Abstract

Wine contains a multitude of volatile and non-volatile compounds. The sensory characteristics of wine are strongly influenced by the volatile aromas. In this study, we used headspace solid-phase micro-extraction (HS-SPME) and gas chromatography mass spectrometry (GC–MS) to analyze the Cabernet Sauvignon Grape samples obtained from Ningxia (China) processed by drying, winemaking, and aging, respectively. Thirty-seven compounds that significantly influenced the wine aroma characteristics were analyzed quantitatively. Results showed a close correlation of grape or wine volatile components with the flavor characteristics. 16, 29, and 32 aroma compounds were characterized during the drying, fermentation, and aging processes, respectively. Drying of Cabernet Sauvignon decreased fruity aromas but enhanced herbaceous and caramel aromas. After fermentation, the aroma component showed substantial increase, with more pronounced caramel, floral, and fruity characteristics in the wine. The aging process decreased the aroma content, but there appeared to be a positive influence on the formation of aging aromas, such as furfuryl alcohol, furfural, and 5-methylfurfural. The aging process not only directly altered the general composition of wine, but also showed a positive influence on sensory properties. These findings shed new light on the mechanism of wine drying, fermentation, and aging process, which can help improve wine characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recent years have witnessed rapid developments in the wine industry to cater to the increasing demand for high-quality fruit wine. Dehydration of grapes is correlated with enhancement of grape flavor, accumulation of sugars, and improved quality of wines [1]. Although, dehydration of grape berry can reduce the wine yield by up to 25–30%, it improves the wine quality and its market value [2]. Dehydration of grapes through high and low temperature alternately leads to increase in anthocyanin concentration and antioxidant activity [3]. Fermentation of a mixture of dehydrated grapes and fresh grapes was shown to rapidly achieve organoleptic harmony and stabilization [5]. Studies have also shown significant differences between the sensory properties of shriveled and non-shriveled berries [4]. Wine makers have discovered that the process of grape dehydration not only decreases the water content in berries, but also increases the aroma compounds and chemical reactions [6, 8]. Moreover, previous studies have shown enhancement of several flavor characteristics during the aging process. In the study by Tomašević et al. [7], the combination of high concentrations of free sulfur dioxide and glutathione was found to slow the decline of aromatic compounds in wines after 12 months of aging. Overall, many studies have separately investigated the effect of drying, fermentation, and aging on aroma compounds. However, systematic study of the changes in aroma characteristics during drying, fermentation, and aging has not been reported.

Recent developments in sorption methods coupled with aroma detection technology such as solid-phase extraction (SPE), headspace solid-phase micro-extraction (HS-SPME), stir-bar sorptive extraction (SBSE) methodologies, Gas Chromatography-Mass Spectrometry (GC–MS), and Liquid Chromatography-Mass Spectrometry (LC–MS) have helped improve the analysis methods and enabled the simultaneous detection of hundreds of metabolites in complex systems [9, 10]. Aroma is considered as one of the most important indicators of the quality of wine. In this context, the detection of aroma presentation in wines offers new opportunities to study the factors that impact on the flavor, quality, and sensory characteristics of wines [11]. Mayr et al. [12] reported a quantitation method for oxidative aromas in aged wines using GC–MS. Jiang et al. [13] identified and quantified a total of 52 and 51 volatile compounds in the Cabernet Sauvignon and Merlot wines, respectively, using SPME-GC/MS. Schueuermann et al. [14] found that the Pinot noir wines vineyard sites can be distinguished through detection of four compounds including β-citronellol, homovanillyl alcohol, N-(3-methylbutyl) acetamide, and N-(2-phenylethyl) acetamide using GC–MS.

Cabernet Sauvignon is the world's most widely planted dark grape varieties. In particular, Cabernet Sauvignon is grown across all warm grape growing regions of the world and has excellent aging potential [15, 17]. China’s main Cabernet Sauvignon appellation is located in the eastern foothills of the Helan Mountains in Ningxia, with a large temperature difference between day and night, strong sunshine, and abundant heat. In consequence, Cabernet Sauvignon grapes produced in this district have the characteristics of luscious flavor, excellent color, and optimal proportion of sugar and acid [16]. However, there is a paucity of published data on the relationship between the changes in aroma compounds and the sensory characteristics of Cabernet sauvignon during drying, fermentation, and aging. Therefore, the purpose of the current study was to systematically detect the changes in volatile aroma of Cabernet Sauvignon grapes in Ningxia, China, during drying, winemaking, and aging process using HS–SPME–GC–MS technology. One novel aspect of this study was that we profiled flavor characteristic changes of Cabernet Sauvignon during various stages of the production process of high-quality dry wine (i.e., drying fermentation, and aging) by testing aromas during the different processes. Our findings may help improve the development of high-quality wine.

Materials and methods

Chemicals

Lafase HE, Zymaflore F15, and Lactoenos 450 PreAC were purchased from LAFFORT (Bordeaux, France); HPLC-grade ethanol, methanol and acetonitrile were purchased from Fisher Scientific (Beijing, China). Standard products (≥ 99%): 3-methyl-1-butanol, 1-octene-3-ol, 1-hexanol, phenylethyl alcohol, benzyl alcohol, cis-3-hexen-1-ol, trans-3-hexen-1-ol,citronellol, decanoic acid ethyl ester, butanedioic acid diethyl ester, octanoic acid ethyl ester, hexanal, phenylacetaldehyde, benzaldehyde, citral (neral and geranial), ethyl phenylacetate, 3-methyl-1-pentanol, ethyl butyrate, isoamyl acetate, 1-heptanol, ethyl caproate, ethyl heptanoate, methyl octanoate, decanoic acid methyl ester, isopentyl hexanoate, ethyl 3-methylbutanoate, beta-damascenone, octanoic acid, linalool, nonanoic acid ethyl ester, 1-nonanol, 1-decanol, hexanoic acid, 3-methylthio-1-propanol, 5-methyl furfural, furfural, and furfuryl alcohol were supplied by Sigma-Aldrich (Castle Hill, NSW/Australia).

Dehydration process

Cabernet Sauvignon grapes were sourced from a commercial vineyard located in Yinchuan (Ningxia, China). Grapes are harvested when the sugar content reaches 208–210 g/L. The ripe grapes were picked and delivered to the winery for immediate processing. Grapes were placed in baskets in groups of five kilos. The baskets and grapes were left to dry naturally in a cool and ventilated place for approximately 12 days. Berry samples for each treatment and replicate were collected every 3 days to determine the glucose and acids. Dried Cabernet Sauvignon wines were produced when the sugar content of the grapes was maintained at 265–275 g/L.

Winemaking

In this experiment, grapes from Ningxia vineyards were used as raw materials. Fresh Cabernet Sauvignon was mechanically destemmed and crushed before transferring into 50 L variable capacity stainless steel tanks. However, the steps in the production of dry Cabernet Sauvignon wines are slightly different. Crushing can only be done when the sugar level in the Cabernet Sauvignon grapes has dropped to 265–275 g/L. The must was added with 0.01% sulfurous acid (Fisher Scientific, Beijing/China) and 0.02 g/L EXV pectinase (Lafford, Bordeaux/France) and soaked in an environment of 10 °C for 12 h. After impregnation, the temperature was raised to 20 °C naturally, and the must was inoculated with 0.2 g/L of Zymaflore F15 (Lafford, Bordeaux/France). Fermentation was carried in a temperature-controlled room to ensure a temperature range of 18–22 °C. The progress of fermentation was regulated every 3 days to measure total reducing sugar content using a PAL-1 Atago refractometer (Atago Inc., Bellevue/WA). When the reducing sugar content had dropped to 4 g/L and remained stable, the alcohol fermentation ended. After fermentation, the original wine was transferred to oak barrels (Seguin Moreau, Maybank/France), respectively. Samples were maintained at 20 ± 2 °C and Lactoenos 450 PreAC (Lafford, Bordeaux/France) was added to allow malolactic fermentation.

Aging process

After fermentation, the Cabernet Sauvignon wine was aged in oak barrels (Seguin Moreau, Maybank/France) for 18 months. After bonding, clarifying, and freezing, the samples obtained from the oak barrels were put in 750 mL glass bottles (BVS Burgundy wine bottle AG056, VinPro/NZ). The samples were bottled at 18–20 °C and aged for 24 months.

Handling of standards

In this study, the external standard method was used to accurately determine the key aroma compounds shared by wine samples analyzed by HS–SPME–GC–MS. The method used in this work was that described by Nie Congning et al. [17] with some modifications. Ethanol was used as a matrix, and equipped with mixed standards of different concentrations first. Then, SPME was used for extraction, and GC–MS was used to analyze the aroma compounds of standers. The concentration of the compound to be quantified in the mixed standard was plotted along the x-axis, and the peak area of the standard was plotted along the y-axis. By adjusting the concentration of the external standards added to the sample, a standard curve was prepared. The compounds were accurately quantified using the standard curves.

With ethanol dilution of 2-octanol as internal standard method, the content of 2-octanol in wine samples reached 500 µg/L, and the aroma content was accurately quantified. The relative amounts of aroma volatiles were obtained by multiplying the area ratio of internal standard by the concentration (µg/L) of the internal standard.

HS–SPME–GC–MS data acquisition

Samples were analyzed by Gas Chromatography-Mass spectrometry (GC/MS) as reported in Alekandra Bojke et al. [18]. For the chromatographic separation, a Thermo ScientificTM TRACETM 1310 gas chromatograph (Thermo Fisher Scientific Inc., Massachusetts/USA) equipped with Thermo ScientificTM TriPlusTM RSH autosampler and Thermo ScientificTM ISQ LT mass spectrometer was used. HS-SPME was performed with a 75 µm divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) capillary column, and allowed separation and qualitative and quantitative analysis. Wine samples (10 mL wines with 100 µL 2-octanol and 3 g sodium chloride) were homogenized in a 20 mL glass vial tightened with a silicon septum and magnetic metal crimp. Glass vials were maintained at 37 °C for 30 min and headspace extraction was performed for 30 min. After sampling, the SPME fiber was attached to the Thermo Scientific TM TRACETM 1310 gas chromatograph injector for 10 min at 270 °C. At the same time, the instrument was started for analysis.

A Trace-GOLD TG-5MS (30 m × 0.25 m × 0.25 µm) capillary chromatographic column from Thermo ScientificTM (Massachusetts, USA) was used for GC/MS. The separation with helium (purity > 99.999%) flowing at a constant flow rate of 1 mL/min. The linear temperature program was as follows: the initial temperature was set to 80 °C, held for 1 min, then ramped up to 280 °C at a heating rate of 10 °C/min, and maintained for 10 min. The GC was run in split-less mode. The GC operating time was approximately 50 min, and the acquisition rate was set to 0.2 s. The ion source for MS detection was EI in positive mode at 70 eV with a temperature of 280 °C, and the transmission line temperature was 250 °C. The m/z scan was carried out from 50 to 350 m/z. Standard curves were established in the concentration range of 5–3000 µg/L for each aroma component.

Sensory analysis

Sensory evaluation was conducted by nine professional tasters from across the country [19]. The same procedure was repeated three times for each of the wine samples. To ensure standardization of the review procedure, the panel was carried out in strict accordance with the unified regulations (GB/T 15,038–2005), using a standard list of vocabulary terms to describe the differences between the wine samples with respect to appearance, aroma, taste, and typicality. The panel scored four aspects of the appearance (10 points), aroma (30 points), taste (40 points), and typicality (20 points) of wine samples and used standardized words to describe. The researcher recorded the characteristics of Cabernet Vintage description and recorded the score of wine and took the average as the final result.

General composition

Along the aging process, alcohol concentration (%, v/v), total acid (expressed as g/L of tartaric acid), volatile acid (g/L), reducing sugar (g/L), polyphenol index, glycerol (g/L), and dry extract (g/L) in wine were measured by OenoFoss™ (Foss, Denmark). Chroma was determined by spectrophotometric assays according to the methods reported by Ju Yanlun et al. [20].

Data analysis

Tables were constructed using Microsoft Word 2019. All data were presented as mean ± standard deviation (mean ± SD, n = 3), and data analysis was performed using SPSS 18.0 software (SPSS Inc., Chicago, IL/USA). The graphs were designed using the Origin 2021 software (OriginLab Corporation, Northampton/MA).

Results and discussion

Changes of flavor substances in grapes

To illustrate the effects of dehydration on grape volatile aromas, HS-SPME-GC/MS analyses were performed on measured aroma compounds of dried Cabernet Sauvignon berries before and after dehydrating. In addition, standard curves (Table 8) were developed for 37 external standards that have a strong influence on aroma characteristics [21]. In dried Cabernet Sauvignon berries, there are 35 aromas, including 12 alcohols, 8 esters, 5 organic acids, and 5 aldehydes. On the basic of qualitative analysis, external standards method was adopted for quantitative analysis of 16 volatile components, including 8 alcohols, 3 esters, 1 organic acid, and 4 aldehydes in Cabernet Sauvignon and dried Cabernet Sauvignon berries, respectively. Table 1 shows the content of aroma compounds of Cabernet Sauvignon grapes before and after dehydrating.

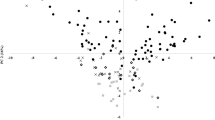

We analyzed the changes in alcohols, esters, organic acids, and aldehydes before and after dehydrating (Fig. 1). In the present study, the contents of esters and organic acids were particularly affected by the dehydrating process, showing an increase by 83.5% and 88.27%. However, alcohols and aldehydes decreased from 7921.51 µg/L to 7621.04 µg/L, and 2925.53 µg/L to 962 µg/L, respectively, after drying of Cabernet Sauvignon grapes. Alcohol accounted for a large proportion of aroma ingredients. Among alcohol, there was a significant change in the content of 1-hexanol and 3-methyl-1-butanol from 4393.83 to 3910.99 µg/L, and from 1667.81 to 2185.69 µg/L, respectively. Organic acid showed the same trend as the esters, which were mostly contributed by octanoic acid and butanedioic acid diethyl ester.

According to the U.C. Davis description about aromas [22], 16 aroma volatile components were divided into 6 distinct categories including herbaceous/vegetative, floral, fruity, caramel, earthy, and nutty. After dehydration, fruity decreased from 2918.2 to 955.22 µg/L, while nutty increased from 4.14 to 24.09 µg/L. Notably, during the dehydrating process, the content of herbaceous, nutty, and caramel were both enhanced, which is consistent with the evaluation of sensory properties. There was a 5.8-fold increase in the 1-octen-3-ol content, which contributed to the earthy aroma. Of note, 3-methyl-1-butanol increased by 23.69%, which reflected the flavor characteristics of Cabernet Sauvignon berries after dehydrating (Table 2).

Changes in flavor substances during fermentation

During the fermentation process, 46 compounds were identified, including 16 alcohols, 22 esters, 5 organic acids, 2 ketones, and 1 alkene. On the basic of qualitative analysis, external standards method was adopted for quantitative analysis of 29 volatile components. The aroma content of alcohols, esters, acids and ketones showed an increasing trend during the fermentation of dried Cabernet Sauvignon grapes (Figs. 2, 3, 4, 5). During the fermentation process, the trend of increase in alcohols was similar to that of esters. Alcohols and esters showed a gradual increase during the first 3 days of fermentation, followed by a rapid increase from 3 to 8 days, indicating the production of a large number of alcohol and ester substances during the active period of alcohol fermentation of dried Cabernet Sauvignon. The alcohol and ester content plateaued after 8 days. In particular, the content of octanoic acid ethyl ester, ethyl caproate, ethyl butyrate, nonanoic acid ethyl ester, and decanoic acid ethyl ester showed at least a tenfold increase, contributing to the sense of the fruit (P < 0.05). The aroma content of ketones shows an increasing trend during the fermentation process of dried Cabernet Sauvignon grape. It should be noted that ketones were greatly reduced on the fourth day of fermentation, induced by separation of waste residue of grape skin [23].

A great number of aromatic substances were produced in wine during fermentation, such as caramel, fruity, floral, herbaceous/vegetative, earthy, and nutty aromas (Table 3). At the beginning of fermentation, the aroma content of floral and caramel showed an increase, which is the main characteristic of grape berries. Conversely, the aroma substances with herbaceous/vegetative characteristics showed a gradual increase, only in the range of 32.8%, at the end of fermentation. The content of fruit aromas increased over the course of the 5 days and then began to decrease. It is worth noting that the fruit aromas on the fifth day of fermentation were similar to that at the end of fermentation. This may be attributable to the different ferment rate [24]. At the peak of fermentation (5–8 days), high production of carbon dioxide volatilizes a large number of esters which are associated with flavors. Therefore, the fruity aromas were low. Conversely, fermentation rate decreased after 8 days leading to a gradual increase in the fruity aroma.

Caramel aromas were the main aroma component in dry Cabernet Sauvignon wines, accounting for about 77.2% of the total aroma. In second place was the floral, accounting for approximately 18.9% of the total aroma. Of note, the fruity aroma has the highest number of aromas compounds, but only 1.9% in total. The content of herbaceous, earthy, nutty aromas was lower than 1% in dried Cabernet Sauvignon aromas.

After fermentation, the variety of aromas in wine showed an obvious increase. Several sensory descriptors aromas, such as fruity, floral, nutty, earthy, and caramel were significantly accentuated in wines made from dried Cabernet Sauvignon grapes compared to dried grapes. However, the number of herbaceous/vegetative aromas of wine was significantly decreased. Caramel and herbaceous/vegetative aromas are the main characteristics of the dried Cabernet Sauvignon berries. While, after fermentation, the wine reflects fermented characteristics such as caramel, floral, and fruity, but herbaceous/vegetative aromas are decreased. After fermentation, the aromatic characteristics are more prominent in the wine.

Changes in flavor substances during the aging process

During the aging process, the oak barrels function as an active vessel that releases a quantity of aromatic material compounds into the wine, promoting its gradual ripening and improving its physical, chemical, and sensory properties [25]. HS-SPME-GC/MS was used to analyze the aroma compounds of Cabernet Sauvignon wines. A total of 72 odors, including esters, alcohols, organic acids, ketones, and aging odors were identified in dried Cabernet Sauvignon wine after aging (Table 4). On the basic of qualitative analysis, external standards method was adopted for quantitative analysis of 32 volatile components, including 14 alcohols, 13 esters, 2 acids, 1 ketone, and 2 aldehydes.

In addition to their concentration, the already known odor threshold values and the odor activity values (OAVs) (the lowest concentration of a compound in vapory phase which can be detected by smell) for each determined compound were also considered (Tables 4 for aged wine and unaged wines). The results showed that the variety of volatile compounds in wines increased as they aged. In addition, some aromas with floral and fruity characteristics, i.e., 3-methyl-1-pentanol and citronellol were reduced in wines during the aging treatment in comparison to non-aged wines. Nevertheless, increased concentrations of some barrel and aging compounds were also noted in wines, such as furaldehyde, furfuryl alcohol, and 5-methyl furfural.

According to the research, compounds with larger OAVs are assumed to be the most dominant contributors to the overall aroma of a complex mixture along the lines of wine [26]. In dried Cabernet Sauvignon wines, 32 aromas were quantified by external standards after aging. These 32 odors with 29 aromas before aging were compared, along with the changes in OAVs (Table 4).

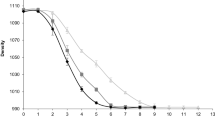

As stated above, approximately 48.19% odors and 14.8% OAVs in dried Cabernet Sauvignon were reduced after aging. A decrease in alcohols, esters, acids, and ketones aromas (Fig. 6), and an increase in aging odors was noticed with aging of dried Cabernet Sauvignon wines. After aging, the aroma of 1-hexanol, phenylethyl alcohol, 1-decanol, ethyl butyrate, isoamyl acetate, and ethyl caproate showed an obvious decrease, among which the components showed fruity and floral characteristics. But there was an increase in some of the aging and oak baking characteristics in wines, such as ethyl 3-methylbutanoate, 1-octene-3-ol, furfural, and furfuryl alcohol. These provide a deeper, longer-lasting characteristics along with cream, coffee, vanilla, roast, and caramel sensory properties.

These results indicate that the aging process affects the aroma characteristics. At the end of aging, the main presenting aromas (OAV > 10) in Cabernet Sauvignon dry red wines changed from 3-methyl-1-butanol, ethyl butyrate, octanoic acid, and beta-damascenone to 1-octene-3-ol, furfural, and beta-dammarone. The experimental results were consistent with those reported by Ferreira et al. [30]. However, in the present study, 3-methyl-1-butanol and 1-octen-3-ol also had higher OAV values, which are unique ingredients contributing to the characteristics of Cabernet Sauvignon in Ningxia. During the aging process of dried Cabernet Sauvignon wine, simple aromas (such as flowers, fruit, and sweetness) were transformed into complex aromas (such as mushroom, dried coconut, caramel, spicy, and coffee aromas) (Table 5). The unique aromatic compounds after barrel storage were furfuryl alcohol, furfural, and 5-methylfurfural, which made the wines more mellow and aromatic. After aging, various aromas of the dried Cabernet Sauvignon wine tend to be balanced, integrated, and coordinated.

General composition of wine

The ripening process of wines during aging generally entails a complex series of physical and chemical changes. After aging, the general compositions of the wines were measured, and the results are summarized in Table 6. After aging, there was an increase in the maturation and stability of the wine. However, there was no significant change in the alcohol, total acid, volatile acid, reducing sugar, polyphenol index, glycerin, chroma, or dry extract contents (P > 0.05). However, there was a decrease in the content of general composition of dried Cabernet Sauvignon wines, as reflected in the reduction of some indices (Table 6). The ethanol difference favoring unaged wines over aged wines, can be explained by the evaporative loss of ethanol via diffusion through the staves observed in oak barrels [27]. The decrease in polyphenol index and chroma was due to the precipitation of pigment and the polymerization of pigment and tannin to form anthocyanin-tannin complex [28]. The decrease in total acid, glycerol, and dry extract was due to the clarification effect during aging, which is conducive to the ripening and stabilization of wine [29]. Conversely, there was a slight increase in volatile acid, ranging from 0.55 to 0.67 g/L during aging.

Descriptive sensory properties of wines

The aromas and flavors of dried Cabernet Sauvignon before and after aging were distinguished, although the differences were subtle. Consequently, the panel of experts evaluated the wines and provided a summary of the sensory properties. There were obvious differences between the unaged and aged dried Cabernet Sauvignon wine in appearance, aroma, taste, and typicality (Table 7). After aging, dried Cabernet Sauvignon wines with a high content of concentrated berries and dried fruit aromas showed stronger structure, fuller taste, and greater typicality. As the wine aged, the aromas of dried Cabernet Sauvignon wines increased and became more complex.

Conclusions

This study demonstrated significant differences between dried Cabernet Sauvignon grape and non-dried Cabernet Sauvignon grape, both with respect to aroma characteristics and the sensory properties, and also demonstrated the significant changes in these attributes during the winemaking and aging process of dried Cabernet Sauvignon. The results show that dried Cabernet Sauvignon had decreased fruity aromas but enhanced herbaceous and caramel aromas. After fermentation, the dried Cabernet Sauvignon wine had prominent fermented characteristics such as caramel, floral, and fruity, with more pronounced aromatic characteristics. The aging process not only altered the general composition of the wine, but also had a positive influence on the sensory properties and formation of complex aromas, such as mushroom, desiccated coconut, caramel, spicy, and coffee. This study provides important insights from an industry perspective, as it provides evidence of the influence of handling, production, and storage processes of grapes on the aroma characteristics of the wine.

References

Mencarelli F, D’onofrio C, Bucci S, Baccelloni S, Cini R, Pica G, Bellincontro A (2021) Management of high-quality dehydrated grape in vinification to produce dry red wines. Food Chem. https://doi.org/10.1016/j.foodchem.2020.127623

Marquez A, Perez-Serratosa M, Varo MA, Merida, (2014) Effect of temperature on the anthocyanin extraction and color evolution during controlled dehydration of tempranillo grapes. J Agric Food Chem 62:7897–7902

Chou HC, Šuklje K, Antalick G, Schmidtke LM, Blackman JW (2018) Late-season shiraz berry dehydration that alters composition and sensory traits of wine. J Agric Food Chem 66:7750–7757

Van WN, Grossmann M, Wendland J, Von WC, Pretorius IS (2019) The whiff of wine yeast innovation: strategies for enhancing aroma production by yeast during wine fermentation. J Agric Food Chem 67:13496–13505

Morales ML, Ochoa M, Valdivia M, Ubeda C, Romero-Sanchez S, Ibeas JI, Valero E (2020) Volatile metabolites produced by different flor yeast strains during wine biological ageing. Food Res Int. https://doi.org/10.1016/j.foodres.2019.108771

Reboredo-Rodríguez P, González-Barreiro C, Rial-Otero R, Cancho-Grande B, Simal-Gándara J (2015) Effects of sugar concentration processes in grapes and wine aging on aroma compounds of sweet wines—a review. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2012.680524

Tomašević M, Gracin L, Ćurko N, Kovačević GK (2017) Impact of pre-fermentative maceration and yeast strain along with glutathione and SO2 additions on the aroma of Vitis vinifera L. Pošip wine and its evaluation during bottle aging. LWT. https://doi.org/10.1016/j.lwt.2017.03.035

Jiang B, Xi Z, Luo M, Zhang Z (2013) Comparison on aroma compounds in Cabernet Sauvignon and Merlot wines from four wine grape-growing regions in China. Food Res Int. https://doi.org/10.1016/j.foodres.2013.01.001

Forde CG, Cox A, Williams ER, Boss PK (2011) Associations between the sensory attributes and volatile composition of Cabernet Sauvignon wines and the volatile composition of the grapes used for their production. J Agric Food Chem 59:2573–2583

Belda I, Ruiz J, Esteban-Fernández A, Navascués E, Marquina D, Santos A, Moreno-Arribas MV (2017) Microbial contribution to Wine aroma and its intended use for Wine quality improvement. Molecules 22:1–29

Borren E, Tian B (2021) The important contribution of non-Saccharomyces yeasts to the aroma complexity of wine: A review. Foods. https://doi.org/10.3390/foods10010013

Mayr CM, Capone DL, Pardon KH, Black CA, Pomeroy D, Francis IL (2015) Quantitative analysis by GC-MS/MS of 18 aroma compounds related to oxidative off-flavor in wines. J Agric Food Chem 63:3394–3401

Jiang B, Luo M, Zhang Z (2015) Influence of altitudes on phenolic compounds and antioxidant activities of cabernet sauvignon and merlot wines in loess plateau region. J Chinese Instit Food Sci Technol https://doi.org/10.16429/j.1009-7848.2015.02.034

Schueuermann C, Khakimov B, Engelsen SB, Bremer P, Silcock P (2016) GC-MS metabolite profiling of extreme southern pinot noir wines: effects of vintage, barrel maturation, and fermentation dominate over vineyard site and clone selection. J Agric Food Chem 64:2342–2351

Zhao Y, Sun Q, Zhu S, Du F, Mao R, Liu L, Tian B, Zhu Y (2021) Biodiversity of non-Saccharomyces yeasts associated with spontaneous fermentation of Cabernet Sauvignon wines from Shangri-La wine region, China. Scient Rep. https://doi.org/10.1038/s41598-021-83216-x

Marcon Filho JL, Rufato L, Bogo A, De Macedo TA, André WD, Kretzschmar AA (2019) Viticultural performance of Cabernet Sauvignon clones in highland region of southern Brazil. Rev Bras Frutic. https://doi.org/10.1590/0100-29452019483

Cn N, Xx Z, He L, Gao Y, Zhang Xw CM, Du X (2019) Comparison of different aroma-active compounds of Sichuan Dark brick tea (Camellia sinensis) and Sichuan Fuzhuan brick tea using gas chromatography–mass spectrometry (GC–MS) and aroma descriptive profile tests. Eur Food Res Technol. https://doi.org/10.1007/s00217-019-03304-1

Ma L, Li J, Han Y, Li W (2018) Meteorological conditions and rating method of quality formation of “Cabernet Sauvignon” grape in eastern foothills of Helan Mountain. Chinese J Eco-Agric https://doi.org/10.13930/j.cnki.cjea.170579

Wang R, Sun Q, Chang Q (2015) Soil types effect on grape and wine composition in Helan Mountain area of Ningxia. PLoS ONE. https://doi.org/10.1371/journal.pone.0116690

Ju YL, Yang L, Yue X, Li Y, He R, Deng S, Yang X, Fang Y (2021) Anthocyanin profiles and color properties of red wines made from Vitis davidii and Vitis vinifera grapes. Food Sci Human Wellness 10:335–344

Bojke A, Tkaczuk C, Bauer M, Kamysz W, Gołębiowski M (2020) Application of HS-SPME-GC-MS for the analysis of aldehydes produced by different insect species and their antifungal activity. J Microbiol Methods. https://doi.org/10.1016/j.mimet.2020.105835

Souza GL, Capone DL, Bastian SEP, Danner L, Jeffery DW (2020) Sensory typicity of regional Australian Cabernet Sauvignon wines according to expert evaluations and descriptive analysis. Food Res Int. https://doi.org/10.1016/j.foodres.2020.109760

Zhao P, Gao J, Qian M, Li H (2017) Characterization of the key aroma compounds in Chinese syrah wine by gas chromatography-Olfactometry-Mass spectrometry and Aroma reconstitution studies. Molecules. https://doi.org/10.3390/molecules22071045

Feng L, Jia H, Wang J, Qin Y, Liu Y, Song Y (2019) Selection of indigenous saccharomyces cerevisiae strains for Winemaking in Northwest China. Am J Enol Vitic. https://doi.org/10.5344/ajev.2018.18035

Gülcü M, Uslu N, Özcan MM, Gökmen F, Özcan MM, Banjanin T, Gezgin S, Dursun N, Geçgel Ü, Ceylan DA, Lemiasheuski V (2019) The investigation of bioactive compounds of wine, grape juice and boiled grape juice wastes. J Food Process Preserv. https://doi.org/10.1111/jfpp.13850

Ma N, Yi F, Zhu J (2020) Characterization of aroma-active compounds and perceptual interaction between esters and sulfur compounds in Xi baijiu. Eur Food Res Technol. https://doi.org/10.1007/s00217-020-03594-w

Chira K, Teissedre PL (2015) Chemical and sensory evaluation of wine matured in oak barrel: effect of oak species involved and toasting process. Eur Food Res Technol. https://doi.org/10.1007/s00217-014-2352-3

Geng S, Jiang J, Qu R, Shi K, Qin Y, Liu Y, Song Y (2021) Managing volatile acidity and aroma of Petit Manseng wine using Torulaspora delbruekii. Nongye Gongcheng Xuebao/Transact Chinese Soc Agricul Eng. https://doi.org/10.11975/j.issn.1002-6819.2021.07.036

Bautista-Ortín AB, Lencina AG, Cano-López M, Pardo-Mínguez F, López-Roca JM, Gómez-Plaza E (2008) The use of oak chips during the ageing of a red wine in stainless steel tanks or used barrels: Effect of the contact time and size of the oak chips on aroma compounds. Aust J Grape Wine Res. https://doi.org/10.1111/j.1755-0238.2008.00008.x

Ferreira V, Aznar M, López R, Cacho J (2001) Quantitative gas chromatography-olfactometry carried out at different dilutions of an extract. Key differences in the odor profiles of four high-quality spanish aged red wines. J Agric Food Chem. https://doi.org/10.1021/jf010283u

Acknowledgements

The authors would like to thank Medjaden Inc. for scientific editing of this manuscript and the technical support of the analysis team of Sino-French Joint-Venture Dynasty Winery Ltd.

Funding

This work was supported by Youth Top Talents Project in Tianjin Special Support Program (Grant No. TJTZJHQNBJRC-1-19), Science and technology Project of Tianjin (Grant No. 21ZYCGSN00410), and Science and technology Project of Tianjin (Grant No. 21YDTPJC00910).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Compliance with ethics requirements

The study does not involve research on human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Schedule

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Y., Zhang, Y., Yu, R. et al. Changes in the aroma characteristics during the different processes of dry Cabernet Sauvignon wine production. Eur Food Res Technol 248, 3025–3036 (2022). https://doi.org/10.1007/s00217-022-04109-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04109-5