Abstract

Bacterial cellulose is an attractive biopolymer for a number of applications including food, biomedical, cosmetics, and engineering fields. In addition to renewability and biodegradability, its unique structure and properties such as chemical purity, nanoscale fibrous 3D network, high water-holding capacity, high degree of polymerization, high crystallinity index, light transparency, biocompatibility, and mechanical features offer several advantages when it is used as native polymer or in composite materials. Structure and properties play a functional role in both the biofilm life cycle and biotechnological applications. Among all the cellulose-producing bacteria, acetic acid bacteria of the Komagataeibacter xylinus species play the most important role because they are considered the highest producers. Bacterial cellulose from acetic acid bacteria is widely investigated as native and modified biopolymer in functionalized materials, as well as in terms of differences arising from the static or submerged production system. In this paper, the huge amount of knowledge on basic and applied aspects of bacterial cellulose is reviewed to the aim to provide a comprehensive viewpoint on the intriguing interplay between the biological machinery of synthesis, the native structure, and the factors determining its nanostructure and applications. Since in acetic acid bacteria biofilm and cellulose production are two main phenotypes with industrial impact, new insights into biofilm production are provided.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

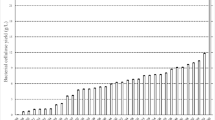

Bacterial cellulose (BC) production has been reported for a variety of bacteria species, including Rhizobium leguminosarum, Burkholderia spp., Pseudomonas putida, Dickeya dadantii, Erwinia chrysanthemi, Agrobacterium tumefaciens, Escherichia coli, and Salmonella enterica species (Chawla et al. 2009; Jahn et al. 2011). Within acetic acid bacteria (AAB), different genera have been reported to be cellulose producers, such as Gluconacetobacter, Acetobacter, and Komagataeibacter (Gullo et al. 2012; Valera et al. 2014). Komagataeibacter xylinus is considered a microbial model in BC production due to its ability to utilize a variety of sugars and the large amount of BC produced in liquid cultures (Table 1). The structure of BC produced by living cells is intimately linked to its synthesis, and the organization and arrangement of cellulose-synthesizing sites on the cell membrane are crucial for the parallel assembly of glucan chains (Brown 1996).

BC is the main active component of the biofilm produced by AAB, which are well known as biofilm producer organisms (Gullo and Giudici 2008). Biofilm production is linked to signaling molecules that control also the synthesis of BC and its detachment in response to environmental factors (Davies et al. 1998). In AAB, biofilm phenotype was first investigated by Louis Pasteur who conducted a systematic study on the “mother of vinegar” showing that it was a mass of living microorganisms causing acetic acid fermentation (Pasteur 1864); the organism was described as Mycoderma aceti and biofilm formation was recognized as synonymous of acetic acid fermentation in wine.

In the era in which the nanomaterial research evolves rapidly, complex structural features, biocompatibility, mechanical, and physicochemical properties of BC are considered of main interest.

Moreover, new biotechnological studies highlight differences in terms of cellulose synthase (CS) complex structural organization, operons, and gene content among BC producers. For instance, these differences can lead to the formation of natural chemical modified cellulose, such as phosphoethanolamine cellulose, as recently discovered (Thongsomboon et al. 2018). These evidences can bring new opportunities to obtain modified cellulosic materials suitable for conventional and innovative applications.

A number of authoritative papers, covering characteristics and potential applications of both native and functionalized BC, have been published. However, as known, researches on the technological transfer are underestimated, in particular, those concerning the biological machinery of the CS complex, the efficient production of BC, and the tailored functionalities for the intended use.

In this mini-review, the BC produced by AAB is evaluated considering the structure, the molecular components of CS, and the biofilm formation. This study contributes to a more efficient exploitation of the state of the art, linking the scientific knowledge to the production of BC for specific biotechnological uses.

Interplay between native structure of bacterial cellulose and properties

Irrespective of the natural source, the common primary structure of the BC consists of long-chain (1-4)-linked ß-d-glucan chains developing from nano- to macroscopic scale in a 3D network, reaching a degree of polymerization up to 20,000 (Habibi et al. 2010). Such linkages give an extended secondary structure with a specific ribbon-like conformation. The tertiary structure is the result of intermolecular hydrogen bonds and van der Waals forces: all ß-1,4-d-glucan chains rings adopt a 4C1 chair conformation, stabilizing the entire structure through an intramolecular hydrogen bond network by hydroxyls and ring oxygen among glucose residues. Each repeating unit has a directional chemical asymmetry with respect to its molecular axis (a hemiacetal unit and hydroxyl group). The molecular directionality underpins the parallel-up structure of native BC (Koyama et al. 1997).

All BC properties strictly depend on the specific characteristics of the architecture from nano- to macro-scale, which is linked to both intracellular biosynthesis and extracellular self-assembling mechanisms. It is widely accepted that BC is synthesized within the bacterial cell as individual molecules, which undergo spinning in a hierarchical order at the bacterial sites of biosynthesis. BC molecules are aligned on the side of the cell surface before bunching together to form ultra-fine bundles embedding crystalline cellulose, having only a limited number of defects or amorphous domains (Brown 1996, 2004).

According to Brown 1996, each microfibril is extruded in a specific region of the outer membrane, called terminal complex (TC), that consists of three subunits (BC-synthesizing sites) and each subunit contains at least 16 CS catalytic subunits. Each catalytic subunit produces a single ß-1,4-glucan chain; 16 glucan chains from a single BC-synthesizing site assemble to form a protofibril of about 2–20 nm in diameter. The protofibrils combine spontaneously to form ribbon-shaped microfibrils of approx. 80.4 nm in diameter and finally a 3D hierarchical network of bundles. All the BC chains in one microfibril can be elongated virtually limitless by the CS complex, while hierarchical ordering follows very closely polymerization and spinning kinetics of the glucan chains.

Studies focused on BC behavior under diluted hydrolyzing conditions evidenced that the nanopolymers are able to nucleate as spherical or spindle-shaped microdomains, leading the liquid medium into a transition state (tactoid) between isotropic and macroscopic liquid crystalline phases showing chiral-nematic ordering (Habibi et al. 2010).

Native BC from AAB has been shown to have fibers alternating needle-shaped microdomains with one dominant crystal structure, i.e., cellulose I sub-allomorph Iα arranged in parallel configurations (Iguchi et al. 2000).

Very appealing properties of native BC from AAB origin from the polyol nature, the chemical directionality, the crystallinity degree, and the very fine ultrastructure. Moreover, such unique structure lends to a plethora of chemical and physical transformations modulating the hydrophilic/lipophilic balance, the aggregation’s change, and the hierarchical organization. From these events, a rich suite of new materials or platforms for further transformations in which BC is treated as a host of non-native chemical functionalities can be developed. Furthermore, different types of artificially encased nanoparticles, including metals, are highly important in order to design AAB cellulose derivatives with tailored nanostructure and functional properties.

Among the most investigated properties of BC from AAB, there are high water-holding capacity (more than 90%), insolubility in most of the solvents, high polymerization degree (4000–20,000 expressed as hydroglucose units) (Gullo et al. 2017), and high crystallinity degree (80–90%).

Both AAB biofilms and BC derivatives have been investigated for their rheological properties such as the Young’s modulus and yield strength measured in compressive or tensile conditions, as well as storage and loss moduli measured into the time and frequency domains. Such properties mainly depend on the microfibril geometry at nanometric scale and on the degree of crystallinity of BC. Iguchi et al. found that AAB biofilm behaves quite differently from pure hydrogels. The complex of the intra- and intermolecular hydrogen bonds of BC determines the relatively high elastic properties of the biofilm, while its viscous properties are determined by the interstitial voids and channels separating the microcolonies, which contain the liquid phase, mainly constituted by water that acts as structure plasticizer (Iguchi et al. 2000). The authors observed that under tensile stress, AAB biofilm shows “elastic” (instantaneously reversible) behavior only under very small deformations and time domain followed by a “viscoelastic” (time-dependent reversible) and “plastic” (stress-dependent irreversible) behavior. Such complex behavior was attributed to the fact that fibrils reorient their chiral ordering along tensile loading direction reorganizing their position, while fiber-on-fiber frictional slippage could lead to an irreversible process of energy loss. When compressed, the AAB hydrogel releases its water content deforming with high stiffness but without crack formation and propagation; the release of water is the main event causing plastic deformation (Frensemeier et al. 2010). The rheological behavior of BC hydrogel produced by a K. xylinus strain was investigated under in-water uniaxial cycling conditions by Gao et al. They postulated that the formation of entanglements and rearrangements of BC fibers fragments are the main factors causing irreversible deformation under loading, unloading, and reloading regimes (Gao et al. 2015).

Iguchi et al. (2000) investigated BC sheets derived from AAB biofilms after heating-pressure treatment. They recorded very high tensile Young’s modulus of about 16–18 GPa: authors observed that microfibrils become tightly bound by inter-fibrillar hydrogen bonds and align in pile of thin layers with very high density. Both tensile strength and elongation decreased with the pressure applied during film preparation; the formation of microcracks was postulated the most probable cause of the decrease of mechanical toughness of the BC films. Through purification steps, the same authors improved the mechanical toughness of BC sheets reaching 30 GPa for the Young’s modulus and superb acoustic characteristics; they suggested to use them in the manufacture of high-performance acoustic diaphragms. BC films have been also investigated for their fundamental rheological properties under dynamic oscillatory experiments as a function of temperature or relative humidity. The dynamic modulus decreased from 15 to 9 GPa with the increase of temperature, while tanδ, i.e., the ratio between loss and storage moduli, showed two maxima at around 50 and 230 °C that were attributed to desorption of water and BC degradation, respectively (Iguchi et al. 2000). Thermomechanical behavior of BC films produced from K. xylinus (UMCC2756) strain has been investigated by Gullo et al. (2017). Authors found that this strain is able to produce a unique biofilm containing the allomorph Iα as the only crystal form of cellulose and a large amount of freezable water (about 12.9% in weight). The plasticizing effect of the absorbed water resulted in a crossover of the storage modulus across the 0 °C.

Shaw et al. (2004) attempted to provide a rheological standpoint supporting the BC environmental functionality and its ability to maintain the bacterial biofilm in a stable homeostatic growth regime. All bacterial biofilms behave as elastic/viscoelastic/plastic polymeric material, i.e., they show elastic solid-like response to short time scale mechanical stimuli (stress or deformation), structure recovery ability under intermediate time scale stimuli conditions, as well as plastic response under long time scale stimuli. This complex structural behavior might provide a significant clue towards explaining biofilm robustness against different environmental mechanical stresses. The elastic structural elements absorb stress energy through rapid mechanical stimuli. The viscoelastic structural elements absorb stress energy through time-dependent and reversible deformation. Plastic properties relax the structural internal stress through nonreversible steady-state deformation rate requiring very long time to reach the new structural equilibrium. The relaxation time of a bacterial biofilm, i.e., the time taken for deformation to entirely account for initial reversible deformation, was approximately estimated about 18 min for a number of bacteria. A possible survival significance of this characteristic time scale is that it is the shortest period over which a bacterial biofilm can mount a phenotypic response to environmental transient mechanical stimuli (Shaw et al. 2004).

Tuning of biotechnological factors for different biofilm morphologies and cellulose nanostructures

Temperature, hydrodynamic conditions, culture medium composition, and surface structure of the material used for BC deposition can be selectively modulated to produce different biofilm morphologies and a plethora of nanostructures. Under static growth regime, for example, pellicles of several centimeters height are usually produced (Fig. 2a), while spheres could be produced under agitated growth conditions (Fig. 2b). Continuous supply of air and suitable carbon sources is primarily required, but elevated temperatures and extremely low ionic concentrations favor the amorphous formation of BC with respect to the crystalline one.

The use of additives into the growth medium, including carbohydrates, proteins, and isoenzymes, may be considered effective for the construction of a functional fiber-network structure. The role of additives in the culture medium could be linked to their ability to compete for hydrogen bonds with the β-1-4 glucan chains, affecting the self-assembling process of formation of both the secondary and tertiary structure of BC network; for example, high molecular weight polysaccharides and cation starches may be used to produce cellulosic composites (Iwata et al. 1998).

Another way to control the BC structure from nano- to macro-scale is linked to the possibility to finely tune both the viscosity and shear rate of the liquid medium in which AAB grow.

The morphology of the biofilm growing in submerged conditions is markedly different, as a function of the flow regime, i.e., laminar or turbulent (Stoodley et al. 1999). Furthermore, biofilms produced at high shear rates tend to be more isotropic with adhering properties: shear rates apply into the laminar flow in which BC bundles align along with a field of tangential and parallel forces, leading both bulk and surface ordering. Drag forces act opposite to the relative motion of BC bundles with respect to the surrounding fluid, being proportional to the speed for a laminar flow and the squared speed for a turbulent flow. Even though the ultimate cause of a drag is viscous friction, the turbulent drag is independent from fluid viscosity. Therefore, at relatively high shear rates, as cells divide, the drag forces tend to push daughter cells in the downstream direction, allowing cell to grow larger, many of them merging to form a biofilm with porous structure. The bacterial growth can affect the flow regime by switching from “isolated roughness” or “wake interaction flow” to “skimming flow” with the formation of a plethora of microenvironments inside the biofilm experiencing different flow regimes (Nowell and Church 1979).

The opportunity to choose the characteristics of surface at the region of BC deposition opens up a new window to control the cellulose nanostructure formation. In this regard, the use of nematically ordered liquid crystalline BC has been used as molecular-imprinting templates allowing the newly synthesized BC to deposit along precise nanotracks (Kondo 2007).

Cellulose synthase machinery

The BC bioassembly is a very complex and well-structured machinery, reflecting the series of events that led to its synthesis. In Fig. 1, the CS complex, as described in Komagataeibacter members, is depicted. It includes a series of subunits working in a concerted way that synthetize and export the β-glucan chains in the extracellular space. CS uses activated glucose monomers by uridine-diphosphate (UDP-glucose) as precursor and is regulated by bis-(3′,5′)-cyclic-dimeric-guanosine monophosphate (c-di-GMP), a key mediator of the biofilm regulation cycle (Ross et al. 1987).

The catalytic subunit of CS is a β-galactosyltransferase named BC synthase A (BcsA) and belongs to the glycosyltransferase family 2 (GT-2) (Saxena and Brown 1995). It is a membrane integrated protein of eight α-helix transmembranes (TM 1–8). The BcsA C-terminal contains a cytosolic domain named PilZ, responsible for c-di-GMP binding (Ross et al. 1987). The TM 3–8 helixes form a membrane channel across the cytoplasmic membrane, which is utilized for glucan chain translocation in the periplasm during elongation (Morgan et al. 2013). The catalytic subunit is a GT-A domain inserted between the TM-4 and the TM-5 (Lairson et al. 2008). The mechanism of reaction proposed for the addition of monomer of UDP-glucose is a classical SN2-like substitution reaction, in which the C-4 hydroxyl group of the rising glucan chain (acceptor) binds the anomeric C-1 carbon of UDP-glucose (donor). This reaction is facilitated by bivalent metal ions (Mn2+ and Mg2+) (Brown et al. 2012).

BcsA is associated to another subunit of CS complex, called BcsB. BcsB is a periplasmic protein anchored to the cytoplasmic membrane by a C-terminal α-helix, together with a preceding periplasmic helix, tightly interacting with the catalytic BcsA subunit. The dome-shaped protein forms two copies of a repeating unit of a carbohydrate-binding domain (CBD) that is C-terminally fused to an α/β domain resembling a flavodoxin-like domain (Morgan et al. 2013). The CBD is structurally related to carbohydrate-binding modules (Christiansen et al. 2009), which form classical β-strand-rich jelly roll motifs interacting with carbohydrates either via the β-sheet surface or with the edges of the jelly roll (Shoseyov et al. 2006). Based on this architecture of the sub-complex BcsA-BcsB, the role of BcsB seems related only to the translocation of rising glucan chain formed by BcsA (Omadjela et al. 2013). This sub-complex is characterized by similarities in terms of structure and functional mechanisms among BC producing bacteria. In AAB, CS complex includes other two Bcs proteins (BcsC and BcsD). BcsC is a large protein having a C-terminal anchored in the outer membrane and a large N-terminal in the periplasmic region. The C-terminal region, about 300 residues, forms an 18-stranded β-barrel in the outer membrane that allows the exportation of the glucan chain in the extracellular space. The periplasmic region (N-terminal) includes tetra-tricopeptide-like repeats, consisting of 34-residue tandem repeats that adapt helix-turn-helix tertiary structures and are frequently involved in mediating protein-protein interactions (Keiski et al. 2010). The N-terminal region could interact with BcsB protein, guiding the glucan chain exportation via the C-terminal β-barrel (Du et al. 2016).

The structure and arrangement of the BcsD protein itself indicate a cylinder with the presence of a functional complex unit in the form of an octamer (Hu et al. 2010). The octamer is localized in the periplasm with an orientation parallel to the long axis of the cell. BcsD seems to play an integral role helping the alignment of the linear TCs along the longitudinal axis of the cell (Mehta et al. 2015).

CS complex of AAB contains other accessories proteins named CcpAx, CMCax, and BlgAx that are codified by the same operon of Bcs proteins. These proteins are not fundamental for the BC biosynthesis itself, but they are involved in the correct glucan chains formation. CcpAx is codified only by Komagataeibacter members and is required for the BC synthesis in vivo. The function of CcpAx is unclear: it has been hypothesized that it can be involved in the structural organization of the TC, cooperating with BcsD. In vitro studies showed the interactions between CcpAx and BcsD proteins, demonstrating their possible cooperation (Sunagawa et al. 2013). From these studies, it can be deduced that CcpAx plays a key role in the maintenance of native structure of BC.

CMCax is an endo-β-1,4-glucanase identified for the first time in K. xylinus (Standal et al. 1994). It is a single domain protein of the glycosyl hydrolase family, containing a signal sequence in the N-terminal region for its secretion in the periplasmic space (Römling 2002). CMCax is formed by 11 α-helixes and seven β-strands organized in a six-barrel motif (Yasutake et al. 2006). The localization of this protein is not well identified but it was supposed to be in the neighborhood of extrusion pore of CS. Recent in vitro BC biosynthesis studies revealed that CMCax is able to degrade single glucan chains but not the crystalline polymer (Nakai et al. 2013), suggesting that it may reduce the twisting of microfibrils. BglAx is a β-glucosidase that seems to have also the glucosyltransferase activity (Tajima et al. 2001). Studies on K. hansenii ATCC 23769 highlight that BglAx is not necessary for BC synthesis but the interruption of its gene causes a yield reduction. It was proposed that the concerted action of CMCax and BglAx is necessary for maintaining the structural characteristics of cellulose Iα (Deng et al. 2013).

Many differences occur in BC-producing bacteria in terms of proteins content and complex organization. Recently, it was demonstrated that E. coli and S. enterica are able to produce naturally modified cellulose (phosphoethanolamine cellulose), which contributes to the extracellular matrix assembly and to biofilm structure (Thongsomboon et al. 2018). In these bacteria, BcsE, BcsF, and BcsG proteins were found.

BcsG is an integrated membrane protein that interacts with periplasmic portion of BcsF protein and seems to be necessary for BC modification. BcsF protein represents the link between BcsG and BcsE, a soluble protein able to bind c-di-GMP, providing a regulation mechanism for BcsG activity (Thongsomboon et al. 2018).

Genetic structure of cellulose synthase

Because of differences in gene order and gene content among BC-producing bacteria, the bcs operons were classified into three major types (Römling and Galperin 2015). The first type of operon is peculiar of K. xylinus and the presence of bcsD gene is the distinguishing feature to classify this operon in subtypes (referred to bcsI, bcsII, and bcsIII). The second type (E. coli-like type) includes two additional genes, bcsZ and bcsQ, and the absence of bcsD. This locus contains also a divergent operon containing genes bcsE, bcsF, and bcsG, codifying proteins involved in natural BC modification (Thongsomboon et al. 2018). The third type of operon, well described in A. tumefaciens, is organized in two convergent operons, celABCG and celDE, in which the first three genes are orthologs of bcsA, bcsB, and bcsZ, whereas the other are specific for this operon type. This type of operon usually includes also another gene, named bcsK, that codifies for a BcsC-like tetra-tricopeptide containing protein (Römling and Galperin 2015).

Within AAB of Komagataeibacter genus, four genomes were whole sequenced and analyzed with respect to CS organization and functions: K. xylinus E25, K. nataicola RZS01, K. medellinensis NBRC 3288, and K. hansenii AY201 (Table 2). In addition, also other six Komagataeibacter strains were sequenced but the genome analysis is still incomplete (https://www.ncbi.nlm.nih.gov/).

The genes codifying CS subunits, first described in K. xylinus, are organized in an operon named bcsABCD (referred also as acsABCD). Some AAB contain multiple operons copies involved in BC production as those found in Komagataeibacter, namely bcsI, bcsII, and in some cases also a third copy referred as bcsIII (Table 2). In the bcsABCD operon, the first discovered four genes were those encoding for BcsA, BcsB, BcsC, and BcsD subunits (Wong et al. 1990). bcsA and bcsB codifying for the catalytic subunit were found to be fused, but any polypeptide of the same size was found, suggesting that post-translational processing generated the two subunits (Chen and Brown 1996). Although in vitro studies showed that only bcsA and bcsB are essential for BC synthesis, all the enzymes codified by the genes of bcsI are required to obtain BC with the final structure in vivo, since bcsC and bcsD are involved in the exportation and/or packing of the glucan chains at the cell surface (Römling 2002; Wong et al. 1990). The operon bcsI includes also accessories enzymes operating in concert with the CS, such as an endo-β-1,4-glucanase (CMCax) and cellulose complementing factor (CcpAx), which are in the upstream region of the operon (Standal et al. 1994; Sunagawa et al. 2013). Studies in which the ccpax gene was interrupted demonstrated low BC crystallinity (Nakai et al. 2002). Disruption of cmcax gene drastically reduced BC yield and caused structure alterations resulting in cellulose II (Nakai et al. 2013). An overexpression of cmcax gene instead led to high enzymatic activity (Kawano et al. 2002; Morgan et al. 2013).

Flanked to bcsA, bcsB, bcsC, and bcsD genes, in downstream region, the gene bglAx encoding BglAx was found (Tonouchi et al. 1995). In most strains belonging to Komagataeibacter genus, the second bcs operon (bcsII) does not display the full enzymatic set of the CS complex. Indeed, it contains the bcsAB2 gene or only bcsA2 and bcsC2. In some species of Komagataeibacter, bcsAB2 or bcsA2 and bcsC genes are interrupted by the presence of other two genes (bcsX and bcsY) (Table 2). About BcsY protein, sequence comparisons show that it could play a role in the BC modification, such as in the acetyl cellulose production via transacylase (Umeda et al. 1999).

In Komagataeibacter genus, only K. medellinensis NBRC 3288 was reported to be no BC producer. The recent genome sequencing of this strain highlighted two mutations localized in both operons. In the bcsABCD, a disrupted bcsB1 gene (BcsB1-N; locus_tag: GLX_25040-GLX_25100) was found, due to a frameshift mutation, whereas in bcsII, the bcsC2 gene seems to be corrupted by an insertion sequence (BcsC-N; locus_tag: GLX_27490-GLX_27560) (Matsutani et al. 2015).

Biofilm formation in acetic acid bacteria

Biofilm can be described as a social consortium of cells embedded in an extracellular matrix that undergo developmental programs resulting in a predictable “life cycle” (McDougald et al. 2012). The need for bacteria to switch from planktonic to biofilm form is a response to their chemical physical environment. The extracellular matrix of a biofilm provides protection to bacteria cells from harsh conditions. It acts as a support avoiding cell washout across liquid flow by the attachment to a surface; it protects cells against antimicrobial compounds by limiting the diffusion of these compounds and increases cell density, enhancing factors for antibiotic resistance, as in the case of eDNA (plasmids) and DNA exchange by conjugation. The extracellular matrix of biofilm produced by bacteria is composed of proteins, exopolysaccharides (EPS), and extracellular DNA. Poly-N-acetylglucosamine (PAG) and BC are main components of the EPS fraction and in particular the BC that was first identified as a biofilm matrix component in gram negative bacteria in 2001 (Zogaj et al. 2001; Rabin et al. 2015). Formation of biofilm is a regulating mechanism and some bacteria use signaling molecules to modulate it. In gram negative bacteria, acyl-homoserine lactones (AHLs) mediate quorum sensing (QS) system. In AAB, QS system is not well studied; however, some studies revealed that they use QS to modulate a number of functions. Iida et al. described the correlation between QS and oxidative fermentation in K. intermedius (NCI1051). K. intermedius produces three different AHLs, N-decanoyl-l-homoserine lactone, N-dodecanoyl-l-homoserine lactone, and an N-dodecanoyl-l-homoserine lactone. The GinI/GinR quorum sensing system found in K. intermedius controls the expression of ginA, which in turn represses oxidative fermentation, including acetic acid and gluconic acid fermentation (Iida et al. 2008). The QS system N-AHL-dependent GinI/GinR detected in K. intermedius is a LuxI/LuxR type system that is homologous to LasI/LasR pathway, well described in Pseudomonas aeruginosa (Passos da Silva et al. 2017). Further studies on wild-type and mutants of K. intermedius strains revealed that GinI/GinR QS system is not involved in BC production. This QS regulation system seems to provide some advantages to the population contrasting toxicity of acetic acid by decreasing the growth rate (Iida et al. 2008). In BC-producing AAB, there are no pieces of evidence about the role of quorum quenching (QQ) mechanisms. Valera et al. found a possible candidate involved in QQ, a protein named GqqA, which affects BC biofilm formation, but the molecular mechanism remains unknown (Valera et al. 2016). Well documented in the signaling system of AAB is the central role of c-di-GMP as second messenger contributing to the regulation of bacteria behaviors. c-di-GMP was described for the first time as an allosteric activator of the CS in K. xylinus (Ross et al. 1987). It regulates also other bacterial processes such as cell motility, transition between sessile and planktonic lifestyle, cell division, and pathogenesis (McNamara et al. 2015). It is synthesized from two GTP molecules by diguanylate cyclase (DGC) characterized by GGDEF domain and degraded by phosphodiesterase (PDE) to 5′-phosphoguanylyl-(3′-5′)-guanosine (pGpG) or GMP. Then, the intracellular concentration of c-di-GMP is regulated by the activity of DGC and PDE. Another level of regulation is provided by specific effector binding proteins, which vary among bacteria (Ross et al. 1991). The c-di-GMP levels can be influenced also by environmental factors such as oxygen availability. In K. xylinus, the synthesis or hydrolysis of c-di-GMP is dependent of PAS domain DGC protein, a well-characterized domain sensitive to oxygen levels (Chang et al. 2001; Qi et al. 2009).

Using vinegar as a model for biofilm and cellulose formation in acetic acid bacteria

In liquid surface, as it has been experienced for long time during the alcohol-to-acetic acid conversion required for vinegar production, the growth of AAB is observed mainly as a biofilm. The biofilm is formed step-by-step and matures close-to-surface, with different shape and thickness. In regular vinegar fermentations, biofilm looks like a very thin layer that persists during fermentation (Fig. 2c). Disturbing the liquid, biofilm is destroyed, and it is still formed after some days. However, since vinegar production is mainly conducted without selected microbial cultures, anomalous fermentations are often observed (Giudici et al. 2009). The most frequent irregular fermentation is due to the formation of a thick EPS layer formed by BC, which is undesired in vinegar production (Gullo and Giudici 2008).

Different morphologies of biofilm and bacterial cellulose in AAB: BC produced by K. xylinus UMCC2756 as multilayer biofilm under static growth regime (a); BC produced by K. xylinus UMCC2756 as spheres under agitated growth regime (b); thin biofilm produced during wine vinegar fermentation (c); filamentous biofilm growth by a high BC producing isolate under static growth regime (d)

Moreover, a broad spectrum of environmental factors including the concentration of oxygen, nutrients or toxic compounds, as well as mechanical stresses can trigger both the biofilm formation and transition to planktonic cells. Macroscopic changes in shape and texture have been well documented during vinegar processes under different operative conditions (Gullo et al. 2016). The vinegars’ AAB biofilm must be considered as a complex hydrogel of living and death AAB cells embedded in the extracellular matrix (Fig. 3). The predictable behavior of AAB biofilm in vinegar production is intended, at least, for the following three aims: (i) to protect the living cells towards the acetic acid accumulation, (ii) to maintain the optimum osmotic and carbon source levels required for growth and survival, and (iii) to be responsive to external mechanical stresses. From one hand, the 3D network of BC bundles is able to compartmentalize the mother liquor within microenvironments that surrounds the living cells, acting as a selective physical barrier controlling diffusion-limited solute transfer between the biofilm and liquid medium bulk.

The structure of biofilm in AAB. Upper side centimeter (cm): BC biofilm formation occurs at the down surface due to solutes availability and oxygen diffusion across the matrix. In the upper surface, cell growth is limited due to evaporation and low solutes availability; lower side micron (μm): BC biofilm formation in the early phase, with oxygen and solute availability. Biofilm filamentous AAB growth is displayed

It is generally reported that AAB-forming biofilm grows at the air surface of liquids. However, as long-time experience at laboratory scale, the site of biofilm formation is not the free surface of the liquid medium, but the submerged layer close to the free surface, since the interstitial liquid voids and channels separating microcolonies are the preferential site for BC production. The upper surface of the biofilm/BC layer, as produced under static growth conditions, undergoes high rate of evaporation reaching shortly lower values of water activity, limiting cell growth.

Gullo et al. 2017 recently studied the optimal conditions to produce high BC yield by K. xylinus UMCC2756. Under static regime, a well-structured and thick pellicle containing only Iα cellulose was obtained. The biofilm has developed through several phases including the transition from single cells initially dispersed in the liquid bulk to mature biofilm (Gullo et al. 2017).

Macroscopic observation of the layer formed by pure culture of K. xylinus clearly shows that the submerged layer is filamentous (Fig. 2d), whereas microscopic examination of such biofilm shows that the number of living cells is higher with respect to the upper surface. All these findings are in accordance with the theory underpinning the dynamic of solute gradient (oxygen, water, and nutrients).

The oxygen tension in gaseous phase of 10 and 15% with respect to the atmospheric conditions plays a lead to an increase of both BC production and yield (Watanabe and Yamanaka 1995). However, irrespectively of the effective oxygen concentration within the biofilm, the major hurdle for living cells to grow onto the upper layer is the poor nutrient availability due to the limited mass transfer from the liquid bulk through the BC matrix, especially of high molecular weight solutes such as sugars. Due to both the low solute permeability and water availability, the optimal growth conditions increase from the biofilm surface towards the filamentous and submerged layers of the biofilm themselves (Fig. 3). All these evidences are also corroborated by several studies regarding the effect of surface dehydration on the isolation and maintenance of living AAB cells in culture media. Indeed, cultivation of slow-growing AAB was improved by developing and optimizing double agar media and semisolid media in which AAB cells grow preferentially within the space at higher relative humidity. Instead, it has been proven that the growth of certain biofilm forming AAB in single agar media is strongly inhibited especially when the incubation is conducted without relative humidity control (Entani et al. 1985; Kittelmann et al. 1989; Sievers et al. 1992; Mamlouk and Gullo 2013).

Acetic acid bacteria and main process issues

From literature, it emerges that, to efficiently switch from a laboratory to an industrial strain, several bottlenecks need to be overcame. The availability of high-producing strains, the carbon substrates utilized as starter material, and the optimization of culture methods seem to be the main requirements for an efficient BC synthesis (Gullo et al. 2017). Several studies focused on the characterization of robust AAB strains, which display suitable technological traits for BC production; however, most of them are well studied at laboratory scale but never tested at industrial scale.

However, the advance in genetic engineering and biotechnology field during the last decades provided different mutant strains able to produce high BC yield (Shigematsu et al. 2005). One of the targets of knockdown was pyrroloquinoline quinone cofactor-dependent glucose dehydrogenase (GDH-PQQ), the enzyme responsible for gluconic acid production from glucose (Cañete-Rodríguez et al. 2016). Silencing GDH-PQQ, most of glucose was available for BC production. One of the most recent work displays the knockout of GDH-PQQ in K. xylinus BCRC12334, which produced both a higher BC yield (about 40 and 230% compared to the wild-type strain) and a reduction of gluconic acid formation (Kuo et al. 2015).

From Table 1, it can be deduced that many efforts in BC production, aimed to optimize culture conditions, have been done. Different studies covered the best combination of the carbon sources and the production system.

To reduce the cost of BC production, different strategies were tested using low costs and waste products as carbon sources. High BC productivity was obtained using molasses from corn steep liquor (CSL) added with citric acid in K. xylinus BCR5 culture (Table 1). Second hand fruits, which are not marketable, are also considered potential sustainable raw materials for BC production. Currently, however, although the use of low costs feedstocks as carbon sources seems appealing, it needs to be carefully evaluated not only for the produced BC yield but also for the upstream and downstream process steps necessary to remove microbial inhibitors, contaminants, and color.

The most investigated methods to produce BC comprise static and submerged regimes by which uniform smooth gels and spheres can be obtained, respectively (Islam et al. 2017). The need of customized bioreactors for BC production, however, is still an open issue in order to increase BC yield for the intended use.

The industrial era of bacterial cellulose

BC possesses higher surface area than plant cellulose and is a very malleable material. Also, distinct types of artificially encased nanoparticles, including metals, are of huge interest in order to design AAB celluloses with tailored nanostructure and functional properties.

Native BC does not require any purification steps that can cause alterations of its structural and physicochemical properties. From this prerequisite, it is clear that it can be suitable for a numbers of biomedical applications. Most of these are very emerging applications, thanks also to the advances in tissues engineering and in regenerative medicine. BC is used as artificial skin, artificial blood vessels, and hemostatic materials. One of the most important uses of BC in biomedical field is as wound healing scaffolds (Picheth et al. 2017). Many BC-based scaffolds are approved by the Food and Drug Administration (FDA) because of the high purity in terms of low proteins and endotoxic units (Petersen and Gatenholm 2011). During the last years, many brands (such as Biofill®, Gengifill®, Bionext®, and Xcell®) developed BC biodevices that can be used in a wide variety regenerative medicine application. These devices are characterized by different effects, such as pain relief, fast skin regeneration, and reduction of inflammatory response (Rajwadee et al. 2015). Furthermore, BC is also applied in drug delivery approach, in which modified variants of BC are used. Such modifications can enhance BC-based delivery properties. In BC hydrogels combined with carboxymethyl cellulose (CMC) and ibuprofen sodium as drug model, it was shown that CMC influences the swelling and drug release, suggesting that BC-CMC hydrogels could be exploited in controlled drug delivery (Pavaloiu et al. 2014).

Thanks to the stabilizing effect of oil-water emulsion, low toxicity, and ability to hydrate the skin without the need of surfactants, BC is extensively used in cosmetic field for facial mask creams and as a powder in facial scrubs in association with other natural materials (as olive oil, Vitamin C, Aloe vera extract, and powdered glutinous rice).

An emerging BC application in cosmetic is the production of contact lenses, due to its transparency, light transmittance, and permeability to liquid and gases. Contact lenses produced from BC can be used also in drug delivery for treatment of the cornea (Ullah et al. 2016).

BC plays a key role also in the food industry. As dietary fiber, BC is labeled as generally recognized as safe (GRAS) by the FDA (Shi et al. 2014). The ability to acquire flavors and colors, makes BC a suitable adjuvant for foods and beverages. Moreover, as a food additive, it is used worldwide for its gelling and thickening properties. The most common BC derivatives used in food are the CMC and hydroxypropyl methylcellulose due to their structure-stabilizing properties. Traditionally, BC occurs in the manufacturing of “nata de coco” and Kombucha tea. Nata de coco” is a Philippine dessert produced from fermented coconut water. The obtained BC is chopped into minute sections and immersed in syrup of sugar (Iguchi et al. 2000), whereas Kombucha tea is a beverage obtained from sugared tea in which an association of yeasts and AAB conducts the fermentation (Mamlouk and Gullo 2013). Monascus-BC complex, which combines limited calories and high fiber content with those of Monascus fungi (healthy nutrients), was proposed as meat or seafood replacement for vegetarian diet (Ng and Shyu 2004). Also, BC is used in low cholesterol diet, thanks to serum lipids and cholesterol-lowering effect (Chau et al. 2008). When compared with other dietary fibers, BC have several main advantages: (i) separability from biofilm without chemical treatments; (ii) biosynthesis and growth conditions can be modulated tailoring structure and functionalities directly in situ and in process; and (iii) complete indigestibility in the human intestinal tract (Pokalwar et al. 2010). Moreover, BC with its hydrogel-like texture could be a new material for salads and low-calorie desserts. The gel by itself is too hard to bite, but it becomes edible through processing either with sugar alcohol or with alginate and calcium chloride aiming to immobilize the water of gelatinous BC (Keshk 2014). In the production of high quantity food, the need of new technology, based on the use of enzymes, is required. In the recent decades BC has been evaluated also for its ability to immobilize enzymes, such as laccases. Laccases are enzymes used to improve the organoleptic properties, such as color and flavor of beverages and oils. They can also improve the quality of sauces, concentrates, and soups by the process of deoxygenation (Osma et al. 2010). Modification of BC is also extensively used in food packaging to increase safety and shelf-life. Antimicrobial effect was shown by adding sorbic acid in mono- and multilayer BC against E. coli (K12-MG1655) (Jipa et al. 2012). Finally, application of BC in heavy metal removal such as mercury and arsenic has been proved. Adsorption of mercury resulted fast with no effect on adsorption rate for long time, whereas, for arsenic, fast adsorption at alkaline pH range was observed (Gupta and Diwan 2017).

Conclusion and perspectives

Native and functionalized BC is considered a high appealing biopolymer by the industry. Several considerations derived by scientific literature indicate K. xylinus, among bacteria, as the most studied species for BC production. The BC produced by K. xylinus, like BC produced by other bacteria, has high degree of purity: this characteristic supported a great interest for industrial uses, where purity is a prerequisite. Moreover, K. xylinus, as a model organism for BC production, is well known concerning the molecular machinery of CS complex and it is also considerable for the obtained BC yield in different conditions.

Studies about BC structure highlighted as the supramolecular assembly can be modulated to obtain specific attribute of the BC membranes. This aspect is particularly important to enlarge the applicability in different uses: the advances in the BC synthase machinery regarding the bioassembing modality, as well as genomic and proteomic data, revealed the high potential of these approaches to obtain high performing AAB strains. Observing the biofilm grow modality of AAB, a lot of information on the ideal site and conditions for BC synthesis can be deduced; this information is significant to create conditions to synthesize a high BC yield. However, these aspects are not well known for AAB, especially the factors that determine biofilm/BC synthesis. Therefore, studies to fill the gaps in the knowledge of QS system in AAB can be really advantageous. A huge amount of literature on the evaluation of specific strains cultivated in different media and conditions has been published; it can be deduced that the stability of the production process strictly depends on the carbon source and possible BC activators.

Currently, the use of sustainable sources (low costs and waste feedstocks) is reported as a frontiers goal, but careful considerations should be made. The use of low costs and waste feedstocks need to be analyzed with respect to the process as a whole, estimating all advantages and disadvantages in order to obtain the required yield and a good quality of BC from these sources.

References

Andres-Barrao C, Falquet L, Calderon-Copete SP, Descombes P, Ortega Perez R, Barja F (2011) Genome sequences of the high-acetic acid-resistant bacteria Gluconacetobacter europaeus LMG 18890T and G. europaeus LMG 18494 (reference strains), G. europaeus 5P3, and Gluconacetobacter oboediens 174Bp2 (isolated from vinegar). J Bacteriol 193:2670–2671. https://doi.org/10.1128/JB.00229-11

Bae SO, Shoda M (2005) Production of bacterial cellulose by Acetobacter xylinum BPR2001 using molasses medium in a jar fermentor. Appl Microbiol Biotechnol 67:45–51. https://doi.org/10.1007/s00253-004-1723-2

Brown RM (1996) The biosynthesis of cellulose. J Macromol Sci A 33:1345.1373–1345.1373. https://doi.org/10.1080/10601329608014912

Brown RM (2004) Cellulose structure and biosynthesis: what is in store for the 21st century? J Polym Sci Pol Chem 42:487–495. https://doi.org/10.1002/pola.10877

Brown C, Leijon F, Bulone V (2012) Radiometric and spectrophotometric in vitro assays of glycosyltransferases involved in plant cell wall carbohydrate biosynthesis. Nat Protoc 7:1634–1650. https://doi.org/10.1038/nprot.2012.089

Cañete-Rodríguez AM, Santos-Dueñas IM, Jiménez-Hornero JE, Ehrenreich A, Liebl W, García-García I (2016) Gluconic acid: properties, production methods and applications—an excellent opportunity for agro-industrial by-products and waste bio-valorization. Process Biochem 51:1891–1903. https://doi.org/10.1016/J.PROCBIO.2016.08.028

Cavka A, Guo X, Tang SJ, Winestrand S, Jönsson LJ, Hong F (2013) Production of bacterial cellulose and enzyme from waste fiber sludge. Biotechnol Biofuels 6:25. https://doi.org/10.1186/1754-6834-6-25

Chang AL, Tuckerman JR, Gonzalez G, Mayer R, Weinhouse H, Volman G, Amikam D, Benziman M, Gilles-Gonzalez MA (2001) Phosphodiesterase A1, a regulator of cellulose synthesis in Acetobacter xylinum, is a heme-based sensor. Biochemistry 40:3420–3426. https://doi.org/10.1021/bi0100236

Chau CF, Yang P, Yu CM, Yen GC (2008) Investigation on the lipid and cholesterol-lowering abilities of biocellulose. J Agric Food Chem 56:2291–2295. https://doi.org/10.1021/jf7035802

Chawla PR, Bajaj IB, Survase S, Singhal RS (2009) Microbial cellulose: fermentative production and applications. Food Technol Biotechnol 47:107–124

Chen HP, Brown RM (1996) Immunochemical studies of the cellulose synthase complex in Acetobacter xylinum. Cellulose 3:63–75. https://doi.org/10.1007/BF02228791

Cheng Z, Yang R, Xu Liu X, Liu X, Chen H (2017) Green synthesis of bacterial cellulose via acetic acid pre-hydrolysis liquor of agricultural corn stalk used as carbon source. Bioresour Technol 234:8–14. https://doi.org/10.1016/j.biortech.2017.02.131

Christiansen C, Abou Hachem M, Janeček Š, Viksø-Nielsen A, Blennow A, Svensson B (2009) The carbohydrate-binding module family 20—diversity, structure, and function. FEBS J 276:5006–5029. https://doi.org/10.1111/j.1742-4658.2009.07221.x

Davies DG, Parsek MR, Pearson JP, Iglewski BH, Costerton JW, Greenberg EP (1998) The involvement of cell-to-cell signals in the development of a bacterial biofilm. Science 280:295–298. https://doi.org/10.1126/science.280.5361.295

Deng Y, Nagachar N, Xiao C, Tien M, Kao T (2013) Identification and characterization of non-cellulose-producing mutants of Gluconacetobacter hansenii generated by Tn5 transposon mutagenesis. J Bacteriol 195:5072–5083. https://doi.org/10.1128/JB.00767-13

Du J, Vepachedu V, Cho SH, Kumar M, Nixon BT (2016) Structure of the cellulose synthase complex of Gluconacetobacter hansenii at 23.4 Å resolution. PLoS One 11:e0155886. https://doi.org/10.1371/journal.pone.0155886

Entani E, Ohmori S, Masai H, Suzuki KI (1985) Acetobacter polyoxogenes sp. nov., a new species of an acetic acid bacterium useful for producing vinegar with high acidity. J Gen Appl Microbiol 31:475–490. https://doi.org/10.2323/jgam.31.475

Euzéby JP (1997) List of bacterial names with standing in nomenclature: a folder available on the internet. Int J Syst Bacteriol 47:590–592. https://doi.org/10.1099/00207713-47-2-590

Florea M, Reeve B, Abbott J, Freemont PS, Ellis T (2016) Genome sequence and plasmid transformation of the model high-yield bacterial cellulose producer Gluconacetobacter hansenii ATCC 53582. Sci Rep 6:23635. https://doi.org/10.1038/srep23635

Frensemeier M, Koplin C, Jaeger R, Kramer F, Klemm D (2010) Mechanical properties of bacterially synthesized nanocellulose hydrogels. Macromol Symp 294:38–44. https://doi.org/10.1002/masy.200900030

Gao X, Shi Z, Liu C, Yang G, Sevostianov I, Silberschmidt VV (2015) Inelastic behaviour of bacterial cellulose hydrogel: in aqua cyclic tests. Polym Test 44:82–92. https://doi.org/10.1016/j.polymertesting.2015.03.021

Giudici P, Gullo M, Solieri L (2009) Traditional balsamic vinegar. In: Giudici P, Solieri L (eds) Vinegars of the world. Springer, Milan, pp 157–177. https://doi.org/10.1007/978-88-470-0866-3_10

Gullo M, Giudici P (2008) Acetic acid bacteria in traditional balsamic vinegar: phenotypic traits relevant for starter cultures selection. Int J Food Microbiol 125:46–53. https://doi.org/10.1016/j.ijfoodmicro.2007.11.076

Gullo M, Mamlouk D, De Vero L, Giudici P (2012) Acetobacter pasteurianus strain AB0220: cultivability and phenotypic stability over 9 years of preservation. Curr Microbiol 64:576–580. https://doi.org/10.1007/s00284-012-0112-9

Gullo M, Zanichelli G, Verzelloni E, Lemmetti F, Giudici P (2016) Feasible acetic acid fermentations of alcoholic and sugary substrates in combined operation mode. Process Biochem 51:1129–1139. https://doi.org/10.1016/j.procbio.2016.05.018

Gullo M, Sola A, Zanichelli G, Montorsi M, Messori M, Giudici P (2017) Increased production of bacterial cellulose as starting point for scaled-up applications. Appl Microbiol Biotechnol 101:8115–8127. https://doi.org/10.1007/s00253-017-8539-3

Gupta P, Diwan B (2017) Bacterial exopolysaccharide mediated heavy metal removal: a review on biosynthesis, mechanism and remediation strategies. Biotechnol Rep 13:58–71. https://doi.org/10.1016/J.BTRE.2016.12.006

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembling, and applications. Chem Rev 110:3479–3500. https://doi.org/10.1021/cr900339w

Hu SQ, Gao YG, Tajima K, Sunagawa N, Zhou Y, Kawano S, Fujiwara T, Yoda T, Shimura D, Satoh Y, Munekata M, Tanaka I, Yao M (2010) Structure of bacterial cellulose synthase subunit D octamer with four inner passageways. Proc Natl Acad Sci 107:17957–17961. https://doi.org/10.1073/pnas.1000601107

Hwang JW, Yang YK, Hwang JK, Pyun YR, Kim YS (1999) Effects of pH and dissolved oxygen on cellulose production by Acetobacter xylinum BRC5 in agitated culture. J Biosci Bioeng 88:183–188. https://doi.org/10.1016/S1389-1723(99)80199-6

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose-a masterpiece of nature’s arts. J Mater Sci 35:261–270. https://doi.org/10.1023/A:1004775229149

Iida A, Ohnishi Y, Horinouchi S (2008) Control of acetic acid fermentation by quorum sensing via N-acylhomoserine lactones in Gluconacetobacter intermedius. J Bacteriol 190:2546–2555. https://doi.org/10.1128/JB.01698-07

Islam MU, Ullah MW, Khan S, Shah N, Park JK (2017) Strategies for cost-effective and enhanced production of bacterial cellulose. Int J Biol Macromol 102:1166–1173. https://doi.org/10.1016/J.IJBIOMAC.2017.04.110

Iwata T, Indrarti L, Azuma JI (1998) Affinity of hemicellulose for cellulose produced by Acetobacter xylinum. Cellulose 5:215–228. https://doi.org/10.1023/A:1009237401548

Iyer PR, Geib SM, Catchmark J, Kao TH, Tien M (2010) Genome sequence of a cellulose-producing bacterium, Gluconacetobacter hansenii ATCC 23769. J Bacteriol 192:4256–4257. https://doi.org/10.1128/JB.00588-10

Jahn CE, Selimi DA, Barak JD, Charkowski AO (2011) The Dickeya dadantii biofilm matrix consists of cellulose nanofibres, and is an emergent property dependent upon the type III secretion system and the cellulose synthesis operon. Microbiology 157:2733–2744. https://doi.org/10.1099/mic.0.051003-0

Jipa IM, Stoica-Guzun A, Stroescu M (2012) Controlled release of sorbic acid from bacterial cellulose based mono and multilayer antimicrobial films. LWT Food Sci Technol 47:400–406. https://doi.org/10.1016/J.LWT.2012.01.039

Jung JY, Park JK, Chang HN (2005) Bacterial cellulose production by Gluconacetobacter hansenii in an agitated culture without living non-cellulose producing cells. Enzym Microb Technol 37:347–354. https://doi.org/10.1016/J.ENZMICTEC.2005.02.019

Kawano S, Tajima K, Uemori Y, Yamashita H, Erata T, Munekata M, Takai M (2002) Cloning of cellulose synthesis related genes from Acetobacter xylinum ATCC23769 and ATCC53582: comparison of cellulose synthetic ability between strains. DNA Res 9:149–156. https://doi.org/10.1093/dnares/9.5.149

Keiski CL, Harwich M, Jain S, Neculai AM, Yip P, Robinson H, Whitney JC, Riley L, Burrows LL, Ohman DE, Howell PL (2010) AlgK is a TPR-containing protein and the periplasmic component of a novel exopolysaccharide secretin. Structure 18:265–273. https://doi.org/10.1016/j.str.2009.11.015

Keshk SM (2014) Bacterial cellulose production and its industrial applications. J Bioprocess Biotech 4. https://doi.org/10.4172/2155-9821.1000150

Kittelmann M, Stamm W, Follmann H, Truper H (1989) Isolation and classification of acetic acid bacteria from high percentage vinegar fermentations. Appl Microbiol Biotechnol 30:47–52. https://doi.org/10.1007/BF00255995

Kondo T (2007) Nematic ordered cellulose: its structure and properties. In: Cellulose: molecular and structural biology. Springer Netherlands, Dordrecht, pp 285–305. https://doi.org/10.1007/978-1-4020-5380-1_16

Koyama M, Helbert W, Imai T, Sugiyama J, Henrissat B (1997) Parallel-up structure evidences the molecular directionality during biosynthesis of bacterial cellulose. Proc Natl Acad Sci U S A 94:9091–9095. https://doi.org/10.1073/pnas.94.17.9091

Kubiak K, Kurzawa M, Jędrzejczak-Krzepkowska M, Ludwicka K, Krawczyk M, Migdalski A, Kacprzak MM, Loska D, Krystynowicz A, Bielecki S, Jedrzejczak-Krzepkowska M, Ludwicka K, Krawczyk M, Migdalski A, Kacprzak MM, Loska D, Krystynowicz A, Bielecki S (2014) Complete genome sequence of Gluconacetobacter xylinus E25 strain-valuable and effective producer of bacterial nanocellulose. J Biotechnol 176:18–19. https://doi.org/10.1016/j.jbiotec.2014.02.006

Kuo CH, Teng HY, Lee CK (2015) Knock-out of glucose dehydrogenase gene in Gluconacetobacter xylinus for bacterial cellulose production enhancement. Biotechnol Bioprocess Eng 20:18–25. https://doi.org/10.1007/s12257-014-0316-x

Lairson LL, Henrissat B, Davies GJ, Withers SG (2008) Glycosyltransferases: structures, functions, and mechanisms. Annu Rev Biochem 77:521–555. https://doi.org/10.1146/annurev.biochem.76.061005.092322

Li Y, Tian C, Tian H, Zhang J, He X, Ping W, Lei H (2012) Improvement of bacterial cellulose production by manipulating the metabolic pathways in which ethanol and sodium citrate involved. Appl Microbiol Biotechnol 96:1479–1487. https://doi.org/10.1007/s00253-012-4242-6

Mamlouk D, Gullo M (2013) Acetic acid bacteria: physiology and carbon sources oxidation. Indian J Microbiol 53:377–384. https://doi.org/10.1007/s12088-013-0414-z

Matsutani M, Ito K, Azuma Y, Ogino H, Shirai M, Yakushi T, Matsushita K (2015) Adaptive mutation related to cellulose producibility in Komagataeibacter medellinensis (Gluconacetobacter xylinus) NBRC 3288. Appl Microbiol Biotechnol 99:7229–7240. https://doi.org/10.1007/s00253-015-6598-x

McDougald D, Rice SA, Barraud N, Steinberg PD, Kjelleberg S (2012) Should we stay or should we go: mechanisms and ecological consequences for biofilm dispersal. Nat Rev Microbiol 10:39–50. https://doi.org/10.1038/nrmicro2695

McNamara JT, Morgan JLW, Zimmer J (2015) A molecular description of cellulose biosynthesis. Annu Rev Biochem 84:895–921. https://doi.org/10.1146/annurev-biochem-060614-033930

Mehta K, Pfeffer S, Brown RM (2015) Characterization of an acsD disruption mutant provides additional evidence for the hierarchical cell-directed self-assembly of cellulose in Gluconacetobacter xylinus. Cellulose 22:119–137. https://doi.org/10.1007/s10570-014-0521-y

Morgan JL, Strumillo J, Zimmer J (2013) Crystallographic snapshot of cellulose synthesis and membrane translocation. Nature 493:181–186. https://doi.org/10.1038/nature11744

Nakai T, Nishiyama Y, Kuga S, Sugano Y, Shoda M (2002) ORF2 gene involves in the construction of high-order structure of bacterial cellulose. Biochem Biophys Res Commun 295:458–462. https://doi.org/10.1016/S0006-291X(02)00696-4

Nakai T, Sugano Y, Shoda M, Sakakibara H, Oiwa K, Tuzi S, Imai T, Sugiyama J, Takeuchi M, Yamauchi D, Mineyukia Y (2013) Formation of highly twisted ribbons in a carboxymethylcellulase gene-disrupted strain of a cellulose-producing bacterium. J Bacteriol 195:958–964. https://doi.org/10.1128/JB.01473-12

Ng CC, Shyu YT (2004) Development and production of cholesterol-lowering Monascus-nata complex. World J Microbiol Biotechnol 20:875–879. https://doi.org/10.1007/s11274-004-0873-9

Noro N, Sugano Y, Shoda M (2004) Utilization of the buffering capacity of corn steep liquor in bacterial cellulose production by Acetobacter xylinum. Appl Microbiol Biotechnol 64:199–205. https://doi.org/10.1007/s00253-003-1457-6

Nowell ARM, Church M (1979) Turbulent flow in a depth-limited boundary layer. J Geophys Res 84:4816–4824. https://doi.org/10.1029/JC084iC08p04816

Omadjela O, Narahari A, Strumillo J, Melida H, Mazur O, Bulone V, Zimmer J (2013) BcsA and BcsB form the catalytically active core of bacterial cellulose synthase sufficient for in vitro cellulose synthesis. Proc Natl Acad Sci 110:17856–17861. https://doi.org/10.1073/pnas.1314063110

Osma JF, Toca-Herrera JL, Rodríguez-Couto S (2010) Uses of laccases in the food industry. Enzyme Res 918761:1–8. https://doi.org/10.4061/2010/918761

Passos da Silva D, Schofield MC, Parsek MR, Tseng BS (2017) An update on the sociomicrobiology of quorum sensing in gram-negative biofilm development. Pathogens 6:51. https://doi.org/10.3390/pathogens6040051

Pasteur L (1864) Memoire sur la fermentation acetique. Ann Scient de l’Ecole Normale Superieure. In Oeuvres des Pasteur, ed. Tome II, Fermentations et generations dites spontanees. Paris, France: masson et Cie 1922;133–158

Pavaloiu RD, Stroescu M, Parvulescu O (2014) Composite hydrogels of bacterial cellulose-carboxymethyl cellulose for drug release. Rev Chim 65:852–855. https://doi.org/10.1016/j.btre.2017.07.002

Petersen N, Gatenholm P (2011) Bacterial cellulose-based materials and medical devices: current state and perspectives. Appl Microbiol Biotechnol 91:1277–1286. https://doi.org/10.1007/s00253-011-3432-y

Pfeffer S, Mehta K, Brown RM Jr (2016) Complete genome sequence of a Gluconacetobacter hansenii ATCC 23769 isolate, AY201, producer of bacterial cellulose and important model organism for the study of cellulose biosynthesis. Genome Announc 4:e00808–e00816. https://doi.org/10.1128/genomeA.00808-16

Picheth GF, Pirich CL, Sierakowski MR, Woehl MA, Sakakibara CN, de Souza CF, Martin AA, da Silva R, de Freitas RA (2017) Bacterial cellulose in biomedical applications: a review. Int J Biol Macromol 104:97–106

Pokalwar SU, Mishra MK, Manwar AV (2010) Production of cellulose by Gluconacetobacter sp. Recent Res Sci Technol 2:14–19

Qi Y, Rao F, Luo Z, Liang ZX (2009) A flavin cofactor-binding PAS domain regulates c-di-GMP synthesis in Ax DGC2 from Acetobacter xylinum. Biochemistry 48:10275–10285. https://doi.org/10.1021/bi901121w

Rabin N, Zheng Y, Opoku-Temeng C, Du Y, Bonsu E, Sintim HO (2015) Biofilm formation mechanisms and targets for developing antibiofilm agents. Future Med Chem 7:493–512. https://doi.org/10.4155/fmc.15.6

Rajwadee JM, Paknikar KM, Kumbhar JV (2015) Applications of bacterial cellulose and its composites in biomedicine. Appl Microbiol Biotechnol 99:2491–2511. https://doi.org/10.1007/s00253-015-6426-3

Römling U (2002) Molecular biology of cellulose production in bacteria. Res Microbiol 153:205–212. https://doi.org/10.1016/S0923-2508(02)01316-5

Römling U, Galperin MY (2015) Bacterial cellulose biosynthesis: diversity of operons, subunits, products and functions. Trends Microbiol 23:545–557. https://doi.org/10.1016/j.tim.2015.05.005

Ross P, Weinhouse H, Aloni Y, Michaeli D, Weinberger-Ohana P, Mayer R, Braun S, de Vroom E, van der Marel GA, van Boom JH, Benziman M (1987) Regulation of cellulose synthesis in Acetobacter xylinum by cyclic diguanylic acid. Nature 325:279–281. https://doi.org/10.1038/325279a0

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in Bacteria. Microbiol Rev 55:35–58. https://doi.org/10.1016/j.bbalip.2012.08.009

Saxena IM, Brown RM (1995) Identification of a second cellulose synthase gene (acsAII) in Acetobacter xylinum. J Bacteriol 177:5276–5283. https://doi.org/10.1128/jb.177.18.5276-5283.1995

Semjonovs P, Ruklisha M, Paegle L, Saka M, Treimane R, Skute M, Rozenberga L, Vikele L, Sabovics M, Cleenwerck I (2017) Cellulose synthesis by Komagataeibacter rhaeticus strain P 1463 isolated from Kombucha. Appl Microbiol Biotechnol 101:1003–1012. https://doi.org/10.1007/s00253-016-7761-8

Seto A, Saito Y, Matsushige M, Kobayashi H, Sasaki Y, Tonouchi N, Tsuchida T, Yoshinaga F, Ueda K, Beppu T (2006) Effective cellulose production by a coculture of Gluconacetobacter xylinus and Lactobacillus mali. Appl Microbiol Biotechnol 73:915–921. https://doi.org/10.1007/s00253-006-0515-2

Shaw T, Winston M, Rupp CJ, Klapper I, Stoodley P (2004) Commonality of elastic relaxation times in biofilms. Phys Rev Lett 93:098102. https://doi.org/10.1103/PhysRevLett.93.098102

Shi Z, Zhang Y, Phillips GO, Yang G (2014) Utilization of bacterial cellulose in food. Food Hydrocoll 35:539–545. https://doi.org/10.1016/J.FOODHYD.2013.07.012

Shigematsu T, Takamine K, Kitazato M, Morita T, Naritomi T, Morimura S, Kida K (2005) Cellulose production from glucose using a glucose dehydrogenase gene (GDH)-deficient mutant of Gluconacetobacter xylinus and its use for bioconversion of sweet potato pulp. J Biosci Bioeng 99:415–422. https://doi.org/10.1263/JBB.99.415

Shoseyov O, Shani Z, Levy I (2006) Carbohydrate binding modules: biochemical properties and novel applications. Microbiol Mol Biol Rev 70:283–295. https://doi.org/10.1128/MMBR.00028-05

Sievers M, Sellmer S, Teuber M (1992) Acetobacter europaeus sp. nov., a main component of industrial vinegar fermenters in Central Europe. Syst Appl Microbiol 15:386–392. https://doi.org/10.1016/S0723-2020(11)80212-2

Standal R, Iversen TG, Coucheron DH, Fjaervik E, Blatny JM, Valla S (1994) A new gene required for cellulose production and a gene encoding cellulolytic activity in Acetobacter xylinum are colocalized with the bcs operon. J Bacteriol 176:665–672. https://doi.org/10.1128/jb.176.3.665-672.1994

Stoodley P, Dodds I, Boyle JD, Lappin-Scott HM (1999) Influence of hydrodynamics and nutrients on biofilm structure. J Appl Microbiol 85:19S–28S. https://doi.org/10.1111/j.1365-2672.1998.tb05279.x

Sunagawa N, Fujiwara T, Yoda T, Kawano S, Satoh Y, Yao M, Tajima K, Dairi T (2013) Cellulose complementing factor (Ccp) is a new member of the cellulose synthase complex (terminal complex) in Acetobacter xylinum. J Biosci Bioeng 115:607–612. https://doi.org/10.1016/j.jbiosc.2012.12.021

Tajima K, Nakajima K, Yamashita H, Shiba T, Munekata M, Takai M (2001) Cloning and sequencing of the beta-glucosidase gene from Acetobacter xylinum ATCC 23769. DNA Res 8:263–269. https://doi.org/10.1093/dnares/8.6.263

Thongsomboon W, Serra DO, Possling A, Hadjineophytou C, Hengge R, Cegelski L (2018) Phosphoethanolamine cellulose: a naturally produced chemically modified cellulose. Science 359:334–338. https://doi.org/10.1126/science.aao4096

Tonouchi N, Tahara N, Tsuchida T, Yoshinaga F, Beppu T, Horinouchi S (1995) Addition of a small amount of an endoglucanase enhances cellulose production by Acetobacter xylinum. Biosci Biotechnol Biochem 59:805–808. https://doi.org/10.1271/bbb.59.805

Ullah H, Santos HA, Khan T (2016) Applications of bacterial cellulose in food, cosmetics and drug delivery. Cellulose 23:2291–2314. https://doi.org/10.1007/s10570-016-0986-y

Umeda Y, Hirano A, Ishibashi M, Akiyama H, Onizuka T, Ikeuchi M, Inoue Y (1999) Cloning of cellulose synthase genes from Acetobacter xylinum JCM 7664: implication of a novel set of cellulose synthase genes. DNA Res 6:109–115. https://doi.org/10.1093/dnares/6.2.109

Valera MJ, Torija MJ, Mas A, Mateo E (2014) Cellulose production and cellulose synthase gene detection in acetic acid bacteria. Appl Microbiol Biotechnol 99:1349–1361. https://doi.org/10.1007/s00253-014-6198-1

Valera MJ, Mas A, Streit WR, Mateo E (2016) GqqA, a novel protein in Komagataeibacter europaeus involved in bacterial quorum quenching and cellulose formation. Microb Cell Factories 15:88. https://doi.org/10.1186/s12934-016-0482-y

Watanabe K, Yamanaka S (1995) NII-electronic library service effects of oxygen tension in the gaseous phase on production and physical properties of bacterial cellulose formed under static culture conditions. Biosci Biotechnol Biochem 59:65–68. https://doi.org/10.1271/bbb.59.65

Wong HC, Fear AL, Calhoon RD, Eichinger GH, Mayer R, Amikam D, Benziman M, Gelfand DH, Meade JH, Emerick AW (1990) Genetic organization of the cellulose synthase operon in Acetobacter xylinum. Proc Natl Acad Sci U S A 87:8130–8134. https://doi.org/10.1073/pnas.87.20.8130

Yasutake Y, Kawano S, Tajima K, Yao M, Satoh Y, Munekata M, Tanaka I (2006) Structural characterization of the Acetobacter xylinum endo-β-1,4-glucanase CMCax required for cellulose biosynthesis. Proteins 64:1069–1077. https://doi.org/10.1002/prot.21052

Zhang H, Xu X, Chen X, Yuan F, Sun B, Xu Y, Yang J, Sun D (2017) Complete genome sequence of the cellulose-producing strain Komagataeibacter nataicola RZS01. Sci Rep 7:4431. https://doi.org/10.1038/s41598-017-04589-6

Zhong C, Zhang GC, Liu M, Zheng XT, Han PP, Jia SR (2013) Metabolic flux analysis of Gluconacetobacter xylinus for bacterial cellulose production. Appl Microbiol Biotechnol 97:6189–6199. https://doi.org/10.1007/s00253-013-4908-8

Zogaj X, Nimtz M, Rohde M, Bokranz W, Römling U (2001) The multicellular morphotypes of Salmonella typhimurium and Escherichia coli produce cellulose as the second component of the extracellular matrix. Mol Microbiol 39:1452–1463. https://doi.org/10.1046/j.1365-2958.2001.02337.x

Acknowledgments

We thank Dr. Luciana De Vero for K. xylinus UMCC2756 maintenance at UMCC (http://www.umcc.unimore.it/) culture collection, Sophia Luche for drawing figures, and Davide Davoli and Dr. Gabriele Zanichelli for taking pictures.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Gullo, M., La China, S., Falcone, P.M. et al. Biotechnological production of cellulose by acetic acid bacteria: current state and perspectives. Appl Microbiol Biotechnol 102, 6885–6898 (2018). https://doi.org/10.1007/s00253-018-9164-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-9164-5