly contaminated and extremely acidic.

Characterization of WTRs

Physico-chemical properties of Al-WTRs and Ca-WTRs are presented in Table 2. pH of Al-WTRs was 5.9 ± 0.06, while that of Ca-WTRs was 9.4 ± 0.3, indicating high potential of the solid to neutralize the acidity of AMD-water. EC of Al-WTRs and Ca-WTRs was 1615 ± 10.2 and 1552 ± 2.7 µS/cm, respectively. Al-WTRs had 6.78% organic matter content; in contrast, Ca-WTRs had only 0.49% organic matter. The C:N ratios of Al- and Ca-WTRs were 21 and 17, respectively. Al-WTRs had 35,691 ± 114 mg/kg and 15.1 ± 1.7 mg/kg of total Al and Fe content, respectively, among which 80% Al and 45% Fe were oxalate-extractable, indicating the presence of large concentrations of amorphous surfaces that are ideal for metal binding. Total Al and Fe contents of Ca-WTRs were 191 ± 2.5 mg/kg and 1200 ± 8.3 mg/kg with 46% oxalate-extractable Al and 45% oxalate-extractable Fe fraction, respectively. Higher oxalate-extractable Al and Fe fractions are indication of amorphous nature of WTRs that correlates to high specific surface areas and abundant active sorption sites (Makris 2004).

Table 3 presents TCLP results for the RCRA8 metals, plus Al and Fe. All RCRA8 metals were much below their corresponding allowable USEPA limits, indicating that both Al-WTRs and Ca-WTRs could be classified as non-hazardous materials. TCLP results also showed that neither of the WTRs leached any significant amount of Al or Fe.

Batch Sorption Experiments

Effect of solid:solution ratio on pH

Figure 2 shows effects of WTR-amendment on solution pH at various solid:solution ratios. For Al-WTRs treatments, the final pH after 24 h of experimental period ranged from 4.73 to 3.32 with increasing solid:solution ratio from 1:10 to 1:150, which indicates that Al-WTRs had a limited capability to raise the pH of AMD-water. For Ca-WTRs treatments, the final pH ranged from 6.32 to 6.11 with increasing solid:solution ratio from 1:10 to 1:150, suggesting that Ca-WTRs could effectively increase pH of AMD-water, bringing it close to neutral. At a solid:solution ratio of 1:100, co-application of Al-WTRs and Ca-WTRs raised the solution pH to 6.8 and 6.6 where the ratio of Al-WTRs:Ca-WTRs was 1:2 and 1:1, respectively. These results indicate that co-application of Al- and Ca-WTRs would be effective in addressing one of the major concerns of AMD, its high acidity. Co-application also reduced the amount of WTRs required to treat AMD-water. These results were in agreement with past studies where WTRs ability to increase system pH was documented (RoyChowdhury et al. 2018). This study showed that WTRs can effectively increase pH of acidic AMD-water.

Effect of solid:solution ratio on metal adsorption onto WTRs surface

After the acid removal capacity of the WTRs was established, experiments were designed to test their metal removal ability from AMD-water. The effect of solid:solution ratio on adsorption of Fe, As, Pb, Cr, and Zn was tested. Concentrations of all these metals were well above their respective USEPA surface water limits in Tab-Simco AMD-water. It is well established that Al-WTRs irreversibly adsorb metals on their surfaces principally via inner-sphere surface complexation (Sarkar et al. 2007; Makris et al. 2007; Hardy 2008; Punamiya et al. 2015). Amorphous nature of WTRs provided abundant active sorption sites for metals present in the AMD-water. The effect of solid:solution ratio on Fe adsorption to WTRs surface is presented in Fig. 3. The initial Fe concentration of AMD-water was 137 mg/L. The final Fe concentration after 24 h experimental period ranged between 1.04 mg/L (for 1:10 dilution) and 4.77 mg/L (for 1:150 dilution) for Al-WTRs treatments, and between 0.3 mg/L (for 1:25 dilution) and 0.8 mg/L (for 1:150 dilution) for Ca-WTRs treatments. Co-application of Al-WTRs and Ca-WTRs further reduced the Fe concentration of AMD to 0.5 mg/L (1:100 WTR:AMD where Al-WTRs and Ca-WTRs were used at 1:1 ratio). In all treatments where Al-WTRs and Ca-WTRs were co-applied, the Fe concentration decreased to well below the USEPA limit for Fe in surface water (1 mg/L). Arsenic (As) concentration after 24 h experimental period ranged between 0.11 mg/L (1:10 dilution) and 1.46 mg/L (1:150 dilution) for Al-WTRs treatments, and between 0.13 mg/L (1:25 dilution) and 0.73 mg/L (1:150 dilution) for Ca-WTRs treatments. The lowest As concentration among the co-application treatments (0.21 mg/L) was observed at 1:100 solid:solution ratio with a Al-WTRs:Ca-WTRs ratio of 1:1 (Figure ESM5 in online resource). Lead concentration after 24 h experimental period ranged from 0.02 to 1.66 mg/L and from 0.18 to 1.81 mg/L for Al-WTRs and Ca-WTRs treatments, respectively. Lead concentration ranged between 0.47 and 2.17 mg/L for treatments where both WTRs were used together (Figure ESM6 in online resource). Chromium concentration after 24 h experimental period ranged between 0.04 and 0.24 mg/L for Al-WTRs and Ca-WTRs treatments, respectively. Chromium concentration varied from 0.06 to 0.23 mg/L for co-application of Al- and Ca-WTRs (Figure ESM7 in online resource). Zinc concentration after 24 h experimental period was measured at 0.09–3.87 mg/L for Al-WTRs treatments, and at 0.11–0.3 mg/L for Ca-WTRs treatments. Once again, co-application of Al-WTRs and Ca-WTRs significantly reduced Zn concentration at a higher solid:solution ratio (Figure ESM8 in online resource). Our results showed that co-application Al-WTRs and Ca-WTRs provides abundant active sorption sites for all metals present in the AMD-water. As the functional groups in WTRs form inner-sphere surface complexes with metals on their surfaces, the overall metal concentration in the AMD-water was significantly reduced. Results from the metal adsorption studies are in agreement with other published reports. Chiang et al. (2012) showed that heavy metal adsorption on WTRs surface in a multi-metal system was higher than other common heavy metal sorbents, such as goethite and zeolite. Castaldi et al. (2015) showed that Al- and Fe-WTRs can adsorb Cu and Pb from acidic aqueous solution. Their study also showed that WTRs form strong inner-sphere surface complexes with those metals. Previous studies by our group also showed that WTRs are effective in the removal of heavy metals such as Pb, Cu, and Zn from simulated AMD-water matrices containing mixture of heavy metals at high concentrations (Hardy 2008). Results from this study show that Al- and Ca-WTRs are able to significantly reduce acidity and metal concentrations from AMD-water. Co-application of Al- and Ca-WTRs is more effective in lowering acidity and metal concentrations from AMD-water. A ratio of 1:100 sorbent:AMD-water—sorbent being a 1:1 ratio of Al-WTRs to Ca-WTRs—was selected for the next phase of our study. There was a possibility that metal precipitation might have attributed to the removal of metal concentration from the system. However, geochemical modeling using Visual MINTEQ (version 3.1) excluded that possibility. Hence, we infer that adsorption is the major mechanism of metal removal. While the ability of WTRs to adsorb heavy metals from various environmental matrices is well investigated by researchers (Sarkar et al. 2007; Makris et al. 2007; Nagar et al. 2009), the use of Al- and Ca-WTRs for treating an extremely acidic multi-metal contaminated real AMD matrix has not been investigated previously. Our results show that co-application of Al- and Ca-WTRs can not only increase the pH of AMD-water, but can also effectively remove heavy metals from the solution, indicating their potential use for AMD remediation.

Effect of contact time

Within the first 3 min of reaction time, apparent equilibrium was achieved for all metals (Fig. 4); metals adsorption did not vary between 3 and 120 min when the experiments were stopped. A majority of the initial Fe, As, Pb, Cr, and Zn concentrations of AMD-water (99, 100, 97, 100, and 95%, respectively) were adsorbed onto WTRs surfaces. Solution pH was 6.9 ± 0.2. Metals sorption on WTRs surface was very strong and irreversible as documented by the results of the desorption study (Fig. 5). Metal binding on the WTRs surface was irreversible and desorption between 0 and 48 h was insignificant (< 5%). Adsorption of metals on WTRs is associated with the formation of inner-sphere complexes. Previous studies, using various indirect and direct mechanisms, including surface complexation modeling (SCM), X-ray absorption near edge structure (XANES), and extended X-ray absorption fine structure (EXAFS) showed that WTRs can adsorb environmental contaminants such as As, Pb, Cu, and P through inner-sphere complexation (Sarkar et al. 2007; Makris et al. 2007; Hardy 2008; Punamiya et al. 2015). Covalent bonds are generally strong and cannot be easily broken. Studies showed that the oxides and hydroxide functional groups provide reaction sites for adsorption where inner-sphere complexations occur. It is also well documented that amorphous surfaces have much larger site density than crystalline surfaces. Therefore, oxalate-extractable Al and Fe fractions that measure the degree of amorphous surfaces are good indicators of the WTRs potential in binding metals. WTR characterization data of this study (Table 2) show that Al-WTRs contained 80% oxalate-extractable Al and 45% oxalate-extractable Fe, and Ca-WTRs contained 46% oxalate-extractable Al and 45% oxalate-extractable Fe. Hence, Al- and Ca-WTRs can be assumed to provide a large number of adsorption sites for the metals present in the AMD solution. Also, the results from desorption study suggested that the metal binding on the WTRs surface was possibly due to the formation of inner-sphere complexes, which are strong and irreversible (Hardy 2008; Makris 2004; Punamiya et al. 2015). Similar behavior of WTRs were also reported by Chiang et al. (2012), where WTRs removed more than 80% of the contaminants such as Cd, Co, Pb, Ni, and Zn from a multi-metal solution. Castaldi et al. (2015) investigated the adsorption mechanisms of Pb and Cu on WTRs surfaces. Their study used FT-IR spectra to show inner-sphere bonding of the metals on WTRs surface. Our study shows that not only very fast multi-metal adsorption from AMD-water occurred on WTRs surfaces, the adsorption was irreversible.

Metals desorption from spent WTRs previously used in adsorption experiments (Fig. 4) as a function of time (n = 3)

Laboratory-Scale WTRs-Filter Column Studies

Batch sorption experiments showed that Al-WTRs and Ca-WTRs were effective sorbents of metals in AMD-water. A 1:1 ratio of Al-WTRs to Ca-WTRs was selected for follow-up column studies. Clear PVC pipes (30 cm height, 2.54 cm wide) were used to build WTRs-filter columns. As WTRs matrices have very poor permeability, they were mixed with sand at various mass ratios. A BV of 53 mL was used for our study, which was equivalent to 10 cm bed height. A series of hydraulic tests were performed to select the optimal WTRs:sand ratio in terms of both hydraulic characteristics and treatment performance, i.e., metal retention (Figures ESM9 and ESM10 in online resource). Hydraulic retention time (HRT) in the filter bed ranged from 6.18 to 1.35 min at different WTRs:sand ratios (Figure ESM9 in online resource). Increasing sand ratios increased the flow rate in the column. After a series of trials, a ratio of 1:6 WTRs to sand was selected for follow-up experiments, as this ensured a desirable flow rate (15 mL/min) at 10 cm water height (Figure ESM11 in online resource).

After optimizing the composition of the filter media, AMD-water was passed through the column at a flow rate of 15 mL/min. Effluents were periodically collected at different bed volumes. The results are presented in Table 4. The WTRs-filter media increased the initial acidic pH of raw AMD-water from 2.27 to 6.5. It was observed that up to 20 bed volumes, the filter media significantly removed acidity and metal concentrations, but beyond that its overall performance dropped, which indicates that after treating 20 BV equivalent of AMD-water, adsorption capacity of the filter media was exhausted. Rust formation in the treatment column was observed (Figure ESM11 in online resource), which was a result of removal of Fe from AMD-water. The pH of filtered AMD-water was 6.5 (at 1 bed volume). During the study, significant metal removal was observed from the AMD-water. More than 90% metals were removed from the AMD-water (Table 3) with 36% removal of sulfate concentration. At the end of the column study, a TCLP test was performed on the spent WTRs media following the USEPA 1311 method. The results showed that no metal leaching occurred under simulated landfill conditions suggestive of strong, irreversible metal binding on WTRs surface. Results from the WTRs-filter column study were in agreement with the results of our earlier batch sorption studies and showed that the effective metal removal was possible from AMD-water by using WTRs-filter media. Our laboratory-scale WTRs-filter column study showed that Al- and Ca-WTRs have the potential to remediate highly acidic and multiple metals contaminated AMD-water.

Field-Scale WTRs-Based Drum Filter Studies

After testing the sorbent in laboratory column studies, the study was scaled up further, and a field-scale 55-gallon drum filter was designed to treat AMD-water. Two types of filter media were used to prepare the drum filters. Filter media 1 was prepared by mixing sand and WTRs at 1:6 ratio while maintaining 1:1 ratio of Al-WTRs and Ca-WTRs. Filter media 2 had an additional layer of clean carbon material in the bottom to improve flow rate. Experiments using these two filter media showed that both filter media 1 and 2 performed well in terms of pH enhancement and metal adsorption (Table 5). Filter media 1 and 2 improved the AMD pH to 7.1 ± 0.03 and 7.8 ± 0.05, respectively. Concentrations of the metals including Fe, As, Cr, Pb, and Zn were all below their respective USEPA permissible limits, after the AMD-water was passed through the filter. Moreover, filter media 1 and 2 reduced the initial \({\mathrm{SO}}_4^{2 - }\) concentration by 20% and 44%, respectively. However, the filtration rates of the filter media varied considerably. The flow rate of filter media 1 was 3.78 L/min (1 gallon/min), which was significantly lower than that of filter media 2, at 15 L/min (4 gallons/min). A visual comparison of AMD samples before and after filtration is presented in Figure ESM12 in online resource.

No visible gypsum saturation was noticed inside the filter media during the AMD filtration process. Chemical equilibrium calculation using the Visual MINTEQ (version 3.1) software with the input of the AMD-water quality parameters confirmed that gypsum saturation is not likely to occur under the experimental conditions. Visual MINTEQ analysis showed no indication of super-saturation of any minerals. Visual MINTEQ analysis predicted potential formation of minerals such as gibbsite, zincite, zincosite, pyrochroite, arsenolite, chalcanthite, etc., but all of them were predicted to be undersaturated under the experimental conditions. Results from the field-scale WTRs-filter study verified the outcomes of our laboratory batch sorption and column studies, and indicated a high possibility of the WTRs-based filter media to be effective in a field-scale setup for removal of acidity and an array of heavy metals from raw AMD-water.

The results from our batch sorption experiments to column filter experiments to field-scale drum filter studies demonstrated high potential of WTRs-based filter media to remediate AMD-water. Many researchers have examined alternative sorbent materials for their effectiveness in AMD remediation. Some of these reports were based on laboratory-scale studies, while a few were pilot-scale field studies. Asokbunyarat et al. (2015) used coal bottom ash to adsorb heavy metals such as Fe, Cu, Zn, and Mn from synthetic AMD-water, both single and multi-metal systems. Their study showed that adsorption efficiency primarily depends on pH, contact time and solid solution ratio. They also found that adsorption efficiency decreased for multi-metal solutions compared to single metal solutions due to the presence of competing ions. Etale et al. (2016) tested the performance of maghemite nanoparticles (NPs) for removal of Cu and Mn from AMD-water. Their study showed that removal of Cu and Mn from AMD-water by NPs was greatly impacted by pH. Metal removal efficiency of NPs increased with the increase in solution pH. They reported that NPs removed 46% of the initial Cu and 54% of initial Mn from AMD contaminated surface water, and 8% of initial Cu and 50% initial Mn from AMD contaminated groundwater. Presence of Mn negatively impacted the retention of Cu from AMD-water. Lee et al. (2016) tested a permeable reactive kiddle (PRK) to remediate AMD-water. The PRK consisted of a permeable membrane, a supporting PVC frame and the sorbent. Three different sorbents were used for this study, namely steel slag (SS), waste cast iron (WCI), and zerovalent iron (ZVI). Various structures, sizes, and arrangements of PRK, and the mixing ratio of different sorbents and cement were tested for their role in AMD remediation. The study showed that one metric ton of AMD could be remediated using 5–13 kg of sorbent material in the PRK system, and they recommended using more than one PRK arrangements and multiple sorbents to obtain the best AMD remediation efficiency. Choi (2015) reported biosorption of heavy metals from AMD-water on a hybrid system consisting of sericite beads and microalgae Chlorella sp. In this study, AMD-water was passed through a reactor filled with sericite beads where the HRT was 3 h. The sericite-treated AMD-water was introduced to an optical panel photobioreactor (OPPBR). The residence time in OPPBR was 6 days. Removal of metals such as Fe, Cu, Zn, Mn, As, and Cd from the AMD-water was between 97.78 and 99.26%. In another biosorption study, Choi and Lee (2015) tested heavy metal removal efficiency of calcined eggshells and microalgae hybrid system from AMD-water. The experimental design was same as the previous experiment reported by Choi (2015) except that sericite was replaced with calcined eggshells. The study showed that the removal efficiency of Fe, Cu, Zn, Mn, As, and Cd from the AMD was between 99.47 and 100%, which is in a similar range of what we observed in this study. Our results show that WTRs-filter media have a significant remediation potential for AMD. The WTRs-filter media was effective in removing 99% of Fe, Al, Zn, Pb, and As, and increased the pH of the AMD from 2.3 to 7.8. While WTRs have been studied previously for the remediation of various contaminants, application of WTRs-based filter media was never tested before using a field-scale filtration setup. Our study demonstrated for the first time that WTRs-based filter media is a realistic, cost-effective, “green”, and efficient method for remediation of AMD-water.

Conclusion

This study showed that Al- and Ca-WTRs-based filters have the potential for remediation of AMD-impacted water. Laboratory- and field-scale tests showed that co-application of Al-WTRs and Ca-WTRs could neutralize the acidity and adsorb multiple metals and sulfate from AMD-water. Results from batch equilibrium studies showed that a 1:100 ratio of sorbent:AMD-water—where sorbent was a 1:1 ratio of Al-WTRs to Ca-WTRs—was most effective in lowering acidity and metal concentrations from AMD-water. Results from batch studies also showed that adsoption of metals from AMD-water by WTRs was very fast, and occurred within first 3 min of reaction time. Once metals were adsorbed on WTRs surfaces, the bonding was strong and irreversible as desorption of all metals from the spent sorbent was <5%. Batch equilibrium studies were followed by dynamic WTRs-filter column experiments in a laboratory scale. To increase the porosity of WTRs-filter column, a ratio of 1:6 WTRs to sand was selected. During the laboratory WTRs-filter column study, significant improvement of pH of AMD-water was noticed, and more than 90% removal of all metals and 36% removal of sulfate concentration was achieved. Optimized WTRs-filter column was scaled up to a 55-gallon drum filter for field-scale application. The results of field-scale WTRs drum filter study showed that the system effectively removed 99% of metals present in the AMD, and increased the pH of the AMD-water from 2.3 to 7.8. Drinking water treatment plants generated large quantities of WTRs, which are primarily disposed of in landfills. This new technology provides the industrial waste a second life, alongside offering a “green” remediation option to combat AMD pollution. WTRs can be obtained free of cost from drinking-water treatment facilities, thereby making the technology green from a financial point of view. This study demonstrated that WTRs-based filtration process is a promising technology to address AMD-induced water pollution issues.

References

Asokbunyarat V, van Hullebusch ED, Lens PNL, Annachhatre AP (2015) Adsorption of Heavy metals from Acid Mine Drainage by Coal Bottom Ash. In: Rene ER, Bhattarai S, Nancharaiah YV and Lens PNL (eds.) Proceedings of the 4th International Conference on Research Frontiers in Chalcogen Cycle Science & Technology, Delft, The Netherlands, May 28–29, pp 29–39

Behum PT, Lefticariu L, Walter E, Kiser R (2013) Passive treatment of coal-mine drainage by a sulfate-reducing bioreactor in the Illinois coal basin. In: Proceedings of the West Virginia Mine Drainage Task Force Symposium, Morgantown, West Virginia, 26–27 March 2013, p 164

Castaldi P, Silvetti M, Garau G, Demurtas D, Deiana S (2015) Copper (II) and lead (II) removal from aqueous solution by water treatment residues. J Hazard Mater 283(2015):140–147

Chiang YW, Ghyselbrecht K, Santos RM, Martens JA, Swennen R, Cappuyns V, Meesschaert B (2012) Adsorption of multi-heavy metals onto water treatment residuals: Sorption capacities and applications. Chem Eng J 200–202(3):405–415. https://doi.org/10.1016/j.cej.2012.06.070

Choi H-J (2015) Biosorption of heavy metals from acid mine drainage by modified sericite and microalgae hybrid system. Water Air Soil Pollut 226:185. https://doi.org/10.1007/s11270-015-2433-3

Choi H-J, Lee S-M (2015) Heavy metal removal from acid mine drainage by calcined eggshell and microalgae hybrid system. Environ Sci Pollut Res 22:13404–13411. https://doi.org/10.1007/s11356-015-4623-3

Etale A, Tutu H, Drake DC (2016) Application of maghemite nanoparticles as sorbents for the removal of Cu (II), Mn (II) and U (VI) ions from aqueous solution in acid mine drainage conditions. Appl Water Sci 6:187–197. https://doi.org/10.1007/s13201-014-0217-3

Gerhardt A, Bisthoven LJde, Soares AMVM (2004) Macroinvertebrate response to acid mine drainage: community metrics and on-line behavioural toxicity bioassay. Environ Pollut 130(2):263–274

Hansen JA, Welsh PG, Lipton J, Cacela D (2002) Effects of copper exposure on growth and survival of juvenile bull trout. Trans Am Fish Soc 131(4):690–697

Hardy MA (2008) Retention of heavy metals from acid-sulfur rich waste water by water treatment residuals: A reconnaissance study. Master Thesis. The University of Texas at San Antonio: Department of Earth and Environmental Sciences

Jennings SR, Neuman DR, Blicker PS (2008) Acid mine drainage and effects on fish health and ecology: A Review. Reclamation Research Group Publication, Bozeman, MT. http://reclamationresearch.net/publications/Final_Lit_Review_AMD.pdf

Johnson DB, Hallberg KB (2005) Acid mine drainage remediation options: a review. Sci Total Environ 338:3–14

Kim AG, Heisey B, Kleinmann R, Duel M (1982) Acid mine drainage: Control and abatement research. U.S. DOI, Bureau of Mines IC 8905, p 22

Klute A (1996) Methods of soil analysis: Part 1: Physical and mineralogical methods. SSSA Publications, Madison, WI

Lee W-C, Lee S-W, Yun S-T, Lee P-K, Hwang YS, Kim S-O (2016) A novel method of utilizing permeable reactive kiddle (PRK) for the remediation of acid mine drainage. J Hazard Mater 301(2016):332–341. https://doi.org/10.1016/j.jhazmat.2015.09.009

Makris KC (2004) Long-term stability of sorbed phosphorus by drinking-water treatment residuals: Mechanisms and implications. PhD Thesis. University of Florida. Soil and Water Science Department, University of Florida

Makris KC, El-Shall H, Harris WG, O’Connor GA, Obreza TA (2004) Intraparticle phosphorus diffusion in a drinking water treatment residual at room temperature. J Colloid Interface Sci 277:417–423

Makris KC, Sarkar D, Datta R (2006a) Aluminum-based drinking-water treatment residuals: A novel sorbent for perchlorate removal. Environ Pollut 140:9–12

Makris KC, Sarkar D, Datta R (2006b) Evaluating a waste by-product as a novel sorbent for arsenic. Chemosphere 64(5):730–741

Makris KC, Sarkar D, Parsons JG, Datta R, Gardea-Torresdey JL (2007) Surface arsenic speciation of a drinking water treatment residual using X-ray absorption spectroscopy. J Colloid Interface Sci 311:544–550

Martin AJ, Goldblatt R (2007) Speciation, behavior, and bioavailability of copper downstream of a mine-impacted lake. Environ Toxicol Chem 26(12):2594–2603

McKeague JA, Brydon JE, Miles NM (1971) Differentiation of forms of extractable iron and aluminum in soils. Soil Sci Soc Am Proc 35:33–38

Nagar R, Sarkar D, Makris KC, Datta R, Sylvia VL (2009) Bioavailability and bioaccessibility of arsenic in a soil amended with drinking water treatment residuals. Arch Environ Contam Toxicol 57:755–766

Neculita C-M, Zagury GJ, Bussière B (2007) Passive treatment of acid mine drainage in bioreactors using sulfate-reducing bacteria: Critical review and research needs. J Environ Qual 36:1–16. https://doi.org/10.2134/jeq2006.0066

North Carolina Administrative Code (2003) NC DENR - Division of Water Quality “Redbook” Surface Waters and Wetlands Standards. NC Administrative Code 15A NCAC 02B .0100 & .0200. Amended Effective: 1 April 2003

Plumb Jr RH (1981) Procedure for handling and chemical analysis of sediment and water samples. Tech. Rep. EPA/CE-81-1, prepared by Great lakes Laboratory. State Univ College at Buffalo. U.S. Environmental Protection Agency and U.S. Army Corps of Engineers, Waterways Experiment Station, Buffalo, NY, Vicksburg, MS

Prakash P, Sengupta AK (2003) Selective coagulant recovery from water treatment plant residuals using donnan membrane process. Environ Sci Technol 37:4468–4474

Punamiya P, Sarkar D, Rakhsit D, Datta R (2013) Effectiveness of aluminum-based drinking water treatment residuals as a novel sorbent to remove tetracyclines from aqueous medium. J Environ Qual 42:1449–1459. https://doi.org/10.2134/jeq2013.03.0082

Punamiya P, Sarkar D, Rakhsit D, Elzinga EJ, Datta R (2015) Immobilization of tetracyclines in manure and manure-amended soils using aluminum-based drinking water treatment residuals. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-015-5551-y

Rhoades JD (1996) Salinity: Electrical conductivity and total dissolved solids. Methods of soil analysis, part 3: Chemical methods. SSSA Book Series. Sparks et al. (eds). Madison, WI. Soil Sci Soc Am 5.3:417–435. https://doi.org/10.2136/sssabookser5.3.c14

RoyChowdhury A, Sarkar D, Datta D (2015) Remediation of acid mine drainage-impacted water. Curr Pollut Rep 1(3):131–141. https://doi.org/10.1007/s40726-015-0011-3

RoyChowdhury A, Sarkar D, Deng Y, Datta D (2017) Assessment of soil and water contamination at the Tab-Simco coal Mine: A case study. Mine Water Environ 36(2):248–256. https://doi.org/10.1007/s10230-016-0401-9

RoyChowdhury A, Sarkar D, Datta R (2018) Preliminary studies on potential remediation of acid mine drainage-impacted soils by amendment with drinking-water treatment residuals. Remediat J 28(3):75–82. https://doi.org/10.1002/rem.2156

Sarkar D, Makris KC, Vandanapu V, Datta R (2007) Arsenic immobilization in soils amended with drinking-water treatment residuals. Environ Pollut 146:414–419. https://doi.org/10.1016/j.envpol.2006.06.035

Schmidt TS, Soucek DJ, Cherry DS (2002) Modification of an ecotoxicological rating to bioassess small acid mine drainage-impacted watersheds exclusive of benthic macroinvertebrate analysis. Environ Toxicol Chem 21(5):1091–1097

Segid YT (2010) Evaluation of the Tab-Simco acid mine drainage treatment system: Water chemistry, performance and treatment processes. Master Thesis. Southern Illinois, Carbondale: Department of Geology, Southern Illinois University Carbondale (May 2010)

Smith PA (2002) Characterization of an acid mine drainage site in Southern Illinois. In: Proceedings of the 19th Annual National Meeting of the American Society for Surface Mining Reclamation, Lexington, KY, 9–13 June 2002, p 472–486

Soucek DJ, Cherry DS, Currie RJ, Latimer HA, Trent GC (2000) Laboratory and field validation in an integrative assessment of an acid mine drainage-impacted watershed. Environ Toxicol Chem 19(4):1036–1043

Stumm W, Morgan JJ (1981) Aquatic chemistry: An introduction emphasizing chemical equilibria in natural waters, 2nd edn. John Wiley & Sons, New York, p 470

Trout Unlimited (2011) The west branch Susquehanna recovery benchmark project. Lock Haven PA: Trout Unlimited. http://www.patrout.org/docs/reference-materials/west_branch_susquehanna_recovery.pdf?sfvrsn=2

USDA Forest Service (1993) Acid mine drainage from mines on the National Forests, A Management Challenge. U S For Serv Publ 1505:1–12

USDA Forest Service (2005) Wildland waters. Issue 4. Winter 2005; FS-812. http://www.fs.fed.us

USEPA (1994a) Technical document: Acid mine drainage prediction. EPA 530-R-94-036. NTIS PB94-201829. December 1994

USEPA (1994b) Water quality standards handbook, 2nd edn. Water Quality Standards Branch, Office of Science and Technology, Washington, DC, EPA 823-B-94-005a. August 1994

USEPA (1996) Test methods for evaluating solid waste, SW 846, 3rd edn. Office of Solid Waste and Emergency Response, Washington, DC

Acknowledgements

Authors gratefully acknowledge funding provided by the United States Department of the Interior, Office of Surface Mining Reclamation and Enforcement under OMB No.: 4040–0004 for this study. DS was the joint-PI of that grant, and RD was the co-PI. ARC acknowledges the PhD Program in Environmental Management at Montclair State University for his Doctoral Assistantship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

RoyChowdhury, A., Sarkar, D. & Datta, R. Removal of Acidity and Metals from Acid Mine Drainage-Impacted Water using Industrial Byproducts. Environmental Management 63, 148–158 (2019). https://doi.org/10.1007/s00267-018-1112-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00267-018-1112-8