Abstract

Microbial contamination of alcoholic fermentation processes (e.g. winemaking and fuel-ethanol production) is a serious problem for the industry since it may render the product unacceptable and/or reduce its productivity, leading to large economic losses. Brettanomyces/Dekkera bruxellensis is one of the most dangerous microbial contaminant of ethanol industrial fermentations. In the case of wine, this yeast species can produce phenolic compounds that confer off-flavours to the final product. In fuel-ethanol fermentations, D. bruxellensis is a persistent contaminant that affects ethanol yields and productivities. We recently found that Saccharomyces cerevisiae secretes a biocide, which we named saccharomycin, composed of antimicrobial peptides (AMPs) derived from the glycolytic enzyme glyceraldehyde-3-phosphate dehydrogenase (GAPDH). Saccharomycin is active against several wine-related yeast species, namely D. bruxellensis. However, the levels of saccharomycin naturally secreted by S. cerevisiae during alcoholic fermentation are not sufficient to ensure the complete death of D. bruxellensis. Therefore, the aim of the present work was to construct genetically modified S. cerevisiae strains to overproduce these GAPDH-derived AMPs. The expression levels of the nucleotides sequences encoding the AMPs were evaluated in the modified S. cerevisiae strains by RT-qPCR, confirming the success of the recombinant approach. Furthermore, we confirmed by immunological tests that the modified S. cerevisiae strains secreted higher amounts of the AMPs by comparison with the non-modified strain, inducing total death of D. bruxellensis during alcoholic fermentations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most industrial processes involving alcoholic fermentations (e.g. winemaking, brewing and fuel-ethanol production) are conducted under non-sterile conditions for economic and technical reasons. Consequently, those processes are subjected to chronic microbial contaminations. The main contaminants of wine and fuel-ethanol production processes are lactic acid bacteria and wild yeasts such as Brettanomyces/Dekkera bruxellensis (Barros Pita et al. 2011; Fugelsang 1997; Loureiro and Malfeito-Ferreira 2003; Souza Liberal et al. 2007). In wine, D. bruxellensis strains produce biogenic amines (Caruso et al. 2002) and phenolic compounds that confer off-flavours to wine described as “barnyard-like” or “horsey” (Fugelsang 1997). In fuel-ethanol fermentations, D. bruxellensis strains affect the fermentation efficiency reducing ethanol yields and productivities and leading to significant economic losses or even to stuck fermentations (Brexó and Sant’Ana 2018; Souza Liberal et al. 2007).

In wineries, the most common preservative practice is the addition of sulphur dioxide (Ribéreau-Gayon et al. 2006), which is highly toxic to most of the non-Saccharomyces yeasts, but not to the majority of Saccharomyces strains (Fleet 1992; Romano and Suzzi 1993). However, the use of excessive doses of sulphur dioxide in wine should be avoided since this chemical may have a negative impact on the wine aroma and can cause health problems. In fuel-ethanol fermentations, microbial contaminants are hard to control since disinfectants usually used to combat them (e.g. antibiotics, acid treatments, ammonia, sulphur dioxide, etc.) can either affect the performance of Saccharomyces strains or put disposal waste problems (e.g. antibiotics) (Beckner et al. 2011). Besides, given the amounts needed to maintain low contaminating levels, and the potentially corrosive and toxic nature of some of those chemicals (e.g. sulphur dioxide), it is not a viable, long-term solution for bioethanol production facilities (Beckner et al. 2011). Therefore, it is important to find alternatives to the classical chemical preservatives (mainly SO2 and antibiotics) that might perform a similar role in industrial ethanol fermentations, without its disadvantages (Beckner et al. 2011; Comitini et al. 2004; Mehlomakulu et al. 2014; Santos et al. 2009).

Recently, we found that S. cerevisiae secretes antimicrobial peptides (AMPs) during alcoholic fermentations that induce death of several non-Saccharomyces wine yeasts, namely of D. bruxellensis strains (Albergaria et al. 2010, 2013; Branco et al. 2014, 2017a). This finding opens interesting prospects regarding the possible use of these AMPs as alternative biopreservatives in alcoholic fermentation industrial processes (Albergaria and Arneborg 2016). The natural biocide, which we named saccharomycin, is composed of peptides derived from the glycolytic enzyme glyceraldehyde-3-phosphate dehydrogenase (GAPDH). However, the GAPDH-derived AMPs levels naturally secreted by S. cerevisiae strains during alcoholic fermentations are not sufficient to assure the complete death of some undesirable contaminants, namely of D. bruxellensis strains (Branco et al. 2014, 2017a). Besides, the minimal inhibitory concentration of saccharomycin varies considerably amongst wine-related non-Saccharomyces yeasts, ranging from 250 μg/ml for Hanseniaspora guilliermondii, Lachancea thermotolerans and Kluyveromyces marxianus, up to 1000–2000 μg/ml for D. bruxellensis strains (Branco et al. 2017a).

Lately, AMPs have received increasing attention due to their potential as novel pharmaceutical agents, as well as alternative natural biopreservatives (Hancock and Sahl 2006). As a result, production of large quantities of AMPs, in an economically viable way, is required (Li 2009). AMPs can be reliably prepared by chemical synthesis, but this is extremely expensive. Isolation from natural sources is typically a complex and time-consuming process that rarely meets the requirements for quantity and cost efficiency. Therefore, none of these processes is an efficient way to obtain AMPs in large amounts (Li 2009; Pyo et al. 2004; Xu et al. 2007). The recombinant approach is relatively low cost and easy to scale up, being a more attractive methodology for large-scale production of AMPs (Li 2009). Escherichia coli and yeast are the two major systems used to produce recombinant AMPs. The first yeast employed to produce recombinant proteins was S. cerevisiae, since vast genetic techniques are available for this species (Xu et al. 2007).

The main goal of the present work was to construct genetically modified S. cerevisiae strains able to overproduce the GAPDH-derived AMPs and to evaluate their biocontrol potential against D. bruxellensis during alcoholic fermentations.

Materials and methods

Strains, plasmid and growth conditions

The following yeasts were used in the present work: S. cerevisiae CCMI 885 (Culture Collection of Industrial Microorganisms of ex-INETI, Lisbon, Portugal) and S. cerevisiae PYCC 5484 (CEN.PK113-5D, MATa ura3-52 HIS3, LEU2 TRP1 MAL2-8c SUC2) (Portuguese Yeast Culture Collection, FCT/UNL, Caparica, Portugal); Pichia pastoris GS115 (Invitrogen, Karlsruhe, Germany); D. bruxellensis ISA 2211 (Instituto Superior de Agronomia, Lisbon, Portugal). All yeasts except D. bruxellensis were maintained in YEPD medium (5 g/l yeast extract, 10 g/l peptone, 20 g/l glucose and 20 g/l agar) and stored at 4 °C. D. bruxellensis was maintained in YEPD medium with 5 g/l of calcium carbonate (Merck, Darmstadt, Germany) and stored at 4 °C.

Inoculums were prepared by transferring biomass from a YEPD-agar slant (pre-grown at 30 °C for 48 h) into 250-ml flasks with 100 ml of YEPD (10 g/l yeast extract, 20 g/l peptone and 20 g/l glucose) and incubating flasks at 30 °C and 150 rpm, for 16 h. All media were autoclaved at 120 °C for 20 min.

The centromeric plasmid p416 TEF (Mumberg et al. 1995), containing TEF promoter and CYC1 terminator, was used for cloning. For propagation of this plasmid, E. coli DH5α strain was used as host (Hanahan 1983). E. coli transformants were grown in Luria-Bertani (LB) medium supplemented with ampicillin (100 μg/ml), at 37 °C. S. cerevisiae PYCC 5484 was used as host strain for heterologous expression of the partial sequences TDH1 (925-963 bp) (codifying region of the TDH1 gene located between 925 and 963 bp) and TDH2/3 (925-963 bp) (codifying region of the TDH2/3 genes located between 925 and 963 bp), previously inserted in p416 TEF. These modified strains are, from now on, called S. cerevisiae pTDH1 and S. cerevisiae pTDH2/3, respectively. S. cerevisiae PYCC 5484 transformed with empty p416 TEF, from now on called S. cerevisiae K1, was used as reference strain and negative control. Transformed yeast strains were grown and maintained in YNB medium without amino acids (DIFCO, Detroit, EUA) with 2% (w/v) glucose.

Production and purification of saccharomycin

Saccharomycin (i.e. the naturally secreted GAPDH-derived AMPs) was purified from the cell-free supernatant (7-day-old) of a synthetic grape juice (SGJ) fermentation performed with S. cerevisiae CCMI 885. The SGJ, containing 120 g/l of glucose plus 120 g/l of fructose and pH 3.5, was prepared as described in Pérez-Nevado et al. (2006). The fermentation supernatant was ultrafiltrated by centrifugal filter units (Vivaspin 15R, Sartorius, Göttingen, Germany) equipped with 10 kDa cut-off membranes, and the permeate fraction (< 10 kDa) was concentrated (10-fold) using 2 kDa centrifugal filter units. The peptidic fraction (2–10 kDa) was then fractionated by gel filtration chromatography using a Superdex-Peptide column (10/300 GL, GE Healthcare, London, UK) coupled to an HPLC system (Merck Hitachi, Darmstadt, Germany) equipped with a UV detector (Merck Hitachi, Darmstadt, Germany). The peptidic supernatant fraction (2–10 kDa) was eluted with 0.1 M ammonium acetate at a flow rate of 0.7 ml/min. The bioactive fraction containing the GAPDH-derived peptides (retention time between 25 and 27 min) was collected and lyophilized.

Sensitivity of yeast species and strains to saccharomycin

To determine the sensitivity of S. cerevisiae PYCC 5484, S. cerevisiae CCMI 885, P. pastoris GS 115 and D. bruxellensis 2211 to saccharomycin (i.e. to the naturally secreted GAPDH-derived AMPs), these yeast strains were grown in the presence of different concentrations of the bioactive peptidic fraction (purified as described in the “Production and purification of saccharomycin” section) that contains the GAPDH-derived AMPs (Branco et al. 2014). Growth inhibitory assays were performed in 96-well microplates in triplicate independent assays, with each well containing 100 μl of YEPD medium without the AMPs (negative control) and with the AMPs at final protein concentrations of 125, 250, 500 and 1000 μg/ml. Media were inoculated with 105 cells/ml of each of the above-mentioned yeast strains, and the microplate was incubated in a Thermo-Shaker (Infors HT, Bottmingen, Switzerland) at 30 °C under strong shaking (700 rpm). Cell growth was followed during 48 h by absorbance measurements (at 590 nm) in a Microplate Reader (Dinex Technologies Inc., Chantilly, USA).

Plasmid DNA manipulations and cloning of the partial nucleotide sequences TDH1 and TDH2/3 in S. cerevisiae strain K1

Plasmid p416 TEF DNA from E. coli DH5α + p416 TEF, previously constructed in our lab, was isolated using GenElute™ Plasmid Miniprep Kit (Sigma-Aldrich, St. Louis, MO, USA). The nucleotide sequence of TDH1 (925–963) encoding AMP1 (ISWYDNEYGYSAR) and the nucleotide sequence of TDH2/3 (925–963) encoding AMP2/3 (VSWYDNEYGYSTR) were used to design primers in order to obtain PCR products containing TDH1 and TDH2/3 sequences, resulting from primer dimerization. Forward and reverse primers were designed with the restriction sites for XbaI and SalI, respectively (Table 1). PCR amplification of the primer dimer corresponding to the DNA sequence codifying for the AMP1 and AMP2/3 was carried out in an Eppendorf thermocycler with Phusion™ High-fidelity DNA polymerase (Thermo Fisher Scientific, Waltham, MA, USA). The amplified products were digested with XbaI and SalI, purified using the purification kit “GFX PCR DNA and Gel Band Purification” (GE Healthcare, Little Chalfont, UK) and cloned into the corresponding restriction sites of the p416 TEF plasmid, digested by the same restriction enzymes.

Cloning was performed according to standard protocols described in Sambrook et al. (1989). The plasmids were cloned into E. coli DH5α strain, propagated, subjected to extraction and restriction analysis. E. coli plasmid isolation was performed by alkaline extraction as described in Birnboim and Doly (1979) and modified as described in Sambrook et al. (1989). The correct insertion of TDH1 (925–963) and TDH2/3 (925–963) in the plasmid was checked by restriction digestion. Transformation of S. cerevisiae PYCC 5484 strain with the plasmids containing the partial sequence of TDH1 (925–963) (S. cerevisiae pTDH1) and TDH2/3 (925–963) (S. cerevisiae pTDH2/3) was performed by the lithium acetate method described in Geitz and Schiestl (1995). Transformants were selected on YNB medium without uracil. Plasmid isolation from yeasts was performed as described in Tillotson et al. (2013) with some modifications. Briefly, one S. cerevisiae colony freshly grown on an YNB plate was transferred into 30 μl of SDS 1% (w/v) in deionised water. Afterward, cells were vortexed for 1 min and then frozen at − 80 °C for 2 min and subsequently heated at 95 °C for 2 min; the freeze/thaw was repeated once more to ensure cell lyses. Cells were centrifuged at maximal speed for 1 min, and the supernatant was used as a template for PCR reaction. PCR products were loaded in an agarose gel for electrophoresis, and band was extracted from the gel and then purified using the purification kit “GFX PCR DNA and Gel Band Purification” (GE Healthcare, Little Chalfont, UK). The purified PCR products were sequenced by external services (STAB VIDA, Monte da Caparica, Portugal) in order to confirm the insertion of the sequences of interest.

RNA extraction and cDNA preparation

The modified S. cerevisiae strains pTDH1 and pTDH2/3 were pre-grown for 24 h in YNB without uracil (approximately 107 cells/ml). RNA extraction from cells was performed with Trizol Reagent (Invitrogen, Carlsbad, CA, USA). Small RNAs from the above-mentioned S. cerevisiae strains were separated and purified from total RNAs with mirVana™ miRNA Isolation Kit (Applied Biosystems, Foster, CA, USA) according to the manufacturer’s protocol. All RNA samples were treated with RNase-free DNase I (Qiagen, Hilden, Germany) and quantified using absorption of UV light at 260 nm. Small cDNAs from modified S. cerevisiae strains were synthesised from small mRNAs using TaqMan® MicroRNA Reverse Transcription Kit (Applied Biosystems, Foster, CA, USA). RT-primers designed by the manufacturer and specific for each small mRNA sequence were used for small cDNAs synthesis (Custom TaqMan® Small RNA Assays, Applied Biosystems, Foster City, CA, USA). Total cDNAs were synthesised from total mRNA of S. cerevisiae pTDH1 and S. cerevisiae pTDH2/3 using TaqMan® MicroRNA Reverse Transcription Kit and oligo (dT) primer (STAB VIDA, Monte da Caparica, Portugal). All cDNAs synthesis were performed following manufacturer’s instructions (Applied Biosystems, Foster City, CA, USA) and used as templates for real-time PCR reactions.

Quantitative reverse transcription PCR (RT-qPCR)

Small and total cDNAs, obtained as described in the “RNA extraction and cDNA preparation” section, were used as templates for two RT-qPCR reactions: one to analyse the expression levels of the partial TDH1 (925–963 bp) and TDH2/3 (925–963 bp) nucleotides sequences from the small cDNA template (plasmid); and another to analyse the expression levels of the same sequences from the total cDNA template (genomic). To determine the best amount of cDNA to be used as template, five dilutions of the cDNA sample were tested. Each dilution was analysed in triplicate.

The specific primers used to quantify the expression levels of the TDH1 (925–963) and TDH2/3 (925–963) nucleotide sequences from the small cDNAs and total cDNAs were obtained from Custom TaqMan® Small RNA Assays (Applied Biosystems, Foster City, CA, USA). RT-qPCR amplifications were obtained by using Luminaris Probe qPCR Master Mix (Thermo Fisher Scientific, Waltham, MA, USA). The RT-qPCR reactions for small cDNAs (2 min, 50 °C; 95 °C 10 min; 40 cycles: 15 s 95 °C, 30 s 60 °C, 30 s 72 °C) and for total cDNA (95 °C 10 min; 40 cycles: 15 s 95 °C, 30 s 60 °C, 30 s 72 °C) were performed in multiplate PCR 96-well clear plates (BIO-RAD, Hercules, CA, USA) in an iCycler iQ™ Real-Time PCR detection system (BIO-RAD, Hercules, CA, USA). RT-qPCR reactions were performed in triplicate. Each run was completed with a melting curve analysis to confirm the specificity of amplification and the lack of primer dimers. Additionally, PCR products were resolved on 2% (w/v) agarose gels, run at 4 V/cm in Tris-acetate-EDTA buffer (TAE), along with a 50-bp DNA-standard ladder (Invitrogen GmbH, Karlsruhe, Germany) to confirm the existence of a single product of the desired length. The comparative Ct method was used to quantify gene expression (Livak and Schmittgen 2001). Gene expression of the nucleotide sequences TDH1 (925–963) and TDH2/3 (925–963) inserted in the plasmid was normalised with respect to the expression of the corresponding genomic sequences (used as the reference genes).

Alcoholic fermentations performed with D. bruxellensis and S. cerevisiae in single- and mixed-culture

Single- and mixed-culture alcoholic fermentations were performed with the S. cerevisiae strains K1, pTDH1 and pTDH2/3 and with the D. bruxellensis strain ISA 2211. Mixed-culture fermentations were carried out with D. bruxellensis at an initial cell density of 5 × 103 and 1 × 105 cells/ml, respectively, together with 1 × 105 cells/ml of each of the S. cerevisiae strains. Two single-culture fermentations were performed with D. bruxellensis at an initial cell density of 5 × 103 and 1 × 105 cells/ml, respectively. These D. bruxellensis single-culture fermentations were used as negative control of the antagonism exerted by each of the above-mentioned S. cerevisiae strains. Single-culture fermentations of S. cerevisiae strains pTDH1, pTDH2/3 and K1 were also performed to determine the relative expression levels of the partial nucleotide sequences TDH1 and TDH2/3 and the overproduction of the GAPDH-derived AMPs in the modified S. cerevisiae strains pTDH1 and pTDH2/3.

All fermentations were carried out in 500-ml flasks containing 300 ml of SGJ (supplemented with 120 mg/l of uracil in fermentations performed with S. cerevisiae strain K1) and incubated at 25 °C, under gentle agitation (80 rpm). SGJ fermentations were carried out in duplicates, and samples were taken daily to determine cell growth, sugars consumption and ethanol production. Culturability (CFU/ml) of S. cerevisiae and D. bruxellensis during the fermentations was determined by the classical plating method. To specifically differentiate colonies forming unit (CFU) counts of D. bruxellensis and S. cerevisiae in mixed-culture samples, we used YEPD agar medium supplemented with 0.01% of cycloheximide, using the procedure described in Branco et al. (2014) to determine the number of CFUs of H. guilliermondii in the mixed-culture fermentations.

Cells of the S. cerevisiae strains K1, pTDH1 and pTDH2/3 were collected from the single-culture fermentations after 12, 24, 48 and 196 h and analysed by RT-qPCR (as described in the “Quantitative reverse transcription PCR” section) to determine the partial TDH1 and TDH2/3 gene expression levels. Supernatants from those fermentation samples were ultrafiltrated by centrifugal filter units (Vivaspin 15R, Sartorius, Göttingen, Germany) equipped with 10 kDa cut-off membranes, and the respective peptidic fractions were analysed by immunological tests, i.e. by indirect Enzyme-Linked Immunosorbent Assay (ELISA).

Quantification of the GAPDH-derived AMPs excreted by the modified S. cerevisiae strains by ELISA

The GAPDH-derived AMPs excreted by the modified S. cerevisiae strains during alcoholic fermentations were determined by the indirect ELISA, as described in Branco et al. (2017b). A specific polyclonal rabbit antiserum raised against the synthetic AMPs (anti-AMP1 and anti-AMP2/3) was obtained from GenScript Inc. Company (GenScript HK Limited, Hong Kong).

Briefly, 100 μl of each of the peptidic fractions (obtained as described in the “Alcoholic fermentations of D. bruxellensis and S. cerevisiae in single- and mixed-culture” section) from fermentation samples (at time 12, 24, 48 and 192 h) were used for coating each well of the 96-well microplate MICROLON® high binding (Greiner Bio-One, Essen, Germany). Then, the 96-well microplate was incubated overnight at 4 °C. Afterwards, 100 μl of 6 M urea was added to samples in order to denature the proteins and improve their detection by indirect ELISA, as previously described by Hnasko et al. (2011). The microplate was thereafter washed 4 times using a PBS-Tween washing solution (0.05% Tween 20 in 0.01 M PBS). The samples were blocked during 2 h at room temperature by adding 200 μl of blocking solution containing bovine serum albumin (BSA 1% w/) in PBS and washed 4 times with washing solution. Next, 100 μl of the primary polyclonal antibody specific to GAPDH-derived AMPs (GenScript HK Limited, Hong Kong) diluted in 1% BSA to a final concentration of 10 μg/ml was added to each well and incubated for 2 h at 37 °C. The unbound material was removed by washing the microplate 4 times with PBS-Tween solution. Thereafter, 100 μl of a secondary antibody (anti-rabbit IgG-fab specific, alkaline phosphatase conjugate, Sigma-Aldrich, St. Louis, USA) diluted in 1% BSA to 1.0 μg/ml was added to each well, followed by 2 h of incubation at 37 °C. Subsequently, the microplate was washed 4 times with PBS-Tween solution, followed by the addition of 100 μl/well of alkaline phosphatase substrate (100 mM Tris-HCL, 100 mM Nacl, 5 mM MgCl2, 1 mg/ml p-Nitrophenylphosphate (PnPP) to the microplate and incubation for 10 to 30 min at room temperature in the dark. The enzyme-substrate reaction was stopped by adding 100 μl of 3 N NaOH to each well. The optical density (OD) was measured at 405 nm using a microplate reader (Bio-Rad, Hercules, USA).

A standard curve was constructed using 1 mg/ml of synthetic AMP1 (309–321) (GenScript HK Limited, Hong Kong) diluted to 1:32, 1:64, 1:128, 1:256, 1:512 in a phosphate-buffered saline solution (PBS) at pH 7.2. Three replicates of 100 μl were taken from each diluted standard and transferred to a 96-well microplate MICROLON® high binding (Greiner Bio-One, Essen, Germany) and analysed as above-mentioned. The concentration (μg/ml) of AMPs present in the fermentation supernatants of the S. cerevisiae strains above-mentioned was calculated according to the linear regression equation. All samples were analysed in triplicate.

Results

Sensitivity of yeasts to saccharomycin and selection of the best strain for cloning the partial genes TDH1 and TDH2/3

In order to select the most adequate host for cloning the genes encoding the GAPDH-derived AMPs, we first tested the sensitivity of S. cerevisiae CCMI 885, S. cerevisiae PYCC 5484, P. pastoris GS115 and D. bruxellensis ISA 2211 to saccharomycin. The wine strain S. cerevisiae CCMI 885 was chosen since it produces high amounts of the GAPDH-derived AMPs (Branco et al. 2017a). The wine strain S. cerevisiae PYCC 5484 was chosen because it contains auxotrophic marks, and thus has been used in our lab for genetic manipulation studies. As for P. pastoris GS115, it is a commonly used strain for high expression levels of recombinant proteins. D. bruxellensis ISA 2211 sensitivity to saccharomycin was evaluated for comparative purposes.

Sensitivity results (Table 2) revealed that S. cerevisiae PYCC 5484 is the most resistant strain to these AMPs, with no growth inhibition observed as compared to the control assay. All the other yeast strains showed growth inhibition by saccharomycin although at different levels (Table 2). Given these results, S. cerevisiae PYCC 5484 was selected to be the host strain for heterologous expression of the partial gene sequences TDH1 (925–963) (codifying for the AMP1) and TDH2/3 (925–963) (codifying for the AMP2/3).

Overproduction of the GAPDH-derived AMPs by the modified S. cerevisiae strains during alcoholic fermentations

In order to check the success of the recombinant approach, single-culture alcoholic fermentations were performed with the S. cerevisiae strain K1 (empty plasmid) and the modified S. cerevisiae strains pTDH1 and pTDH2/3. The cell viability (CFU/ml) profiles during those fermentations are shown in Fig. 1, showing that the modified strains S. cerevisiae pTDH1 and S. cerevisiae pTDH2/3 exhibited similar growth rates and profiles than the non-modified S. cerevisiae strain K1. The relative expression levels of the partial genes TDH1 (925–963) and TDH2/3(925–963) inserted in the modified S. cerevisiae strains pTDH1 and pTDH2/3 were evaluated by RT-q PCR and the respective AMPs production was determined by indirect ELISA.

Evaluation by RT-qPCR of the relative expression levels of the partial genes TDH1 and TDH2/3 in the modified S. cerevisiae strains

The expression levels of the nucleotide sequences TDH1 and TDH2/3 inserted in the plasmid p416 TEF of the modified S. cerevisiae strains were normalised with the expression levels of the corresponding genomic sequences (Fig. 2). Both modified S. cerevisiae strains (i.e. pTDH1 and pTDH2/3) expressed higher levels of the partial TDH1 (1.5 fold at 12 h) and partial TDH2/3 (0.8 fold at 12 h) sequences, relatively to the respective genomic expression levels (Fig. 2). As expected, the amplification cycle threshold (Ct) of both plasmidic partial sequences (i.e. TDH1 and TDH2/3) did not change significantly along the fermentation (data not shown). Conversely, the relative expression of the corresponding genomic sequences TDH1 and TDH2/3 varied along the fermentation (data not shown). Consequently, it is not surprising that at 24 h, when the TDH1 gene starts to be expressed (i.e. at the beginning of the stationary growth phase), the relative expression level of the plasmidic partial sequence TDH1 in the modified strain pTDH1 was lower than the relative expression level at 12 h (Fig. 2), when the genomic TDH1 gene is not expressed (Boucherie 1995). As for the partial TDH2/3 sequence, relative expression levels increased at the end of the fermentation (i.e. at 192 h) (Fig. 2), reflecting the decrease in genomic expression of TDH2/3. Our results agree well with those reported by Varela et al. (2005) who found that, under winemaking conditions, S. cerevisiae expressed lower levels of TDH1 during the exponential growth phase than during the stationary growth phase, while the opposite occurred for the TDH2/3 expression levels.

Relative expression levels of the nucleotide partial sequences TDH1 (925–963) and TDH2/3 (925–963) in the modified S. cerevisiae strains pTDH1 (dark grey bars) and pTDH2/3 (light grey bars) during single-culture fermentations. The expression levels of the partial sequences TDH1 and TDH2/3 in the modified strains was normalised against the respective genomic partial sequences TDH1 and TDH2/3. Values represented are means ± SD (error bars) of the log2 expression values of two independent biological experiments analysed in triplicate by RT-qPCR. The cut-off value was set to 1.5

Determination by indirect ELISA of the AMPs production levels in the modified S. cerevisiae strains

The total amount (both genomic and plasmidic) of the GAPDH-derived AMPs excreted by the modified S. cerevisiae strains pTDH1 and pTDH2/3 during single-culture alcoholic fermentations was evaluated by indirect ELISA and normalised with the AMPs amount excreted by the non-modified strain S. cerevisiae K1 (empty plasmid). Results (Fig. 3) show that there was an increase in the total amount of the GAPDH-derived AMPs excreted by each of the modified S. cerevisiae strains relatively to the reference strain K1. At 12 h, strain pTDH1 produced 44% more AMPs than strain K1, and strain pTDH2/3 17% more (Fig. 3), in agreement with the higher expression levels observed by RT-qPCR. At the beginning of the stationary growth phase (24–48 h), both S. cerevisiae modified strains (i.e. pTDH1 and pTDH2/3) reached the maximum overproduction of AMPs. Strain pTDH1 produced 63% more AMPs than strain K1 at 24 h and 65% more at 48 h, while strain pTDH2/3 produced 26% more AMPs than strain K1 at 24–48 h (Fig. 3).

Relative levels (%) of the GAPDH-derived AMPs secreted by the modified S. cerevisiae strains pTDH1 (dark grey bars) and pTDH2/3 (light grey bars) in respect to those secreted by the non-modified S. cerevisiae reference strain K1. Values represented are means ± SD (error bars) of two independent biological assays analysed in triplicate by indirect ELISA

Biocontrol of D. bruxellensis in alcoholic fermentations by S. cerevisiae strains (non-modified strain K1 and modified strains pTDH1 and pTDH2)

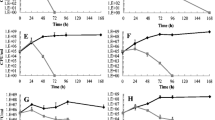

The biocontrol potential of S. cerevisiae strains against D. bruxellensis was evaluated performing mixed-culture alcoholic fermentations with the non-modified strain K1 (containing the empty vector p416 TEF) (Fig. 4b, b’) and the modified strains pTDH1 (Fig. 4c, c’) and pTDH2/3 (Fig. 4d, d’), respectively. Alcoholic fermentations were also performed with D. bruxellensis in single-culture and used as negative control of the antagonistic effect exerted by the S. cerevisiae strains (Fig. 4a, a’). The mixed-culture fermentations were performed with different initial cell density ratios of S. cerevisiae/D. bruxellensis 20:1 of S. cerevisiae (105 cells/ml) for D. bruxellensis (5 × 103 cells/ml) (Fig. 4b–d) and 1:1 for both yeasts (105 cells/ml) (Fig. 4b’–d’).

Cell viability profiles of D. bruxellensis (black diamonds) and S. cerevisiae (grey circles) during alcoholic fermentations performed with D. bruxellensis in single-culture (a, a’) and in mixed-culture with the S. cerevisiae strains K1 (b, b’), pTDH1 (c, c’) and pTDH2/3 (d, d’), respectively. a–d show fermentations performed at an initial cell density of 5 × 103 cells/ml for D. bruxellensis and 1 × 105 cells/ml for S. cerevisiae, while a’–d’ show fermentations performed at an initial cell density of 1 × 105 cells/ml for both species. Data represented correspond to means ± SD (error bars) of two independent biological assays

In both single-culture fermentations (Fig. 4a, a’), D. bruxellensis reached cell density levels of about 108 CFU/ml in the first 48 h, keeping high cell viability levels until the end of the process. Conversely, in all mixed-culture fermentations, D. bruxellensis grew during the first day but then began to die-off, independently of its initial cell density (Fig. 4b–d and b’–d’). On the contrary, all S. cerevisiae strains (i.e. strains K1, pTDH1 and pTDH2/3) grew up to 107–108 CFU/ml within the first 24–48 h and maintained this cell viability until the end of fermentation, both in the single-culture (Fig. 1 a–c) and mixed-culture fermentations (Fig. 4b–d and b’–d’). Comparing the D. bruxellensis growth profiles in the mixed-culture fermentations performed with S. cerevisiae K1 (at both initial cell density ratios of 20:1 and 1:1) (Fig. 4b, b’) with those performed with the modified strains pTDH1 (Fig. 4c, c’) and pTDH2/3 (Fig. 4d, d’), it is clear that both modified strains exerted a much stronger antagonistic effect against D. bruxellensis than strain K1. Indeed, the cell viability of D. bruxellensis was entirely lost within the first 96 h in the mixed-culture fermentations performed with strain pTDH1 at both initial cell densities (Fig. 4c, c’), while in the mixed-culture fermentations performed with strain pTDH2/3 at initial cell densities of 1 × 105 CFU/ml (Fig. 4d) and 5 × 103 CFU/ml (Fig. 4d’), D. bruxellensis viability was lost within 144 and 192 h, respectively. In contrast, in the mixed-culture fermentations performed with S. cerevisiae K1, D. bruxellensis viability was never completely lost during 192 h, even when the initial cell density of D. bruxellensis was lower than the initial cell density of S. cerevisiae, remaining at approximately 102–103 CFU/ml in both cases (Fig. 4b, b’). These results demonstrate that the modified S. cerevisiae strains exerted a significantly stronger antagonist effect than the non-modified strain K1. Besides, comparing the effect of initial cell density ratios (20:1 and 1:1) on the viability of D. bruxellensis (Fig. 4b–d compared with b’–d’), one can see that it is negligible vis-à-vis the effect induced by overproduction of AMPs by the modified S. cerevisiae strains (Fig. 4b, b’ compared with c, c’ and d, d’). In the present work, we did not use K1 strains with knockouts in the TDH1 and TDH2/3 genes to confirm if deletion of those genomic genes would prevent the growth inhibition of D. bruxellensis induced by the overexpressing strains TDH1 and TDH2/3. However, in a previous work (Branco et al. 2014), we confirmed that mutants of the S. cerevisiae strain BY4741 deleted in each of the THD1–3 genes, significantly reduced the antimicrobial effect against H. guilliermondii by comparison with that induced by the non-deleted strain (i.e. BY4741). Thus, we are positive that the TDH1-3 genes are responsible for the growth inhibition of D. bruxellensis.

Discussion

Saccharomycin is a natural biocide composed of GAPDH-derived AMPs, which was isolated from S. cerevisiae fermentation supernatants and is active against several wine-related non-Saccharomyces yeasts and bacteria (Albergaria et al. 2010; Branco et al. 2014, 2017a). This natural biocide inhibits the growth of different D. bruxellensis strains, although at different concentrations (Albergaria et al. 2013). However, the GAPDH-derived AMPs levels naturally secreted by S. cerevisiae strains during alcoholic fermentation are not sufficient to induce the total death of D. bruxellensis. Indeed, the minimal inhibitory concentration (MIC) of saccharomycin against D. bruxellensis strains ranges from 1000 to 2000 μg/ml, which is approximately 10-fold the levels found in S. cerevisiae fermentation supernatants (Branco et al. 2017a). Thus, the aim of the present work was to construct genetically modified S. cerevisiae strains to overproduce the GAPDH-derived AMPs that compose the natural biocide.

The recombinant approach consisted in cloning the plasmid vector p416 TEF in the auxotrophic S. cerevisiae strain PYCC 5484, without insertion (strain K1) and with the insertion of the partial gene sequences TDH1 (925–963) and TDH2/3 (925–963) that codify for the AMP1 and AMP2/3, respectively. Results showed that both modified S. cerevisiae strains (i.e. pTDH1 and pTHD2/3) expressed higher levels of the partial sequences TDH1 and TDH2/3, comparatively with the respective genomic partial sequences (Fig. 2), which means that the plasmidic partial sequences were correctly expressed. In addition, the modified strains were also able to excrete higher amounts of the respective GAPDH-derived AMPs (i.e. AMP1 and AMP2/3) by comparison with the non-modified strain K1 (Fig. 3). These results not only confirm the success of the recombinant approach but also demonstrate that the GAPDH-derived AMPs expressed by the plasmidic vector are excreted to the extracellular medium. Although we do not know how these peptides are transported outside cells, the presence of secretion-signal less-proteins, such as GAPDH, in the cell wall and extracellular media of yeast is now firmly confirmed (Branco et al. 2017b; Delgado et al. 2001; Nombela et al. 2006).

The modified S. cerevisiae strains exerted a significantly higher antagonistic effect on D. bruxellensis than the non-modified strain K1 during the mixed-culture alcoholic fermentations (Fig. 4c, c’ and d, d’ compared with b, b’). More importantly, the modified S. cerevisiae strains induced the total death of D. bruxellensis during the mixed-culture fermentations, conversely to strain K1 (Fig. 4b, b’), independently of its initial cell density ratios (Fig. 4c, c’ and d, d’). Thus, one can conclude that production of higher amounts of the AMPs was the key factor for total death of D. bruxellensis. In addition, strain pTDH1 exhibited a relatively higher antagonistic effect than the strain pTDH2/3 (Fig. 4c, c’ compared with d, d’), which agrees with our previous finding showing that the AMP1 exerts a stronger antimicrobial effect than the AMP2/3 (Branco et al. 2017a).

The ability of the modified S. cerevisiae strains to fully eliminate big populations (> 106 cells/ml) of D. bruxellensis from fermenting broth (Fig. 4c’, d’) is an important feature for biocontrol of this contaminant both in fuel-ethanol and wine fermentations. In fuel-ethanol fermentations, D. bruxellensis often proliferates up to 107–108 cells/ml (Souza Liberal et al. 2007). In the case of wine, D. bruxellensis is only regarded as spoilage agent when its population is big enough to produce 4-ethylphenol at levels higher than 620 μg/l, which is the minimal level perceived as negative in red wines (Loureiro and Malfeito-Ferreira 2003). In recent years, several killer toxins (e.g. Kwkt, Pikt, PMTK2, CpKT1, CpKT2) secreted by different yeasts (e.g. Kluyveromyces wickerhamii, Pichia anomala, Pichia membranifaciens and Candida pyralidae) have been suggested as biocontrol agents of D. bruxellensis under winemaking conditions (Comitini and Ciani 2011; Comitini et al. 2004; Mehlomakulu et al. 2014, 2017; Santos et al. 2009). However, the efficacy of those killer toxins has been demonstrated mainly for low D. bruxellensis contamination levels (< 104 cells/ml) (Comitini and Ciani 2011; Mehlomakulu et al. 2017).

Conclusively, in the present work, we developed a successful genetic approach to overexpressed GAPDH-derived AMPs codifying genes in S. cerevisiae strains that were able to induce the total death of D. bruxellensis during alcoholic fermentation. Although we tested only one D. bruxellensis strain, previous work from our lab demonstrated that saccharomycin is active against other D. bruxellensis strains and also against lactic acid bacteria (LAB) (Albergaria et al. 2013; Branco et al. 2014, 2017a). The contamination of bioethanol fermentations with LAB and wild yeasts is a significant industrial problem causing production losses ranging from 2 to 22% (Beckner et al. 2011). The present work gives experimental evidence about the possibility of obtaining saccharomycin-overproducing S. cerevisiae strains that could be directly applied to bioethanol fermentations as starter cultures and, simultaneously, act as biocontrol agents of contaminants. Alternatively, recombinant strains could be used to produce saccharomycin at large-scale, thus obtaining a new biopreservative for use in wine and/or in other food products. This alternative biopreservative might allow reducing the levels of chemical preservatives commonly used in the wine industry, namely of sulphur dioxide, thus preventing economic losses and satisfying consumers health concerns.

References

Albergaria H, Arneborg N (2016) Dominance of Saccharomyces cerevisiae in alcoholic fermentation processes: role of physiological fitness and microbial interactions. Appl Microbiol Biotechnol 100:2035–2046. https://doi.org/10.1007/s00253-015-7255-0

Albergaria H, Branco P, Francisco D, Coutinho R, Monteiro M, Malfeito-Ferreira M, Arneborg N, Almeida MG, Caldeira J (2013) Dominance of Saccharomyces cerevisiae in wine fermentations: secretion of antimicrobial peptides and microbial interactions. In: Gallego JB, Cardinalli G, Casella S, Cocolin L, Neviani E (eds) Proceedings of the 2nd international conference on microbial diversity: microbial interactions in complex ecosystems. Società Italiana di Microbiologia Agraria-Alimentare e Ambientale, Firenze, pp 98–101

Albergaria H, Francisco D, Gori K, Arneborg N, Gírio F (2010) Saccharomyces cerevisiae CCMI 885 secretes peptides that inhibit the growth of some non-Saccharomyces wine-related strains. Appl Microbiol Biotechnol 86:965–972. https://doi.org/10.1007/s00253-009-2409-6

Barros Pita W, Leite FCB, Souza Liberal AT, Simoes DA, Morais MA (2011) The ability to use nitrate confers advantage to Dekkera bruxellensis over S. cerevisiae and can explain its adaptation to industrial fermentation processes. Antonie Van Leeuwenhoek 100:99–107. https://doi.org/10.1007/s10482-011-9568-z

Beckner M, Ivey ML, Phister TG (2011) Microbial contamination of fuel ethanol fermentations. Lett Appl Microbiol 53(4):387–394

Birnboim HC, Doly J (1979) A rapid alkaline extraction procedure for screening recombinant plasmid DNA. Nucleic Acids Res 7:1513–1523. https://doi.org/10.1093/nar/7.6.1513

Boucherie H (1995) Differential synthesis of glyceraldehyde-3-phosphate dehydrogenase polypeptides in stressed yeast cells. FEMS Microbiol Lett 125:127–133. https://doi.org/10.1016/0378-1097(94)00484-9

Branco P, Francisco D, Chambon C, Hébraud M, Arneborg N, Almeida MG, Caldeira J, Albergaria H (2014) Identification of novel GAPDH-derived antimicrobial peptides secreted by Saccharomyces cerevisiae and involved in wine microbial interactions. Appl Microbiol Biotechnol 98:843–853. https://doi.org/10.1007/s00253-013-5411-y

Branco P, Francisco D, Monteiro M, Almeida MG, Caldeira J, Arneborg N, Prista C, Albergaria H (2017a) Antimicrobial properties and death-inducing mechanisms of saccharomycin, a biocide secreted by Saccharomyces cerevisiae. Appl Microbiol Biotechnol 101:159–171. https://doi.org/10.1007/s00253-016-7755-6

Branco P, Kemsawasd V, Santos L, Diniz M, Caldeira J, Almeida MG, Arneborg N, Albergaria H (2017b) Saccharomyces cerevisiae accumulates GAPDH-derived peptides on its cell surface that induce death of non-Saccharomyces yeasts by cell-to-cell contact. FEMS Microbiol Ecol 93:fix055. https://doi.org/10.1093/femsec/fix055

Brexó RP, Sant’Ana AS (2018) Impact and significance of microbial contamination during fermentation for bioethanol production. Renew Sustain Energy Rev 73:423–434. https://doi.org/10.1016/j.rser.2017.01.151

Caruso M, Fiore C, Contursi M, Salzano G, Paparella A, Romano P (2002) Formation of biogenic amines as criteria for the selection of wine yeasts. World J Microbiol Biotechnol 18:159–163. https://doi.org/10.1023/A:1014451728868

Comitini F, Ciani M (2011) Kluyveromyces wickerhamii killer toxin: purification and activity towards Brettanomyces/Dekkera yeasts in grape must. FEMS Microbiol Lett 316:77–82. https://doi.org/10.1111/j.1574-6968.2010.02194.x

Comitini F, de Ingeniis J, Pepe L, Mannazzu I, Ciani M (2004) Pichia anomala and Kluyveromyces wickerhamii killer toxins as new tools against Dekkera/Brettanomyces spoilage yeasts. FEMS Microbiol Lett 238:235–240. https://doi.org/10.1016/j.femsle.2004.10.019

Delgado ML, O'Connor JE, Azorín I, Renau-piqueras J, Gil ML, Gozalbo D (2001) The glyceraldehyde-3-phosphate dehydrogenase polypeptides encoded by the genes Saccharomyces cerevisiae TDH1, TDH2 and TDH3 are also cell wall proteins. Microbiol 147:411–417. https://doi.org/10.1099/00221287-147-2-411

Fleet GH (1992) Spoilage yeasts. Crit Rev Biotechnol 12:1–44. https://doi.org/10.3109/07388559209069186

Fugelsang KC (1997) Wine spoilage. In: Fugelsang KC, Edwards CG (eds) Wine microbiology. The Chapman and Hall Enology Library, New York, pp 162–179

Geitz RD, Schiestl RH (1995) Transforming yeast with DNA. Methods Mol Cell Biol 5:255–269

Hanahan D (1983) Studies on transformation of Escherichia coli with plasmids. J Mol Biol 166:557–580

Hancock RE, Sahl HG (2006) Antimicrobial and host-defense peptides as new anti-infective therapeutic strategies. Nat Biotechnol 24:1551–1557. https://doi.org/10.1038/nbt1267

Hnasko R, Lin A, McGarvey JA, Stanker LH (2011) A rapid method to improve protein detection by indirect ELISA. Biochem Biophys Res Commun 410:726–731. https://doi.org/10.1016/j.bbrc.2011.06.005

Li Y (2009) Carrier proteins for fusion expression of antimicrobial peptides in Escherichia coli. Biotechnol Appl Biochem 54:1–9. https://doi.org/10.1042/BA20090087

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2−ΔΔC T method. Methods 25:402–408. https://doi.org/10.1006/meth.2001.1262

Loureiro V, Malfeito-Ferreira M (2003) Spoilage yeasts in the wine industry. Int J Food Microbiol 86:23–50. https://doi.org/10.1016/S0168-1605(03)00246-0

Mehlomakulu NN, Prior KJ, Setati ME, Divol B (2017) Candida pyralidae killer toxin disrupts the cell wall of Brettanomyces bruxellensis in red grape juice. J Appl Microbiol 122:747–758. https://doi.org/10.1111/jam.13383

Mehlomakulu NN, Setati ME, Divol B (2014) Characterization of novel killer toxins secreted by wine-related non-Saccharomyces yeasts and their action on Brettanomyces spp. Int J Food Microbiol 188:83–91. https://doi.org/10.1016/j.ijfoodmicro.2014.07.015

Mumberg D, Müller R, Funk M (1995) Yeast vectors for the controlled expression of heterologous proteins in different genetic backgrounds. Gene 156:119–122. https://doi.org/10.1016/0378-1119(95)00037-7

Nombela C, Gil C, Chaffin WL (2006) Non-conventional protein secretion in yeast. Trends Microbiol 14:15–21. https://doi.org/10.1016/j.tim.2005.11.009

Pérez-Nevado F, Albergaria H, Hogg T, Gírio F (2006) Cellular death of two non-Saccharomyces wine-related yeasts during mixed fermentations with Saccharomyces cerevisiae. Int J Food Microbiol 108:336–345. https://doi.org/10.1016/j.ijfoodmicro.2005.12.012

Pyo SH, Lee JH, Park HB, Cho JS, Kim HR, Han BH, Park YS (2004) Expression and purification of a recombinant buforin derivative from Escherichia coli. Process Biochem 39:1731–1736. https://doi.org/10.1016/j.procbio.2003.07.007

Ribéreau-Gayon P, Dubourdieu D, Donèche B, Lonvaud A (2006) The use of sulfur dioxide in must and wine treatment. In: Ribéreau-Gayon P, Dubourdieu D, Donèche B, Lonvaud A (eds) Handbook of Enology: The Microbiology of Wine and Vinifications. John Wiley and Sons Ltd., Chichester, pp 193–221

Romano P, Suzzi G (1993) Sulfur dioxide and wine microorganisms. In: Fleet GH (ed) Wine microbiology and biotechnology. Harwood Academic Publishers, Chur, pp 373–393

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual (2th edn). Cold Spring Harbor Laboratory Press, New York

Santos A, Mauro MS, Bravo E, Marquina D (2009) PMKT2, a new killer toxin from Pichia membranifaciens, and its promising biotechnological properties for control of the spoilage yeast Brettanomyces bruxellensis. Microbiology 155:624–634. https://doi.org/10.1099/mic.0.023663-0

Souza Liberal AT, Basilio ACM, Resende AD, Brasileiro BTV, da Silva EA, de Morais JOF, Simoes DA, de Morais MA (2007) Identification of Dekkera bruxellensis as a major contaminant yeast in continuous fuel-ethanol fermentation. J Appl Microbiol 102:538–547. https://doi.org/10.1111/j.1365-2672.2006.03082.x

Tillotson BJ, Cho YC, Shusta EV (2013) Cells and cell lysates: a direct approach for engineering antibodies against membrane proteins using yeast surface display. Methods 60:27–37. https://doi.org/10.1016/j.ymeth.2012.03.010

Varela CJ, Cárdenas J, Melo F, Agosin E (2005) Quantitative analysis of wine yeast gene expression profiles under winemaking conditions. Yeast 22:369–383. https://doi.org/10.1002/yea.1217

Xu XX, Jin FL, Yu XQ, Ji SX, Wang J, Cheng HX, Wang C, Zhang CWQ (2007) Expression and purification of a recombinant antibacterial peptide, cecropin, from Escherichia coli. Protein Expr Purif 53:293–301. https://doi.org/10.1016/j.pep.2006.12.020

Acknowledgements

The authors thank Fundação para a Ciência e Tecnologia for financial support of this work through the project PTDC/BII-BIO/31761/2017 and also through the Research Units “Linking Landscape, Environment, Agriculture and Food” (LEAF) and “Unidade de Ciências Biomoleculares Aplicadas” (UCIBIO). P. Branco was the recipient of a PhD fellowship (SFRH/ BD/ 89673/ 2012) funded by FCT, Portugal.

Funding

The present work was financed by FEDER funds through POFC-COMPETE in the scope of project FCOMP-01-0124-FEDER-014055 and by national funds through Fundação para a Ciência e Tecnologia (FCT) in the scope of project PTDC/BII-BIO/31761/2017 and also through the research units LEAF (UID/AGR/04129/2013) and UCIBIO (UID/Multi/04378/2013). P. Branco received a PhD fellowship (SFRH/ BD/ 89673/ 2012) funded by FCT, Portugal.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Branco, P., Sabir, F., Diniz, M. et al. Biocontrol of Brettanomyces/Dekkera bruxellensis in alcoholic fermentations using saccharomycin-overproducing Saccharomyces cerevisiae strains. Appl Microbiol Biotechnol 103, 3073–3083 (2019). https://doi.org/10.1007/s00253-019-09657-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-019-09657-7