Abstract

This study aims to reveal the effect of each of prominent lactic acid bacteria (LAB) in the microbiota of kefir grain on the chemical and biochemical properties of kefir and especially, the formation of the volatile aroma compound (VAC) profile. Thus, fermented samples were produced in milk using single strains of Lactobacillus kefiranofaciens (LKF), Lentilactobacillus parakefiri (LP) and Lentilactobacillus kefiri (LK), as well as two control samples using kefir grain (TK) and commercial kefir culture (CK). In the samples, the change in LAB amounts, physicochemical (pH, titration acidity), rheological and chemical properties (organic acid, sugar and volatile flavour compound content) were investigated. The results showed no significant difference between LAB numbers and physicochemical properties of the samples. The LK, the LP and the LKF strains, respectively, were observed more activity in acetic acid production, citrate and lactose consumption. In VAC profiles, the LKF strain was associated with hexanol, 2-octanol, and octanal and LK with ethyl octanoate, ethyl hexanoate, acetaldehyde and geraniol. The LP strain was characterized by aldehydes including heptanal, nonanal and decanal. Thus, the L. parakefiri strain was highlighted in terms of the desired aroma profile. These results provide a clearer understanding of possible metabolic pathways and functions of the prominent strains in the kefir grain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the centuries, kefir has been widely consumed. It is a fermented milk product, where kefir grain is used in traditional production methods and several microorganism genus/species isolated from kefir grain in commercial production are used together as a starter culture [1]. The microbial consortium of the kefir grain consists of a balanced symbiotic association of bacteria and yeasts. The lactic acid bacteria (LAB) including Lentilactobacillus kefiri, Lactobacillus kefiranofaciens, Lactobacillus kefiranofaciens subsp. kefirgranum, Lentilactobacillus parakefiri, Lactobacillus delbrueckii, Lactobacillus acidophilus, Levilactobacillus brevis, Lactobacillus helveticus, Lacticaseibacillus casei, Limosilactobacillus reuteri, Lacticaseibacillus paracasei, Limosilactobacillus fermentum, Lactiplantibacillus plantarum and Lactobacillus gasseri, and the yeasts including Kluyveromyces marxianus, Kluyveromyces lactis and Saccharomyces cerevisiae are the most common species in kefir grains. Acetic acid bacteria are rarely found in some grains, as kefir grains vary depending on the origin [2,3,4].

In kefir fermentation, several metabolites are synthesised by the metabolism of certain microorganisms and their interactions with each other. The variety of microorganisms that play a role in fermentation also increases the variety of synthesised metabolites. Some strains of homofermentative LAB, L. kefiranofaciens and L. acidophilus, only synthesise lactic acid from lactose. Other strains of heterofermentative LAB, L. kefiri, Lentilacto. parakefiri and L. reuteri, synthesise compounds, such as CO2, acetic acid, formic acid and ethanol [1, 5,6,7]. Some citrate positive-LAB strains, Leuconostoc mesenteroides subsp. cremoris and Lactococcus lactis subsp. lactis biovar diacetylactis, are also known to synthesise many different compounds from citrates, such as acetoin, diacetyl, acetaldehyde, 2,3-butanediol, ethanol and ethyl acetate [5, 8]. During fermentation, ingredients such as protein and lipids in the milk could break down into building blocks by the LAB and/or yeasts (for example, some strains of Candida lypolitica). For instance, the aminopeptidase activity of some Lactobacillus. helveticus strains in kefir grain may cause proteins to break down and release free amino acids [9]. On the other hand, microbial reaction products produced by microorganisms are sometimes also the substrate of a biochemical reaction. For example, it is well known that oxaloacetate, which is produced by the degradation of citrate by a Leuconostoc mesenteroides subsp. mesenteroides strain could be transformed into aspartate by transamination. While these reactions change and/or increase the nutritional value of food, at the same time, they lead to the formation of flavour and tat compounds, or precursors of them in food [10]. The kefir aroma occurs as a result of these complex chemical and biochemical reactions during fermentation. In the literature, limited studies investigate the individual effect of microorganisms that play a role in fermentation on the physical, chemical and organoleptic (sensory) properties of kefir [11].

This study aims to reveal the compounds formed as a result of the fermentation of cow's milk using three individual LAB strains that are most abundant in kefir grain microbiota. We also aim to individually investigate the effect of these compounds on the physical, chemical and sensory properties of the fermented end products, especially to determine the effect of single LAB cultures used on the volatile compound profile of fermented samples. Thus, it will prepare the ground for future studies in which double, triple strains and other combinations will be applied.

Materials and methods

Materials and properties

In this study, to prepare the single-strain bacterial kefir starter, strains that isolated from kefir grains, representative of dominating and unique microbiota, were selected [2]. The standard strains L. kefiranofaciens ATCC 43761, L. kefiri ATCC 35411 and L. parakefiri NBRC 15890, respectively, were obtained from DSMZ (Deutsche Sammlung von Mikroorganismen und Zellkulturen, German Collection of Microorganisms and Cell Cultures, Almanya) and NBRC (National Biological Research Centre; National Institute of Technology and Evaluation [NITE], Tokyo, Japan). Kefir grain for the production of traditional kefir and eXact®-KEFIR-2 (Debaryomyces hansenii, Leuconostoc spp, Streptococcus thermophilus, Lactobacillus lactis, Lactobacillus diacetlylactis, Lactobacillus cremoris) for the production of commercial kefir, were purchased from Danem Co. (Milk and Dairy Products LLC., Isparta, Turkey) and CHR Hansen Co. (Denmark), respectively, as starter cultures of the two control samples. UHT milk (semi-skimmed; 1.5% fat, 4.7% carbohydrate, 3.0% protein; pH: 6.6) used as raw material, was obtained from SÜTAŞ Co. (Milk Products Inc., Turkey). Analytical-grade chemicals and reagents were purchased from Sigma-Aldrich Co. (St. Louis, MO, USA) and Supelco Co. (Bellefonte, PA, USA), and the microbial growth mediums from Merck Co. (Germany) and Biolife Co. (Italy).

Activation and preparation of starter cultures

The three strains (LKF: L. kefiranofaciens, LK: L. kefiri, LP: L. parakefiri) were activated twice. First, the strains were inoculated with 2% of De Man, Rogosa and Sharpe (MRS) broth and incubated for 48 h at 37 °C under anaerobic conditions, using an anaerobic jar (Anaerocult® Merck, Germany). The developing cultures were inoculated again into sterile MRS broths at a rate of 2% and activated a second time, incubated at 25 °C for 18 h. After then, the resulting active cultures were centrifuged at 6000×g (Hettich Rotina 380/380 R, Hettich Co., Germany) for 15 min, the microbial pellets were washed with a physiological saline solution (PSS, 0.85% NaCl), and the turbidity of each of these pellets was adjusted to a 0.5 McFarland value (108 CFU/mL). 10 mL of each of microbial pellet solutions were used as active starter culture. On the other hand, commercial culture were prepared with that commercial kefir culture (eXact-KEFIR-2; CK; 0.015 g/L in final product) were added to 10 mL of UHT-milk, and activated at 25 °C for 6 h. Finally, 10 g of kefir grains were used as traditional kefir culture (TK; 2% in final product).

Production of products fermented by the most prominent strains in kefir grain

Each (10 mL) of the activated cultures (LKF, LK, LP, CK and TK) was inoculated into 490 mL of UHT milk (500 mL UHT-milk including 106 log CFU/mL of the active strains in total) and fermented at 25 °C until pH reached 4.6 value. On the other hand, two other 490 mL of UHT-milk was inoculated with active CK solution (10 mL), and with active TK (10 g). Subsequently, they were also fermented at 25 °C until pH reached 4.6 value. These are the kefir production parameters. After the incubation, only the TK (grains) were separated using a sieve from the product produced (TK-p) with kefir grain. All of the fermented products (LKF-p, LK-p, LP-p, CK-p and TK-p, respectively) were then matured at + 4 °C for 1 day (Fig. 1). Microbiological, chemical and rheological analyses and sensory evaluation were made on the same day and the remaining samples for other analyses were stored at − 20 °C. Three repetitions of the fermentations per each strain were applied.

Production process of the fermented milk samples produced using prominent strains in kefir grain. *LKF-p, LP-p and LK-p are the samples produced using Lactobacillus kefiranofaciens (LKF), Lentilactobacillus parakefiri (LP), and Lentilactobacillus kefiri (LK) strains, also respectivity. TK-p and CK-p are the control kefirs produced using kefir grain and commercial kefir culture

Chemical analysis and enumeration of lactic acid bacteria

The pH values of the samples were measured with a pH-meter (Schott Instruments Lab 860, USA). Their acidity values in term of percentage (%) lactic acid and the total dry matter contains were determined according to AOAC standard method [12]. Lactobacillus spp. contents were determined using the pour plate method, in MRS agar at 37 °C under 5% CO2 for 24–48 h [13].

Rheological analysis

Rheological properties of the samples were determined using a Brookfield DV-II Pro LV model viscometer equipped with a small sample adapter. Rheological measurements were made using the SC4-18 spindle at 25 °C. Ten mL (4 °C) were put into a sample chamber; measurements started at 1 rpm and were repeated seven times with one increase of 6 rpm every 5 s. Viscosity, shear stress and the deformation rate of the samples were determined using the RHEOCALC® application (Brookfield Engineering Laboratories Inc., A.B.D.) [1]. Power-Law model (τ = K(γ˙)n) was applied.

Organic acid and sugar profile analyses

Two grams of the sample were diluted in double-distilled H2O and homogenised for 180 s at 4000 rpm. Subsequently, 10 mL of the homogenate were treated with 12.5 mL 0.01 N H2SO4 and vortexed for 1 min and the upper phase of the homogenate was taken into the Eppendorf tube and centrifuged at 10.000×g for 5 min. Afterwards, the middle phase was filtered through a 0.45 μm filter (Merck, Millipore, Millex-LG). The filtrates were injected into high-performance liquid chromatography (HPLC; pump (LC-20AD), UV–visible detector (SPD-20A), column oven (CTO-20A), Shimadzu, Japan) for quantification of the organic acids. Inertsil ODS-3 V C18 (GL Sciences Inc; 250 × 4.60 mm, 5 μm) was used to separate organic acids. Five mM H2SO4 solution (adjusted to pH 3.0 with 4 N NaOH) were used as the mobile phase at a flow rate of 1.0 mL/min and the column temperature was 30 °C. Organic acids were identified by comparing the retention time of pure standards at 210 nm [14]. The results were calculated by linear equations obtained using standard solutions (lactic (500–3000 ppm), acetic (250–1250 ppm), citric (50–300 ppm) and formic acid (100–500 ppm) standards: R2 = 0.9991, 0.9998, 0.9992 and 0.9988, respectively).

Glucose, galactose and lactose contents were also determined in the fermented milk samples. The pre-extraction process for determining the sugar content (glucose, galactose and lactose) was the same as in organic acid section. HPLC (Shimadzu, Japan), a refractive index detector and a Transgenomic CARBOSep COREGEL-87P column were used. Ultra-pure water was used in the mobile phase at a flow rate of 0.8 mL/min and the column temperature was 80 °C. The results were calculated by linear equations obtained using standard solutions (R2 = 0.9936 (100–2500 ppm), 0.9914 (500–7500 ppm) and 0.9984 (100–1250 ppm), respectively, for glucose, lactose and galactose).

Volatile compounds analysis

Volatile compounds in the samples were determined by gas chromatography–mass spectroscopy (GC–MS; QP2010, Shimadzu, Japan) using solid-phase micro-extraction technique (SPME). The sample (2 g) was put into a 15 mL SPME vial before adding 1 g NaCl and 2.5 µL of internal standard (4 methyl 2 pentanol; 0.5 mL/L in dH2O). The vial was held in a water bath for 30 min at 60 °C to equilibrate the volatiles in the headspace. Then, the SPME fibre (2 cm–50/30 mm; DVB/Carboxen/PDMS, Stable Flex Supelco, Bellefonte, PA, USA) was inserted into the vial and exposed to a depth of 2 cm in the headspace of the vial for 30 min at 60 °C in a water bath. The fibre was placed in the GC port at 250 °C for thermal desorption and held for 10 min. A polar Stabilwax column (60 m length × 0.32 mm i.d. × 0.25 μm thickness; Restek, Bellefonte, USA), was used to separate volatile compounds. Helium (99.9%) was used as the carrier gas at 3 mL/min flow rate. The oven temperature was programmed as follows: 1; initially held at 40 °C for 1 min, 2; increased from 40 to 100 °C at a rate of 7 °C/min and held at 100 °C for 5 min, 3; reached 180 °C at a rate of 2 °C/min and held at 180 °C for 1 min and 4; increased to 250 °C at a rate of 15 °C/min and held at 250 °C for 4 min. The volatiles were expressed as μg/L kefir resulting from the area ratio of each compound against an internal standard and were identified by comparing their linear retention indexes (LRIs) and mass spectra with those of the libraries (Wiley 6 and FFNSC; Flavours and Fragrances of Natural and Synthetic Compounds) in the MS. the LRIs were calculated by injecting alkane (C7–C30) series.

Sensory analysis

Descriptive sensory analysis was conducted to evaluate the sensory properties of the fermented milk samples. Eight females and seven males between the ages of 25 and 40 years participated in the sensory evaluation. During early training sessions, the panellists who already were familiar with kefir properties, sensory protocols and sensory testing were trained with kefir samples manufactured without any treatment. Ten mL of samples were put in a 3-digit-coded plastic cap (PET) and presented to the participants with water and unsalted crackers to cleanse the palate between samples. Panellists quantified the attributes using a 7-point hedonic scale on appearance, consistency, taste and aroma and ranked the products according to their liking.

Statistical analyses

It was done in triplicate for each analysis. The data was analysed using the one-way analysis of variance (ANOVA) test in SPSS 20.0 (SPSS Inc., Chicago, IL, USA). Duncan’s test was utilised to assess the significantly different results (P < 0.05) between samples. Principle component analysis (PCA) was applied to the data to determine the similarities and differences of the samples, according to the volatile compounds determined. PCA analysis was carried out with XLSTAT software (trial version, 2017, Addinsoft, Inc., ABD).

Results and discussion

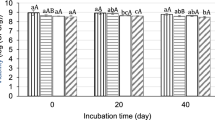

The microbiological and chemical properties of the fermented samples

Fermentation times, LAB counts and some chemical properties of fermented samples produced using the prominent single strains in the kefir grain were analysed, along with the two kefir control samples. Table 1 shows that the LAB contents of all samples were determined above the minimum target value, 8 log CFU/mL. In addition, at the end of fermentation, the pH values of the samples reached about pH 4.60 (pH 4.67–4.60). In the study, the same fermentation time was not applied. The reason for this can be explained as follows. It is known that; it is terminated at pH 4.6 in kefir production. It was considered that the application of the same fermentation times could not fully reflect the individual behavior of the strains studied in kefir production. Because the early termination of the fermentation process of a strain that has a slow acidity reduction rate and cannot reach a pH value of 4.6 may not accurately reflect the pH behavior of the real kefir matrix (especially regarding volatile components). In the present study, it was also found that the pH value of the LK-p sample, which had lower LAB content than the others, was found to be higher. In contrast, it was determined that the titratable acidity values of the products were between 0.99 and 1.11%. The fact that these values were greater by at least 0.6% than the value stated in the Turkish Food Codex Communiqué on Fermented Milk Products [15], indicated that each of the strains used in this study was effective in lowering the acidity.

In the samples, the rate at which the strains develop the acidity of the product determines their fermentation time. While the fermentation times of the sample produced with a single culture (LKF-p, LP-p, and LF-p) were close to each other (Table 1), due to a large number of LAB in the fermentation and their ability to produce lactic acid, the fermentation times of the TK-p and the CK-p samples were shorter (17 h and 13 h) than the others. The dry matter content of the products was determined in the range of 9.15–10.02%, as per the communiqué [15] and the literature [16].

The rheological properties of the fermented samples

Flow behaviours were determined according to shear stress and deformation velocity values. The data obtained were in the range of 53.0–142.75. mPas. The control kefir produced from TK-p had the highest value, followed by the control sample (CK-p) produced with the commercial culture (P < 0.05). Exopolysaccharides (EPS) that produce from LAB strains increase viscosity and decrease serum separation in fermented milk products [1]. It is considered that the high viscosity values of the control samples in this study are related to their yeast content. This can be explained by the presence of a variety of EPS-producing microorganisms (such as L. kefiranofaciens ssp.) in the TK-p sample and the presence of the D. hansenii yeast strain capable of producing high gel tightness in the CK-p sample [17]. The lowest viscosity value was also determined in the LP-p sample (P < 0.05). On the other hand, the sample with the closest value to the control samples was LKF-p, because its L. kefiranofaciens starter strain produces EPS [18]. Furthermore, the viscosity values of the other samples were higher than the values reported in previous studies, except for LP-p [16].

The power-law model was used to determine the rheological properties of the samples. The rheogram showing shear stress/deformation rate ratios of all the samples are shown in Fig. 2. According to this study, the fluid type of all samples were non-Newtonian flow as the index (n) is n < 1, and all samples belonged to the group of pseudoplastic fluids. The LP-p sample was also observed to be more pseudoplastic than the LK-p and LKF-p samples, respectively. As for the flow behaviour of the samples, the shear rates and deformation rates increased, but their viscosity values decreased. They exhibited thixotropic properties, because they viscosity increases over time [17].

Rheological properties of the fermented milk samples produced using prominent strains in kefir grain. *LKF-p, LP-p and LK-p, are the samples produced using Lactobacillus kefiranofaciens, Lentilactobacillus parakefiri, and Lentilactobacillus kefiri strains, respectivity. CK-p and TK-p are the fermented control products produced using commercial kefir culture and kefir grain, respectively. a–c Different lowercase letters indicate significant differences between the samples (P < 0.05)

The organic acid profiles of the fermented samples

In the fermented samples, the values of lactic, acetic, citric and formic acid were determined in the range of 0.71–0.80, 0.43–0.73, 0.05–0.18 and 0.12–0.15 g/100 mL, respectively (Table 2). As one of the most important organic acids, the values of lactic acid were examined in each sample and statistically, were not significantly different from each other (P > 0.05). It has been considered that the lactic acid produced reacted with different compounds in the medium and directly or indirectly converted to esters or other compounds. For example, ethyl lactate had a pleasant fruit–flower flavour, formed by the esterification reaction of lactic acid and ethyl alcohol. However, it was determined that the LKF-p sample had the highest value (P > 0.05), because the L. kefiranofaciens strain was homofermentative. On the other hand, the L. kefiri and the L. parakefiri strains used in other samples were heterofermentative. Homofermentative LAB can only synthesise lactic acid during fermentation and heterofermentative LAB can synthesise lactic acid by-products, such as lactic acid, ethanol, acetic acid and CO2. These properties explain the high lactic acid values of LKF-p.

As for the acetic and citric acid contents of the products, the TK-p sample had the highest amount of acetic acid, followed by the LK-p and CK-p samples, respectively (P < 0.05). In contrast, the citric acid values of the three samples were significantly lower than the other samples (LKF-p and LP-p; P < 0.05). According to the results, while the high acetic acid contents of the control kefir samples, TK-p and CK-p, resulted from the diversity of microorganisms in their microbiota and the number of heterofermentative microorganisms, it seems that the LK-p sample was most similar to the control kefir samples in terms of acetic and especially, citric acid values. Citric acid, produced as an intermediate of tricarboxylic acid (TCA)/Krebs cycle, is converted to acetic acid and pyruvic acid by some LAB strains belonging to species, such as L. kefiri, L. plantarum and L. diacetylactis, under fermentative conditions [8]. Therefore, in the LK-p sample, it was thought that the citric acid, which is produced in milk by the Krebs (citric acid) cycle, was converted to acetic acid by the L. kefiri strain used as a starter culture, thereby increasing its acetic acid content [5]. Finally, in the study, the highest formic acid value belonged to the control kefir sample produced from grain, while the lowest value belonged to the kefir sample produced with the commercial starter culture. However, there were no significant differences between fermented samples produced with a single strain, each other (P > 0.05) and both control samples. According to the organic acid contents, all the evaluations showed that the three LAB strains are suitable for kefir fermentation. However, in terms of aroma properties, the LK-p sample came into prominence.

The sugar profiles of the fermented samples

Lactose naturally present in milk and/or the monosaccharides of the lactose, glucose and galactose, are sugars used by microorganisms during fermentation. Hence, in the study, the lactose, glucose and galactose contents of the samples were determined (Table 2). It was found that the lactose content of the control samples (CK-p: 3.065 g/100 mL, TK-p: 2.87 g/100 mL) were significantly higher than those of the fermented samples produced with the single strain (LKF-p: 2.69, LP-p: 2.66, LK-p: 2.53 g/100 mL, P < 0.05). The various LAB and yeasts used as starter in the production of the control samples had been thought to cause more lactose usage. However, since the production times of the control samples (13 and 17 h) were shorter than the other samples (24, 26 and 24 h), it was observed that the amount of lactose usage in the fermented samples was higher (P < 0.05). Furthermore, among the control samples, lactose usage in the TK-p sample was higher than the CK-p sample. This could be explained by the use of only one yeast and four LAB strains in the production of the CK-p sample and that this yeast strain, belonging to the D. hansenii species, could not metabolise lactose as it shows poor growth in anaerobic environments [19]. In contrast, the kefir grains used in the production of the TK-p sample contained strains of various LAB (Str. thermophilus, L. acidophilus, L. reuteri and Bifidobacterium bifidum) and yeast (K. marxianus), which had been detected in a study conducted by Kok-Tas et al. [1]. On the other hand, the TK-p sample had both the higher content of acids and the higher amount of residual lactose. It has been considered that the reason for this is that in a complex microbiota, organic acids may not be produced solely from sugar.

As for the glucose and galactose monosaccharides produced by the degradation of the lactose, it was determined that the LP-p sample had the lowest glucose and galactose values (0.64 and 0.11 g/mL, respectively); these values were statistically different from the other samples (P < 0.05) and were also the closest values to the TK-p control sample (0.49 and 0.11 g/mL, respectively). On the other hand, while the LK-p sample had the highest galactose value (0.21 g/mL), the LKF-p sample had the highest glucose value (1.05 g/mL). It was thought that the starter culture of the LK-p sample, the L. kefiri strain, was either unable or slowly able to ferment galactose [20, 21].

According to all sugar results, the L. parakefiri strain was highlighted due to its ability to metabolise lactose. The results of the LP-p sample used singly in this strain had the closest result to the TK-p sample produced by the kefir grain, where several bacteria played a role in fermentation. Thus, it has been thought that L. parakefiri may be one of the strains that can be used in the production of the diets of lactose intolerant people or/and for direct use.

The volatile compound profiles of the fermented samples

The volatile profiles of the fermented samples are given in Table 3 and the distributions of volatiles according to chemical classes are shown in Fig. 3A, B. The sample with the highest total amount of volatiles was LKF-p, while the lowest sample was CK-p. When examined according to chemical classes, in the TK-p control sample, the total amount of ketone was determined as the predominant chemical class, followed by acids. Whereas, in the CK-p example, the ketone and acid contents were found to be very close to each other. (Fig. 3B; P > 0.05). However, in the CK-p sample, the total amount of ketone was lower than in the TK-p sample and conversely, the total acid content was higher than the TK-p sample (P > 0.05).

Volatile compound profiles of the fermented milk samples produced using prominent strains in kefir grain. A Distribution of VACs in the samples by chemical groups, B Representation of VACs in the samples as a percentage. *LKF-p, LP-p and LK-p, are the samples produced using Lactobacillus kefiranofaciens, Lentilactobacillus parakefiri, and Lentilactobacillus kefiri strains, respectivity. CK-p and TK-p are the fermented control products produced using commercial kefir culture and kefir grain, respectivity. a–d Different lowercase letters indicate significant differences between the samples (P < 0.05)

In all the fermented samples, the total amount of alcohol compound was the predominant chemical, followed by the acid in the LK-p and LP-p samples, but by aldehyde in the LKF-p sample. In particular, the alcohol content (46.56 µg/L) of the LKF-p sample and ketone content (22.37 µg/L) of the TK-p sample was significantly higher than the other compounds (P < 0.05). Furthermore, in the distributions within their own chemical classes, it was observed that the chemical class values in the first order were significantly higher than the chemical class values in the second order (11.61 µg/L, 25.03% for the acid in the TK-p and 13.05 µg/L, 17.31% for the aldehyde in the LKF-p) (P < 0.05; Fig. 3A, B).

Ketones are products of lipid and carbohydrate (lactose) metabolism by microorganisms [22]. They generally have low perception thresholds and some ketones (e.g., acetoin) have been known to contribute several positive aroma properties (22–23). In this study, the TK-p sample had the highest ketone rate with 48.24% (22.37 µg/L), followed by the CK-p sample with 37.60% (7.74 µg/L). The percentage rates of the fermented samples produced with a single strain were LKF-p (2.87%), LP-p (3.19%) and LK-p (3.02%), as shown in Fig. 3B. The reason for higher ketone rates in the control samples (P < 0.05) might be that some yeast and LAB species, such as D. hansenii and L. lactis, had lipase activity [24]. This activity is undesirable as it may cause oxidised flavours in dairy products; however, the presence of some methyl ketone compounds produced by β-oxidation of saturated free fatty acids, such as 2-octanone, 2-nonanone and 2-undecanone, have a positive effect on beverage flavour [25].

Among the ketone compounds, 2-heptanone, 2-nonanone and 2-undecanone had higher values in all samples. These compounds have a fruity, floral flavour [26], and had significantly higher amounts in the LKF-p sample than the LK-p and LP-p samples (Table 3). Therefore, it was detected that L. kefiranofaciens might be responsible for the production of 2-nonanone. A previous study reported similar results [27]. Furthermore, both the 3,4-dimethyl-1 and 2-cyclopentanedione compound, associated with sweet maple, caramel sugar flavour [28] and γ-lactone, associated with an undesirable coffee or caramel-like aroma [23, 29], were detected at high values (P < 0.05) in the LK-p sample. It was thought that L. kefiri might be responsible for the production of these two compounds.

The alcohol compounds resulted from the catabolism of amino acids and lactose, a reduction of methyl ketones and degradation of unsaturated fatty acids, such as linoleic and linolenic acids [25]. In particular, higher alcohol levels occurred through decarboxylation and the reduction of α-keto acids, which derive either from central carbon metabolism or from the transamination of amino acids [30]. In this study, mainly LKP-p, then the LP-p and LK-p samples had the higher alcohol amounts (46.54 µg/L; P < 0.05, 29.61 and 26.25 µg/L, respectively) than the total alcohol rates of the CK-p and TK-p samples (Fig. 3A, B; P < 0.05). Large amounts of alcohol were related to ethanol content. Interestingly, it was detected that of the samples using a single strain in production, the LFK-p sample had the highest alcohol amount (43.61 µg/L; P < 0.05), although its starter strain was L. kefiranofaciens, a homofermentative LAB bacterium. The control samples had been expected to have high ethanol values, since yeasts are generally responsible for the production of alcohol. However, when the results were interpreted, the situation has been thought to be related to the long fermentation times of the samples produced using a single strain and the limited number of chemical and biochemical reactions occurring during fermentation. The high amount of alcohol in the LKF-p sample can be explained by the possibility that L. kefiranofaciens may have some enzymes, such as threonine aldolase and alcohol dehydrogenase [31], because it was reported in the literature that a strain of L. acidophilus, which is homofermentative, contributed to flavour production in fermented milk. It has been thought that the threonine aldolase enzyme converted threonine (an amino acid) in milk to acetaldehyde and then the alcohol dehydrogenase enzyme converted acetaldehyde to alcohol. This may explained why the high alcohol value might be related to L. kefiranofaciens. The contribution of ethanol to overall aroma and flavour is not clear in the literature. Therefore, it has been considered that ethanol probably provides a complementary flavour and an excess amount of ethanol is not desirable for non-alcoholic beverages [33].

On the other hand, ethanol, 2-nonanol and 2-heptanol compounds (1.78 and 1.84 µg/L) had high values, especially in the LK-p sample (P < 0.05). Therefore, it was considered that L. kefiri might be responsible as these are a higher group of alcohol compounds formed by a reduction of methyl ketones during the metabolism of fatty acids [33]. It is known that large amounts of higher alcohols may negatively affect the aroma of fermented beverages. In this study, in particular, it was considered that 2-heptanol, has an earthy, oily, mushroom off-flavour [34] and 2-nonanol, has a waxy, fatty, creamy, buttery, milky, dairy, cheesy, musty flavour, negatively affected the aroma. In addition, the LK-p sample contained high amounts of 2-furanmethanol, which is associated with burnt sugar flavour Another alcohol compound, 2-octanol, has a fresh spicy green woody herbal, mushroom, and unripe banana flavour [27] and was also detected in the LKF-p sample. It was thought that L. kefiranofaciens might not be responsible for the production of 2-octanol, as there was not much of it in the samples.

Hexanol, which has a fresh, slightly floral flavour, positively affects the aroma of fermented beverages [31]. In this study, the highest value of it was detected in LP-p (P < 0.05). Therefore, it was considered that L. parakefiri contributed to the refreshing taste and slight floral odour of kefir. However, it was thought that L. parakefiri might not be responsible for the production of 1-hexanol, as there was not much difference between the amounts in each sample.

Acid-based volatiles are important for fermented milk products. In this study, butanoic acid had a pungent, cheesy, sour and rancid flavour, hexanoic acid was similar but also tasted sweaty and putrid and acetic acid had acidic, sour, vinegar, pungent a flavour [25]. Of these compounds, butanoic acid and hexanoic acid were especially undesirable as they tasted rancid. Therefore, LKF-p and LK-p negatively affected the taste. On the other hand, the acetic acid compound was found only in the LP-p sample. It is produced by the metabolism of carbohydrate (lactose) by LAB, or the metabolism of citric and lactic acid, or the catabolism of amino acids and it can play a role as a precursor to the formation of methyl ketones, alcohols, lactones and esters [5, 32]. For this reason, the LP-p sample came into prominence and it was thought that L. kefiri might be responsible for the butanoic acid.

Aldehydes are the simplest carbohydrate molecules produced as a result of the transamination and decarboxylation of amino acids, or by Strecker degradation, or by lipid metabolism by microorganisms. They are also intermediate products of the reactions. Aldehydes have little impact on the general aroma because of their lower threshold [35]. However, excess concentrations of aldehydes may cause an astringent off-flavour [23]. Among the aldehyde components in all samples in this study, the aldehyde compound with the highest amount was 2-methylbutanal, which was produced by leucine degradation, and had almond, cocoa, hazelnut, malt and a very slightly burnt flavour [36]. Due to the high content of 2-methylbutanal in LKF-p (10.86 µg/L), it was revealed that L. kefiranofaciens was associated with 2-methylbutanal and it negatively affected LKF-p due to its malty flavour.

Of the more important compounds, acetaldehyde had the desired aroma with a fresh, green apple, mildly creamy and slightly sweet flavour and benzaldehyde, which had a natural, fruity flavour in low quantity, had higher values in the LK-p and LP-p samples, respectively, than LKF-p (P < 0.05; Table 3). Thus, it was revealed that L. kefiri and then L. parakefiri were associated with acetaldehyde and benzaldehyde. The other aldehydes, heptanal, hexanal, nonanal and octanal, are products of lipid metabolism. Nonanal which has a green citrus-like, floral, cheesy, soapy and fatty flavour [27] was found in higher amounts in the LKF-p and LK-p samples than the LP-p. Thus, it can be revealed that L. kefiri and L. kerifanofaciens were associated with nonanal. Octanal which has a citrus orange–green peel odor was found in higher amounts in the LKF-p.

Esters are compounds formed either via the chemical esterification of alcohols and fatty acids or by de-novo microbial synthesis using alcohol acetyltransferase on acetyl-CoA and the alcohol compounds, during fermentation [37]. Esters are generally the desired compounds in fermented milk products. In this study, in terms of the total amount of ester compounds, the LK-p sample had a higher total (3.57 µg/L) than the others (P < 0.05; Fig. 3A). In the LK-p sample, two desired ester compounds, ethyl hexanoate (ethyl caproate) and ethyl octanoate, which had sweet, fruity, floral, green apple and orange odours, had high values. However, the compounds were also found in the other samples. These had the best relationship with L. kefiri, because they had the highest amount (1.20 and 1.14 µg/L, respectively) in the LK-P sample. In addition, the ethyl acetate compound that had floral-fruity odours had similarly high values in both the LK-p and LP-p samples. In contrast, ethyl decanoate, which had fruity, grape cognac flavours, were detected only in the LK-p sample and ethyl butyrate, which had ripe fruit, buttery, pineapple and banana flavours, was only detected in the LFK-p sample. According to the results, L. parakefiri was highlighted, because it was associated the compounds which give desired fruity and floral flavours.

Terpenes are volatile unsaturated hydrocarbons. In general, the degradation or biosynthesis of monoterpenes and sesquiterpenes by LAB is limited. However, the biosynthetic activity of terpenes has been reported for some LAB, such as L. acidophilus and L. paracasei, through a non-mevalonate pathway [26, 38]. In this study, two terpenes, β-myrcene and d-limonene, were found in high values in the LKF-p and LP-p samples, respectively. Therefore, first, L. kefiranofaciens and then L. parakefiri might be responsible for the formation of these compounds and L. kefiranofaciens was considered to have a negative effect because of the high amounts of β-myrcene that had balsamic, geranium, herby, musty and spicy odours, unlike d-limonene that had citrus and mint flavours and was thought to have a refreshing flavour. Finally, 3-methyl-2-butanethiol, from the reaction in the LP-p sample, had a savoury, meaty flavour and can be used in bakery, cereal and milk products.

Principle component analysis (PCA) was conducted to reveal the similarities and dissimilarities of all samples based on volatile profiles. PCA is a common statistical tool used to reveal the relationship between foods in terms of volatile and sensory characteristics. It was determined that the variations in all samples in terms of their volatile profile could be explained by two basic components at the rate of 70.33%. The PCA diagram is shown in Fig. 4. It was observed that the TK-p and CK-p samples were similar to each other in terms of flavour profile. They could be characterised by volatile compounds, especially those belonging to the ketone and aldehyde group. CK-p is well characterized by 3-methyl-2-butanone, 3-methyl butanal, 2-furanmetahnol and benzaldehyde, while acetoin, 2,3-butadione (diacetyl), 2-nonanone, 2-heptanone and nonyl methyl ketone were found to contribute the volatile profile of TK-p. Furthermore, the LP-p and LKF-p samples appeared to be characterised by both alcohol and aldehyde-derived volatile compounds. According to this, volatiles including hexanol, 2-octanol (capryl alcohol), octanal contribute the aroma profili of LFK-p, whereas aldehydes including heptanal, nonanal and decanal primarily characterized the volatile profile of LP-p. Moreover, it was found that hexanal contributes aroma profiles of both kefir samples. On the other hand, it was determined that the LK-p sample was characterised by ethyl octanoate, ethyl hexanoate, acetaldehyde, 2-heptanol and geraniol compounds apart from other kefir samples.

Principle component analysis of VACs data of the fermented milk samples (LKF-p, LP-p and LK-p) produced using Lactobacillus kefiranofaciens, Lentilactobacillus parakefiri, and Lentilactobacillus kefiri strains, respectivity. CK-p and TK-p are the fermented control products produced using commercial kefir culture and kefir grain, respectivity

Sensory properties of the fermented samples

Sensory analysis was evaluated in terms of appearance, smell and taste characteristics (Fig. 5A, B). There was no difference between the samples in terms of colour and serum separation. However, a significant difference was found between LF-p, with the highest score and LFK-p, with the lowest score in foam formation (P < 0.05). Foam formation is a desired feature in kefir-based beverages. Only fluency was evaluated in the structure parameter and the sample produced with a single culture were lower than the control-kefir samples (P > 0.05).

Sensory properties; A appearance, consistency, aroma and taste and B overall-like scores of the fermented milk samples using prominent strains in kefir grain. *LKF-p, LP-p and LK-p, are the samples produced using Lactobacillus kefiranofaciens, lactobacillus parakefiri, and Lactobacillus kefiri strains, respectivity. CK-p and TK-p are the fermented control products produced using commercial kefir culture and kefir grain, respectivity. a–d Different lowercase letters indicate significant differences between the samples (P < 0.05)

When smell and taste parameters were examined, the LKF-p and LK-p samples had higher burnt, animalistic and metallic aroma scores than the others (P < 0.05). This relates to their 2-methylbutanal, 2-octanol and ethyl hexanoate compounds. On the other hand, the LKF-p and LP-p samples had high fruity aroma scores. Of the taste parameters, the burnt and metallic tastes had higher scores in the LKF-p and LK-p samples than the control samples (P < 0.05). However, the LP-p sample was found to have a very high flower and yeast flavour score, so L. parakefiri had a more positive effect on the odour and taste properties of the fermented milk samples produced with a single culture.

Conclusion

The results showed the effect of the three prominent LAB strains in kefir grain microflora, L. kefiranofaciens, L. parakefiri and L. kefiri, on chemical and biochemical properties of kefir, especially their strong relationship with the VACs of the fermented milk samples produced with a single culture. The strain that showed the highest activity in acetic acid production and citrate and lactose consumption, which are important for organic acid content and aroma formation, was identified as L. kefiri. In addition, L. kefiranofaciens was associated with hexanol, 2 octanol, and 1-octanal and L. kefiri with ethyl octanoate, ethyl hexanoate, acetaldehyde and geraniol. L. parakefiri was characterised by 3-methyl-2-butanethiol and heptanal. Therefore, the L. parakefiri strain was highlighted in terms of a desired aroma profile, as well as with the support of the sensory results. Thus, it has provided a clearer understanding of the functions of the prominent strains in the kefir grain.

Data availability

Data will be made available on reasonable request.

Code availability

Not applicable.

References

Kok-Tas T, Ekinci FY, Guzel- Seydım ZB (2021) Identification of microbial flora in kefir grains produced in Turkey using PCR. Int J Dairy Technol 65:126–131

Bengoa AA, Iraporda C, Garrote GL, Abraham AG (2019) Kefir micro- organisms: their role in grain assembly and health properties of fermented milk. J Appl Microbiol 126:686–700

Vardjan T, Lorbeg PM, Rogelj I, Majhenič AČ (2013) Characterization and stability of lactobacilli and yeast microbiota in kefir grains. J Dairy Sci 96:2729–2736

Miguel MGDCP, Cardoso PG, De Assis LL, Schwan RF (2010) Diversity of bacteria present in milk kefir grains using culture-dependent and culture-independent methods. Food Res 43:1523–1528

Delgado-Fernández P, Corzo N, Lizasoain S, Olano A, Moreno FJ (2019) Fermentative properties of starter culture during manufacture of kefir with new prebiotics derived from lactulose. Int Dairy J 93:22–29

Kim DH, Kim H, Seo KH (2019) Microbial 622 composition of Korean kefir and antimicrobial activity of Acetobacter fabarum DH1801. J Food Safety 40:e12728

Łopusiewicz Ł, Drozłowska E, Siedlecka P, Mężyńska M, Bartkowiak A, Sienkiewicz M, Zielinska-Blizniewska H, Kwiatkowski P (2019) Development, characterization, and bioactivity of non-dairy kefir-like fermented beverage based on flaxseed oil cake. Foods 8:544

García-Quintáns N, Blancato VS, Repizo GD, Magni C, López P (2008) Citrate metabolism and aroma compound production in lactic acid bacteria. In: Mayo B, López P, Pérez-Martínez G (eds) Molecular aspects of lactic acid bacteria for traditional and new applications. Research Signpost India, Thiruvananthapuram, pp 65–88

Simova E, Simov Z, Beshkova D, Frengova G, Dimitrov Z, Spasov Z (2006) Amino acid profiles of lactic acid bacteria, isolated from kefir grains and kefir starter made from them. Int J Food Microbiol 107:112–123

Rattray FP, O’connell O (2011) Fermented milks kefir. In: Fukay JW (ed) Encyclopedia of dairy sciences. Academic Press, San Diego, pp 518–524

Nejati F, Junne S, Neubauer P (2020) A big world in small grain: a review of natural milk kefir starters. Microorganisms 8:192

AOAC (2000) Association of official analytical chemistry official methods of analysis of the association of analytical in chemists, 17th edn. AOAC International, Washington, USA

Holt JG, Krieg NR, Sneath PHA, Staley JT, Williams ST (1994) Bergey’s manual of determinative bacteriology, 9th edn. Williams and Wilkins, Baltimore, USA, pp 757–787

Güzel-Seydim ZB, Seydim AC, Greene AK, Bodine AB (2000) Determination of organic acids and volatile flavor substances in kefir during fermentation. J Food Compost Anal 13:35–43

Anonymous (2009) Turkish Food Codex Communiqué on Fermented Milk Products (Communiqué Number: 2009/25) Official newspaper. 16.02.2009, Issue 27143, http://www.kkgm.gov.tr/TFC/2001–21.html. Accessed on 13.05.2020

Nambou K, Gao C, Zhou F, Guo B, Ai L, Wu ZJ (2014) A novel approach of direct formulation of defined starter cultures for different kefir-like beverage production. Int Dairy J 34:237–246

Yovanoudi M, Dimitreli G, Raphaelides SN, Antoniou KD (2013) Flow behaviour studies of kefir type systems. J Food Eng 118:41–48

Ahmed Z, Wang Y, Anjum N, Ahmad A, Khan ST (2013) Characterization of exopolysaccharide produced by Lactobacillus kefiranofaciens ZW3 isolated from Tibet kefir–Part II. Food Hydrocoll 30:343–350

Breuer U, Harms H (2006) Debaryomyces hansenii—an extremophilic yeast with biotechnological potential. Yeast 23:415–437

Endo A, Okada S (2007) Lactobacillus farraginis sp. nov. and Lactobacillus parafarraginis sp. nov., heterofermentative lactobacilli isolated from a compost of distilled shochu residue. Int J Syst Evol Micr 57:708–712

Kandler O, Kunath P (1993) Lactobacillus kefir sp. nov., a component of the microflora of kefir. Syst Appl Microbiol 4:286–294

Li L, Ma Y (2018) The effect of soluble saccharides on the activity of key enzymes linked to methyl ketone synthesis in Lactococcus lactis. CyTA-J Food 16:325–330

Di Cagno R, Filannino P, Gobbetti M (2017) Lactic acid fermentation drives the optimal volatile flavor-aroma profile of pomegranate juice. Int J Food Microbiol 248:56–62

Papagora C, Roukas T, Kotzekidou P (2013) Optimization of extracellular lipase production by Debaryomyces hansenii isolates from dry-salted olives using response surface methodology. Food Bioprod Process 91:413–420

Chen C, Zhao S, Hao G, Yu H, Tian H, Zhao G (2017) Role of lactic acid bacteria on the yogurt flavour: a review. Int J Food Prop 20:S316–S330

Sharma A, Sharma P, Singh J, Singh S, Nain L (2020) Prospecting the potential of agroresidues as substrate for microbial flavor production. Front Sustain Food Syst 4:18

Walsh AM, Crispie F, Kilcawley K, O’Sullivan O, O’Sullivan MG, Claesson MJ, Cotter PD (2016) Microbial succession and flavor production in the fermented dairy beverage kefir. Msystems 1:00052–00116

Lee LW, Liu X, Wong WSE, Liu SQ (2017) Effects of sucrose monopalmitate (P90), Tween 80 and modified starch on coffee aroma retention and release in coffee oil-based emulsions. Food Hydrocoll 66:128–135

Mantzourani I, Kazakos S, Terpou A, Mallouchos A, Kimbaris A, Alexopoulos A, Bezirtzoglou E, Plessas S (2018) Assessment of volatile compounds evolution, antioxidant activity, and total phenolics content during cold storage of pomegranate beverage fermented by Lactobacillus paracasei K5. Fermentation 4:95

Eder M, Sanchez I, Brice C, Camarasa C, Legras JL, Dequin S (2018) QTL mapping of volatile compound production in Saccharomyces cerevisiae during alcoholic fermentation. BMC Genomics 19:166

Magalhães KT, Dragone G, De Melo Pereira GV, Oliveira JM, Domingues L, Teixeira,Almeida e Silva JB, Schwan RF JA (2011) Comparative study of the biochemical changes and volatile compound formations during the production of novel whey-based kefir beverages and traditional milk kefir. Food Chem 126:249–253

Vedamuthu ER (2006) Starter cultures for yogurt and fermented milk. Manufacturing yogurt and fermented milks. Blackwell, Iowa, pp 89–116

Kaminarides S, Stamou P, Massouras T (2007) Changes of organic acids, volatile aroma compounds and sensory characteristics of Halloumi cheese kept in brine. Food Chem 100:219–225

Carunchia-Whetstine ME, Karagul-Yuceer Y, Avsar YK, Drake MA (2003) Identification and quantification of character aroma components in fresh Chevre- style goat cheese. J Food Sci 68:2441–2447

Dan T, Wang D, Wu S, Jin R, Ren W, Sun T (2017) Profiles of volatile flavour compounds in milk fermented with different proportional combinations of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophiles. Molecules 22:1633

Dragone G, Mussatto SI, Oliveira JM, Teixeira JA (2009) Characterization of volatile compounds in an alcoholic beverage produced by whey fermentation. Food Chem 112:929–935

Ledauphin J, Guichard H, Saint-Clair JF, Picoche B, Barillier D (2003) Chemical and sensorial aroma characterization of freshly distilled calvados. 2. Identification of volatile compounds and key odorants. J Agric Food Chem 51:433–442

Belviso S, Giordano M, Dolci P, Zeppa G (2011) Degradation and biosynthesis of terpenoids by lactic acid bacteria isolated from cheese: first evidence. Dairy Sci Technol 91:227

Funding

This work was supported by Süleyman Demirel University Scientific Research Projects Management Unit [Grant No. FYL-2019-7079].

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of the experiments, their performance, interpretation of the obtained results, writing of the article and revising it. All authors have approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Duran, F.E., Özdemir, N., Güneşer, O. et al. Prominent strains of kefir grains in the formation of volatile compound profile in milk medium; the role of Lactobacillus kefiranofaciens subsp. kefiranofaciens, Lentilactobacillus kefiri and Lentilactobacillus parakefiri. Eur Food Res Technol 248, 975–989 (2022). https://doi.org/10.1007/s00217-021-03936-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03936-2