Abstract

This study investigates the use of calcined eggshells and microalgae for the removal of heavy metals from acid mine drainage (AMD) and the simultaneous enhancement of biomass productivity. The experiment was conducted over a period of 6 days in a hybrid system containing calcined eggshells and the microalgae Chlorella vulgaris. The results show that the biomass productivity increased to ~8.04 times its initial concentration of 0.367 g/L as measured by an optical panel photobioreactor (OPPBR) and had a light transmittance of 95 % at a depth of 305 mm. On the other hand, the simultaneous percent removal of Fe, Cu, Zn, Mn, As, and Cd from the AMD effluent was found to be 99.47 to 100 %. These results indicate that the hybrid system with calcined eggshells and microalgae was highly effective for heavy metal removal in the AMD.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acid mine drainage (AMD) is a serious environmental issue that is greatly contaminating water bodies in and around abandoned mine industries. When sulfide/pyretic minerals are exposed to the atmosphere in the presence of water, the oxidation of sulfide produces sulfuric acid and enters into water bodies along with several toxic heavy metal ions in the effluent waters. AMD causes enhanced acidity of water bodies along with elevated levels of iron, sulfates, and heavy metals. This varies depending upon the type of originating mineral deposit. The metallic load in the effluent water is of greater concern than the acidity in terms of environmental damage (Tolonen et al. 2014; Zhang and Wang 2014). Several methods are described for the treatment of AMD. Adsorption is one of the most commonly used methods and is efficient, particularly in the removal of toxic pollutants from effluent waters (Ndlovu 2014; Kim 2015). In summary, the identification and development of low-cost and eco-friendly adsorbents are currently gaining momentum for effective and useful AMD treatment (Johnson and Hallberg 2005; Chen et al. 2014). If low-cost biosorbents are used in AMD treatment processes, the process cost may be significantly reduced.

In this paper, hen eggshells are used as a low-cost biological sorbent of heavy metal ions. The Korean food industry generates 90,000 t of eggshell waste a year (Kim et al. 2009). The disposal uses for eggshell waste include 26.6 % in fertilizer, 21.1 % in animal feed ingredients, 26.3 % in waste discarded in municipal dumps, and 15.8 % in other uses (Tsai et al. 2008; Liu et al. 2013). Many landfills are unwilling to accept the waste because the eggshells and the attached membrane attract vermin. Eggshell waste has been recommended for use as an adsorbent because of its low cost, copious availability in nature, nontoxicity, high specific surface area, and high potential of ion exchange for charged pollutants and because it is safe to handle (Wei et al. 2009; Elwakeel and Yousif 2010; Zang et al. 2012). Eggshell consists of approximately 95 % CaCO3 (which is also the main ingredient in sea shells). The remaining 5 % includes calcium phosphate, magnesium carbonate, and soluble and insoluble proteins (Nys and Guyot 2011; Guru and Dash 2014). Because eggshell is mainly composed of calcium carbonate, it should behave like known sorbents that also contain this compound, such as calcite or calcareous soil (Tsai et al. 2006; Gao and Chunli 2012; Wang et al. 2013). Sorption by eggshells occurs mainly by an exchange reaction, and it should be usable as a new biological sorbent of metal ions. Natural eggshells are less porous than calcined eggshells; therefore, in this paper, calcined eggshells are used to increase the heavy metal removal in the AMD.

Microalgae can sequester heavy metal ions by the same adsorption and absorption mechanisms as other microbial biomass (Yang et al. 2015). Algae are a renewable natural biomass that proliferate ubiquitously and abundantly in the littoral zones of the world and have attracted the attention of many investigators as organisms that can be tested and used as new adsorbents to adsorb metal ions. Several advantages in applying algae as a biosorbent include its wide availability, low cost, high metal sorption capacity, and reliable quality (Fu and Wang 2011; Kumar et al. 2015). There is much research about the metal biosorption using algal biomass. Examples of recent reports include the biosorption of Cu and Zn using Chlorella minutissima (Yang et al. 2015); the biosorption of Cu, Cd, Pb, and Zn using Caulerpa lentillifera (Kumar et al. 2015); the biosorption of chromium from wastewater using Ulva lactuca (El-Silaily et al. 2007); and the biosorption of lead(II) from wastewater by Cladophora fascicularis (Deng et al. 2007).

Many researchers reported several biological, chemical, and physical processes for heavy metal removal from AMD. However, it seems that there is no report examining the effect of calcined eggshell and microalgae hybrid system for the treatment of AMD. The novelty in this study is to propose an effective use of a hybrid system using calcined eggshells and microalgae for the removal of heavy metals and biomass productivity in AMD.

Materials and methods

Microalgae cultures and medium

Seed cultures of Chlorella vulgaris were cultivated in Jaworski’s medium (JM) under light-emitting diode (LED) lamps at ambient temperature. JM consisted of 4.0 g of Ca(NO3)2·H2O, 2.48 g of KH2PO4, 10.0 g of MgSO4·7H2O, 3.18 g NaHCO3, 0.45 g of EDTAFeNa, 0.45 g of EDTANa2, 0.496 g of H3BO3, 0.278 g of MnCl2·4H2O, 0.20 g of (NH4)6Mo7O24·4H2O, 0.008 g of cyanocobalamin, 0.008 g of thiamine HCl, 0.008 g of biotin, 16.0 g of NaNO3, and 7.2 g of Na2HPO4·12H2O in 200 ml of deionized water. The microalgae were cultured in a 200-mL conical flask containing 100 mL of JM, pH (7.2 ± 0.3), and then, 10 mL of C. vulgaris was added. The cultures were maintained in a dark and light cycle of 8 and 16 h, respectively.

Calcined eggshells

Waste eggshell samples were collected from a chicken farm in Gangneung City in Korea. To remove any adhesion and interference materials, such as organics and salts, the sample was rinsed several times with deionized water and boiled in water. After cleaning, eggshells were dried in an oven at 105 °C for 24 h and crushed into fine powder using a mortar and pestle. This raw eggshell powder (325 mesh) was then calcined in a Muffle furnace to 900 °C, and the temperature was maintained for 2 h. This fraction was approximately 60 % of the total dried sample. The thermal treatment had two parts: for the first 30 min, most of the organic materials were burnt off, and during in the second part, the eggshells were transformed into a soft white powder that was designated as calcined eggshells.

The high cationic charge density of eggshells allows it to strongly adsorb the negative regions of other particles. The main ingredient in eggshells is calcium carbonate (the same brittle white material that chalk, limestone, cave stalactites, sea shells, coral, and pearls are made of). Approximately 85–95 % of the eggshell is calcium carbonate, 1.4 % is magnesium carbonate, 0.76 % is phosphate, and 4 % is organic matter. Eggshells also contain traces of sodium, potassium, zinc, manganese, iron, and copper. If calcium from the shell is removed, the organic materials that are left possess calcium (or other metal cation)-binding properties (Chojnacka 2005). Because eggshell is composed mainly of calcium carbonate, it should behave like known sorbents that also contain this compound, such as calcite (Witoon 2011) and calcareous soil (Park et al. 2013). Sorption by eggshells should occur mainly by an exchange reaction, and it should be possible to use it as a new biological sorbent of metal ions.

Characteristics of AMD

The chemical characteristics of the AMD used for this investigation are shown in Table 1. A pilot scale AMD treatment plant was installed at the Yongdong mine located in Gangneung city, Korea. This AMD contained excesses of Fe, Cu, Zn, Mn, As, and Cd content and was low in nutrients compared to the municipal wastewaters. The average pH and electrical conductivity of AMD were measured to be 2.41 and 2295 μS/cm, respectively.

Experimental design

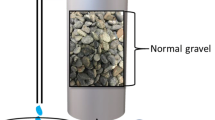

A schematic diagram of the hybrid calcined eggshell and microalgae system for the treatment of AMD is shown in Fig. 1. The operation period of the pilot plant was 180 days. The reactor contained two compartments. The first compartment was filled with the calcined eggshell powder, and the AMD water was introduced here first. The calcined eggshell technique relies on the suspension of small particles that flow upward in the wastewater. This process is capable of neutralizing and removing heavy metals from the AMD. Then, the supernatant is transferred to a microalgae reactor for the treatment of the remaining heavy metals.

The hybrid calcined eggshell and microalgae process treated a total volume of 40 L with calcined eggshells at 120 g/L for 3 h for the neutralization phase and a 40-L working volume for 6 days for the microalgae phase to cultivate microalgae and for the removal of the investigated heavy metal ions. After 6 days, grown microalgae were harvested using chitosan.

OPPBR construction and operation

The optical panel photobioreactor (OPPBR) is operated with a 40-L working volume and is equipped with an optical panel (OP) (Fig. 1). The initial concentration of the inoculated microalgae C. vulgaris is 0.367 ± 0.6 g/L. The experiments are conducted at neutral pH (7.2 ± 0.3) under dark and light cycles of 8 and 16 h, respectively. The temperature is maintained at 23 ± 1 °C using LEDs for 20 days. The OPPBRs are aerated continuously at an aeration rate of 0.5 L/min. CO2 at the equivalent aeration rate of 0.02 vvm is used for cultivation. CO2 with a flow rate of 0.74 L/min is introduced into the reactor. The OPPBR is designed such that the light source (22 LEDs), an LED panel (bar type), is placed in the OPPBR. A v-grooved OP is inserted underneath in the photobioreactor (PBR). The OP exhibits 94 % transmittance and 1.19 specific gravity. The OP dimensions are 210 mm (L) × 290 mm (H) × 6 mm (W) and are constructed from a transparent panel of pure poly-methylmethacrylate (PMMA). This material is fairly transparent, and it has almost negligible light absorption in the visible region (Choi 2014; Choi and Lee 2014). The thickness of the OP is 6 mm. The incident light is uniformly distributed across both sides of the OP in the reactor and provides greater functionality. The LED light source is used because it is efficient and provides a required wavelength of light from 430 to 670 nm, which is selective for microalgal growth. The light intensity, which represents the amount of light used for photosynthesis, is 200~250 μmol photons/m2/s.

Analytical methods

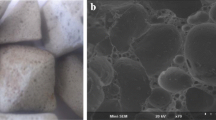

To characterize the calcinations of eggshell, a thermal gravimetric analyzer (TGA-951 DuPont Instruments Co., USA) was used. A portion of the dried eggshell previously freed of impurities and interfering materials, such as organics and salts, was loaded in the TGA analyzer, and then, pyrolysis was performed at up to 900 °C, raising the temperature 40/min with a continuous injection of N2. X-ray fluorescence (XRF-1500, Shimadzu, Japan) was used for the qualitative and quantitative analyses of the inorganic compositions in the natural and calcined eggshells. The mineralogy of the natural and calcined eggshells was characterized by an X-ray diffractor (X-ray Diffractometer, Rigaku PMG-S2, 30 kV × 10 mA). Images of the surface of natural and calcined eggshells were obtained by a scanning electron microscope (SM-300, Topcon, Japan).

To determine the biomass concentration, a sample of microalgae in growth medium was centrifuged for 10 min at 628g, washed with distilled water, and then dried in an oven at 105 °C for 24 h to a constant weight. The biomass productivity P (g/L/day) was calculated from the variation in biomass concentration (g/L) within a cultivation time (in days) according to the following equation:

The specific growth rate μ (in days) was calculated using Eq. (2)

where X 1 and X 0 are the biomass concentrations (g/L) on days t 1 and t 0, respectively.

Uniformity was calculated using Eq. (3)

where L min is the minimum light intensity and L max is the maximum light intensity. All samplings and measurements were conducted at the same time every day.

The Fe, Cu, Zn, Mn, As, and Cd were analyzed using an inductively coupled plasma optical emission spectrometry (ICP-OES: Optima 3300XL, PerkinElmer, MA, USA), following the standard method of measurements (vide APHA 2012). The Eh and EC were measured using a pH/ORP meter (ISTEK, pH-20N) and an EC/TDS/salinity meter (ISTEK, EC-40N), respectively.

Results and discussion

Neutralization process and heavy metal removal using eggshells in the AMD

Calcination of eggshells

Before calcinations, Ca2+ as limestone (91.86 %) and Si (4.32 %) were the important inorganic compositions of eggshells. A similar result has been reported for the chemical composition of natural and boiled hen and duck eggshells, as determined by X-ray fluorescence spectrometry (Liu et al. 2013). They reported that all eggshells had similar chemical contents and were mainly composed of CaCO3 and a few of other elements, such as S, Mg, P, Al, K, and Sr. After calcination, the major inorganic composition was identified as lime (99.54 %), and K, P, and Sr were minor components. This result indicates that the compositions of eggshell can be changed by calcination, as shown in Table 2, and suggests that a relatively pure sample can be obtained from eggshells by removal of more organic compositions.

SEM images of eggshell samples before and after calcinations are shown in Fig. 2a, b, respectively. Before calcination, natural eggshells had a generally irregular crystal structure. After calcinations at 800 °C for 2 h, as shown in Fig. 2b, the crystal structure changed and a developed pore was observed, resulting from the emission of CO2. The formation of CO2 is assumed to follow an endothermic reaction, as described in reaction (4).

Change of pH by various dosages of calcined eggshells and mixing times

Figure 3 depicts the change in AMD effluent pH in the presence of calcined eggshells. These results show that a fast initial increase of pH occurred for AMD effluents in presence of calcined eggshells and that the pH rose to 7.0 ± 0.23 from 2.41 ± 0.11 within just 30 min of contact with calcined eggshells. After 30 min, the pH increased slowly and reached a value of 7.6 ± 0.87 after 3 h of contact. The pH rose to 7.2 ± 0.19 and 7.51 ± 0.21 for 2.5 and 3 g/L calcined eggshells, respectively. Up to 3 g/L of calcined eggshell concentration did not significantly change the pH value, and the highest pH value obtained was 7.5 ± 0.21 for 5 g/L calcined eggshells. To neutralize the AMD using the calcined eggshells, a 30-min mixing time and a 2.5–3 g/L dose were recommended.

Natural eggshell has the major constituent CaCO3. A calcium carbonate feedstock is used to neutralize the acidity in AMD systems by removing free hydrogen ions from the AMD, thereby increasing the effluent pH (Köse and KivanÇ 2011). Calcium carbonate changes to CaO when eggshells are calcined. CaO remains in the solution to play an important role in correcting the adverse effects of acidic conditions. In solution, the carbonate anion is very active in neutralizing H+ cations. While its mode of action is quite different from eggshell, the ability of CaO to neutralize acid solutions is equivalent to eggshell. The resultant high solution pH could be explained by the dissolution of CaO as described in reaction (5).

Moreover, the surface of calcined eggshell provides active sites that are capable of adsorbing several heavy metal toxic ions from aqueous solutions, and this ability is further enhanced under elevated solution pH conditions (Tsai et al. 2006).

Heavy metal removal using calcined eggshells

The adsorption of several heavy metals by the calcined eggshells in the AMD is shown in Table 3. In this study, the results indicate that the heavy metal adsorption efficiency is 80.30, 82.31, 80.27, 80.58, 82.22, and 81.48 % for Fe, Cu, Zn, Mn, As, and Cd, respectively, using calcined eggshells. Cu apparently has a higher percent adsorption than As. The removal rate of natural eggshell also had some removal capacity of heavy metal, 42 % for Fe, 37 % for Cu, 48 % for Pb, 24 % for Cd, and 30 % for Cr (Liu et al. 2013). The calcined eggshell provides a good medium that not only increases the pH of the AMD effluent but also significantly adsorbs heavy metal toxic ions simultaneously. Calcined eggshell is a nontoxic, noncorrosive, and safe-to-handle material; hence, it has wider potential applications in wastewater treatment technologies. It is biocompatible and has attractive adsorption properties and polyelectrolicity; additionally, it can be regenerated by a number of applications. The high cationic charge density of calcined eggshells allows it to strongly adsorb negative regions on other particles.

Biomass productivity and heavy metal removal using microalgae

Biomass productivity

Light is one of the most vital factors that influences the growth and productivity of microalgae. The uniformity was defined in Eq. 3, and hence, the luminance uniformity (%) was obtained as a function of the varied depth level of OP. The light transmittance is found to be 95 % at 305-mm depth in the OPPBR. The OP radiates light with adequate uniformity, prevailing from the top to the bottom of the PBR. The results clearly demonstrate that enhanced light intensity is achieved even deep inside of the PBR using an OP. Moreover, the performance of the PBR containing OP is better than the PBR that does not have an OP unit. The OP of PBR increases the illumination surface to volume ratio as well, providing efficient utilization of light radiation for biomass production. The use of OP provides an equal amount of light energy passing through the reactor, and the irradiance profile is redistributed due to diffuse light from the OP (Choi and Lee 2014). The redistributed irradiance profile results in the higher photosynthetic efficiency of microalgae and leads to effective light utilization. Consequently, the photobioreactor with OP not only increases the illumination area for cultivation but also provides conditions for the effective utilization of light energy to increase the growth rate of microalgae compared with OP unused PBR.

The average biomass growth in the AMD is shown in Fig. 4. The biomass productivity growth reaches 2.95 g/L/day 6 days from the initial concentration of 0.367 ± 0.6 g/L. It is observed that the biomass growth is approximately 8.04 times higher than the initial concentration. It is further noted that the biomass growth in OPPBR is significantly increased during the initial 1–3 days and slows at the latter period and attains an almost constant growth after 5–6 days.

The specific biomass growth rate is known as the increase in cell mass per unit time. This is calculated using Eq. (2). This rate is also considered to be an indicator of the photosynthetic efficiency of the microalgae. The maximum specific growth rate from the initial cell concentration is found to be significant as 0.98 ± 0.015 1/day. This is because the OP affects the high transparent surfaces, high illumination surfaces, and high mass transfer rates, which enable an increased specific growth rate in the OPPBR. Hsieh and Wu (2009) reported 1.745 1/day of specific growth rate using Chlorella sp. in transparent rectangular chamber PBR. Ong et al. (2010) obtained a 0.238 1/day specific growth rate using Chlorella sp. during an 8-day cultivation in an outdoor photobioreactor.

Heavy metal removal by microalgae in the AMD

The removal percentage of heavy metal ions in AMD using C. vulgaris is represented in Table 4. The results show that the average percent of investigated heavy metal removal is 98.27, 97.02, 99.49, 99.00, 100, and 100 % for Fe, Cu, Zn, Mn, As, and Cd, respectively, in the OPPBR using microalgae. Microalgae require heavy metal ions as trace elements for growth. However, large amounts of heavy metal ions have inhibited effect on the microalgae growth (Romera et al. 2007).

Microalgae are one of the most important biosorbents. Metals are taken up by algae through adsorption. First, the metal ions are quickly adsorbed over the cell surface; this process is called physical adsorption. Then, these ions are transported slowly into the cytoplasm in a process called chemisorptions (Deng et al. 2007; Fu and Wang 2011). In the present investigation, by increasing the exposure time, the rate of the percent of metal ion removal slowed down gradually and an apparent equilibrium was established. After the equilibrium period, the metal ion sorption by the microalgae biomass was not changed significantly, further increasing the operation time. The results are in agreement with those obtained by Shanab et al. (2012). Various studies have been carried out to show the role of microalgae in the bioremediation of heavy metals. Johnson and Hallberg (2005) reported that the percentage adsorbed by microalgae is 90.26, 90.21, 93.48, 91.26, 90.87, and 90.12 % for Fe, Cu, Zn, Mn, As, and Cd, respectively. Similarly, Yang et al. (2015) removed 90.24 % Cu and 98.42 % Zn from aqueous solutions using C. minutissima.

The mechanism of binding metal ions by inactivated algal biomass may depend on the species and the ionic changes of the metal ion, the algal organism, and the chemical composition of the metal ion solution (Fu and Wang 2011). To use algal biomass effectively for water purification and metal reclamation, it is important to understand the chemical nature of the metal-binding process (Kumar et al. 2015). Microalgae biomass has been successfully used as a sorbing agent. Because microalgae use light as an energy source, facilitating the maintenance of metabolism in the absence of organic carbon sources, an electron acceptor is required by bacteria or fungi (Deng et al. 2007).

Relationship between biomass productivity and the removal of heavy metal ions

Figure 5 shows the linear relationship of Cu, Zn, Mn, As, and Cd and biomass productivity. The coefficient (R 2) of determination is an important tool for determining the degree of linear correlation of variables in regression analysis (Song et al. 2005). In this experiment, a relatively high correlation coefficient (R 2) of 0.9958 for Cu, 0.9905 for Zn, 0.975 for Mn, 0.9941 for As, 0.9203 for Cd, and 0.968 for Fe is obtained. The investigated heavy metal concentration in the AMD is decreased linearly with the increasing biomass productivity. Specifically, the obtained percentage removal of As and Cd with microalgae was higher than that of other heavy metal ions. However, the relationship between biomass productivity and the As and Cd concentrations is relatively lower than other investigated heavy metal ions.

Total heavy metal removal by calcined eggshell and the microalgae hybrid system

The experimental results indicate that the total percent removal of the investigated heavy metal ions from the AMD effluents using the calcined eggshell and microalgae hybrid system is 99.66, 99.47, 99.90, 99.81, 100, and 100 % for Fe, Cu, Zn, Mn, As, and Cd, respectively (Fig. 6). These results clearly demonstrate that the calcined eggshell and microalgae hybrid process is effective for heavy metal removal and is comparable to the individual application of calcined eggshells or microalgae process. Moreover, an enhanced growth of C. vulgaris could further be utilized as a potential biodiesel source.

Conclusions

This study investigated the heavy metal removal and biomass productivity in acid mine drainage (AMD) using calcined eggshell and microalgae hybrid systems. Calcined eggshells effectively neutralized the acidity and partially removed heavy metals from AMD effluents. The biomass productivity increased from 0.367 to 2.95 g/L within 6 days of operation. The biomass growth was ~8.04 times higher than that of the initial concentration. The total removal rate of Fe, Cu, Zn, Mn, As, and Cd was 99.66, 99.47, 99.90, 99.81, 100, and 100 %, respectively, from the AMD effluent using calcined eggshell and a microalgae hybrid system. A fairly good linear relationship was achieved between the investigated heavy metal removal and the biomass productivity because a high value of correlation coefficient (R 2) was obtained. The calcined eggshell and microalgae hybrid system was highly effective for heavy metal removal. Therefore, the calcined eggshell and microalgae system is a useful alternative for a large-scale treatment of effluent waters emanating from AMDs.

References

APHA (2012) Standard methods for the examination of water and wastewater, 22nd edn. Washington DC, USA

Chen T, Chang BY, Lei C, Xiao X (2014) Pollution control and metal resource recovery for acid mine drainage. Hydrometallurgy 147–148:112–119

Choi HJ (2014) Effect of optical panel distance in a photobioreactor for nutrient removal and cultivation of microalgae. World J Microbiol Biotechnol 30:2015–2023

Choi HJ, Lee SM (2014) Effect of optical panel thickness for nutrient removal and cultivation of microalgae in the photobioreactor. Bioprocess Biosyst Eng 37(4):697–705

Chojnacka K (2005) Biosorption of Cr(III) ions by eggshells. J Hazard Mater B121:167–173

Deng LP, Su YY, Su H, Eang XT, Zhu XB (2007) Sorption and desorption of lead(ll) from wastewater by green algae Cladophora fascicularis. J Hazard Mater 143:220–225

El-Silaily A, Nemr AE, Khaled A, Abdelwehab O (2007) Removal of toxic chromium removal from wastewater using green alga Ulva lactuca and its activated carbon. J Hazard Mater 148:216–228

Elwakeel KZ, Yousif AM (2010) Adsorption of malathion on thermally treated eggshell material. Water Sci Technol 61(4):1035–1041

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92:407–418

Gao Y, Chunli X (2012) Synthesis of dimethyl carbonate over waste eggshell catalyst. Catal Today 190:107–111

Guru PS, Dash S (2014) Sorption on eggshell waste—a review on ultrastructure, biomineralization and other applications. Adv Colloid Interf Sci 209:49–67

Hsieh CH, Wu WT (2009) A novel photobioreactor with transparent rectangular chambers for cultivation of microalgae. Biochem Eng J 46(3):300–305

Johnson DB, Hallberg KB (2005) Acid mine drainage remediation options: a review. Sci Total Environ 338:3–14

Kim YK (2015) Mineral phases and mobility of trace metals in white aluminum precipitates found in acid mine drainage. Chemosphere 119:803–811

Kim JE, Mon DH, Kim DJ, Yang JE, Ok YS (2009) Evaluation of the feasibility of oyster-shell and eggshell wastes for stabilization of arsenic-contaminated soil. J Korean Soc Environ Eng 31(12):1095–1104

Köse TE, KivanÇ B (2011) Adsorption of phosphate from aqueous solutions using calcined waste eggshell. Chem Eng J 178:34–39

Kumar KS, Dahms HU, Won FJ, Lee JS, Shin KH (2015) Microalgae—a promising tool for heavy metal remediation. Ecotoxicol Environ Saf 113:329–352

Liu N, Liu Y, Luan Y, Hu X (2013) The elimination of heavy metal-containing wastewater by eggshells membrane. Appl Mech Mater 299:207–210

Ndlovu S (2014) Acid mine drainage: challenges and opportunities. J Environ Chem Eng 2(3):1785–1803

Nys Y, Guyot N (2011) 6-egg formation and chemistry. Improving the safety and quality of eggs and egg products: egg chemistry, production and consumption. Woodhead publishing 6:83–132

Ong SC, Kao CY, Chiu SY, Tsai MT, Lin CS (2010) Characterization of thermal-tolerant mutants of Chlorella sp. with high growth rate and application in outdoor photobioreactor cultivation. Bioresour Technol 101:2880–2883

Park YT, Lee HK, Yun HS, Song KG, Yeom SH, Choi JY (2013) Removal of metal from acid mine drainage using a hybrid system including a pipes inserted microalgae reactor. Bioresour Technol 150:242–248

Romera E, González F, Ballester A, Blázquez ML, Muñoz JA (2007) Comparative study of biosorption of heavy metals using different types of algae. Bioresour Technol 98(17):3344–3353

Shanab S, Essa A, Shalaby E (2012) Bioremoval capacity of tree heavy metals by some microalgae species (Egyptian Isolates). Plant Signal Behav 7(3):392–399

Song NI, Lee YS, Lee MH (2005) Remediation process by using lime and calcium carbonate for heavy metal contaminated groundwater originated from landfills. Econ Environ Geol 38(3):273–284

Tolonen ET, Sarpola A, Hu T, Rämö J, Lassi U (2014) Acid mine drainage treatment using by-products from quicklime manufacturing as neutralization chemicals. Chemosphere 117:419–424

Tsai WT, Yang JM, Lai CW, Cheng YH, Lin CC, Yeh CW (2006) Characterization and adsorption properties of eggshells and eggshell membrane. Bioresour Technol 97:488–493

Tsai WT, Hsien KJ, Hsu HC, Lin CM, Lin KY, Chiu CH (2008) Utilization of ground eggshell waste as an adsorbent for the removal of dyes from aqueous solution. Bioresour Technol 99(6):1623–1629

Wang S, Wei MH, Huang YM (2013) Biosorption of multifold toxic heavy metal ions from aqueous water onto food residue eggshell membrane functionalized with ammonium thioglycolate. J Agric Food Chem 61:4988–4996

Wei Z, Chunli X, Baoxin L (2009) Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour Technol 100:2883–2885

Witoon T (2011) Characterization of calcium oxide derived from waste eggshell and its application as CO2 sorbent. Ceram Int 37(8):3291–3298

Yang JS, Cao J, Xing GL, Yuan HL (2015) Lipid production combined with biosorption and bioaccumulation of cadmium, copper, manganese and zinc by oleaginous microalgae Chlorella minutissima UTEX 2341. Bioresour Technol 175:535–544

Zang RH, Yang XL, Liu J, Cheng XZ (2012) Eggshell membrane biomaterials for adsorption and determination of Mn(II, VII) in environmental water. Adv Mater Res 457–458:175–181

Zhang M, Wang H (2014) Organic wastes as carbon sources to promote sulfate reducing bacterial activity for biological remediation of acid mine drainage. Miner Eng 69:81–90

Acknowledgments

This study was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2013006899).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Zhihong Xu

Rights and permissions

About this article

Cite this article

Choi, HJ., Lee, SM. Heavy metal removal from acid mine drainage by calcined eggshell and microalgae hybrid system. Environ Sci Pollut Res 22, 13404–13411 (2015). https://doi.org/10.1007/s11356-015-4623-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-4623-3