Abstract

Ellagitannins are the predominant bioactive tannins present in the peel of pomegranate. Studies have explored different extraction solvents to maximize recovery of the bioactive phytochemicals in pomegranate peel but lack proper statistical correlation between the extraction solvent, phytochemistry and bioactivity. This study employed advanced chemometrics models, including principal component analysis (PCA) and orthogonal projections to latent structures (OPLS) in determining the solvent extraction (among methanol, ethanol, acetone and water) that will yield optimum antioxidant and ellagitannins profiles from “Wonderful” pomegranate peel. Acetone extraction had the highest (p ˂ 0.05) total phenol (TFC) and flavonoid contents and strongest (p ˂ 0.05) Fe3+ reducing effect, while methanol extraction had the strongest (p ˂ 0.05) radical scavenging activity. The oxygen radical absorbance capacity (ORAC) and anti-lipid peroxidative activities of both solvent extractions outperformed that of the ethanol and water extractions. Tannins purified using Amberlite® XAD16N resin were highest for acetone and methanol extractions. LCMS-quantified ellagitannins in the tannins varied for the different extractions. PCA and OPLS models adequately characterized, described and predicted the variation and patterns in the antioxidant and ellagitannins datasets (up to 95% for PCA). OPLS bi-plot showed that the high ellagic acid constituents and total tannins yield of the methanol extraction influenced its potent radical scavenging activity, while the ellagitannin constituents including punicalagins, granatin A, geraniin and casuarinin influenced the high TFC, as well as the potent Fe3+ reducing, ORAC and anti-lipid peroxidative activities of acetone extraction. Acetone and methanol extraction of pomegranate peel are promising for optimum ellagitannins recovery and antioxidant profile.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pomegranate fruit is well recognized for its benefits on oxidative and cardiovascular health [1]. It, also, has antibacterial, anti-diabetic, anti-atherosclerotic, anti-inflammatory and anti-allergic potentials [1]. These medicinal properties can be attributed to the fruit's many secondary metabolites—the most significant being the ellagitannins (punicalagin and ellagic acid), as well as other polyphenols like flavonoids, anthocyanidins, flavonones, catechins and phenolic acids [2,3,4]. These phenolic compounds account for up to 92% of the fruits antioxidant property and are mostly concentrated in the fruit peel and juice compared to other parts of the fruit [5, 6]. Evidence of the radical scavenging property of pomegranate peel has been documented [3] and in some cases was stronger than that of the pulp [7]. In rats the peel improved antioxidant status, thus protecting against hepatic oxidative damage caused by tetrachloromethane [8].

The rising fruit production and commercialization of pomegranate causes accumulation of the fruit’s wastes, particularly the peels [9]. To avoid wastage, reduce environmental biomass and maximize the therapeutic potential of the fruit’s wastes, the fruit's peel has been researched as a possible source of antioxidants [3, 4, 7, 8, 10]. The results offer a justification for the potential relevance of the peel in managing oxidative stress and insults.

Several solvent extracts have been explored for extracting phytoconstituents with promising antioxidant and other bioactivity profiles from pomegranate peel. This is because solvent polarity largely influences the type of compounds extracted from a plant material, which consequently influences the antioxidant and other bioactivity profiles of the resulting extracts [1]. Previous data have shown that the type of solvent extraction strongly influences the chemical and antioxidant profiles of pomegranate fruit peel extracts [3, 4, 7, 8, 10]. However, these studies lack a proper statistical correlation between the extraction solvent, phytochemistry and antioxidant activity. The studies lack statistical validation to determine the influence of the solvent extraction on the phytochemical and antioxidant profile of pomegranate peel extracts. Thus, may not be able to ascertain the solvent extraction for optimum recovery of antioxidant ellagitannins from pomegranate peel. Therefore, this study was done to determine the effect of different solvent extraction on the antioxidant and phytochemical profiles of ellagitannins from pomegranate peel using advanced chemometrics analyses. This will potentially provide a more reliable information regarding what extraction solvent system will facilitate optimum recovery of antioxidant ellagitannins from pomegranate peel.

Materials and methods

Fruit procurement and removal of peel

Class 1 (processing grade) “Wonderful” variety of pomegranate fruits were procured from Sonlia Marketing, a subsidiary of Sonlia Fruit Packhouse (Wellington, Western Cape Province, South Africa) on 03 May 2021. The fruits were washed, and the peel was thoroughly removed. The fruit peel was dried at 37 °C until all the moisture were completely removed and a constant dry weight was attained.

Preparation of dried peel and solvent extraction

The dried peel was pulverized using a Kinematica POLYMIX® PX-MFC 90 D milling machine equipped with a blade grinding attachment [Lasec (Pty) Ltd, Cape Town, South Africa]. About 250 g of the pulverized dried peel was separately extracted using 1 L of methanol, ethanol, acetone and water. The extraction was done at room temperature on an orbital shaker [OrbiShake, Model 262, Labotec (Pty) Ltd, Johannesburg, South Africa] set at 125 rpm for 72 h. The fruit peel debris was removed by filtering with a filter paper. The filtrate of the organic extracts was concentrated using a Buchi Rotavapor® R-300 [Labotec (Pty) Ltd, Johannesburg, South Africa] and dried under a fume hood. The filtrate of the water extract was dried using a Martin Christ Alpha 1–2 LDplus Freeze Dryer (Separations, Johannesburg, South Africa). The recovered extracts were stored in air-tight vials at – 20 °C until they were used.

Total phenol and total flavonoid contents measurement in extracts

The total phenol content (TPC) and total flavonoid content (TFC) of the extracts were measured using a previously reported protocol [10] and expressed as mg/g gallic acid equivalent (GAE) and mg/g quercetin equivalent (QE), respectively. The extracts were tested at 45 µg/mL.

Antioxidant analyses

The antioxidant effect of the extracts was analysed at 45 µg/mL using the following in vitro and cell-based experimental models described below. The activity of the extracts was compared to an equivalent concentration of the positive controls (ascorbic acid and Trolox) or standard phytoconstituents (punicalagin A + B and ellagic acid).

Radical scavenging action

The 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical and 2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonic acid) radical (ABTS* +) scavenging effects of the extracts were determined using methods described in a previous report [11] and expressed as percentage radical scavenging activity.

Oxygen radical absorbance capacity (ORAC) assay

A previous method [12] was slightly modified to perform this assay. The assay was performed in a clear bottom opaque/black 96-well plate. A 0.112 μM fluorescein sodium salt solution and 152.66 mM 2,2′-Azobis(2-methylpropionamidine) dihydrochloride (AAPH) solution were prepared using a 75 mM potassium phosphate buffer (pH 7.3). Twenty-five microlitres of the samples or the positive control (ascorbic acid) or the standards (punicalagin A + B and ellagic acid) at the tested concentration (45 µg/mL in assay volume) or their solvents (controls) was added into the wells of the plate. Next, 150 μL of the fluorescein sodium salt solution was added to the wells and the plate was incubated at 37 °C for 30 min. After incubation, 25 μL of the AAPH solution was added to the wells and the fluorescence (Excitation/Emission wavelength = 490 nm/515 nm) was immediately measured at 1 min interval for 35 min using a SpectraMax M2 microplate reader (Molecular Devices, San Jose, CA, USA) set at 37 °C. The time intervals (x-axis) were plotted against their corresponding fluorescent reading (y-axis) and the slope of the plot was computed from a linear regression. The positive version of the slopes was used to compute the ORAC of the tested samples (extracts, positive control and standards) using the following formula:

Fe3+ reducing activity

A previous method [11] was slightly modified to perform this assay. First, 25 μL of the tested samples or positive controls (ascorbic and Trolox) (45 μg/mL in reaction mixture) or increasing concentrations (3.75–60 μg/mL in reaction mixture) of gallic acid standard, 25 μL of 0.2 M phosphate buffer (pH 6.6) and 25 μL of 1% potassium ferricyanide were mixed in the wells of a 96-well clear bottom plate. The mixture was incubated for 20 min at 50 ˚C, before successively adding, 25 μL of 10% trichloroacetic acid, 100 μL of distilled water and 50 μL of 0.1% FeCl3 solution. Thereafter, absorbance was measured at 700 nm and blanked with the sample blank. The Fe3+ reducing activity was determined from a gallic acid standard curve and computed as mg/g equivalent of the gallic acid (mg/g GAE) using the following formula:

where, “C” is the concentration (mg/mL) extrapolated from gallic acid standard curve; “SV” is the sample volume (mL), and “M” is the amount (g) of the sample in the “SV” (mL) of the sample solution; “GAE” means “gallic acid equivalent”.

Measurement of inhibitory action on FeSO4-induced linoleic acid peroxidation in vitro

To perform this assay, the method reported by Ramorobi et al. (2022) [13], which was modified from the method reported by Choi et al. (2002) [14] was adopted.

Measurement of inhibitory action on FeSO4-induced lipid peroxidation in Chang liver cells

The protocol reported previously [4] was slightly modified to perform this assay. First, Chang liver cells (ATCC® CCL-13™, ATCC, Virginia, USA) were grown in an EMEM media, which contained 10% FBS. When the cell confluence reached 85%, the cells were trypsinized and plated into a 96-well plate with 200 µL aliquot of the culturing medium. The cell density in each well of the plate was about 8000 cells. The plate was incubated for 36 h in a CO2 incubator (NÜVE EC 160, Ankara, Turkey) set at 5% CO2 supply and 37 °C temperature, during which the cells attached to the plate. After the incubation, the medium in the wells was removed by aspiration. Thereafter, the tested samples were dissolved in fresh culturing medium, which was added to designated wells of the plate. The tested samples or the positive controls (ascorbic acid and Trolox) or the standards (punicalagin A + B and ellagic acid) were added to wells at the tested concentration concentration (45 µg/mL in the incubation medium). Some wells were assigned as the control and negative control, which contained the solvent (water or 0.5% DMSO) used in dissolving the tested samples. The plate was incubated for 30 min. Thereafter, 50 µL of FeSO4.7H2O solution (1 mM in incubation medium) was aliquoted into the wells containing the tested samples and the wells that were assigned as the negative control to initiate oxidative stress. An equivalent volume of distilled water was aliquoted into the wells that were assigned as the control. Immediately, the plate was put into the CO2 incubator and kept there for 1 h. Thereafter, the medium in the wells was removed by aspiration and replaced with 250 µL of cold lysis buffer (50 mM sodium phosphate buffer with 0.5% v/v Triton X-100, pH 7.5). A gentle agitation was applied to lyse the cells in the wells. Next, the plate was immediately centrifuged for 1 min at 5000 g and 4 °C to pellet the cell debris. The supernatant was quickly collected and kept on ice. Immediately, lipid peroxidation was measured in the supernatant as described below.

Approximately 100 µL of the supernatant or malondialdehyde standards (0, 7.5, 15, 22.5, 30, and 45 μM in the assay volume) was put into designated vials. Next, 0.25% w/v thiobarbituric acid, 20% v/v acetic acid, and distilled water were aliquoted into the vials at a volume ratio of 500 µL:200 µL:200 µL, respectively. A boiling water bath was then used to heat all the vials for 50 min. After heating, the vials were cooled under room temperature and centrifuged for 10 min at 3500 g and ambient temperature. Two hundred microlitres of the supernatant in each vial was aliquoted into a 96-well plate and absorbance was read at 532 nm. A malondialdehyde standard curve was used to compute the lipid peroxidation, which was estimated as thiobarbituric acid reactive substances. The inhibitory activity (%) of the tested samples on lipid peroxidation was calculated as follows:

where, “E” means “Extrapolated equivalent malondialdehyde concentration".

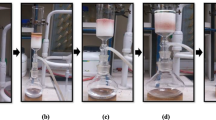

Crude recovery of tannins from extracts

Tannins were recovered from the extracts using an Amberlite® XAD16N resin (product code: XAD16; Sigma Aldrich, Johannesburg, South Africa) according to a protocol slightly modified from a previous article [15]. First 1.52 g of the extracts was dissolved in 100 mL of distilled water and filtered with a filter paper. The filtrate was collected as a yellowish-brown liquid (Fig. 1a). Approximately 35 g of the XAD16N resin was first washed trice with methanol and then equilibrated with distilled water in a sealed flash column for 12 h (Fig. 1b). After the 12 h equilibration, the flash column was connected to a water jet vacuum pump and the distilled water was completely removed using the water jet vacuum pump. Next, the extract solution was gradually loaded onto the XAD16N resin in the flash column (Fig. 1c). The column was continuously eluted with distilled water using the water jet vacuum pump until the eluent consistently remained colourless and all the tannins in the extract were trapped in the XAD16N resin (Fig. 1d). The column was vacuum aspirated to dry up the remaining water. Next the trapped ellagitannins/tannins were gradually eluted using methanol (Figs. 1e – h). The eluent was air-dried in a fume hood. The recovered tannins fractions were weighed, and the percentage yield was computed using the formula below. The fractions were stored at -20 OC until further analysis.

Liquid chromatography—mass spectroscopic (LCMS) quantification of ellagitannins

The LCMS analysis was done using a Waters Synapt G2 (Waters Corporation, MA, USA), ESI probe, ESI Pos, Cone Voltage 15 V. Liquid chromatography was operated with an Acquity binary solvent manager. A HSS T3 column with dimension of 2.1 × 150 mm and particle size of 1.8 µm (Waters Corporation, MA, USA) was used for chromatographic separation. The mobile phase was made up of A (0.1% formic acid in HPLC grade water) and B (0.1% formic acid in HPLC grade acetonitrile) solvents. The flow rate for mobile phase was 0.25 mL/min. A gradient chromatographic condition was applied as follows: 100% of A and 0% of B for 10 min; then 72% of A and 28% of B for 21 min; then 60% of A and 40% of B for 50 s; then 0% of A and 100% of B for 2 min. Chromatographic separation was done at 30 °C. Samples were reconstituted in 1 mL of 50%:50% acetonitrile and water, centrifuged at 14,000 rpm for 5 min and filtered using a 0.22 µm filter. A 20 μL injection volume was applied. A UV wavelength of 254 nm was used to record the chromatographic signals. Puniculagin A, punicalagin B and ellagic acid in the ellagitannins fraction were identified and quantified from calibration curves established using a range of calibration standards prepared from stock solutions of Puniculagin A + B (product code: PHL80524, Sigma Aldrich, Johannesburg, South Africa) and ellagic acid (product code: 14,668, Sigma Aldrich, Johannesburg, South Africa). The other compounds (granatin A, corilagin, casuarinin, geraniin and quercetin hexoside) in the tannins fractions were identified and quantified in a relative fashion against ellagic acid. They were identified based on accurate mass elemental composition and quantified using extracted ion chromatography against ellagic acid. The quantification was presented as a triplicate analysis.

Statistical analysis

Statistical analysis was done on the Window’s version 27.0 of IBM SPSS (IBM Corp, Armonk, NY, USA). Multiple comparison of data averages among the groups (extracts or standards) was done for the different studied parameters using the Tukey multiple post hoc test and one-way analysis of variance (ANOVA). Statistically significant difference (p) was set at p < 0.05 when comparing the mean values of the different groups.

Advanced chemometrics analysis

Advanced chemometrics models were employed to scrutinize the data to extract maximum useful information and interpret the patterns and distribution in the data. Principal component analysis (PCA) and orthogonal projections to latent structures (OPLS) were performed using SIMCA-P + 16.0 software (Umetrics, MKS Instruments Inc., Sweden) as described by Gbashi et al. (2020) [16]. Prior to PCA and OPLS analysis, the data were mean-centered, and Unit-Variance scaled since both PCA and OPLS are sensitive to the scale of the input variables. Further, for OPLS, the data were classified into X variable (i.e., predictors) and Y variables (i.e., responses). The X variables are the independent predictors, which included ellagitannins or total tannins yield, punicalagin A, punicalagin B, ellagic acid, granatin A, corilagin, casuarinin, geraniin and quercetin hexoside. These are essentially the extracted components/metabolites from the peel biomass present in the solvent extracts. The Y variables consisted of the various investigated antioxidant assays, namely TPC, TFC, Fe3+ reducing activity (FRAP), DPPH and ABTS radical scavenging activity, oxygen radical absorbance capacity (ORAC), in vitro anti-linoleic acid peroxidation and anti-lipid peroxidation in Chang liver cells. Class labels were accordingly assigned to the observations for extracts obtained from the various extraction solvents, namely methanol, ethanol, water, and acetone. This was crucial because OPLS is a supervised model and requires information about observation classes in order to learn the patterns in the data. This essentially enables the algorithm to better approximate the relationships in the data and improve the interpretability and predictive capability of the model.

Model fit evaluation and validation was performed by assessing various modelling diagnostic parameters such as R2X (fraction of explained X variation in the component using the X model), R2X(cum) (combined fractions of X variation modelled up to the specified component using the X model), R2Y (fraction of explained Y variation in the component using the Y model), R2Y(cum) (combined fractions of Y variation modelled up to the specified component using the Y model), R2 (fraction Y variation modelled by the X model in the component), R2(cum) (cumulative fractions of explained variation in the Y data using the X model up to the specified component). The coefficient of determination (R2), root mean square error of estimation (RMSEE), and root-mean-standard error for cross-validation (RMSECV) for the observed versus predicted values of the response variables were also evaluated. The statistical significances of model components were determined based on Rule 1 (R1), Rule 2 (R2), or Rule 3 (R3). For R1, a component is considered significant when Q2 > Limit. For R2, a component is significant if Q2V > Limit. For R3, in terms of PCA, a component is labeled undecided (U) when it is insignificant. However, if the subsequent component is significant and has similar eigenvalues (tolerance of 5%) as the previous component, then both components are considered significant, and the component labeled undecided is re-labeled R5. The specific calculations and determinations of the Limits for both PCA and OPLS, as well as a description of the model validation parameters are described in the SIMCA® manual [17].

Results

Total phenol and total flavonoid contents

The total phenol content (TFC) of the acetone extract was significantly (p ˂ 0.05) higher than that of the other extracts (Fig. 2a). The ethanol extract had the least TFC, which was significantly (p ˂ 0.05) lower than that of the methanol and water extracts. The total flavonoid content of the acetone extract was more than 2 folds compared to that of the other extracts (Fig. 2b).

Fe3+ reducing and radical scavenging antioxidant properties

Although not as potent as ascorbic acid, the Fe3+ reducing activity of the acetone extract was significantly (p ˂ 0.05) stronger than that of Trolox, as well as the other extracts (methanol, ethanol and water extracts) (Fig. 3a). The methanol and water extracts, however, outperformed the ethanol extracts.

a Fe3+ reducing, b DPPH and ABTS radicals scavenging and c oxygen radical absorbance antioxidant capacities of the different solvent extracts. Data are presented as mean ± SD of triplicate analysis. For each assay, the letters at the top of the bars represent significant differences (p < 0.05) between groups, when there are no similar letters

The DPPH radical scavenging activity of the methanol extract was statistically comparable to that of ascorbic acid and Trolox (Fig. 3b) and significantly (p ˂ 0.05) stronger than the activities of the other extracts. The ethanol extract had the least potent DPPH radical scavenging activity, which was significantly (p ˂ 0.05) less potent than that of the methanol and water extracts. The ABTS radical scavenging activity of the extracts followed similar trend as their DPPH radical scavenging activity (Fig. 3b).

The oxygen radical absorbance capacity (ORAC) of the acetone and methanol extracts was notably stronger than that of the other extracts and statistically comparable to the activity of ellagic acid and punicalagin A + B standards. Among all the extracts, the acetone extracts had the most potent ORAC.

Anti-lipid peroxidative antioxidant properties

The ability of the extracts to inhibit linoleic acid peroxidation in vitro (Fig. 4a) and lipid peroxidation in Chang liver cells (Fig. 4b) is shown in Fig. 4. The acetone and methanol extracts were the most potent among the extracts. Their activity was statistically comparable to that of ascorbic acid, Trolox, ellagic acid and punicalagin A + B standards.

Inhibitory effect of the solvent extracts on a in vitro linoleic acid peroxidation and b lipid peroxidation in Chang liver cells. Data are presented as mean ± SD of triplicate analysis. For each assay, the letters at the top of the bars represent significant differences (p < 0.05) between groups, when there are no similar letters

Total tannin yields and ellagitannins phytochemical profile

The yield of total tannins from the extracts is presented in Table 1. The yield from the methanol and acetone extracts was significantly higher than that of the ethanol and water extracts, with the ethanol extract having the least yield. LCMS-quantified phytochemicals included punicalagin A, punicalagin B, ellagic acid, granatin A, corilagin, casuarinin, geraniin and quercetin hexoside (Table 1 and supplementary material). The ellagitannin constituents in the above mentioned phytochemicals were more mostly predominant in the acetone extracts compared to the other extracts, and in some case, significantly (p ˂ 0.05).

Advanced chemometrics analysis

The PCA scores plot showed a clear clustering pattern of the various observation classes in the data (Fig. 5a). A total of five principal components were generated from the analysis, with the first two components describing 73% of the patterns in the data (PC1 = 41.7%, PC2 = 31.3%) and predicting 53.9% of the variation in the data by cross-validation (Table 2). Overall, the five components of the PCA model could explain up to 95.4% of the variation in the obtained data (Table 2).

a Scores plot of unsupervised linear transformation and multivariate dimensional reduction analysis of the data (PCA), b scores plot of supervised linear transformation, dimensionality reduction, and modelling of the patterns in the data (OPLS) and c OPLS biplot showing the clustering of sample classes and spatial distribution the X and Y variables

The OPLS scores plot (Fig. 5b) showed distinct grouping patterns for all observation classes. On the OPLS biplot (Fig. 5c), the predictors (i.e., X variables) are coloured purple and the responses (i.e., Y variables) are coloured black. The grouping patterns on this plot showed the closeness of the water and ethanol extracts (Figs. 5a and c), indicating the inherent similarities of these two groups of samples. Also, it can be seen that acetone was very distinct from the other three classes. Further, it can be deduced from this plot that ABTS and DPPH radical scavenging properties were the strongest Y variables contributing to the differential clustering of the methanol extracts compared to the other extracts. TFC had the highest influence on the differential clustering of the acetone extracts. TPC, FRAP and in vitro anti-linoleic acid peroxidation also strongly contributed to the spatial distribution of acetone extracts. None of the variables were distributed close to the ethanol and water class along PC1 axis (i.e., x-axis). Also, none of the variables were located within the same quadrant with the two sample classes (water and ethanol). The biplot showed a clustered grouping of TFC and a number of predictors including granatin A, geraniin, casuarinin, punicalagin A, quercetin hexoside and punicalagin B. This cluster was also in and around the acetone sample class. It can also be deduced from Fig. 5c that ABTS and DPPH bioactivities are strongly linked to the presence of ellagic acid, corilagin and tannin yield. The phytochemical content in the water and ethanol extracts appeared not to potently influence their bioactivity (Table 1 and Fig. 5c).

The HCA dendrogram (Fig. 6a) identifies groupings of similar sample classes, where observations in a cluster are more similar than those in separate clusters. Thus, in terms of similarity of the extraction solvents (in the context of tannins recovery, ellagitannins profile and antioxidant properties), the HCA dendrogram indicates that water extracts were more similar to ethanol extracts, which was more similar to methanol extracts, which was in turn the closest to acetone extracts. A pattern which is also corroborated on the PCA and OPLS scores plots, as well as the OPLS biplot.

Indeed, there exist an empirical relationship between extracted compounds and the bioactivities of the respective extracts, a phenomenon well-captured by the OPLS analysis as it reveals that the X model could predict up to 62.3% of the patterns in the response variables (Table 3). The variable contributions plot (Fig. 6b) for TPC show that ellagic acid, granatin A, geraniin and corilagin appeared to be the strongest predictors of TPC and TFC. It appeared that ellagic acid had the highest effect on FRAP, DPPH, ABTS, ORAC and cellular anti-lipid peroxidation (Fig. 6b). Total tannins yield had the strongest impact on in vitro anti-linoleic acid peroxidation followed closely by ellagic acid and corilagin. Overall, punicalagin A, geraniin and punicalagin B were the most important variables (in descending order) in the construction of the OPLS model and description of the patterns in the entire dataset (Fig. 6c).

Model overview, evaluation, and validation

It is important to validate any fitted model in order to ascertain its adequacy, efficiency and predictive ability, where applicable. The goodness-of-fit, goodness-of-prediction and other relevant model fit parameters for the PCA and OPLS models are presented in (Tables 2 and 3). Model fit diagnostics show that all PCA and OPLS generated components were significant (Tables 2 and 3). The OPLS algorithm generated a total of 3 PCs from the dataset and could describe over 80% of the variation in the X data [R2X(cum) = 0.804] and 86.2% of the variation in the Y data [R2(cum) = 0.862]. The first two components had a R2X(cum) value of 62.5%, R2(cum) value of 82.0%, R2Y value of 89% and Q2(cum) value of 53.3%. The Y model described 94.9% of the variation in the response variables (R2Y = 0.949). The goodness-of-prediction parameter Q2(cum) indicated a predictive capability of 62.8% for the model, i.e., the X model had a cumulative prediction accuracy of approximately 63% based on cross-validation. Interestingly, the fractions of Y variation predicted by the X model in components 2 and 3 (PC2 and PC3) were higher (Q2 49.7 and 9.6%, respectively) than that of PC1 (Q2 3.6%). Results of regression of observations versus the corresponding predictions using the X model for each response variable were as follows: TPC (R2: 0.87, RMSEE: 43.62, RMSECV: 64.33), TFC (R2: 0.85, RMSEE: 2.67, RMSECV: 3.11), FRAP (R2: 0.88, RMSEE: 16.33, RMSECV: 25.12), DPPH (R2: 0.90, RMSEE: 5.58, RMSECV: 8.36), ABTS (R2: 0.95, RMSEE: 4.08, RMSECV: 6.47), ORAC (R2: 0.77, RMSEE: 6.68, RMSECV: 9.38), in vitro anti-linoleic acid peroxidation (R2: 0.82, RMSEE: 6.21, RMSECV: 6.67) and cellular anti-lipid peroxidation (R2: 0.86, RMSEE: 4.32, RMSECV: 5.08).

Discussion

The peel of pomegranate has been shown to have a rich phytochemical profile, which could be of medicinal relevance if not wasted. Ellagitannins are the predominant tannins present in the peel of pomegranate, which have been documented to have medicinal relevance [3]. Different studies have explored different extraction solvents to maximize recovery of the bioactive phytochemicals in pomegranate peel but lack a proper statistical correlation between the extraction solvent, phytochemistry and bioactivity. The present study used advanced chemometric models to correlate between the solvent extraction used, bioactivity and ellagitannins recovery from the peel of “Wonderful” variety pomegranate, with the aim of ascertaining the extraction solvent that will optimally recover antioxidant ellagitannins.

Data showed that the acetone extracts had the highest TPC and TFC (Fig. 2), which could be attributed to its suitable polarity for extracting polyphenols and flavonoids [18]. The methanol extracts also had an appreciable TPC content, which is linked to its compatible polarity with polyphenols. The TPC and TFC of these extracts may be partly influential in their potent radical scavenging/quenching effects (Fig. 3). This is due to the ability of polyphenols to form stable phenoxy radicals by donating electron or transferring hydrogen atom, which are able to react with and quench the deleterious effects of other radicals [19]. In both in vitro and Chang liver cells experimental models, the acetone and methanol extracts outperformed the ethanol and water extracts in inhibiting FeSO4-induced linoleic acid or lipid peroxidation (Fig. 4). Their potent effects may be attributed to their rich tannins yield, which also had higher constituents of ellagic acid and punicalagin A/B (Figure Table 1) relative to the other extracts. Moreover, these constituents also demonstrated appreciable anti-lipid peroxidative effects (Fig. 4), while ellagitannin-rich dietary supplement from pomegranate, as well as ellagic acid have be shown to have potent anti-lipid peroxidative activity in obese animals [20] and human subjects [21].

PCA and OPLS are advanced dimensionality reduction algorithms that emphasize differences or similarities between data observations by constructing a smaller number of interpretable, linearly uncorrelated variables [latent variables or principle components (PCs)] from the dataset [16, 22]. In order to detect any outliers and have a global appraisal and overview of the inherent patterns in the dataset without any reference to pre-assigned observation class labels, PCA was performed. Overall, the five components of the PCA model could explain up to 95.4% of the variation in the obtained data (Table 2). OPLS was further adopted to scrutinize the data for inherent discriminatory patterns since it is a supervised learning algorithm and can aggressively differentiate between sample groups following training on the labelled data. Clearly distinct grouping patterns were observed for all the observation classes (Figs. 5a and b; Table 3).

The biplot combines the information from the scores plot with information from the loadings plot, thus further elucidating information on data distribution patterns, observation classes and variable relationships. The distinct distribution of the acetone extract (Fig. 5c) suggests that extracts from this solvent performed uniquely in terms of the monitored parameters (i.e., X and Y variables). The differential clustering of the acetone extracts was influenced by its anti-lipid peroxidative and ORAC activities, which can be attributed to its higher TFC, TPC and ellagitannin constituents (punicalagin, granatin A, geraniin and casuarinin) (Fig. 5c). Ellagic appears to be most influencing component influencing the remarkable radical scavenging effect of the methanol extract, which further influenced it distribution in the biplot (Fig. 5c). The high tannins yield, as well as some key ellagitannins constituents, such as ellagic acid and corilagin appear as the most predominant components influencing the antioxidant effects of the extracts (Fig. 6b). Moreover, the higher tannins yield and ellagitannins composition of the acetone and methanol extract (Table 1) correlates with the stronger antioxidant profiles of these extracts compared to that of the water and ethanol extracts (Figs. 3 and 4).

It is important to note that the computed values obtained from the evaluation and validation of the advanced chemometrics models indicate strong linearity and correlation between the predicted and observed values and demonstrate a good predictability of the response variables by the model. Therefore, it can be said that the OPLS model was able to adequately characterize, describe, and predict the variation and patterns in the dataset.

Conclusion

It can be concluded that the ethanol and water extracts overall had lower yield of total tannins and contained lower amounts of key influencing ellagitannins, particularly, ellagic acid and corilagin, which are located the furthest away from these observation classes on the biplot. Consequently, ethanol and water extracts nominally possessed the least bioactivities of the solvent extracts. It can be deduced from the biplot that tannins crudely purified from the acetone extracts nominally contained the highest amounts of most of the ellagitannins and thus showed the highest bioactivity of all the solvent extracts. Methanol extracts also, had promising bioactivity, which may be largely influenced by the high ellagic acid content in the tannins purified from it. It is, however, important to note that there may be other phytochemicals influencing the antioxidant capacities of the acetone and methanol extracts, which have not been profiled in the present study. In the context of ellagitannins from pomegranate peel, acetone and methanol solvent extraction may be promising for optimum ellagitannins recovery and antioxidant profile.

Data Availability

The data of this study is available from the corresponding author on request.

References

Singh M, Jha A, Kumar A, Hettiarachchy N, Rai AK (2014) Sharma D (2014) Influence of the solvents on the extraction of major phenolic compounds (punicalagin, ellagic acid and gallic acid) and their antioxidant activities in pomegranate aril. J Food Sci Technol 51(9):2070–2077. https://doi.org/10.1007/s13197-014-1267-0

Qua W, Breksa AP, Pan Z, Ma H (2021) Quantitative determination of major polyphenol constituents in pomegranate products. Food Chem 132:1585–1591. https://doi.org/10.1016/j.foodchem.2011.11.106

Middha SK, Usha T, Pande V (2013) HPLC evaluation of phenolic profile, nutritive content, and antioxidant capacity of extracts obtained from Punica granatum fruit peel. Adv Pharmacol Sci 2013:296236. https://doi.org/10.1155/2013/296236

Akuru EA, Chukwuma CI, Oyeagu CE, Erukainure OL, Mashile B, Setlhodi R, Mashele SS, Makhafola TJ, Unuofin JO, Abifarin TO, Mpendulo TC (2022) Nutritional and phytochemical profile of pomegranate (“wonderful variety”) peel and its effects on hepatic oxidative stress and metabolic alterations. J Food Biochem 46(4):e13913. https://doi.org/10.1111/jfbc.13913

Ismail T, Sestili P, Akhtar S (2012) Pomegranate peel and fruit extracts: a review of potential anti-inflammatory and anti-infective effects. J Ethnopharmacol 143(2):397–405. https://doi.org/10.1016/j.jep.2012.07.004

Yaritz U, Schweitzer R, Holland D, Tian L, Amir R (2022) Metabolic profiling of outer fruit peels from 15 accessions of pomegranate (Punica granatum L.). J Food Compos Anal. https://doi.org/10.1016/j.jfca.2022.104482

Li Y, Guo C, Yang J, Wei J, Xu J, Cheng S (2006) Evaluation of antioxidant properties of pomegranate peel extract in comparison with pomegranate pulp extract. Food Chem 96(2):254–260. https://doi.org/10.1016/j.foodchem.2005.02.033

Chidambara Murthy KN, Jayaprakasha GK, Singh RP (2002) Studies on antioxidant activity of pomegranate (Punica granatum) peel extract using in vivo models. J Agric Food Chem 50(17):4791–4795. https://doi.org/10.1021/jf0255735

Bertolo MRV, Martins VCA, Plepis AMG, Bogusz S (2021) Utilization of pomegranate peel waste: Natural deep eutectic solvents as a green strategy to recover valuable phenolic compounds. J Clean Prod 327:129471. https://doi.org/10.1016/j.jclepro.2021.129471

Chukwuma CI, Mashele SS, Akuru EA (2020) Evaluation of the in vitro ⍺-amylase inhibitory, antiglycation, and antioxidant properties of Punica granatum L. (pomegranate) fruit peel acetone extract and its effect on glucose uptake and oxidative stress in hepatocytes. J Food Biochem 44(5):e13175. https://doi.org/10.1111/jfbc.13175

Chukwuma CI, Mashele SS, Swain SS (2021) Antidiabetic and antioxidative properties of novel Zn(II)-cinnamic acid complex. Med Chem 17(8):913–925. https://doi.org/10.2174/1573406416666200929143257

Ou B, Chang T, Huang D, Prior RL (2013) Determination of total antioxidant capacity by oxygen radical absorbance capacity (ORAC) using fluorescein as the fluorescence probe: First Action 2012.23. J AOAC Int 96(6):1372–1376. https://doi.org/10.5740/jaoacint.13-175

Ramorobi LM, Matowane GR, Mashele SS, Swain SS, Makhafola TJ, Mfengwana PH, Chukwuma CI (2022) Zinc(II) - Syringic acid complexation synergistically exerts antioxidant action and modulates glucose uptake and utilization in L-6 myotubes and rat muscle tissue. Biomed Pharmacother 154:113600. https://doi.org/10.1016/j.biopha.2022.113600

Choi CW, Kim SC, Hwang SS, Choi BK, Ahn HJ, Lee MY, Park SH, Kim SK (2002) Antioxidant activity and free radical scavenging capacity between Korean medicinal plants and flavonoids by assay-guided comparison. Plant Sci 163(6):1161–1168. https://doi.org/10.1016/S0168-9452(02)00332-1

Seeram N, Lee R, Hardy M, Heber D (2005) Rapid large-scale purification of ellagitannins from pomegranate husk, a by-product of the commercial juice industry. Sep Purif Technol 41(1):49–55. https://doi.org/10.1016/j.seppur.2004.04.003

Gbashi S, Njobeh PB, Madala NE, De Boevre M, Kagot V, De Saeger S (2020) Parallel validation of a green-solvent extraction method and quantitative estimation of multi-mycotoxins in staple cereals using LC-MS/MS. Sci Rep 10(1):1–16. https://doi.org/10.1038/s41598-020-66787-z

Sartorius Stedim. (2018). SIMCA® - SIMCA® 15 user guide. Sweden: Sartorius Stedim Data Analytics AB. Retrieved from https://www.sartorius.com/download/544940/simca-15-user-guide-en-b-00076-sartorius-data.pdf (accessed 11 December 2022).

Tsao R (2010) Chemistry and biochemistry of dietary polyphenols. Nutrients 2(12):1231–1246. https://doi.org/10.3390/nu2121231

Platzer M, Kiese S, Tybussek T, Herfellner T, Schneider F, Schweiggert-Weisz U, Eisner P (2022) Radical scavenging mechanisms of phenolic compounds: a quantitative structure-property relationship (QSPR) study. Front Nutr 9:882458. https://doi.org/10.3389/fnut.2022.882458

Xu Q, Li S, Tang W, Yan J, Wei X, Zhou M, Diao H (2021) The effect of ellagic acid on hepatic lipid metabolism and antioxidant activity in mice. Front Physiol 12:751501. https://doi.org/10.3389/fphys.2021.751501

Heber D, Seeram NP, Wyatt H, Henning SM, Zhang Y, Ogden LG, Dreher M, Hill JO (2007) Safety and antioxidant activity of a pomegranate ellagitannin-enriched polyphenol dietary supplement in overweight individuals with increased waist size. J Agric Food Chem 55(24):10050–10054. https://doi.org/10.1021/jf071689v

Worley B, Powers R (2013) Multivariate analysis in metabolomics. Curr. Metabolomics 1:92–107. https://doi.org/10.2174/2213235X11301010092

Funding

The study was funded by the postgraduate scholarship (reference: MND210530604823) and Thuthuka grant (reference: 129865) of the National Research Foundation, South Africa.

Author information

Authors and Affiliations

Contributions

Conceptualization: CIC; Data curation: RS, BM, GOI; Funding acquisition: CIC; Methodology: RS, BM, GOI, SG, SSM, SLB, TJM and CIC; Resources: SSM, TJM and CIC; Software: SG, SLB and CIC; Supervision: SSM and CIC; Formal analysis: RS, BM, GOI, SG and CIC; Writing—original draft: RS; Writing—review & editing: BM, GOI, SG, SSM, SLB, TJM and CIC.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest with this work.

Compliance with Ethics requirements

This article complies with the applicable ethics requirements.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Setlhodi, R., Mashile, B., Izu, G.O. et al. Effect of solvent extraction on the antioxidant and phytochemical profiles of ellagitannins from “wonderful” pomegranate peel: an advanced chemometrics analysis. Eur Food Res Technol 249, 1807–1820 (2023). https://doi.org/10.1007/s00217-023-04255-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04255-4