Abstract

Simultaneous saccharification and fermentation (SSF) of d-lactic acid was performed using brown rice as both a substrate and a nutrient source. An engineered Lactobacillus plantarum NCIMB 8826 strain, in which the ʟ-lactate dehydrogenase gene was disrupted, produced 97.7 g/L d-lactic acid from 20% (w/v) brown rice without any nutrient supplementation. However, a significant amount of glucose remained unconsumed and the yield of lactic acid was as low as 0.75 (g/g-glucose contained in brown rice). Interestingly, the glucose consumption was significantly improved by adapting L. plantarum cells to the low-pH condition during the early stage of SSF (8–17 h). As a result, 117.1 g/L d-lactic acid was produced with a high yield of 0.93 and an optical purity of 99.6% after 144 h of fermentation. SSF experiments were repeatedly performed for ten times and d-lactic acid was stably produced using recycled cells (118.4–129.8 g/L). On average, d-lactic acid was produced with a volumetric productivity of 2.18 g/L/h over 48 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Technologies for the production of fuels and plastics from inexpensive and renewable biomass resources are currently being developed to prevent the exhaustion of oil reserves and global warming (Ohara et al. 2007). In this respect, polylactic acid (PLA) is considered as an important raw material for bioplastics that can be produced from biomass resources. There are two optical isomers of ʟ- and d-lactic acid. Since the optical purity of lactic acid is crucial to physical properties of PLA, the production of enantiomeric pure lactic acid is an important goal (Okano et al. 2010). Moreover, stereocomplex PLA, which is composed of both poly ʟ- and d-lactic acid, has recently attracted attention owing to its high thermostability. Stereocomplex-type polymers have a high melting point (ca. 230 °C) that is approximately 50 °C higher than that of the corresponding single polymers (Ikada et al. 1987). Although ʟ-lactic acid and its polymer have been manufactured on an industrial scale (Wee et al. 2006), a cost-effective process for d-lactic acid production remains to be established. Therefore, the production of d-lactic acid is of significant importance.

Rice is one of the basic components of the daily diet for nearly half of the world’s population (Saman et al. 2011). According to the statistics of the Food and Agriculture Organization of the United Nations (FAO) (http://faostat3.fao.org/home/E), the world production of rice was estimated to be about 740 million metric tons in 2014 and approximately 90% of rice is produced in Asian countries. Although rice production is predicted to increase, a significant amount of rice is wasted. For instance, nearly 10 million metric tons of rice (milled basis), corresponding to 15% of total regional production, are wasted in Southeast Asian countries every year (Baldwin et al. 2012). Together with wasted rice, rice bran is an abundant agricultural by-product. The weight ratio of the bran to the whole rice particle is about 10% and the bran is removed in the rice milling process (Tanaka et al. 2006; Wang et al. 2014). Since wasted rice and rice bran have a high content of fermentable carbohydrates (mainly starch), they can be used as an inexpensive substrate for lactic acid fermentation, reducing the cost of both lactic acid fermentation and waste disposal.

Tanaka et al. (2006) reported d-lactic acid production in a modified de Man–Rogosa–Sharpe (MRS) medium, in which glucose was replaced with defatted rice bran. By simultaneous saccharification and fermentation (SSF) with Lactobacillus delbrueckii subsp. delbrueckii IFO 3202, 28 g/L d-lactic acid was produced from 100 g/L defatted rice bran with an optical purity of 95%. Fukushima et al. (2004) also reported that L. delbrueckii produced 62.6 g/L d-lactic acid from 107 g/L rice saccharificate with an optical purity of 97.5%. On the other hand, some lactic acid bacteria are known to produce lactic acid using rice bran hydrolysate as not only a carbon source but also a nutrient source, enabling further reduction of the cost of lactic acid production. Yun et al. (2004) reported that Lactobacillus sp. RKY2 produced racemic dʟ-lactic acid using rice bran hydrolysate without any additional nutrients. Likewise, ʟ-lactic acid production was achieved by Lactobacillus rhamnosus LA-04-1 (Wang et al. 2014). However, to the best of our knowledge, there have been no reports on d-lactic acid production from rice or rice components without nutrient supplementation.

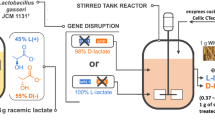

Previously, we constructed a metabolically engineered Lactobacillus plantarum NCIMB 8826 strain, in which the ʟ-lactate dehydrogenase gene (ldhL1) was replaced with an α-amylase-secreting expression cassette (Okano et al. 2009). By using the ldhL1::amyA strain, we achieved direct d-lactic acid fermentation from raw corn starch. In addition, Saman et al. (2011) reported that L. plantarum NCIMB 8826 can grow in a rice medium containing only autoclaved brown rice. Encouraged by these findings, in the present study, we examined the feasibility of d-lactic acid production from brown rice without any nutrient supplementation. L. plantarum ldhL1::amyA was found to efficiently produce enantiomeric pure d-lactic acid from brown rice using it as both a substrate and a nutrient source. Interestingly, the productivity of d-lactic acid was markedly improved by initial exposure of the cells to a low-pH environment.

Materials and methods

Materials

L. plantarum NCIMB 8826 ldhL1::amyA (Okano et al. 2009) was used for lactic acid fermentation. The strain was cultivated at 37 °C in corn steep liquor (CSL) medium consisting of 2% (v/v) CSL (Nihon Starch Co., Ltd., Kagoshima, Japan) and 0.5% (v/v) soluble starch (Wako Pure Chemical Industries, Ltd., Osaka, Japan). Brown rice, which was obtained locally, was pulverized into small particles (2 × 2 mm2 in size) using a millstone-type mill (Micro Powder; West Co., Ltd, Niigata, Japan). The glucose content of the brown rice was 80.2%, which was determined by high-performance liquid chromatography (HPLC) after hydrolysis with sulfuric acid. General composition of other components of brown rice is 6.8% proteins, 2.7% fats, and 3% fiber (Council for Science and Technology 2015). Brown rice also contains a lot of vitamins (1.2 mg α-tocopherol, 0.41 mg thiamine, 0.040 mg riboflavin, 6.3 mg niacin, 0.45 mg vitamin B6, 27 mg folate, 1.4 mg pantothenic acid, and 3.0 μg biotin per 100 g brown rice) and minerals (290 mg phosphorus, 2.1 mg iron, 1.8 mg zinc, 0.27 mg copper, 2.1 mg manganese, 3.0 μg selenium, and 64 μg molybdenum per 100 g brown rice). Bacillus α-amylase (Spitase CP-40FG; Nagase ChemteX, Co., Osaka, Japan) and Rhizopus glucoamylase (Glucozyme #20000, Nagase ChemteX) were used for enzyme saccharification of the brown rice.

Lactic acid fermentation

The SSF of lactic acid was performed using a 3-L bioreactor (Tokyo Rikakikai, Co., Ltd., Tokyo, Japan) with a 1 L working volume. To prepare the inoculum, L. plantarum ldhL1::amyA was cultivated in 50 mL CSL medium (2% (v/v) CSL; 0.5% (w/v) soluble starch). Since CSL contains significant amount of ʟ-lactic acid (136.0 g/L), the addition of overnight culture inevitably decreases the optical purity of d-lactic acid. To prevent decrease of the optical purity of d-lactic acid by contamination of ʟ-lactic acid derived from CSL, the supernatant from 50 mL of an overnight culture was removed by centrifugation. Then, collected cells were washed twice with 0.85% (w/v) saline and used as an inoculum. Prior to SSF, a mixture containing the pulverized brown rice (15 or 20%, w/v) and CSL (0–6%, v/v) was added to the reactor vessel. Since the pH of CSL is slightly acidic (pH = 3.7), the pH of the mixture was adjusted to 5.5 or 6.0 by adding 20% (w/v) NaOH. To minimize energy consumption by sterilization, low-temperature sterilization was adopted. The mixture was incubated at 60 °C for 3 h and then cooled to 37 °C. SSF was initiated by adding the inoculum and amylolytic enzymes. For 200 g of brown rice, 0.13 g of Spitase (α-amylase derived from Bacillus sp.) and 0.1 g of Glucozyme (glucoamylase derived from Rhizopus sp.) (corresponding to 2.0 and 15.1 U of enzymes, respectively) were used. The temperature was maintained at 37 °C and the agitation speed was kept at 200 rpm. The pH was kept at 5.5 or 6.0 by the automatic addition of 20% (w/v) NaOH solution unless stated. After incubation, the culture was harvested at specified intervals and subjected to the following analyses. In the repeated utilization of the cells, the first batch fermentation was carried out for 96 h, and then the large residues of brown rice were removed from the culture using a self-made strainer having a 40 mesh size. The cells and fine particles of rice residues were collected from the resulting suspension by centrifugation at 12,000×g for 10 min. The recovered cells were suspended in a presterilized brown rice suspension (20%; w/v). Spitase (0.39 g) and Glucozyme (0.3 g) were immediately added to the reactor and the next batch fermentation was initiated. Repeated SSF experiments were continuously performed ten times. In each cycle, SSF was carried out for 96 h.

Analytical procedure

Glucose concentration was determined using a BF-5 biosensor (Oji Scientific Instruments, Hyogo, Japan) equipped with an enzyme electrode. Lactic acid, acetic acid, and formic acid concentrations were determined by HPLC, as described previously (Hama et al. 2015). The yield of lactic acid was calculated as the amount of lactic acid produced per amount of glucose contained in the brown rice. Since 100-g brown rice contains 80.2 g glucose, 80.2 g of lactic acid can be theoretically produced. The concentrations of d-lactic acid and ʟ-lactic acid were also determined by HPLC equipped with a chiral column, as described previously (Hama et al. 2015). The optical purity was defined as follows: optical purity (%) = 100 × (d-lactic acid concentration − ʟ-lactic acid concentration)/(d-lactic acid concentration + ʟ-lactic acid concentration).

Results

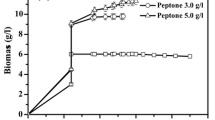

SSF from brown rice with supplementation of CSL

SSF of d-lactic acid from 15% (w/v) brown rice was performed using the L. plantarum ldhL1::amyA strain at pH 5.5 with the supplementation of 1 or 6% (v/v) of CSL (Fig. 1). Although L. plantarum ldhL1::amyA produced α-amylase extracellularly, additional α-amylase and glucoamylase were added to the reactor (0.1 g and 0.075 g, respectively) to achieve rapid degradation of rice starch. When 6% (v/v) of CSL was supplemented to the culture, ldhL1::amyA rapidly produced d-lactic acid over 24 h and 87.3 g/L lactic acid was produced. If it was hypothesized that all of saccharified glucose from the brown rice was converted to lactic acid, saccharification rate of the brown rice can be estimated as 3.64 g/L/h. Thereafter, the concentration of lactic acid gradually increased to 107.4 g/L after 72 h of fermentation. No accumulation of glucose was observed during fermentation, indicating that the saccharification of rice starch was the rate-limiting step in SSF. In contrast, reduction in the dose of CSL (1%; v/v) caused the significant accumulation of glucose, probably due to the decrease in the metabolic activity of the ldhL1::amyA strain under a nutrient-poor condition. After 19 h of fermentation, the concentration of accumulated glucose reached 25.2 g/L. Even after 72 h of fermentation, glucose remained unconsumed and the residual glucose concentration was 7.1 g/L. As a result, a reduction of 20% was observed in the lactic acid concentration (86.0 g/L).

Effect of CSL concentration on lactic acid fermentation. SSF from 15% (w/v) brown rice was performed with the supplementation of 1% (dashed line) or 6% (solid line) CSL. Symbols: circles, lactic acid concentrations; triangles, glucose concentrations. Data points represent means and standard deviations from three independent experiments

Effect of temporal acid adaptation of ldhL1::amyA cells on SSF

Since brown rice contains a lot of vitamins and minerals in addition to carbohydrates and proteins, we considered that increased dose of brown rice increases the metabolic activity of ldhL1::amyA at a low concentration of CSL (1%; v/v). Therefore, SSF of d-lactic acid was performed using an increased dose of brown rice (20%; w/v) (Fig. 2). However, no significant increase in glucose consumption was observed and 31.5 g/L glucose accumulated after 19 h of fermentation. Although lactic acid production almost reached a plateau after 96 h, nearly 20 g/L glucose was found to remain in the culture. Incidentally, however, we found that glucose consumption of L. plantarum ldhL1::amyA cells was increased by exposing the cells to the low-pH condition in the early stage of fermentation. When SSF was performed without controlling the pH during the first 17 h, the pH of the culture rapidly decreased to under 4.0 after 8 h (data not shown). Then, the pH gradually decreased to 3.6 after 17 h. As a result, ldhL1::amyA cells were exposed to an acidic environment at least more than 9 h. This temporal acid adaptation significantly increased glucose consumption and lactic acid production. While glucose accumulated up to 19 h (42.0 g/L) (Fig. 2), it was subsequently consumed up to 48 h and no glucose was detected after 72 h of fermentation. As a result, 127.1 g/L lactic acid was produced from 20% (w/v) of brown rice after 144 h of fermentation, which is significantly higher than that obtained by SSF without initial acid adaptation (109.8 g/L). The reason for this is unclear, but acid adaptation appears to increase the metabolic activity of L. plantarum cells under a nutrient-poor condition. To determine the time required for acid adaptation, the cultivation time under non-controlled pH conditions was set to 5, 8, or 15 h (Fig. 3a). When the time for acid adaptation was shortened to 8 or 15 h, the changes in glucose concentration showed almost the same pattern (Fig. 3b) as that observed in SSF employing 17 h of acid adaptation (Fig. 2). In contrast, 5 h of adaptation had no effect on glucose consumption (Fig. 3b). Therefore, at least 8 h of cultivation under a non-pH-controlled condition appeared to be required to increase glucose consumption. Although efficient lactic acid fermentation was achieved by using the acid-adaptation technique, the optical purity of d-lactic acid was as low as 96.8%. This is mainly due to the contamination of ʟ-lactic acid derived from CSL because CSL contains significant of ʟ-lactic acid (136.0 g/L).

Effect of acid adaptation on lactic acid fermentation. SSF from 20% (w/v) brown rice was performed with the supplementation of 1% CSL. L. plantarum ldhL1::amyA was cultivated under controlled (dashed line) or non-controlled (solid line) pH conditions during the first 17 h of the fermentation. Then, the pH was maintained at 5.5. Symbols: circles, lactic acid concentrations; triangles, glucose concentrations. Data points represent means and standard deviations from three independent experiments

Effect of time for acid adaptation on glucose accumulation. a Time-course data of the pH. b Time-course data of glucose concentration. L. plantarum ldhL1::amyA was cultivated under non-controlled pH conditions during the first 5 h (dotted line), 8 h (dashed line), or 17 h (solid line) of the fermentation. Then, the pH was maintained at 5.5. Data points represent means and standard deviations from three independent experiments

SSF from brown rice without any nutrient supplementation

Using the acid-adaptation technique, SSF using 20% (w/v) brown rice was carried out without the supplementation of CSL (Fig. 4). For the initial 15 h, SSF was performed without controlling the pH, and then the pH control was initiated. The pH was set at 6.0 because it was found that this pH gave the highest productivity of lactic acid after experimental optimization (data not shown). As expected, glucose was completely consumed in 72 h and 117.1 g/L lactic acid was successfully produced in 144 h. No acetic acid or formic acid was detected. Table 1 summarizes the results of SSF using brown rice with/without initial acid adaptation. In SSF without initial acid adaptation, 97.7 g/L lactic acid was produced. The yield of lactic acid was as low as 0.75 (g-lactic acid produced/g-glucose contained in brown rice) owing to the incomplete conversion of glucose. In contrast, a significantly higher lactic acid yield of 0.93 was achieved by SSF with temporal exposure of the cells to a low-pH environment. Given the dilution of the culture by neutralization with NaOH solution, the amount of lactic acid produced per liter of the initial culture was calculated to be 148.7 g, which is comparable to the theoretical value of 160.4 g. Moreover, the optical purity of d-lactic acid was as high as 99.6%, which is considerably higher than that obtained in the fermentation using 1% CSL (96.8%). These results suggested that prevention of the use of CSL not only decreases the medium cost but also increases the optical purity of d-lactic acid.

Lactic acid fermentation using 20% (w/v) brown rice without any nutrient supplementation. L. plantarum ldhL1::amyA was cultivated under controlled (dashed line) or non-controlled (solid line) pH conditions during the first 15 h of the fermentation. Then, the pH was maintained at 6.0. Symbols: circles, lactic acid concentrations; triangles, glucose concentrations. Data points represent means and standard deviations from three independent experiments

Repeated batch fermentation using recycled cells

The feasibility of repeated batch fermentation using recycled cells was investigated (Fig. 5). SSF experiments were repeatedly performed ten times. In each cycle, SSF was performed under a non-pH-controlled condition during the first 15 h for acid adaptation. To accelerate lactic acid fermentation, three times the amount of enzymes was added to the culture (0.39 g Spitase and 0.3 g of Glucozyme). This led to slight increases in the productivity and final concentration of lactic acid. In the first batch, lactic acid was produced with a volumetric productivity of 1.93 g/L/h over 48 h, which is slightly higher than that observed in SSF with the standard dose of enzymes (1.67 g/L/h). The final concentration of lactic acid reached 124.8 g/L. After the second batch, lactic acid was stably produced using recycled cells (118.4–129.8 g/L). On average, lactic acid was produced with a volumetric productivity of 2.18 g/L/h over 48 h.

Repeated batch fermentation using recycled cells. SSF from 20% (w/v) brown rice was performed without any nutrient supplementation. After each batch fermentation, the cells were collected from the reactor. Then, the cells were used as an inoculum for the next batch fermentation. In each cycle, SSF was performed under a non-pH-controlled condition during the first 15 h for acid adaptation. Symbols: circles, lactic acid concentrations; triangles, glucose concentrations

Discussion

In the present study, d-lactic acid production from brown rice was demonstrated without any nutrient supplementation. There are many reports of lactic acid production from biomass resources with high efficiency. Dumbrepatil et al. (2008) reported that L. delbrueckii mutant Uc-30 produced 166 g/L of lactic acid from 190 g/L cane sugar molasses with a yield of 0.95. Linko and Javanainen (1996) reported that Lactobacillus casei NRRL B-441 produced 162 g/L of lactic acid from 170 g/L barley starch with a yield of 0.87. However, lactic acid bacteria require a large number of nutrients such as amino acids and B-vitamins for their growth and lactic acid production (Wegkamp et al. 2010). Accordingly, an expensive nutrient source such as yeast extract must be used to fulfill the nutrient requirements of lactic acid bacteria in most studies. Wang et al. (2014) reported that yeast extract accounted for 46% of the total cost of lactic acid production from corn starch. Even when CSL was used as an inexpensive nutrient source, it still accounted for 12% of the production cost. Although corn starch has been widely used as the substrate in lactic acid fermentation (Lunt 1998), its material cost accounted for 40% of the production cost (Wang et al. 2014). Therefore, the use of biomass resource as both a substrate and a nutrient source should significantly reduce the cost of lactic acid production. Previously, Oh et al. (2005) reported that Enterococcus faecalis RKY1 produced 94.4 g/L ʟ-lactic acid with a high yield (0.94) using whole wheat flour hydrolysate as both a substrate and a nutrient. However, there have been no reports on d-lactic acid production without nutrient supplementation. Unlike known d-lactic-acid-producing bacteria (Fukushima et al. 2004; Tanaka et al. 2006), the L. plantarum ldhL1::amyA strain was shown to produce d-lactic acid from brown rice without nutrient supplementation (Fig. 4 and Table 1). Remarkably, d-lactic acid production was achieved with higher titer (117.1 g/L), yield (0.93), and optical purity (99.6%) in this study than in the previous studies (Fukushima et al. 2004; Tanaka et al. 2006). Repeated d-lactic acid production using recycled cells (Fig. 5) should reduce the cost further because it enables the omission of precultivation before every fermentation, shortening of the fermentation time, and reduction in the amount of fermentation residue.

Although brown rice (200 g) contains all kinds of essential vitamins for the growth of L. plantarum (Wegkamp et al. 2010) and the amounts of the vitamins (0.080 mg riboflavin, 13 mg niacin, 0.90 mg vitamin B6, 54 mg folate, and 2.7 mg pantothenic acid, respectively; Council for Science and Technology 2015) are comparable to those in 6% (v/v) CSL medium (0.16 mg riboflavin, 4.3 mg niacin, 1.0 mg vitamin B6, 18 μg folate, and 0.89 mg pantothenic acid, respectively), reduction in the dose of CSL decreased glucose consumption and lactic acid productivity (Fig. 1). Therefore, the other components other than vitamins seem to limit the glucose consumption of L. plantarum. Interestingly, glucose consumption and lactic acid productivity were significantly improved by cultivating the cells without the pH control for more than 8 h and exposing the cells to a low-pH environment (Fig. 4). Since this phenomenon was also observed by forcibly decreasing the pH of the culture using HCl after cultivation of the cells with the pH control (data not shown), pH seems to be the only factor to increase glucose consumption and lactic acid production. The use of the pre-adapted cells to low-pH condition and the shorter cultivation period (less than 8 h; Fig. 3) under non-pH-controlled condition had no effect for improving glucose consumption and lactic acid production. This is probably due to low population of the adapted cells in these conditions because inoculum size was as small as 5% and the cultivation less than 8 h caused insufficient growth of the adapted cells. The increase in metabolic activity is attributed to the increased amount of glycolytic enzymes resulting from acid adaptation. A comparative proteomic analysis of four L. plantarum strains cultivated in a nutrient-poor/rich medium revealed that the amount of glycolytic enzymes was markedly decreased during cultivation in the nutrient-poor medium (Siragusa et al. 2014). On the other hand, Silva et al. (2005) reported an increase in the amount of glycolytic enzymes upon cultivating L. delbrueckii subsp. bulgaricus under a non-controlled pH. Therefore, temporal acid adaptation may increase the amount of glycolytic enzymes in L. plantarum ldhL1::amyA even in the nutrient-poor brown rice medium. Proteomic analysis is expected to provide further insights into the increased metabolic activity upon acid adaptation.

Another advantage of ldhL1-deficient L. plantarum is its ease of genetic modification. Unlike known d-lactic-acid-producing lactic acid bacteria, a variety of genetic tools have been developed for L. plantarum (Pavan et al. 2000; Rud et al. 2006; Yang et al. 2015). Therefore, ldhL1-deficient L. plantarum may be an attractive platform for d-lactic acid production from biomass resources (Hama et al. 2015; Zhang et al. 2016). Increasing the copy number of amyA in the genome and co-expression with glucoamylase should allow efficient d-lactic acid production without additional enzymes. Along with amylolytic enzymes, the co-expression of other hydrolytic enzymes is expected to further improve the productivity of d-lactic acid. Gao et al. (2008) reported that the preliminary acid digestion of rice bran caused proteolytic degradation and significantly increased lactic acid productivity. Such a positive effect was also observed by treating rice bran with protease (Wang et al. 2014). The expression of extracellular proteinases such as the well-known lactococcal proteinase PrtP (Bruinenberg et al. 1992) should enable the strain to efficiently utilize the protein in brown rice.

In conclusion, our results successfully demonstrated the production of optically pure d-lactic acid from brown rice without any nutrient supplementation. By introducing an acid-adaptation phase into the early stage of the SSF, we realized markedly improved glucose consumption and lactic acid productivity. The use of L. plantarum ldhL1::amyA with the acid-adaptation technique should significantly reduce the cost reduction of d-lactic acid production. Further studies should be performed to analyze the mechanism underlying the increased metabolic activity due to acid adaptation and to increase the productivity of d-lactic acid production in the near future.

References

Baldwin K, Childs N, Dyck J, Hansen J (2012) Southeast Asia’s rice surplus. A report from the economic research service. United States Department of Agriculture

Bruinenberg P, Vos P, de Vos WM (1992) Proteinase overproduction in Lactococcus lactis strains: regulation and effect on growth and acidification in milk. Appl Environ Microbiol 58:78–84

Council for Science and Technology (2015) Standard tables of food composition in Japan 7th ed. Ministry of Education, Culture, Sports, Science and Technology, Japan. National Printing Bureau, Tokyo, Japan

Dumbrepatil A, Adsul M, Chaudhari S, Khire J, Gokhale D (2008) Utilization of molasses sugar for lactic acid production by Lactobacillus delbrueckii subsp. delbrueckii mutant Uc-3 in batch fermentation. Appl Environ Microbiol 74:333–335

Fukushima K, Sogo K, Miura S, Kimura Y (2004) Production of d-lactic acid by bacterial fermentation of rice starch. Macromol Biosci 4:1021–1027

Gao MT, Kaneko M, Hirata M, Toorisaka E, Hano T (2008) Utilization of rice bran as nutrient source for fermentative lactic acid production. Bioresour Technol 99:3659–3664

Hama S, Mizuno S, Kihara M, Tanaka T, Ogino C, Noda H, Kondo A (2015) Production of d-lactic acid from hardwood pulp by mechanical milling followed by simultaneous saccharification and fermentation using metabolically engineered Lactobacillus plantarum. Bioresour Technol 187:167–172

Ikada Y, Jamshidi K, Tsuji H, Hyon SH (1987) Stereocomplex formation between enantiomeric poly (lactides). Macromolecules 20:904–906

Linko YY, Javanainen P (1996) Simultaneous liquefaction, saccharification, and lactic acid fermentation on barley starch. Enzym Microb Technol 19:118–123

Lunt J (1998) Large-scale production, properties and commercial applications of polylactic acid polymers. Polym Degrad Stabil 59:145–152

Oh H, Wee YJ, Yun JS, Han SH, Jung S, Ryu HW (2005) Lactic acid production from agricultural resources as cheap raw materials. Bioresour Technol 96:1492–1498

Ohara H, Owaki M, Sonomoto K (2007) Calculation of metabolic flow of xylose in Lactococcus lactis. J Biosci Bioeng 103:92–94

Okano K, Tanaka T, Ogino C, Fukuda H, Kondo A (2010) Biotechnological production of enantiomeric pure lactic acid from renewable resources: recent achievements, perspectives, and limit. Appl Microbiol Biotechnol 85:413–423

Okano K, Zhang Q, Shinkawa S, Yoshida S, Tanaka T, Fukuda H, Kondo A (2009) Efficient production of optically pure d-lactic acid from raw corn starch using genetically modified ʟ-lactate dehydrogenase gene-deficient and α-amylase-secreting Lactobacillus plantarum. Appl Environ Microbiol 75:462–467

Pavan S, Hols P, Delcour J, Geoffroy MC, Grangette C, Kleerebezem M, Mercenier A (2000) Adaptation of the nisin-controlled expression system in Lactobacillus plantarum: a tool to study in vivo biological effects. Appl Environ Microbiol 66:4427–4432

Rud I, Jensen PR, Naterstad K, Axelsson L (2006) A synthetic promoter library for constitutive gene expression in Lactobacillus plantarum. Microbiology 152:1011–1019

Saman P, Fuciños P, Vázquez JA, Pandiella SS (2011) Fermentability of brown rice and rice bran for growth of human Lactobacillus plantarum NCIMB 8826. Food Technol Biotechnol 49:128–132

Silva J, Carvalho AS, Ferreira R, Vitorino R, Amado F, Domingues P, Teixeira P, Gibbs PA (2005) Effect of the pH of growth on the survival of Lactobacillus delbrueckii subsp. bulgaricus to stress conditions during spray-drying. J Appl Microbiol 98:775–782

Siragusa S, De Angelis M, Calasso M, Campanella D, Minervini F, Di Cagno R, Gobbetti M (2014) Fermentation and proteome profiles of Lactobacillus plantarum strains during growth under food-like conditions. J Proteome 96:366–380

Tanaka T, Hoshina M, Tanabe S, Sakai K, Ohtsubo S, Taniguchi M (2006) Production of d-lactic acid from defatted rice bran by simultaneous saccharification and fermentation. Bioresour Technol 97:211–217

Wang Y, Yang Z, Qin P, Tan T (2014) Fermentative ʟ-(+)-lactic acid production from defatted rice bran. RSC Adv 4:8907–8913

Wee YJ, Kim JN, Ryu HW (2006) Biotechnological production of lactic acid and its recent applications. Food Technol Biotechnol 44:163–172

Wegkamp A, Teusink B, de Vos WM, Smid EJ (2010) Development of a minimal growth medium for Lactobacillus plantarum. Lett Appl Microbiol 50:57–64

Yang P, Wang J, Qi Q (2015) Prophage recombinases-mediated genome engineering in Lactobacillus plantarum. Microb Cell Factories 14:154

Yun JS, Wee YJ, Kim JN, Ryu HW (2004) Fermentative production of dʟ-lactic acid from amylase-treated rice and wheat brans hydrolyzate by a novel lactic acid bacterium, Lactobacillus sp. Biotechnol Lett 26:1613–1616

Zhang Y, Vadlani PV, Kumar A, Hardwidge PR, Govind R, Tanaka T, Kondo A (2016) Enhance d-lactic acid production from renewable resources using engineered Lactobacillus plantarum. Appl Microbiol Biotechnol 100:279–288

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was partly financed by the Strategic Foundational Technology Improvement Support Operation of the Kinki Bureau of Economy, Trade and Industry, Japan. We acknowledge Special Coordination Funds for Promoting Science and Technology, Creation of Innovative Centers for Advanced Interdisciplinary Research Areas (Innovative Bioproduction Kobe) from the Ministry of Education, Culture, Sports, Science and Technology, Japan. We also thank the Japan Society for the Promotion of Science (JSPS), KAKENHI Grant (16K18299).

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Okano, K., Hama, S., Kihara, M. et al. Production of optically pure d-lactic acid from brown rice using metabolically engineered Lactobacillus plantarum . Appl Microbiol Biotechnol 101, 1869–1875 (2017). https://doi.org/10.1007/s00253-016-7976-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-7976-8