Abstract

Anthocyanins are the phenolic compounds responsible for coloring pigments in fruits and vegetables. Anthocyanins offer a wide range of health benefits to human health. Their scope has expanded dramatically in the past decade, making anthocyanin control, influx, and outflow regulation fascinating for many researchers. The main culprit is anthocyanin stability and concentration form, which demands novel ways because these are critical in the food industry. This review aims to examine anthocyanin synthesis via triggering transcription genes that code for anthocyanin-producing enzymes. The balance between production and breakdown determines anthocyanin accumulation. Thus, increasing the anthocyanin content in food requires the stability of molecules in the vacuolar lumen, the pigment fading process, and a better understanding of the mechanism. The promising option is biosynthesis by metabolically engineered microorganisms with a lot of success. This study aims to look into and evaluate the existing literature on anthocyanin production, namely the biosynthesis of anthocyanin pathway genes, production by microbial cell factories, and the regulatory factors that can modulate the production of anthocyanins. Understanding these mechanisms will provide new biotechnological approaches.

Key points

• Factors affecting the regulation of anthocyanins

• Focus on degradation, biosynthesis pathway genes, and alternative systems for the production of anthocyanins

• Microbial cell factories can be used to produce large amounts of anthocyanins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

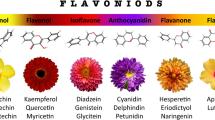

Natural colorants are of significant importance to the food and pharmaceutical industries because of the rising interest in natural pigments as a substitute for synthetic colors that may have harmful effects on people and their health advantages (De Mejia et al. 2020). The name anthocyanin comes from the Greek words anthos, which means flower, and kianos, which means blue. Anthocyanins are the largest group of secondary plant metabolites that come under the class flavonoids. More than 635 anthocyanins have been identified in nature, including six common aglycones and various acylations and glycosylations (Zhang et al. 2014; Smeriglio et al. 2016). Anthocyanins are coloring pigments, which give a range of colors such as orange, red, purple, and blue in fruits, flowers, seeds, and vegetative tissues (Bueno et al. 2012). Anthocyanins are plant pigments formed by coupling sugars to the anthocyanidin molecule. Anthocyanidins are sugar-free counterparts of anthocyanins present in plants. Cyanidin, pelargonidin, peonidin, delphinidin, malvidin, and petunidin are the most prevalent anthocyanidins found in plants (Kerio et al. 2012). Fruits and vegetables are the primary natural sources of anthocyanins, and the richest sources of anthocyanins in fruits are elderberry, chokeberry, bilberry, raspberry, blueberry, grapes, and pomegranates (Makus and DJ 1973; Kriventsov and Arendt 1981; Lamikanra 1989; Mazza and Miniati 1993; Delgado-Vargas and Paredes-Lopez 2002; Cevallos-Casals and Cisneros-Zevallos 2003; Wu et al. 2006). Anthocyanins are present in dark-colored foods, including black carrots, purple maize, black beans, red cabbage, purple sweet potato, and aubergines (Cevallos-Casals and Cisneros-Zevallos 2003; Wu et al. 2006). Anthocyanins absorb the same wavelength of light as chlorophyll b, which aids in plant tissue protection (Stintzing and Carle 2004). Because of their powerful antioxidant properties, anthocyanin pigments also help protect plants from UV damage. In vitro studies have shown that they can inhibit viruses like a syncytial virus, parainfluenza virus, herpes simplex, adenovirus, and rotavirus from replicating (Mohammadi Pour et al. 2019). The antioxidant activity of anthocyanin-rich fruits and vegetables provides health advantages by reducing cardiovascular illnesses, cancer, diabetes, and other chronic diseases (Smeriglio et al. 2016; Wallace et al. 2016; Putta et al. 2017; Hu et al. 2020).

The degree of glycosylation and acylation affects anthocyanin’s chemical stability, bioavailability, and biological activity (Yang et al. 2011). The color and stability of anthocyanin are affected by many parameters, including pH, the degree of aromatic acylation, metal complexion, and phenolic chemical co-pigments (Ekici et al. 2014; Fenger et al. 2021). Anthocyanin chemical stability improves when glycosylation and acylation levels increase during synthesis. As a result, acylated anthocyanins have a higher potential for food coloring than non-acylated anthocyanins (Zhao et al. 2017). Understanding anthocyanin production, transport, storage, and degradation will lead to stable anthocyanin pigments that may be utilized as nutraceuticals and natural colorants. The types of anthocyanins differ from each other due to (i) the degree of methylation of hydroxyl (OH) groups, (ii) the number and position of OH groups, (iii) the number of aromatic or aliphatic groups attached to the sugar, and (iv) the nature and number of sugars attached to the molecule (Fig. 1). The need for anthocyanin production has increased since they are natural and alternative colorants used in the beverage and food sectors (Cortez et al. 2017).

Extraction of natural food sources of anthocyanins usually takes place under harsh conditions like high temperature, pressure, and pH, resulting in the loss of natural pigments and antioxidants. The limitation of using natural anthocyanins in food industries is their low stability, storage conditions, formulations, and loss of color during different processing conditions. The stability of anthocyanins varies greatly, and pure anthocyanins are particularly unstable and prone to deterioration (Zhao et al. 2017). Furthermore, because of difficulties with anthocyanin stability, which influence their usage in a wide range of applications, these processing conditions result in the finished product having an unpleasant flavor, color, and odor (Castañeda-Ovando et al. 2009).

Colorants are essential quality indicators in both fresh and processed foods like fruits and vegetables. Figure 2 depicts the richest and most concentrated sources of anthocyanins found in fruits and vegetables. Natural sources of anthocyanins from plants, on the other hand, have drawbacks over microbial cell factories and in vitro cultures owing to seasonal changes, regional variances, and the difficulty of generating high-purity products (Zhu et al. 2017). As a result, researchers attempt to decipher their manufacturing and molecular mechanisms to develop higher and more stable anthocyanin yields. Furthermore, tissue culture and microbes are being used to produce high-quality and stable products (Espinosa-Leal et al. 2018; Ruta and Farcasanu 2019). Fruit polyphenols in microemulsion and nanoemulsion can improve the stability of anthocyanin and be utilized as functional components and colorants in the food industry (Nazareth et al. 2021). The availability of genetic tools for metabolic engineering and the cost-effective, controlled, and quick growth of microbes are advantages of microbial production (Pandey et al. 2016; Chouhan et al. 2017).

The high demand for anthocyanin production, environmental concerns, and climatic changes, along with significant pressure on anthocyanin supply and availability, have prompted researchers to focus their biotechnology-based alternatives for anthocyanin synthesis. The development of modern techniques has helped identify and characterize biosynthetic pathway key enzymes. Recently, substantial progress has been made in understanding and describing the biosynthetic pathway genes, transcription factors, and anthocyanin transporters in fruits (Shi et al. 2019; Li et al. 2020; Poudel et al. 2021). These techniques give a platform and knowledge of anthocyanin regulation and biosynthesis. Some parameters, including pH, ventilation, agitation, and culture media, should be adjusted appropriately to maximize anthocyanin production in plants or cell cultures (Saad et al. 2018a, b). Besides these factors, precursor feeding and culture conditions like temperature, pH, light, nutrients, and plant growth regulators can maximize the utilization of enzymes involved in the biosynthesis pathway, leading to increased production of the desired end products (Simões et al. 2012). Although the anthocyanin biosynthetic pathway genes have been extensively studied, the regulation and microbial cell factories for producing stable anthocyanins are still poorly understood.

This review summarizes the most recent research progress of the regulation of anthocyanin pathway genes, biosynthesis, and alternative systems for the higher production of anthocyanins. Firstly, the chemistry and variables that impact anthocyanin regulation and stability are described, such as pH, enzymes, chelating characteristics, temperature, and light. We also focus on anthocyanin degradation, biosynthesis mechanisms, and production. In addition, recent advances in genetically engineered microbial cell factories are discussed to provide a future perspective on the production of stable anthocyanins.

Chemistry of anthocyanins

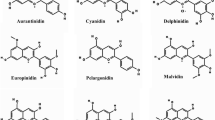

Anthocyanins are poly-methoxyl or poly-hydroxyl derivatives of the flavylium ion, consisting of a double benzoyl ring A and B separated by a C heterocyclic ring (Fig. 1). Anthocyanins are arabinose, galactose, glucose, or rhamnose 3-glycosides or 3,5-diglycosides connected to a sugar residue (Lucioli 2012). The six basic structures of anthocyanidins present in fruits and vegetables are shown in Table 1 (de Pascual-Teresa and Sanchez-Ballesta 2008). The distribution of most common six anthocyanidins in plants is cyanidin (50%), delphinidin (12%), peonidin (12%), pelargonidin (12%), malvidin (7%), and petunidin (7%).

Aglycones are also called anthocyanidins, and when they are glycosylated, they are known as anthocyanins. The flavylium ion is the core of anthocyanidins. It has the distinctive C6-C3-C3 skeleton of flavonoids, which has one fused aromatic ring (as the A ring), one phenyl constituent (as the B ring), and one heterocyclic benzopyran ring (as the C ring) (Fig. 1). Anthocyanidins are positively charged cations with two double bonds in the C ring (Bueno et al. 2012). Glycosylation, B ring substitution, sugar esterification, co-pigments, temperature, and pH influence anthocyanin structure and color diversity. Additional methoxyl or hydroxyl groups and B ring substituents alter the stability of anthocyanin-rich foods. Anthocyanins are glycosides linked to a sugar group found naturally in plants (glucose, galactose, xylose, rhamnose, or arabinose) (Mazza 2018). The physical and chemical properties of anthocyanins are dependent on acylation and glycosylation, which influence the polarity and molecular size of the molecule. The solubility of anthocyanins in water increases with glycosylation and decreases with acylation. Glycosylation of anthocyanins improves water solubility and stability by forming intermolecular hydrogen bonding (Zhao et al. 2017). The most common acyl groups are caffeic acid, p-coumaric acid, dicarboxylic acid, 3,5-dihydrocinnamic acids, ferulic acid, p-hydroxybenzoic acid, gallic acid, and sinapic acid (Andersen and Jordheim 2010).

Studying the chemical stability of anthocyanins plays a crucial role in the potential application and their benefits for replacing artificial colorants. However, the primary factor for the stability of anthocyanin is believed to be its chemical structure. It has been reported that increased B-ring hydroxylation of cyanidin, pelargonidin, and delphinidin decreases stability in in vitro studies (Woodward et al. 2011). Anthocyanins are soluble in water, ethanol, and methanol. Most extraction techniques are intended to use such solvents for this reason. In the flavylium cation, these solvents are acidified to produce stable anthocyanin.

Anthocyanin degradation

Understanding the metabolic pathway enzymes is critical to designing a microbial platform for producing anthocyanins in microorganisms. More production does not always equal increased yield, at least in the case of anthocyanins. Anthocyanins are commonly assumed to be stable once they accumulate in the vacuole, although this is not the case. Anthocyanin degradation could be caused by spontaneous reactions, enzymatic activity, or combining the two (Oren-Shamir 2009). Other factors include light, pH, oxygen, metal ions, ascorbic acid, and enzymes that lead to the degradation of anthocyanin color, structure, and stability. It is essential to retain color to increase stability because anthocyanins degrade quickly due to their high reactivity rate (Shipp and Abdel-Aal 2010). Only limited studies have been done on anthocyanin degradation mechanisms (Passeri et al. 2016). The stability of anthocyanins usually requires O-glycosylation, making it possible for the anthocyanins to accumulate in the vacuole without hydrolysis by the enzyme anthocyanase. The anthocyanins in grape cells (Vitis vinifera) are easily hydrolyzed into anthocyanidins and sugars, which are easily degraded by non-enzymatic and enzymatic oxidation. However, in plants, the degradation does not occur in intact, healthy fruits, and it only happens when the fruit is damaged by physical disturbance or pathogen attack. The main factors influencing the stability and degradation of anthocyanins are pH, enzymes, co-factors, chelating agents, temperature, and light.

Anthocyanins and pH

Anthocyanins can change the structure with changes in pH value. They are most brightly colored and stable at a relatively low pH level (Fig. 1, Table 1). In aqueous conditions, anthocyanins occur in four equilibrium transformation forms: flavylium cation, carbonyl base or pseudobase, quinoidal base, and chalcone (Pina et al. 2012). Anthocyanins are more stable at acidic conditions (pH 1–3), where they exist as flavylium cations, which are the most stable form and give red and purple colors. At pH 5, anthocyanin is less-stable, colorless carbinol pseudobase and forms chalcone structures, leading to anionic quinonoidal species. The less stability could be due to the thermodynamic and kinetic competition between the hydration and flavylium ions. The blue-purple quinoidal base is formed at pH 7–8. At physiological pH, anthocyanins are chemically unstable due to pH variations, and they form complexes as they undergo different structural changes. Their bioavailability is limited due to the degradation as influenced by pH fluxes. This barrier can be overcome by cultivating modified bacteria or yeast in a medium with an initial pH level of 7 to achieve proper growth and production, then transferring the culture to a new medium with a lower pH level to improve anthocyanin production and stabilization.

The color of anthocyanins in the vacuolar lumen, where they accumulate in plants, is pH dependent. In the acidic environment of plant vacuoles, anthocyanins co-exist with red-colored flavylium cations and blue quinoidal species. In addition to pH, the color of the plant and the color of the anthocyanin affect the stability of these two forms. Anthocyanin color can combine with other flavonoid pigments and metal ions to stabilize at acidic pH. The color red is produced by a very acidic vacuolar lumen, while a light acidic environment makes the color blue. The myeloblastosis (MYB)-basic helix-loop-helix (bHLH)-WD (MBW) repeat transcription complex regulates the production of anthocyanins. They are further transported to the vacuolar lumen, where the color differs due to the pH value (Hu et al. 2016). The diglycosidic derivatives are highly stable at pH 7, and this is because the sugar molecules prevent the degradation of intermediates into aldehyde compounds and phenolic acid.

Enzymes

Polyphenol oxidases and peroxidase enzymes are suspected of inducing anthocyanin fading or discoloration in plants. The anthocyanin degradation was first observed in Brunfelsia calycina (Solanaceae) flowers from dark purple to completely white color (Vaknin et al. 2005). Peroxidases were discovered to be involved in fading after anthocyanin degradation was studied in conjunction with a vacuolar class III peroxidase (Zipor et al. 2015). In litchi and orange fruits, the enzymes peroxidase, polyphenol oxidase, and β-glucosidase were responsible for the degradation of anthocyanins during the ripening stage. This was because the enzyme bound to the solid part of the fruit (particularly pectins) decreased the anthocyanin levels (Zhang et al. 2005). Peroxidases control free radicals and hydrogen peroxide concentrations in the vacuolar lumen, affecting the anthocyanin’s stability. The fading usually affects the final yield of anthocyanin. Thus, identifying the factors influencing pigment fading can improve anthocyanin’s final quality and yield.

Co-factors and chelating properties

Regulation of anthocyanins requires an adequate balanced supply of certain co-factors/co-substrates for electron transport, stabilization, and enzyme activation. Anthocyanins can chelate certain metals such as aluminum (Al), tin (Sn), copper (Cu), and iron (Fe). Their packaging material or medium presence results in undesirable pigment color changes. The co-pigmentation is due to weak acidity (pH 4–6), where anthocyanins exist in colorless forms. Specific colorless components and pigments make complex moieties to generate compounds that change the intensity of the color. Color is one of the qualities demanded by the beverage industry. Co-pigmentation with other compounds is the primary mechanism for stabilizing coloring plants (Molaeafard et al. 2021). The co-pigments are usually colorless compounds such as amino acids, alkaloids, flavonoids, nucleotides, polysaccharides, or other anthocyanins. When anthocyanins interact with these co-pigments in the UV–vis region of the absorption spectrum, they undergo a bathochromic shift or hyperchromic effect. The co-pigments are rich in π-electrons and capable of interacting with flavylium ions, usually deficient in electrons. This aids in preventing a nucleophilic water attack on the flavylium ion’s second position.

The interaction between anthocyanins and co-pigments is explained in many ways for different species. When anthocyanins interact with any metal, they form complexes, and when it reacts with another anthocyanin, an intramolecular pigmentation or a self-association is formed. Anthocyanins react with co-pigments with free electron pairs; they form intermolecular co-pigmentation by protons, sugar, and aglycone simultaneously (Molaeafard et al. 2021). Despite less interest in anthocyanin metal complexation in the food industry, there is a demand to study the metal complex with anthocyanin as it helps in anthocyanin stabilization.

Temperature

Temperature plays a vital role in the synthesis of anthocyanins. Anthocyanins are more prone to oxidation and are relatively unstable. Nevertheless, the mechanisms are not well understood. Climatic changes also influence the levels of anthocyanins in fruits and vegetables. Warm weather was connected with low levels of anthocyanins, and cool weather was associated with the rapid accumulation of anthocyanins in fruit skin (Li et al. 2004). Anthocyanin production declines under high temperatures in plants due to inhibiting structural genes, expression of MYB activators, and enhancement of repressors (Lin-Wang et al. 2011). Reduction in anthocyanin production was observed by overexpressing a grapevine class III peroxidase in Petunia petals under heat stress, indicating high-temperature degradation (Movahed et al. 2016). Thus, overall, anthocyanin degradation might be due to increased enzyme activity, e.g., peroxidase, in response to thermal stress. When it comes to the relationship between anthocyanin synthesis and temperature, it is easy to see why, during the winter, a low temperature typically increases the concentration of anthocyanin in the leaves of evergreen species (Niu et al. 2017).

High processing temperature reduces the content of anthocyanins significantly in strawberries but not raspberry during jam processing. The loss was due to the differences in total concentrations of anthocyanins and ascorbic acid, content in the fruits, and individual anthocyanin composition of the berries (Martinsen et al. 2020). The stability of anthocyanins is higher at low temperature (4 °C), and anthocyanin-rich foods can better be preserved as jams even at room temperature (23 °C) since they are in the food matrix. In conclusion, temperature directly affects anthocyanin stability, color, and storage life. Anthocyanin-rich foods can be stored at a lower temperature to increase the shelf life of the products.

Light

Light is the most crucial factor that affects anthocyanin accumulation. High light intensity stimulates anthocyanin production in most plants (Maier and Hoecker 2015). The surface of fruits directly exposed to light showed high, intense anthocyanin pigment accumulation than the shaded parts (Mazzucato et al. 2013). It has been shown that blue light wavelengths induce anthocyanin production compared to dark conditions (Xu et al. 2014; Liu et al. 2015). Anthocyanin production was enhanced by continuous UV irradiation exposure, which protected Centaurea cyanus L. cells against UV light (Takahashi et al. 1991). Another study reported an increase in the accumulation of anthocyanins in carrot cell culture with continuous UVA light exposure (Hirner et al. 2001). Higher production of anthocyanins was also achieved by providing 8000 lx to strawberry cells and 3478 lx to Cleome rosea cells (Simões et al. 2009). The light induces regulatory factors, structural genes, and the expression of genes involved in anthocyanin biosynthesis. Another study showed that the tomato seedlings were exposed to blue light, and the biosynthesis of anthocyanins was elevated (Hernández et al. 2016). The anthocyanin biosynthetic gene stimulation mainly influences the anthocyanin content by the intensity and spectrum of light. Several studies have investigated Arabidopsis thaliana and other plants and reported that blue and red light wavelengths enhance the production of anthocyanins by activating structural genes and transcription of the R2R3-MYB genes (Shi et al. 2014; Xu et al. 2014; Liu et al. 2015). Liu et al. (2017) found that the biosynthetic genes for anthocyanins in tobacco leaves were downregulated in darkness and upregulated in light by overexpressing the StMYBA1 gene from potatoes. Therefore, post-translational mechanisms and transcriptional factors play a significant role in controlling anthocyanin pathway gene expression. Furthermore, various transcriptional factors and phytohormones are crucial for the cellular regulation of anthocyanin biosynthesis (He et al. 2010).

Anthocyanin regulation

In past years, regulatory and structural genes required for anthocyanin production have been cloned, expressed, and described in a wide range of plant species (Wang et al. 2011; Timmers et al. 2017). A genetic engineering approach was, for the first time, used by Meyer et al. (1987) to transfer a dihydroflavonol 4-reductase (DFR) gene from maize to develop a novel red flower coloring Petunia hybrida, thus establishing a new flower pigmentation pathway. The enzyme DFR converts dihydrokaempferol (DHK) to leucopelargonidin, leading to pelargonidin production in Petunia, changing color from pale pink to brick red. The complex protein tryptophan-aspartic acid repeat protein (WD40) interacts with bHLH and MYB transcription factors to regulate the biosynthesis of flavan-3-ols. MYB-bHLH-WD40 are highly conserved proteins that activate structural genes that code for anthocyanin pathway enzymes (Koes et al. 2005; Jaakola 2013). Hence, anthocyanin production can be enhanced by expressing the transcription factor complex in plants to improve production and stability.

The WD40 is a regulatory protein that promotes the accumulation of anthocyanins and expression in all species. On the other hand, the expression of bHLH and MYB proteins depends on different pigmented tissues, and they are likely orthologues. The proanthocyanin pathway is activated by the MYB component’s MBW complex, which can also stimulate its companion, bHLH. As a result, it is referred to as a “master regulator,” as it can activate the pathway independently, and its expression affects the pigmentation pattern in plants (Kiferle et al. 2015; Nesi et al. 2001; Spelt et al. 2000). The anthocyanins are transported in the endoplasmic reticulum by transporters and stored inside the vacuole after the synthesis. The process is still not well understood despite its essential role in the final anthocyanin content in plant tissues (He et al. 2010; Francisco et al. 2013; Chanoca et al. 2015). The repeated amino acid sequence of bHLH regulates the anthocyanin pathway in a wide variety of species, and the sequences are conserved (Lloyd et al. 2017; Wang et al. 2019). The Lc (leaf color) gene is one of the transcription factors determining maize’s timing, location, and amount of anthocyanin accumulation (Li et al. 2007). The bHLH-encoded myc-type R gene and the Lc gene in maize enhanced the overexpression of anthocyanin in Petunia, Caladium bicolor, Arabidopsis, and tobacco (Li et al. 2007).

Biosynthetic mechanisms of anthocyanins

Anthocyanin production has been extensively studied to understand the metabolic pathway enzymes in their natural hosts. At the transcriptional level, numerous regulatory genes influence the production of anthocyanins. Such information is sourced via studying biosynthetic pathway genes, which will be the subject of this section.

Anthocyanin biosynthetic pathway mechanisms are well characterized and conserved in many plant species (Holton and Cornish 1995; Tanaka and Ohmiya 2008). Anthocyanin production begins with the conversion of phenylalanine to para-coumaroyl-CoA in the phenylpropanoid pathway, and this is the first precursor chemical in the flavonoid biosynthetic route. Starting with chalcone synthase (CHS), the anthocyanin route extends the flavonoid pathway of secondary metabolites (Fig. 3). Naringenin chalcone is produced from condensing one molecule of p-coumaroyl-CoA and three malonyl-CoA molecules by CHS (Durbin et al. 2000; Tian et al. 2006). CHS encodes three genes (Chs1-AB015872, Chs2-AB066275, Chs3-AB066274), which are essential components for making red wine as it improves the quality of the grapes. Chs1 and Chs2 are found in the leaves and skin of grape berries, while Chs3 is found mainly in the berry skin. Different transcription factors control these three genes in grapes to produce various secondary metabolites (Ageorges et al. 2006). Although their protein and transcript expression is minimal, their high biosynthetic efficiency may enhance production (Goto-Yamamoto et al. 2002; Ageorges et al. 2006). By the action of chalcone-flavanone isomerase (CHI), naringenin chalcone can be quickly converted to the stereospecific isomer naringenin flavanone. Naringenin plays a role in synthesizing anthocyanins or proanthocyanins, besides forming other phenolic compounds. Naringenin is hydroxylated at the 3rd position to produce dihydrokaempferol by the action of flavanone 3-hydroxylase (F3H).

Biosynthetic pathways of anthocyanins. CHS, chalcone synthase; FLS, flavonol synthase; CHI, chalcone isomerase; F3H, flavanone 3-hydroxylase; F3′H, flavonoid 3′-hydroxylase; F3′5′H, flavonoid 3′,5′-hydroxylase; DFR, dihydroflavonol 4-reductase; ANS, anthocyanidin synthase; LAR, leucoanthocyanidin reductase; UFGT, flavonoid 3-O-glucosyltransferase; UDP-glucose, uridine diphosphate glucose; asterisk indicates multiplication

F3′H and F3′5′H have used the oxidized products of naringenin flavanone and dihydroflavonols as substrates to produce the dihydroflavonols dihydroquercetin and dihydromyricetin (Sparvoli et al. 1994) (Fig. 3). Both F3′H and F3′5′H introduce hydroxylation of the flavonoid B ring of anthocyanins, which is required to produce other anthocyanidins like delphin and cyanidin. In plant species like Chrysanthemum morifolium and Rosa hybrida, delphinidin is not delivered due to the lack of blue/violet color variation due to the absence of the F3′5′H gene (Tanaka and Ohmiya 2008). In the next step, the three dihydroflavonols are converted into 3,4-cis-leucoanthocyanidins, a colorless compound, by the action of DFR. In some plants, e.g., varieties of Cymbidium and Petunia, the DFR gene shows substrate specificity and cannot use dihydrokaempferol. Therefore, they do not produce pelargonidin, resulting in no brick, red, or orange color in flowers (Tanaka and Ohmiya 2008). Subsequently, the colorless leucoanthocyanidins are converted into colored anthocyanidins by the anthocyanidin synthase (ANS) enzyme (Fig. 3).

ANS is the first key enzyme that directs the flavonoid flux into the anthocyanin biosynthetic pathway branch. ANS plays an essential role in producing both proanthocyanidins and anthocyanins (Li et al. 2016; Zhang et al. 2018). Additionally, the product of ANS can also be catalyzed by anthocyanin reductase (ANR), leading to (2R,3R)-cis-flavan-3-oils, which are proanthocyanidin production substrates (Gargouri et al. 2009). The action of ANS produces colored anthocyanidins from colorless leucoanthocyanidins. Following the production of colored anthocyanidins, acylation, methylation, and glycosylation are necessary to stabilize the vacuolar anthocyanins. This occurs in the cytosol after the biosynthesis of unstable anthocyanidins. The compounds anthocyanidins (ACDs) and 3,4-cis-leucoanthocyanidins (LCDs) are not stable intermediates; thus, they are 3-O-glucosylated for stability by the enzyme 3-O-glycosyl transferase (A3GT), a uridine (UDP)-glucose-dependent anthocyanidin transferase (Tanaka et al. 2008). Cyanidin-3-O-glucoside (C3G), delphinidin-3-O-glucoside (D3G), and pelargonidin-3-O-glucoside (P3G) are the basic anthocyanins, and they differ by the B ring, based on the number of hydroxyl groups. In some cases, these hydroxyl groups are further O-methylated by O-methyl transferase to produce other anthocyanidins such as malvidin, peonidin, and petunidin. These are commonly found in bilberry, red grape, and strawberry (Davies 2008). Sugar moieties such as arabinose, galactose, glucose, glucuronic acid, rhamnose, and xylose can also be glycosylated and acylated (Tanaka et al. 2008).

The flavonoid pathway shares the upstream path of proanthocyanidins until the formation of anthocyanidins by ANS to produce anthocyanins in fruits (Dincheva et al. 2015). Specific anthocyanin biosynthetic genes from a plant source such as Gerbera hybrida and Arabidopsis thaliana can be introduced to yeast strains to produce flavonoid precursors to produce anthocyanins. Biosynthetic genes can be introduced, optimized, and integrated into the yeast genome to avoid side or intermediate products in the culture (Levisson et al. 2018). Many studies on anthocyanin heterologous production have been conducted, but the main barriers to increased anthocyanin production are gene expression levels, enzyme degradation, stability concerns, kinetic characteristics, and activity (Eichenberger et al. 2018; Lyu et al. 2019; Shrestha et al. 2019; Du et al. 2020). Microbial production in Escherichia coli or yeast is the best way to improve production of anthocyanins by inserting the metabolic pathway enzymes and performing precursor feeding for industrial applications. Furthermore, using metabolomics analysis to examine and understand the proteomics of these enzymes can increase anthocyanin production.

Anthocyanin production in microorganisms

Microbial cell factories are the most promising system for the higher production of anthocyanins. Recent advances in metabolic and genetic engineering approaches have been made to modify or introduce the particular pathway genes into different host systems (particularly in microorganisms) to increase production of anthocyanins (Pandey et al. 2016; Marchev et al. 2020). However, microorganisms like E. coli and yeast systems require the insertion of genes from the anthocyanin biosynthetic pathway to produce the simplest anthocyanin from phenylalanine (Fig. 3).

Production of anthocyanins using anthocyanin pathway genes by a genetic engineering approach is depicted in Table 2. Anthocyanin pathway enzyme expression can be improved using a codon optimization strategy because of codon bias between the engineered microbial hosts and native plant hosts (Lanza et al. 2014). The codon optimization depends on the codon usage in the microbial species to be used. The expression of anthocyanin pathway genes in E. coli is often successful based on the experience from the past two decades. However, the expression in another host microorganism like yeast could be a better option for heterologous expression. The expression of non-codon-optimized pathway genes in the naringenin production of Corynebacterium glutamicum was unsuccessful (Kallscheuer et al. 2016). In a few cases, the anthocyanin pathway enzymes showed misfolding. They formed inclusion bodies, which are generally biologically inactive, in contrast to soluble fractions of these particular interest enzymes. Fusion proteins or peptide tags such as small ubiquitin-like modifier (SUMO) and maltose-binding protein (MBP) are highly soluble at high expression levels in the host strain. SUMO tagging was fused at the N-terminal end of flavonoid 3-O-glucosyl transferase to increase the expression of engineered C. glutamicum for the biosynthesis of cyanidin 3-O-glucoside from catechin (Zha et al. 2018).

Microbial factories such as Escherichia coli and yeast, with well-established bioprocessing and upscaling technologies, are promising for the large-scale production of anthocyanins (Marienhagen and Bott 2013; Lyu et al. 2019; Shrestha et al. 2019; Palmer et al. 2020). Some studies indicate that anthocyanins are adsorbed on the yeast cell walls (Scudamore-Smith et al. 1990; Vasserot et al. 1997). The degree of adsorption is based on the polarity of anthocyanins in yeast. Delphinidin has the highest polarity among anthocyanins, and it will be adsorbed to a high degree, whereas malvidin has the lowest polarity and will be adsorbed less. Temperature, sulfur dioxide, pH, and ethanol are other factors influencing adsorption. Thus, the higher the temperature, the lower the adsorption capacity, and the amount of anthocyanin adsorbed decreases with an increase in sulfur dioxide concentration. High pH lowers the adsorption of anthocyanins, and as ethanol concentration increases, the amount of anthocyanin adsorption decreases. The simplest anthocyanin, pelargonidin 3-O-glucoside from phenylalanine, requires 11 genes to be inserted into the organism. The flavonoid 3′- and 3′,5′-hydroxylase (F3′H and F3′5′H) are plant cytochrome P450 monooxygenases. Still, they are inefficient in producing anthocyanins because they result in protein misfolding, and the co-factor pools are inadequate (Dudnik et al. 2018). Hence, it requires separate modifications of F3′H and F3′5′H cytochrome P450 monooxygenases (Ajikumar et al. 2010).

Anthocyanin production in Escherichia coli

The microbial cell factory E. coli has been considered the most suitable for anthocyanin production. The production of flavonoids in E. coli by metabolic engineering is extensively employed to improve efficiency by increasing biosynthetic co-factors. For example, the sugar donor UDP-glucose is required to synthesize anthocyanins (Fig. 3). Overexpression of the UDP-glucose biosynthetic gene fused with an anthocyanin synthase-3-O-glucosyltransferase (ANS-3GT) yielded a higher concentration of anthocyanins in E. coli (Yan et al. 2007). Additionally, improvements in yields were observed after deleting UDP-glucose pathways (He et al. 2008). The combinatorial biosynthetic approach was performed in E. coli to produce anthocyanins and 5-deoxyflavanones in raspberry (Beekwilder et al. 2007; Yan et al. 2007).

Table 3 shows the yield from the heterologous production of naringenin, kaempferol, anthocyanidins, and anthocyanins in microorganisms. Anthocyanins are produced from naringenin when the F3H, DFR, ANS, and 3GT genes are generated. The highest production of engineered naringenin was 421.6 mg/L in E. coli (Wu et al. 2015). The engineered kaempferol yielded 57 mg/L of kaempferol in E. coli (Yang et al. 2014). The anthocyanin pathway genes such as F3′H, DFR, ANS, and F3′GT were expressed in E. coli using a pET vector (Yan et al. 2005). According to the study by Lim et al. (2015), 122.3 mg/L of cyanidin was obtained by enhancing the precursor availability, substrate level, and controlling gene expression levels in E. coli. In another recent study, multi-monocistronic and multivariate vectors were designed to improve C3G production in E. coli BL21, which achieved 439 mg/L of C3G (Shrestha et al. 2019). Yan et al. (2008) produced 78.9 mg/L P3G by optimizing the culture pH level, rational manipulation, and creating a fusion protein in E. coli. The anthocyanin peonidin O-glucoside (56 mg/L) was obtained by engineering the microbial production of an O-methylated anthocyanin (Cress et al. 2017). The yield can be increased using several efflux pumps (TolC and YadH), which can be incorporated in engineered E. coli cells to accumulate and transport anthocyanins.

Anthocyanin production in yeast

Production of anthocyanins was achieved using a genetically engineered cell factory approach in yeast, and the yield is shown in Table 3. Recently, it has been reported that the engineered yeast Saccharomyces cerevisiae strain produced 220 mg/L naringenin and a yeast Yarrowia lipolytica strain produced 898 mg/L naringenin, respectively (Lyu et al. 2019; Palmer et al. 2020). In another study, the produced naringenin was used as precursor feeding to engineered S. cerevisiae cells resulted in the production of other flavonoids, such as quercetin, kaempferol, and genistein (Trantas et al. 2009). Genetic engineering strategies for producing anthocyanins in crops mimic natural selection by acting on MYBs to comply with anthocyanin biosynthetic gene expression. Recently, Du et al. (2020) developed an S. cerevisiae co-culture platform to boost the production of naringenin (144.1 mg/L), kaempferol (168.1 mg/L), cyanidin (31.7 mg/L), pelargonidin (33.3 mg/L), and delphinidin (15.8 mg/L). This co-culture strategy gave the best platform for the production of microbial anthocyanins efficiently and economically. However, the production titers are still relatively low for commercial requirements, and hence, different strategies should be applied for the higher titer production. Other heterologous hosts like Pichia pastoris have been used for microbial production of flavonoids, and they can also be engineered to produce anthocyanins. The efficient promoter selection would also be an excellent approach to enhancing the yield of anthocyanins in prokaryotes and eukaryotes. Despite these challenges, optimizing the culture and advances in biotechnology, the multidimensional engineering of pathway genes can increase the yield of anthocyanins for commercial and industrial purposes.

Bottlenecks for the production of anthocyanins

F3′H and F3′5′H enzymes are bottlenecks in the microbial production of anthocyanins in plant cytochrome P450 monooxygenases. Both F3′H and F3′5′H are not efficient co-factors and often fail to cause membrane insertion and protein folding in E. coli (Dudnik et al. 2018). The main bottleneck for anthocyanin production is observed after converting dihydrokaempferol from naringenin. The majority of naringenin is converted into dihydrokaempferol, indicating that F3H is functioning correctly.

The DFR gene is considered the rate-limiting step for the anthocyanin pathway (Huang et al. 2012). The DFR gene in Arabidopsis thaliana accepts only dihydromyricetin (DHM) and dihydroquercetin (DHQ) as substrates, and it is unable to convert the anticipated substrate DHK into leucopelargonidin. In Gerbera hybrida species, the DFR gene can produce the respective leucopelargonidin (Leonard et al. 2008). A few numbers of DFR enzymes from various plant species were able to convert dihydrokaempferol to leucopelargonidin. The efficiency of different DFR enzymes from other species in S. cerevisiae showed low efficiency, indicating that the DFR reaction is not performing well in yeast (Levisson et al. 2018). Similar studies have been done before in prokaryotic systems like E. coli (Zhao et al. 2015). The malfunctioning of the DFR gene in microbial systems could be due to the level of substrate inhibition. Trabelsi et al. (2008, 2011) have observed a complete study on the kinetics of the DFR enzyme from Vitis vinifera. Results revealed that a high concentration of dihydroquercetin as a substrate results in the formation of dead-end enzyme–substrate complexes (Trabelsi et al. 2008, 2011). Therefore, controlling the expression of the F3H enzyme may be necessary to obtain adequate concentrations of dihydrokaempferol and enable DFR to function without inhibition. According to Halbwirth et al. (2006), excess amounts of leucoanthocyanidin could be the reason that catalase reverses the reaction to produce dihydroflavonols from leucoanthocyanidins (Schwinn et al. 2014).

Another obstacle for anthocyanin production in yeast is the accumulation of by-products, i.e., flavonols (FLO) and glycosides (Eichenberger et al. 2018). The direct activity of flavonol synthase on anthocyanins is not optimal, and these by-products usually result in the loss of carbon in the commercial production of anthocyanins. Polycultures of E. coli can be used to avoid this. A strain of E. coli was used to create a flavan-3-ol substrate, while another strain was used to make P3G. By this strategy, the ANS does not encounter the LCD substrate as ANS can produce flavan-3-ol to ACDs in E. coli (Jones et al. 2017). The inefficiency of ANS in yeast to absorb the substrate catechin cannot be ruled out, in contrast to flavonoids, which are easily absorbed. As a result, an alternative option is rational mutagenesis or random selection to design the ANS gene to prevent the second oxidation cycle by using screening assays to develop the color corresponding to anthocyanin production. The anthocyanin content can be increased by using effective promoters, gene editing, amino acid substitution, and RNAi-mediated gene silencing techniques.

Conclusions

Anthocyanins are becoming more popular due to their health benefits and appealing colors. Consumers are willing to pay more for healthier natural products and provide health advantages in addition to nutritional value. Therefore, food manufacturers are focusing on clean, higher-quality anthocyanin. Despite the fact that employing anthocyanins in food poses a number of obstacles due to their stability, significant progress has been made in understanding the various aspects that might enhance color and provide health advantages. Anthocyanin stability has been studied extensively in co-pigmentation with other substances such as phenolics, flavonoids, and natural dietary components. A few studies have looked into spray-drying technologies for anthocyanin microencapsulation to improve food product durability. Inserting metabolic designed enzymes for microbial anthocyanin production into microbial cell factories is another technique to enhance anthocyanin stability. Biosynthetic genes were integrated into the yeast genome to enhance anthocyanin production, and the generation of a side product was prevented by altering the yeast chassis. Researchers have successfully inserted biosynthetic pathway enzymes of many flavonoid compounds in E. coli, Streptomyces venezuelae, C. glutamicum, Y. lipolytica, P. pastoris, and S. cerevisiae to produce anthocyanins.

The tissue cultures or plant has attracted attention for sustainable and efficient commercial production of anthocyanins. However, the anthocyanin yield is low due to inconsistent culture conditions, higher cost, and difficulty in the upscaling processes in plants and microorganisms. To get better yields for large-scale production, numerous parameters such as culture conditions, including production media, light, temperature, agitation, pH, and precursor feeding, can be optimized. Genetic engineering and synthetic biology appear to be promising tools to enhance anthocyanin productions in plants and microbes. Despite these obstacles, constant culture optimization and biotechnological developments in creating recombinant microorganisms are promising candidates for producing stable bioactive molecules for novel functional products with health-related benefits.

References

Ageorges A, Fernandez L, Vialet S, Merdinoglu D, Terrier N, Romieu C (2006) Four specific isogenes of the anthocyanin metabolic pathway are systematically co-expressed with the red colour of grape berries. Plant Sci 170:372–383

Ajikumar PK, Xiao W-H, Tyo KE, Wang Y, Simeon F, Leonard E, Mucha O, Phon TH, Pfeifer B, Stephanopoulos G (2010) Isoprenoid pathway optimization for Taxol precursor overproduction in Escherichia coli. Science 330:70–74

Andersen ØM, Jordheim M (2010) 3.16-Chemistry of flavonoid-based colors in plants. Compr Nat Prod II Elsevier 547–614

Austin MB, Bowman ME, Ferrer J-L, Schröder J, Noel JP (2004) An aldol switch discovered in stilbene synthases mediates cyclization specificity of type III polyketide synthases. Chem Biol 11:1179–1194

Beekwilder J, van der Meer IM, Sibbesen O, Broekgaarden M, Qvist I, Mikkelsen JD, Hall RD (2007) Microbial production of natural raspberry ketone. Biotechnol J Healthc Nutr Technol 2:1270–1279

Boss PK, Davies C, Robinson SP (1996) Analysis of the expression of anthocyanin pathway genes in developing Vitis vinifera L. cv Shiraz grape berries and the implications for pathway regulation. Plant Physiol 111:1059–1066

Bueno JM, Sáez-Plaza P, Ramos-Escudero F, Jiménez AM, Fett R, Asuero AG (2012) Analysis and antioxidant capacity of anthocyanin pigments. Part II: chemical structure, color, and intake of anthocyanins. Crit Rev Anal Chem 42:126–151

Castañeda-Ovando A, de Lourdes P-H, Páez-Hernández ME, Rodríguez JA, Galán-Vidal CA (2009) Chemical studies of anthocyanins: a review. Food Chem 113:859–871

Cevallos-Casals BA, Cisneros-Zevallos L (2003) Stoichiometric and kinetic studies of phenolic antioxidants from Andean purple corn and red-fleshed sweetpotato. J Agric Food Chem 51:3313–3319

Chanoca A, Kovinich N, Burkel B, Stecha S, Bohorquez-Restrepo A, Ueda T, Eliceiri KW, Grotewold E, Otegui MS (2015) Anthocyanin vacuolar inclusions form by a microautophagy mechanism. Plant Cell 27:2545–2559

Cheng H, Li L, Cheng S, Cao F, Wang Y, Yuan H (2011) Molecular cloning and function assay of a chalcone isomerase gene (GbCHI) from Ginkgo biloba. Plant Cell Rep 30:49–62

Chouhan S, Sharma K, Zha J, Guleria S, Koffas MA (2017) Recent advances in the recombinant biosynthesis of polyphenols. Front Microbiol 8:2259

Cortez R, Luna-Vital DA, Margulis D, Gonzalez de Mejia E (2017) Natural pigments: stabilization methods of anthocyanins for food applications. Compr Rev Food Sci Food Saf 16:180–198

Courtney-Gutterson N, Napoli C, Lemieux C, Morgan A, Firoozabady E, Robinson KE (1994) Modification of flower color in florist’s chrysanthemum: production of a white–flowering variety through molecular genetics. Biotechnology 12:268–271

Cress BF, Leitz QD, Kim DC, Amore TD, Suzuki JY, Linhardt RJ, Koffas MA (2017) CRISPRi-mediated metabolic engineering of E. coli for O-methylated anthocyanin production. Microb Cell Factories 16:1–14

Davies KM (2008) Modifying anthocyanin production in flowers. In: Anthocyanins. Springer, pp. 49–80

De Mejia EG, Zhang Q, Penta K, Eroglu A, Lila MA (2020) The colors of health: chemistry, bioactivity, and market demand for colorful foods and natural food sources of colorants. Annu Rev Food Sci Technol 11:145–182

de Pascual-Teresa S, Sanchez-Ballesta MT (2008) Anthocyanins: from plant to health. Phytochem Rev 7:281–299

Delgado-Vargas F, Paredes-Lopez O (2002) Natural colorants for food and nutraceutical uses. CRC Press

Dincheva I, Badjakov I, Kondakova V (2015) Metabolic engineering of bioactive compounds in berries. Biotechnol Bioact Compd Sources Appl 463

Du Y, Yang B, Yi Z, Hu L, Li M (2020) Engineering Saccharomyces cerevisiae coculture platform for the production of flavonoids. J Agric Food Chem 68:2146–2154

Duan L, Ding W, Liu X, Cheng X, Cai J, Hua E, Jiang H (2017) Biosynthesis and engineering of kaempferol in Saccharomyces cerevisiae. Microb Cell Factories 16:1–10

Dudnik A, Almeida AF, Andrade R, Avila B, Bañados P, Barbay D, Bassard J-E, Benkoulouche M, Bott M, Braga A (2018) BacHBerry: BACterial hosts for production of Bioactive phenolics from bERRY fruits. Phytochem Rev 17:291–326

Durbin ML, McCaig B, Clegg MT (2000) Molecular evolution of the chalcone synthase multigene family in the morning glory genome. Plant Mol Evol 79–92

Eichenberger M, Hansson A, Fischer D, Dürr L, Naesby M (2018) De novo biosynthesis of anthocyanins in Saccharomyces cerevisiae. FEMS Yeast Res 18:foy046

Ekici L, Simsek Z, Ozturk I, Sagdic O, Yetim H (2014) Effects of temperature, time, and pH on the stability of anthocyanin extracts: prediction of total anthocyanin content using nonlinear models. Food Anal Methods 7:1328–1336

Espinosa-Leal CA, Puente-Garza CA, García-Lara S (2018) In vitro plant tissue culture: means for production of biological active compounds. Planta 248:1–18

Fenger J-A, Roux H, Robbins RJ, Collins TM, Dangles O (2021) The influence of phenolic acyl groups on the color of purple sweet potato anthocyanins and their metal complexes. Dyes Pigments 185:108792

Francisco RM, Regalado A, Ageorges A, Burla BJ, Bassin B, Eisenach C, Zarrouk O, Vialet S, Marlin T, Chaves MM (2013) ABCC1, an ATP binding cassette protein from grape berry, transports anthocyanidin 3-O-glucosides. Plant Cell 25:1840–1854

Fukui Y, Tanaka Y, Kusumi T, Iwashita T, Nomoto K (2003) A rationale for the shift in colour towards blue in transgenic carnation flowers expressing the flavonoid 3′,5′-hydroxylase gene. Phytochemistry 63:15–23

Gao S, Lyu Y, Zeng W, Du G, Zhou J, Chen J (2019) Efficient biosynthesis of (2 S)-naringenin from p-coumaric acid in Saccharomyces cerevisiae. J Agric Food Chem 68(4):1015–1021

Gargouri M, Manigand C, Mauge C, Granier T, Langlois d’Estaintot B, Cala O, Pianet I, Bathany K, Chaudiere J, Gallois B (2009) Structure and epimerase activity of anthocyanidin reductase from Vitis vinifera. Acta Crystallogr D Biol Crystallogr 65:989–1000

Goto-Yamamoto N, Wan GH, Masaki K, Kobayashi S (2002) Structure and transcription of three chalcone synthase genes of grapevine (Vitis vinifera). Plant Sci 162:867–872

Halbwirth H, Kahl S, Jäger W, Reznicek G, Forkmann G, Stich K (2006) Synthesis of (14C)-labeled 5-deoxyflavonoids and their application in the study of dihydroflavonol/leucoanthocyanidin interconversion by dihydroflavonol 4-reductase. Plant Sci 170:587–595

He F, Mu L, Yan G-L, Liang N-N, Pan Q-H, Wang J, Reeves MJ, Duan C-Q (2010) Biosynthesis of anthocyanins and their regulation in colored grapes. Molecules 15:9057–9091

He X-Z, Li W-S, Blount JW, Dixon RA (2008) Regioselective synthesis of plant (iso)flavone glycosides in Escherichia coli. Appl Microbiol Biotechnol 80:253–260

Helariutta Y, Elomaa P, Kotilainen M, Seppänen P, Teeri TH (1993) Cloning of cDNA coding for dihydroflavonol-4-reductase (DFR) and characterization of dfr expression in the corollas of Gerbera hybrida var. Regina (Compositae). Plant Mol Biol 22:183–193

Hernández R, Eguchi T, Deveci M, Kubota C (2016) Tomato seedling physiological responses under different percentages of blue and red photon flux ratios using LEDs and cool white fluorescent lamps. Sci Hortic 213:270–280

Hirner AA, Veit S, Seitz HU (2001) Regulation of anthocyanin biosynthesis in UV-A-irradiated cell cultures of carrot and in organs of intact carrot plants. Plant Sci 161:315–322

Holton TA, Cornish EC (1995) Genetics and biochemistry of anthocyanin biosynthesis. Plant Cell 7:1071

Hu D-G, Sun C-H, Ma Q-J, You C-X, Cheng L, Hao Y-J (2016) MdMYB1 regulates anthocyanin and malate accumulation by directly facilitating their transport into vacuoles in apples. Plant Physiol 170:1315–1330

Hu M, Du J, Du L, Luo Q, Xiong J (2020) Anti-fatigue activity of purified anthocyanins prepared from purple passion fruit (P. edulis Sim) epicarp in mice. J Funct Foods 65:103725

Huang Y, Gou J, Jia Z, Yang L, Sun Y, Xiao X, Song F, Luo K (2012) Molecular cloning and characterization of two genes encoding dihydroflavonol-4-reductase from Populus trichocarpa. PLoS One 7:e30364

Jaakola L (2013) New insights into the regulation of anthocyanin biosynthesis in fruits. Trends Plant Sci 18:477–483

Jones JA, Vernacchio VR, Collins SM, Shirke AN, Xiu Y, Englaender JA, Cress BF, McCutcheon CC, Linhardt RJ, Gross RA (2017) Complete biosynthesis of anthocyanins using E. coli polycultures. MBio 8

Kallscheuer N, Vogt M, Stenzel A, Gätgens J, Bott M, Marienhagen J (2016) Construction of a Corynebacterium glutamicum platform strain for the production of stilbenes and (2S)-flavanones. Metab Eng 38:47–55

Kerio LC, Wachira FN, Wanyoko JK, Rotich MK (2012) Characterization of anthocyanins in Kenyan teas: extraction and identification. Food Chem 131:31–38

Kiferle C, Fantini E, Bassolino L, Povero G, Spelt C, Buti S, Giuliano G, Quattrocchio F, Koes R, Perata P (2015) Tomato R2R3-MYB proteins SlANT1 and SlAN2: same protein activity, different roles. PLoS One 10:e0136365

Kim DH, Kim B-G, Lee Y, Ryu JY, Lim Y, Hur H-G, Ahn J-H (2005) Regiospecific methylation of naringenin to ponciretin by soybean O-methyltransferase expressed in Escherichia coli. J Biotechnol 119:155–162

Koes R, Verweij W, Quattrocchio F (2005) Flavonoids: a colorful model for the regulation and evolution of biochemical pathways. Trends Plant Sci 10:236–242

Koopman F, Beekwilder J, Crimi B, van Houwelingen A, Hall RD, Bosch D, van Maris AJ, Pronk JT, Daran J-M (2012) De novo production of the flavonoid naringenin in engineered Saccharomyces cerevisiae. Microb Cell Factories 11:1–15

Kriventsov VI, Arendt NK (1981) Anthocyanins of pomegranate juice. T Gos Nikits Bot Sad 83:110–116

Lamikanra O (1989) Anthocyanins of Vitis rotundifolia hybrid grapes. Food Chem 33:225–237

Lanza AM, Curran KA, Rey LG, Alper HS (2014) A condition-specific codon optimization approach for improved heterologous gene expression in Saccharomyces cerevisiae. BMC Syst Biol 8:1–10

Leonard E, Yan Y, Fowler ZL, Li Z, Lim C-G, Lim K-H, Koffas MA (2008) Strain improvement of recombinant Escherichia coli for efficient production of plant flavonoids. Mol Pharm 5:257–265

Levisson M, Patinios C, Hein S, de Groot PA, Daran J-M, Hall RD, Martens S, Beekwilder J (2018) Engineering de novo anthocyanin production in Saccharomyces cerevisiae. Microb Cell Factories 17:1–16

Li C, Wu J, Hu K-D, Wei S-W, Sun H-Y, Hu L-Y, Han Z, Yao G-F, Zhang H (2020) PyWRKY26 and PybHLH3 cotargeted the PyMYB114 promoter to regulate anthocyanin biosynthesis and transport in red-skinned pears. Hortic Res 7:1–12

Li H, Flachowsky H, Fischer TC, Hanke M-V, Forkmann G, Treutter D, Schwab W, Hoffmann T, Szankowski I (2007) Maize Lc transcription factor enhances biosynthesis of anthocyanins, distinct proanthocyanidins and phenylpropanoids in apple (Malus domestica Borkh.). Planta 226:1243–1254

Li H, Gao S, Zhang S, Zeng W, Zhou J (2021) Effects of metabolic pathway gene copy numbers on the biosynthesis of (2S)-naringenin in Saccharomyces cerevisiae. J Biotechnol 325:119–127

Li P, Chen B, Zhang G, Chen L, Dong Q, Wen J, Mysore KS, Zhao J (2016) Regulation of anthocyanin and proanthocyanidin biosynthesis by Medicago truncatula bHLH transcription factor MtTT8. New Phytol 210:905–921

Li X-J, Hou J-H, Zhang G-L, Liu R-S, Yang Y-G, Hu Y-X, Lin J-X (2004) Comparison of anthocyanin accumulation and morpho-anatomical features in apple skin during color formation at two habitats. Sci Hortic 99:41–53

Lim CG, Wong L, Bhan N, Dvora H, Xu P, Venkiteswaran S, Koffas MA (2015) Development of a recombinant Escherichia coli strain for overproduction of the plant pigment anthocyanin. Appl Environ Microbiol 81:6276–6284

Lin-Wang KUI, Micheletti D, Palmer J, Volz R, Lozano L, Espley R, Hellens RP, Chagne D, Rowan DD, Troggio M (2011) High temperature reduces apple fruit colour via modulation of the anthocyanin regulatory complex. Plant Cell Environ 34:1176–1190

Liu B, Falkenstein-Paul H, Schmidt W, Beerhues L (2003) Benzophenone synthase and chalcone synthase from Hypericum androsaemum cell cultures: cDNA cloning, functional expression, and site-directed mutagenesis of two polyketide synthases. Plant J 34:847–855

Liu Y, Wang L, Zhang J, Yu B, Wang J, Wang D (2017) The MYB transcription factor StMYBA1 from potato requires light to activate anthocyanin biosynthesis in transgenic tobacco. J Plant Biol 60:93–101

Liu Z, Zhang Y, Wang J, Li P, Zhao C, Chen Y, Bi Y (2015) Phytochrome-interacting factors PIF4 and PIF5 negatively regulate anthocyanin biosynthesis under red light in Arabidopsis seedlings. Plant Sci 238:64–72

Lloyd A, Brockman A, Aguirre L, Campbell A, Bean A, Cantero A, Gonzalez A (2017) Advances in the MYB–bHLH–WD repeat (MBW) pigment regulatory model: addition of a WRKY factor and co-option of an anthocyanin MYB for betalain regulation. Plant Cell Physiol 58:1431–1441

Lucioli S (2012) Anthocyanins: mechanism of action and therapeutic efficacy. Med Plants Antioxid Agents Underst Their Mech Action Ther Effic 27–57

Lyu X, Zhao G, Ng KR, Mark R, Chen WN (2019) Metabolic engineering of Saccharomyces cerevisiae for de novo production of kaempferol. J Agric Food Chem 67:5596–5606

Maier A, Hoecker U (2015) COP1/SPA ubiquitin ligase complexes repress anthocyanin accumulation under low light and high light conditions. Plant Signal Behav 10:e970440

Makus DJ, DJ M (1973) Characterization of anthocyanins during ripening of fruit of Vaccinium corymbosum, L. cv. Wolcott

Marchev AS, Yordanova ZP, Georgiev MI (2020) Green (cell) factories for advanced production of plant secondary metabolites. Crit Rev Biotechnol 40:443–458

Marienhagen J, Bott M (2013) Metabolic engineering of microorganisms for the synthesis of plant natural products. J Biotechnol 163:166–178

Martinsen BK, Aaby K, Skrede G (2020) Effect of temperature on stability of anthocyanins, ascorbic acid and color in strawberry and raspberry jams. Food Chem 316:126297

Matus JT, Loyola R, Vega A, Peña-Neira A, Bordeu E, Arce-Johnson P, Alcalde JA (2009) Post-veraison sunlight exposure induces MYB-mediated transcriptional regulation of anthocyanin and flavonol synthesis in berry skins of Vitis vinifera. J Exp Bot 60:853–867

Mazza G (2018) Anthocyanins in fruits, vegetables, and grains. CRC Press

Mazza G, Miniati E (1993) Grapes. Anthocyanins Fruits Veg Grains 149–199

Mazzucato A, Willems D, Bernini R, Picarella ME, Santangelo E, Ruiu F, Tilesi F, Soressi GP (2013) Novel phenotypes related to the breeding of purple-fruited tomatoes and effect of peel extracts on human cancer cell proliferation. Plant Physiol Biochem 72:125–133

Meyer P, Heidmann I, Forkmann G, Saedler H (1987) A new petunia flower colour generated by transformation of a mutant with a maize gene. Nature 330:677–678

Mohammadi Pour P, Fakhri S, Asgary S, Farzaei MH, Echeverria J (2019) The signaling pathways, and therapeutic targets of antiviral agents: focusing on the antiviral approaches and clinical perspectives of anthocyanins in the management of viral diseases. Front Pharmacol 10:1207

Molaeafard S, Jamei R, Marjani AP (2021) Co-pigmentation of anthocyanins extracted from sour cherry (Prunus cerasus L.) with some organic acids: color intensity, thermal stability, and thermodynamic parameters. Food Chem 339:128070

Movahed N, Pastore C, Cellini A, Allegro G, Valentini G, Zenoni S, Cavallini E, D’Incà E, Tornielli GB, Filippetti I (2016) The grapevine VviPrx31 peroxidase as a candidate gene involved in anthocyanin degradation in ripening berries under high temperature. J Plant Res 129:513–526

Muir SR, Collins GJ, Robinson S, Hughes S, Bovy A, van Ric De Vos CH, van Tunen AJ, Verhoeyen ME (2001) Overexpression of petunia chalcone isomerase in tomato results in fruit containing increased levels of flavonols. Nat Biotechnol 19:470–474

Nakamura N, Fukuchi-Mizutani M, Miyazaki K, Suzuki K, Tanaka Y (2006) RNAi suppression of the anthocyanidin synthase gene in Torenia hybrida yields white flowers with higher frequency and better stability than antisense and sense suppression. Plant Biotechnol 23:13–17

Nakatsuka T, Abe Y, Kakizaki Y, Yamamura S, Nishihara M (2007) Production of red-flowered plants by genetic engineering of multiple flavonoid biosynthetic genes. Plant Cell Rep 26:1951–1959

Napoli C, Lemieux C, Jorgensen R (1990) Introduction of a chimeric chalcone synthase gene into petunia results in reversible co-suppression of homologous genes in trans. Plant Cell 2:279–289

Nazareth MS, Shreelakshmi SV, Rao PJ, Shetty NP (2021) Micro and nanoemulsions of Carissa spinarum fruit polyphenols, enhances anthocyanin stability and anti-quorum sensing activity: comparison of degradation kinetics. Food Chem 359:129876

Nesi N, Jond C, Debeaujon I, Caboche M, Lepiniec L (2001) The Arabidopsis TT2 gene encodes an R2R3 MYB domain protein that acts as a key determinant for proanthocyanidin accumulation in developing seed. Plant Cell 13:2099–2114

Niu J, Zhang G, Zhang W, Goltsev V, Sun S, Wang J, Li P, Ma F (2017) Anthocyanin concentration depends on the counterbalance between its synthesis and degradation in plum fruit at high temperature. Sci Rep 7:1–16

Oren-Shamir M (2009) Does anthocyanin degradation play a significant role in determining pigment concentration in plants? Plant Sci 177:310–316

Palmer CM, Miller KK, Nguyen A, Alper HS (2020) Engineering 4-coumaroyl-CoA derived polyketide production in Yarrowia lipolytica through a β-oxidation mediated strategy. Metab Eng 57:174–181

Pandey RP, Parajuli P, Koffas MA, Sohng JK (2016) Microbial production of natural and non-natural flavonoids: pathway engineering, directed evolution and systems/synthetic biology. Biotechnol Adv 34:634–662

Passeri V, Koes R, Quattrocchio FM (2016) New challenges for the design of high value plant products: stabilization of anthocyanins in plant vacuoles. Front Plant Sci 7:153

Pina F, Melo MJ, Laia CA, Parola AJ, Lima JC (2012) Chemistry and applications of flavylium compounds: a handful of colours. Chem Soc Rev 41:869–908

Poudel PR, Azuma A, Kobayashi S, Koyama K, Goto-Yamamoto N (2021) VvMYBAs induce expression of a series of anthocyanin biosynthetic pathway genes in red grapes (Vitis vinifera L.). Sci Hortic 283:110121

Putta S, Yarla NS, Peluso I, Tiwari DK, Reddy GV, Giri PV, Kumar N, Malla R, Rachel V, Bramhachari PV (2017) Anthocyanins: Multi-target agents for prevention and therapy of chronic diseases. Curr Pharm Des 23:6321–6346

Rodriguez A, Strucko T, Stahlhut SG, Kristensen M, Svenssen DK, Forster J, Nielsen J, Borodina I (2017) Metabolic engineering of yeast for fermentative production of flavonoids. Bioresour Technol 245:1645–1654

Ruta LL, Farcasanu IC (2019) Anthocyanins and anthocyanin-derived products in yeast-fermented beverages. Antioxidants 8:182

Saad KR, Kumar G, Giridhar P, Shetty NP (2018) Differential expression of anthocyanin biosynthesis genes in Daucus carota callus culture in response to ammonium and potassium nitrate ratio in the culture medium. 3 Biotech 8:1–11

Saad KR, Parvatam G, Shetty NP (2018) Medium composition potentially regulates the anthocyanin production from suspension culture of Daucus carota. 3 Biotech 8:1–13

Santos CNS, Koffas M, Stephanopoulos G (2011) Optimization of a heterologous pathway for the production of flavonoids from glucose. Metab Eng 13:392–400

Schwinn K, Miosic S, Davies K, Thill J, Gotame TP, Stich K, Halbwirth H (2014) The B-ring hydroxylation pattern of anthocyanins can be determined through activity of the flavonoid 3′-hydroxylase on leucoanthocyanidins. Planta 240:1003–1010

Scudamore-Smith PD, Hooper RL, McLaran ED (1990) Color and phenolic changes of Cabernet Sauvignon wine made by simultaneous yeast/bacterial fermentation and extended pomace contact. Am J Enol Vitic 41:57–67

Seitz C, Vitten M, Steinbach P, Hartl S, Hirsche J, Rathje W, Treutter D, Forkmann G (2007) Redirection of anthocyanin synthesis in Osteospermum hybrida by a two-enzyme manipulation strategy. Phytochemistry 68:824–833

Shi L, Cao S, Chen W, Yang Z (2014) Blue light induced anthocyanin accumulation and expression of associated genes in Chinese bayberry fruit. Sci Hortic 179:98–102

Shi Q, Li X, Du J, Li X (2019) Anthocyanin synthesis and the expression patterns of bHLH transcription factor family during development of the Chinese jujube fruit (Ziziphus jujuba Mill.). Forests 10:346

Shimada N, Aoki T, Sato S, Nakamura Y, Tabata S, Ayabe S (2003) A cluster of genes encodes the two types of chalcone isomerase involved in the biosynthesis of general flavonoids and legume-specific 5-deoxy (iso)flavonoids in Lotus japonicus. Plant Physiol 131:941–951

Shipp J, Abdel-Aal E-SM (2010) Food applications and physiological effects of anthocyanins as functional food ingredients. Open Food Sci J 4

Shrestha B, Pandey RP, Darsandhari S, Parajuli P, Sohng JK (2019) Combinatorial approach for improved cyanidin 3-O-glucoside production in Escherichia coli. Microb Cell Factories 18:1–15

Simões C, Albarello N, Castro TC, Mansur E (2012) Production of anthocyanins by plant cell and tissue culture strategies. Biotechnol Prod Plant Second Metab 1st Ed Orhan IE Ed 67–86

Simões C, Bizarri CHB, da Silva CL, de Castro TC, Coutada LCM, da Silva AJR, Albarello N, Mansur E (2009) Anthocyanin production in callus cultures of Cleome rosea: modulation by culture conditions and characterization of pigments by means of HPLC-DAD/ESIMS. Plant Physiol Biochem 47:895–903

Smeriglio A, Barreca D, Bellocco E, Trombetta D (2016) Chemistry, pharmacology and health benefits of anthocyanins. Phytother Res 30:1265–1286

Solopova A, van Tilburg AY, Foito A, Allwood JW, Stewart D, Kulakauskas S, Kuipers OP (2019) Engineering Lactococcus lactis for the production of unusual anthocyanins using tea as substrate. Metab Eng 54:160–169

Sparvoli F, Martin C, Scienza A, Gavazzi G, Tonelli C (1994) Cloning and molecular analysis of structural genes involved in flavonoid and stilbene biosynthesis in grape (Vitis vinifera L.). Plant Mol Biol 24:743–755

Spelt C, Quattrocchio F, Mol JN, Koes R (2000) anthocyanin1 of petunia encodes a basic helix-loop-helix protein that directly activates transcription of structural anthocyanin genes. Plant Cell 12:1619–1631

Stintzing FC, Carle R (2004) Functional properties of anthocyanins and betalains in plants, food, and in human nutrition. Trends Food Sci Technol 15:19–38

Sun H, Li Y, Feng S, Zou W, Guo K, Fan C, Si S, Peng L (2013) Analysis of five rice 4-coumarate: coenzyme A ligase enzyme activity and stress response for potential roles in lignin and flavonoid biosynthesis in rice. Biochem Biophys Res Commun 430:1151–1156

Takahashi A, Takeda K, Ohnishi T (1991) Light-induced anthocyanin reduces the extent of damage to DNA in UV-irradiated Centaurea cyanus cells in culture. Plant Cell Physiol 32:541–547

Tanaka Y, Fukui Y, Fukuchi-Mizutani M, Holton TA, Higgins E, Kusumi T (1995) Molecular cloning and characterization of Rosa hybrida dihydroflavonol 4-reductase gene. Plant Cell Physiol 36:1023–1031

Tanaka Y, Ohmiya A (2008) Seeing is believing: engineering anthocyanin and carotenoid biosynthetic pathways. Curr Opin Biotechnol 19:190–197

Tanaka Y, Sasaki N, Ohmiya A (2008) Biosynthesis of plant pigments: anthocyanins, betalains and carotenoids. Plant J 54:733–749

Tian L, Kong WF, Pan QH, Zhan JC, Wen PF, Chen JY, Wan SB, Huang WD (2006) Expression of the chalcone synthase gene from grape and preparation of an anti-CHS antibody. Protein Expr Purif 50:223–228

Timmers MA, Grace MH, Yousef GG, Lila MA (2017) Inter-and intra-seasonal changes in anthocyanin accumulation and global metabolite profiling of six blueberry genotypes. J Food Compos Anal 59:105–110

Trabelsi N, d’Estaintot BL, Sigaud G, Gallois B, Chaudière J (2011) Kinetic and binding equilibrium studies of dihydroflavonol 4-reductase from Vitis vinifera and its unusually strong substrate inhibition. J Biophys Chem 2:332–344

Trabelsi N, Petit P, Manigand C, Langlois d’Estaintot B, Granier T, Chaudiere J, Gallois B (2008) Structural evidence for the inhibition of grape dihydroflavonol 4-reductase by flavonols. Acta Crystallogr D Biol Crystallogr 64:883–891

Trantas E, Panopoulos N, Ververidis F (2009) Metabolic engineering of the complete pathway leading to heterologous biosynthesis of various flavonoids and stilbenoids in Saccharomyces cerevisiae. Metab Eng 11:355–366

Turnbull JJ, Nakajima J, Welford RW, Yamazaki M, Saito K, Schofield CJ (2004) Mechanistic studies on three 2-oxoglutarate-dependent oxygenases of flavonoid biosynthesis: anthocyanidin synthase, flavonol synthase, and flavanone 3β-hydroxylase. J Biol Chem 279:1206–1216

Ueyama Y, Suzuki K, Fukuchi-Mizutani M, Fukui Y, Miyazaki K, Ohkawa H, Kusumi T, Tanaka Y (2002) Molecular and biochemical characterization of torenia flavonoid 3′-hydroxylase and flavone synthase II and modification of flower color by modulating the expression of these genes. Plant Sci 163:253–263

Vaknin H, Bar-Akiva A, Ovadia R, Nissim-Levi A, Forer I, Weiss D, Oren-Shamir M (2005) Active anthocyanin degradation in Brunfelsia calycina (yesterday–today–tomorrow) flowers. Planta 222:19–26

Vasserot Y, Caillet S, Maujean A (1997) Study of anthocyanin adsorption by yeast lees. Effect of some physicochemical parameters. Am J Enol Vitic 48:433–437

Wallace TC, Slavin M, Frankenfeld CL (2016) Systematic review of anthocyanins and markers of cardiovascular disease. Nutrients 8:32

Wang H, Hu T, Huang J, Lu X, Huang B, Zheng Y (2013) The expression of Millettia pinnata chalcone isomerase in Saccharomyces cerevisiae salt-sensitive mutants enhances salt-tolerance. Int J Mol Sci 14:8775–8786

Wang L, Tang W, Hu Y, Zhang Y, Sun J, Guo X, Lu H, Yang Y, Fang C, Niu X (2019) A MYB/bHLH complex regulates tissue-specific anthocyanin biosynthesis in the inner pericarp of red-centered kiwifruit Actinidia chinensis cv. Hongyang Plant J 99:359–378

Wang Y, Chen S, Yu O (2011) Metabolic engineering of flavonoids in plants and microorganisms. Appl Microbiol Biotechnol 91:949–956

Woodward GM, Needs PW, Kay CD (2011) Anthocyanin-derived phenolic acids form glucuronides following simulated gastrointestinal digestion and microsomal glucuronidation. Mol Nutr Food Res 55:378–386

Wu J, Du G, Chen J, Zhou J (2015) Enhancing flavonoid production by systematically tuning the central metabolic pathways based on a CRISPR interference system in Escherichia coli. Sci Rep 5:1–14

Wu X, Beecher GR, Holden JM, Haytowitz DB, Gebhardt SE, Prior RL (2006) Concentrations of anthocyanins in common foods in the United States and estimation of normal consumption. J Agric Food Chem 54:4069–4075

Xu F, Cao S, Shi L, Chen W, Su X, Yang Z (2014) Blue light irradiation affects anthocyanin content and enzyme activities involved in postharvest strawberry fruit. J Agric Food Chem 62:4778–4783

Yan Y, Chemler J, Huang L, Martens S, Koffas MA (2005) Metabolic engineering of anthocyanin biosynthesis in Escherichia coli. Appl Environ Microbiol 71:3617–3623

Yan Y, Huang L, Koffas MA (2007) Biosynthesis of 5-deoxyflavanones in microorganisms. Biotechnol J Healthc Nutr Technol 2:1250–1262

Yan Y, Li Z, Koffas MA (2008) High-yield anthocyanin biosynthesis in engineered Escherichia coli. Biotechnol Bioeng 100:126–140

Yang M, Koo IS, Song OW, Chun KO (2011) Food matrix affecting anthocyanin bioavailability. Curr Med Chem 18:291–300

Yang S-M, Han SH, Kim B-G, Ahn J-H (2014) Production of kaempferol 3-O-rhamnoside from glucose using engineered Escherichia coli. J Ind Microbiol Biotechnol 41:1311–1318

Zha J, Zang Y, Mattozzi M, Plassmeier J, Gupta M, Wu X, Clarkson S, Koffas MA (2018) Metabolic engineering of Corynebacterium glutamicum for anthocyanin production. Microb Cell Factories 17:1–13

Zhang Y, Butelli E, Martin C (2014) Engineering anthocyanin biosynthesis in plants. Curr Opin Plant Biol 19:81–90

Zhang Y, Hu W, Peng X, Sun B, Wang X, Tang H (2018) Characterization of anthocyanin and proanthocyanidin biosynthesis in two strawberry genotypes during fruit development in response to different light qualities. J Photochem Photobiol B 186:225–231

Zhang Z, Pang X, Xuewu D, Ji Z, Jiang Y (2005) Role of peroxidase in anthocyanin degradation in litchi fruit pericarp. Food Chem 90:47–52

Zhao C-L, Yu Y-Q, Chen Z-J, Wen G-S, Wei F-G, Zheng Q, Wang C-D, Xiao X-L (2017) Stability-increasing effects of anthocyanin glycosyl acylation. Food Chem 214:119–128

Zhao S, Jones JA, Lachance DM, Bhan N, Khalidi O, Venkataraman S, Wang Z, Koffas MA (2015) Improvement of catechin production in Escherichia coli through combinatorial metabolic engineering. Metab Eng 28:43–53

Zhou S, Lyu Y, Li H, Koffas MA, Zhou J (2019) Fine-tuning the (2S)-naringenin synthetic pathway using an iterative high-throughput balancing strategy. Biotechnol Bioeng 116:1392–1404

Zhu L, Huang Y, Zhang Y, Xu C, Lu J, Wang Y (2017) The growing season impacts the accumulation and composition of flavonoids in grape skins in two-crop-a-year viticulture. J Food Sci Technol 54:2861–2870

Zipor G, Duarte P, Carqueijeiro I, Shahar L, Ovadia R, Teper-Bamnolker P, Eshel D, Levin Y, Doron-Faigenboim A, Sottomayor M (2015) In planta anthocyanin degradation by a vacuolar class III peroxidase in Brunfelsia calycina flowers. New Phytol 205:653–665

Acknowledgements

The authors are grateful to the Director of CSIR-CFTRI, Mysore, India, and the Department of Biotechnology-Biotechnology Research Assistance Council (DBT-BIRAC), Delhi, India, for giving the Research Associate award to SL.

Author information

Authors and Affiliations

Contributions

SL and NPS designed the study. SL drafted the manuscript. NPS contributed to the revision of the manuscript. The authors read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies on human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sunil, L., Shetty, N.P. Biosynthesis and regulation of anthocyanin pathway genes. Appl Microbiol Biotechnol 106, 1783–1798 (2022). https://doi.org/10.1007/s00253-022-11835-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-022-11835-z