Abstract

Fermented milk has been shown to have beneficial effects on human health exerted through its bioactive peptides. The lactose-fermenting brown rot fungus Neolentinus lepideus has been shown to ferment milk; however, its ability to produce bioactive peptides has not been explored. This study, therefore, aimed to investigate the ability N. lepideus for the production of antihypertensive peptides in fermented milk and to characterize the peptides. Here we have used 9% skim milk as the substrate and fermented it with the mycelia of N. lepideus. The fermented milk exhibited higher angiotensin I-converting enzyme (ACE) inhibitory activity as compared to the commercially available sour milk containing Ile-Pro-Pro and Val-Pro-Pro. As a result of isolation and purification by reverse-phase high-performance liquid chromatography, followed by peptide sequencing and MS analysis, the dipeptide Tyr-Pro (YP) was identified as an active peptide. The concentration of YP in the fermented milk reached up to 450 μg/ml, which was > twofold higher than the IC50 for ACE inhibition. Subsequently, the antihypertensive effect of YP was validated through intravenous injection of the peptide, which exhibited a significant lowering of blood pressure in a rat model of genetic hypertension. In addition, the transcriptomic analysis revealed the probable role of the carboxypeptidases for the increased yield of YP. These results together indicated that the fermentation with basidiomycete fungus could be a viable approach to produce bioactive peptides, and may, therefore, be applicable in the development of a cost-effective mass production system for functional peptides.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hypertension, also known as high blood pressure, is defined by systolic blood pressure ≥ 130 mmHg and/or diastolic blood pressure ≥ 80 mmHg. It is associated with a high risk of serious diseases such as arteriosclerosis, cardiovascular disease, myocardial infarction, stroke, and renal failure [1]; it also raises the risk of developing cerebrovascular dementia [2]. Thus, hypertension, as a silent killer, is one of the most prevalent risk factors for premature death worldwide. According to a report from the World Health Organization, 9.4 million people die from complications of hypertension, such as myocardial infarction, cerebral stroke, and renal failure, every year [3]. Therefore, reducing the incidence of hypertension worldwide is imperative.

The renin–angiotensin–aldosterone system (RAAS) is one of the most important systems regulating blood pressure [4, 5], and several antihypertensive drugs have been developed to target the angiotensin I-converting enzyme (ACE, EC 3.4.15.1), a key enzyme in RAAS that catalyzes the conversion of angiotensin I to angiotensin II and causes blood vessel contraction [6, 7]. Although these synthetic inhibitors have shown an excellent antihypertensive effect, the use of such synthetic drugs to prevent or treat hypertension is not preferable owing to the related cost and side effects [8, 9].

In this context, several studies have been performed to identify nutrients with antihypertensive effects in regular foods [10], of which the studies evaluating the peptides with ACE inhibitory activity, have attracted much attention considering that they may provide a safe and inexpensive strategy to control blood pressure by inhibiting RAAS through regular meals [11]. Such studies attempted to produce functional peptides by in vitro enzymatic hydrolysis of, or fermentation of, protein-rich foods, such as fish, milk, peanuts, and soybean [12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27]. Although some of these studies have achieved commercial success by the development of foods with health-promoting benefits, these methods, in general, are limited in terms of cost-effectiveness, specifically, relatively low recovery of target peptides.

In our previous study, we had identified a basidiomycete fungus Neolentinus lepideus that harbored the unique ability to produce ethanol from whey or milk [28]. The study has also reported that milk protein was decomposed during the fermentation, besides the production of ethanol. We thus hypothesized that this basidiomycete fungus might be able to produce bioactive peptides from milk.

Therefore, the current study aimed to investigate the ability of N. lepideus to produce bioactive peptides in fermented milk and to evaluate the peptides quantitatively and qualitatively. In addition, we examined the effect of fermented milk on the ACE inhibitory activity to explore its possible physiological functions.

Materials and methods

Fungal strain and culture conditions

The N. lepideus strain YP6096, used in this study, was isolated from fruiting bodies on decaying wood in Tottori Prefecture, Japan. The strain, YP6096, revealed the best casein degrading ability among the wild strains of N. lepideus collected by us (data not shown). The fungus was initially grown on an MYG agar plate (consisting of 10 g/l malt extract, 4 g/l yeast extract, 4 g/l glucose, and 15 g/l agar powder) at 28 °C for 7 days. Three 0.5 cm2 pieces of the mycelial mat were then inoculated in 500 ml Erlenmeyer flasks containing 50 ml of MYG liquid medium, and capped with silicone plugs (Shin-Etsu Polymer Co., Ltd., Tokyo, Japan) for mycelial growth; the flasks were incubated for 7 days at 28 °C without shaking. The mycelia were then inoculated into a 500 ml Erlenmeyer flask containing 50 ml of 9% (w/w) skim milk without any nutrient supplementation and sealed with a silicone rubber plug (AS ONE Co., Ltd., Osaka, Japan) for fermentation. The cultures were incubated at 28 °C without shaking. The fermented milk was then centrifuged for 15 min at 15,000 rpm at 4 °C in an Eppendorf bench-top centrifuge, and the supernatant was filtered through a 0.22-μm membrane filter (Millex-GP; Millipore Corp., Billerica, MA) to obtain a stock solution for further analysis.

Amino acid analysis

The free amino acid content in the fermented milk was measured by an automatic amino acid analyzer (JLC-500/V2; JEOL Ltd., Tokyo, Japan). The release rate of each amino acids in the supernatant of the fermented milk was calculated using the amino acid content in 9% skim milk as reported earlier [29], and the release rate was calculated as follows;

Release rate (%) = (Free amino acid content in the fermented milk/Amino acid content in 9% skim milk) × 100.

Determination of ACE inhibitory activity

The ACE inhibitory activity of samples was determined using an ACE Kit-WST (Dojindo, Japan), according to manufacturer’s instructions, modified based on the method described by Cushman and Cheung [30]. The absorbance of the released 3-hydroxybutyric acid in the reaction mixtures at 450 nm was recorded using a microplate reader (Multiskan™ GO; Thermo Fisher Scientific, Waltham, MA, USA). The ACE inhibitory activity of N. lepideus fermented milk was measured by diluting the fermented milk 100-fold with sterile distilled water.

Comparison and evaluation of ACE inhibitory activities

We compared the ACE inhibitory activities of the N. lepideus fermented milk and the commercially available sour milk (Ameal S™; Calpis Co., Ltd., Tokyo, Japan) containing the potent ACE inhibitory peptides Ile-Pro-Pro (IPP) and Val-Pro-Pro (VPP), at a total concentration of 17 μg/ml. The fermented milk by N. lepideus and the sour milk were aseptically collected, centrifuged, and the supernatant was filtered in the same way as described earlier (in “Fungal strain and culture conditions” section), which was subsequently diluted for comparative analysis of their ACE inhibitory activities.

Separation and purification of peptides released in fermented milk

At periodic intervals of 2 days starting from day 0 till day 8 followed by an interval of six and seven days till day 21, 1 ml of the sample was aseptically collected, centrifuged, and filtered in the same way as described earlier (in “Fungal strain and culture conditions” section). Then the filtrate was used for separation of the peptides by reverse-phase high-performance liquid chromatography (RP-HPLC) using an HPLC system (Shimadzu Co., Ltd., Kyoto, Japan) equipped with a UV/VIS detector, SPD-20A, and reverse-phase column Cadenza CD-C18 (4.6 mm × 150 mm; Imtakt Corp., Kyoto, Japan). The analysis was performed at 28 °C with deionized water containing 0.1% (v/v) trifluoroacetic acid (TFA) and acetonitrile containing 0.1% (v/v) TFA as solvents A and B, respectively. The C18 column was conditioned with solvent A. The sample volume injected into the column was 10 μl, and the flow rate was 0.6 ml/min. The linear concentration gradient settings were as follows: 0–22% solvent B for 50 min. The UV absorbance of the eluent was monitored by recording the absorbance at 215 nm, and the fractions were collected for the estimation of ACE inhibitory activities. The fraction with the highest ACE inhibitory activity was then separated, concentrated, freeze-dried, and re-dissolved in 0.1% TFA. The purification was repeated thrice with the same elution conditions.

Identification of amino acid sequences of the purified peptide

Amino acid sequences of the purified peptide were determined by a protein sequencer PPSQ-31A (Shimadzu Co., Ltd., Kyoto, Japan).

Mass spectrometry analysis of the purified peptide

MS analysis of the active peptide was performed in a positive ion mode through electrospray ionization mass spectrometry (ESI–MS) using a mass spectrometer (Exactive™; Thermo Fisher Scientific, Waltham, MA, USA).

Synthesis and quantification of the purified peptide

The peptides IPP, VPP, VY, and GY, reported to have the ACE inhibitory activities, were chemically synthesized (BEX Co., Ltd. Japan) for analyzing the antihypertensive properties. In addition, we also synthesized the purified peptide based on its amino acid sequence for quantification and performed a comparative analysis to confirm its properties. All the peptides were synthesized using a solid-phase method. The purified peptide was quantified using a standard curve developed by inferring to the area and concentration of the synthesized one by RP-HPLC.

The antihypertensive effect of YP on stroke-prone spontaneously hypertensive rats

The acute effects of YP and other peptides on blood pressure were studied in a rat model of genetic hypertension, the stroke-prone spontaneously hypertensive rat (SHRSP). Rats were housed under conditions of 12/12 h light/dark cycle, at 25 ± 1 °C, and 60% humidity. Male rats at 12 weeks of age were anesthetized by intraperitoneal injection of pentobarbital (50.0 mg/kg BW). The femoral vein was cannulated and connected to an auto-injector (ESP-32; Eicom, Kyoto, Japan) for continuous infusion of propofol to control anesthesia throughout the experiment (30.0 mg/kg/h). After that, the femoral artery was cannulated and connected to a pre-calibrated transducer (PowerLab 8/30; ADInstruments, NSW, Australia) to monitor intra-arterial blood pressure directly. The trachea was intubated for artificial respiration. Each peptide (1 mg/kg BW) was administered by a single intravenous injection through the indwelling venous catheter. Changes in blood pressure were monitored continuously, and the maximal change from baseline was considered for analysis.

RNA extraction, library preparation, and sequencing

Total RNA was extracted from freshly frozen mycelia using the RNeasy Plant Mini Kit (Qiagen, Hilden, Germany) according to the manufacturer's instructions. The quality and concentration of RNA were validated using a BioSpec-nano spectrophotometer (Shimadzu, Kyoto, Japan). Total RNA integrity was checked using the Agilent 2100 bioanalyzer system (Agilent Technologies, Palo Alto, CA, USA), and the samples with an RNA Integrity Number of ≥ 7.0 were used for paired-end sequencing. The mRNA sequencing was performed on the Illumina HiSeq platform. Library construction and sequencing were performed by Macrogen (Seoul, Korea). To obtain quantification scores between the two samples, fragments per kilobase of transcript per million mapped reads (FPKM) values were calculated using Cufflinks, which correct for transcript length and the total number of mapped reads from the library to compensate for different read depths in different samples. Annotation of the raw data and differences in gene expression levels were analyzed by Maze Inc. (Tokyo, Japan).

Statistical analysis

Data were expressed as mean ± standard deviation (SD) of 3–5 independent experiments. Statistical analyses were performed using one-way analysis of variance (ANOVA) followed by the Student’s t test for comparison of two means or Dunnett’s post hoc test for multiple comparisons. The p value of < 0.05 was considered significant.

Results

The amino acid content of milk fermented by Neolentinus lepideus

Analysis of the amino acid content of the supernatant of milk fermented by N. lepideus for 8 days revealed the release of 17 of the 20 amino acids suspected to be derived from casein (Table 1). The release rates of 7 of the 9 essential amino acids except for Met (13.25%) and His (40.02%) were > 50%, indicating that the fermented milk has a relatively high content of essential amino acids.

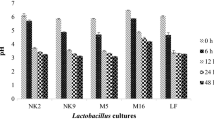

ACE inhibitory activity of the fermented milk

The ACE inhibitory activity of the N. lepideus fermented milk was observed to be increased daily, with approximately 70% or more on the fourth day of fermentation, and approximately 80% on the sixth day or later (Fig. 1).

Comparison of ACE inhibitory activity between the milk fermented by N. lepideus and the commercially available sour milk

The milk fermented by N. lepideus and sour milk containing the antihypertensive tri-peptides (IPP and VPP) was diluted 100-fold, 500-fold, and 1000-fold, each to prepare the test samples. The ACE inhibitory activity of the fermented milk was significantly higher (~ twofold) than that of sour milk (p < 0.05, Student’s t test) in all the three dilutions (Fig. 2).

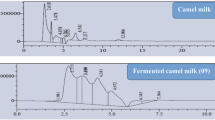

Isolation and purification of the fraction with maximum ACE inhibitory activity

Next, we separated the peptides by RP-HPLC. We focused on peaks that increased remarkably following the progression of fermentation, and the ACE inhibitory activity was measured after fractionation. Among 12 fractions collected, the fraction 9 displayed the highest ACE inhibitory activity (Fig. 3) and purified (Fig. 4a) for further analysis.

Identification of the peptide from fraction 9

The amino acid sequencing of the purified peptide in the fraction 9 (Fig. 4a) identified the dipeptide Tyr-Pro (YP) and the retention time of YP (31 min) in fermented milk was confirmed to be consistent with that of synthetic YP, by RP-HPLC analysis (Fig. 4a, b). Further, the ESI–MS analysis showed the signal m/z 279.1337 [M + H]+, corresponding to one proton added to the molecular weight of 278.31 of YP (Fig. 5). Taken together, these results confirmed that the main component showing ACE inhibitory activity in the N. lepideus-fermented milk was YP.

The yield of YP by N. lepideus over time

Fermentation was performed using N. lepideus in a liquid containing 9% skim milk, and the sample was collected at different time intervals up to 21 days to measure the yield of YP, using RP-HPLC. The results are shown in Fig. 6. The concentration of YP in samples collected on day 2 was approximately 100 μg/ml, which reached a maximum of 450 μg/ml on day 21.

Intravenous injection of YP to SHRSP

Antihypertensive effects of YP and other peptides with ACE inhibitory activity, chemically synthesized as acetate salts, were investigated in vivo. As shown in Fig. 7, YP and IPP had a strong antihypertensive effect while VPP, VY, and GY were relatively weak. Blood pressure returned to the initial level after about 1 hour of injection. In Dunnett’s test, YP was significantly different from VPP, VY, GY (p < 0.001). However, no significant difference was observed between YP and IPP (p > 0.05).

Transcriptome analysis

Transcriptome analysis was performed to identify the proteolytic enzymes involved in YP production that is expressed during the fermentation process. A total of 22 proteolytic enzymes, including endopeptidases, aminopeptidases, carboxypeptidases, dipeptidases, dipeptidyl peptidases, and tripeptidyl peptidases were identified to be expressed with at least 10-times higher FPKM after 2 days of fermentation than at the beginning of fermentation (Table 2).

Discussion

Among the various kinds of mushrooms, the brown rot fungus, N. lepideus, is not only capable of assimilating carbon sources in woods but can also ferment dairy products, despite not requiring such materials as nutrients for their survival [28]. This fungus could not only grow in milk, but also decomposed casein, a major component of milk proteins. In this study, we newly discovered that, in addition to amino acids, this fungus produced physiologically active peptides during the fermentation of milk.

Seventeen amino acids were found abundantly in the fungus-fermented milk (Table 1). In particular, arginine and tryptophan, which are not so rich in lactic acid bacteria fermented milk, constitute a unique content of this fungus-fermented milk. Various beneficial effects of the amino acids in the body, such as reducing anxiety and promoting recovery of muscle damage after exercise [31], the fungus-fermented milk could be potentially valuable as a health-promoting food.

In addition to the production of amino acids, the release of peptides with ACE inhibitory activity was remarkable in the fermented milk. As fermentation progressed, ACE inhibitory activity of the milk increased over time (Fig. 1); the fungus-fermented milk showed a more potent ACE inhibitory effect than lactic acid bacteria-fermented milk (Fig. 2).

Among the various ACE inhibitory peptides found in lactic acid bacteria-fermented milk [20,21,22,23], IPP and VPP have been reported to have a strong antihypertensive effect [15,16,17,18]. In this report, the fungus-fermented milk was clearly shown to have a stronger ACE inhibitory activity than the commercially available sour milk rich in IPP and VPP, although the fungus-fermented milk did not contain these tripeptides (data not shown). We identified that the peptide playing a central role in the fungus-fermented milk was a dipeptide, YP. As shown in Table 3, many different peptides with the YP sequence were reported to be produced in fermentation [19, 32,33,34,35,36,37,38]; however, L. helveticus was reported to be the only one that could release YP from casein per se [19].

As the IC50 of YP for ACE inhibition was reported to be 720 μM [19], which is equivalent to 200 μg/ml, the fermented milk must contain such a high concentration of YP to elicit ACE inhibition. In the present study, we observed that the concentration of YP in milk gradually increased during the fermentation process, and finally reached as high as 450 μg/ml (Fig. 6), twice as high as that required to achieve the IC50, which confirmed the ACE inhibitory activity of YP. The YP content in 9% skim milk has been estimated to be about 640 μg/ml, whereas it was 450 μg/ml (70.3%) in N. lepideus fermented milk, which indicated a comparatively high efficiency of the fungus to release most of the YP residues from skim milk. This is the advantage of fermentation using N. lepideus since lactic acid bacteria produced YP at a maximum concentration of 10 μg/ml [19]. This difference might be due to the poor sensitivity of fungi to acidification of the medium during their growth. In contrast, lactic acid bacteria are known to stop their growth and peptide production in the acidified medium due to the accumulation of lactic acid and feedback inhibition of peptidase by branched-chain amino acids [39, 40]. Considering the high ACE inhibitory activity of the fungus-fermented milk, we may, in the future, need to examine the possibility of co-production of other peptides with potent ACE inhibitory activity.

An antihypertensive effect of YP was confirmed in vivo using a rat model of genetic hypertension. Although the ACE inhibitory activity of YP in vitro, was comparatively lower than other di- and tripeptides with antihypertensive effects (IC50 was 720 μM, 5 μM, 9 μM, 22 μM, and 210 μM for YP, IPP, VPP, VY, and GY, respectively) [14, 19, 41], YP showed the largest reduction of blood pressure; however, was comparable to the antihypertensive effect of IPP (Fig. 7). This discrepancy between the ACE inhibitory activity in vitro and antihypertensive effect in vivo implied that the antihypertensive effect of the peptides, observed in vivo, may not be via inhibition of ACE. This is consistent with the result of the oral administration test of YP to SHR by Yamamoto et al. [19]. Additional studies would be required to understand the antihypertensive mechanisms of YP in vivo.

Many genes encoding putative proteolytic enzymes, active in casein decomposition, were expressed and up-regulated even in an early stage of fermentation with N. lepideus (Table 2). In addition to endopeptidase, this fungus seemed to have a balanced expression of aminopeptidase, XPDAP, and carboxypeptidase, indicating that YP might be specifically produced. Previously, it was reported that the exopeptidase treatment of whey protein had a positive effect on its ACE inhibitory activity and antihypertensive action [42]. In particular, the transcriptomic data showing higher FPKM for carboxypeptidases indicated that N. lepideus expressed the gene(s) encoding carboxypeptidase, which is not found in lactic acid bacteria [43,44,45] could be associated with higher ACE inhibitory activity and higher YP production (30–40 times) than lactic acid bacteria. Furthermore, many genes, found in N. lepideus, had a low homology (around 40%) with Aspergillus fungi (to be reported elsewhere’), thus suggesting a possibility that N. lepideus could be unique in terms of YP production, even amongst fungi. Through transcriptome analysis, we further found that prolidase, an enzyme degrading the bond between Y and P, was expressed in N. lepideus. This suggested that we could recover more YP through ‘knockout’ of the prolidase gene in N. lepideus. This possibility would be worth exploring in a future study.

Conclusion

This is the first report that identifies the brown rot fungus, N. lepideus, as a promising microorganism for the production of the antihypertensive peptide, YP, also having ACE inhibitory activity from milk. However, further studies are warranted to verify the antihypertensive effect of fermented milk, containing YP, on SHR or SHRSP, and to improve the productivity of peptides by this fungus. Production of peptides from milk by the naturally occurring basidiomycete fungus would be preferable not only for peptide production, but also for its cost-effectiveness, and lower environmental footprint.

Abbreviations

- ACE:

-

Angiotensin I-converting enzyme

- RP-HPLC:

-

Reverse-phase high-performance liquid chromatography

- HPLC:

-

High-performance liquid chromatography

- ESI–MS:

-

Electrospray ionization mass spectrometry

- YP:

-

Dipeptide Tyr-Pro

- RAAS:

-

Renin-angiotensin aldosterone system

- TFA:

-

Trifluoroacetic acid

- IPP:

-

Ile-Pro-Pro

- VPP:

-

Val-Pro-Pro

- FPKM:

-

Fragments per kilobase of transcript per million mapped reads

- SHR:

-

Spontaneously hypertensive rat

- SHRSP:

-

Stroke-prone spontaneously hypertensive rat

- MAP:

-

Mean arterial pressure

References

De la Sierra A (2019) New American and European hypertension guidelines, reconciling the differences. Cardiol Ther 8:157–166

Qiu C, Winblad B, Fratiglioni L (2005) The age-dependent relation of blood pressure to cognitive function and dementia. Lancet Neurol 4:487–499

World Health Organization (2013) A global brief on HYPERTENSION—silent killer, global public health crisis, Geneva, World Health Organization. https://ish-world.com/downloads/pdf/global_brief_hypertension.pdf

Laragh JH, Baer L, Brunner HR, Buhler FR, Sealey JE, Vaughan ED Jr (1972) Renin, angiotensin and aldosterone system in pathogenesis and management of hypertensive vascular disease. Am J Med 52:633–652

Atlas SA (2007) The renin–angiotensin aldosterone system: pathophysiological role and pharmacologic inhibition. J Manag Care Pharm 13:9–20

Atkinson AB, Robertson JI (1979) Captopril in the treatment of clinical hypertension and cardiac failure. Lancet 2:836–839

Brown NJ, Vaughan DE (1998) Angiotensin-converting enzyme inhibitors. Circulation 97:1411–1420

Angelo A, Marco C (2001) Drug-induced angioedema without urticaria. Drug Saf 24:599–606

Chen J, Wang Y, Ye R, Wu Y, Xia W (2013) Comparison of analytical methods to assay inhibitors of angiotensin I-converting enzyme. Food Chem 141:3329–3334

Hieda K, Sunagawa Y, Katanasaka Y, Hasegawa K, Morimoto T (2015) Antihypertensive effects of foods. World J Hypertens 5:53–62

Iwaniak A, Minkiewicz P, Darewicz M (2014) Food-originating ACE inhibitors, including antihypertensive peptides, as preventive food components in blood pressure reduction. Compr Rev Food Sci Food Saf 13:114–134

Korhonen H, Pihlanto A (2006) Bioactive peptides: production and functionality. Int Dairy J 16:945–960

Yokoyama K, Chiba H, Yoshikawa M (1992) Peptide inhibitors for angiotensin I-converting enzyme from thermolysin digest of dried bonito. Biosci Biotechnol Biochem 56:1541–1545

Matsui T, Matsufuji H, Seki E, Osajima K, Nakashima M, Osajima Y (1993) Inhibition of angiotensin I-converting enzyme by Bacillus licheniformis alkaline protease hydrolyzates derived from sardine muscle. Biosci Biotechnol Biochem 57:922–925

Nakamura Y, Yamamoto N, Sakai K, Okubo A, Yamazaki S, Takano T (1995) Purification and characterization of angiotensin I-converting enzyme inhibitors from sour milk. J Dairy Sci 78:777–783

Nakamura Y, Yamamoto N, Sakai K, Takano T (1995) Antihypertensive effect of sour milk and peptides isolated from it that are inhibitors to angiotensin I-converting enzyme. J Dairy Sci 78:1253–1257

Nakamura Y, Masuda O, Takano T (1996) Decrease of tissue angiotensin I-converting enzyme activity upon feeding sour milk in spontaneously hypertensive rats. Biosci Biotechnol Biochem 60:488–489

Hata Y, Yamamoto N, Ohni M, Nakajima K, Nakamura Y, Takano T (1996) A placebo-controlled study of the effect of sour milk on blood pressure in hypertensive subjects. Am J Clin Nutr 64:767–771

Yamamoto N, Maeno M, Takano T (1999) Purification and characterization of antihypertensive peptide from a yogurt-like product fermented by Lactobacillus helveticus CPN4. J Dairy Sci 82:1388–1393

Pan D, Luo Y, Tanokura M (2005) Antihypertensive peptides from skimmed milk hydrolysate digested by cell-free extract of Lactobacillus helveticus JCM1004. Food Chem 91:123–129

Fitzgerald RJ, Murray BA (2006) Bioactive peptides and lactic fermentations. Int J Dairy Technol 59:118–125

Beltrán-Barrientos LM, Hernández-Mendoza A, Torres-Llanez MJ, González-Córdova AF, Vallejo-Córdoba B (2016) Fermented milk as antihypertensive functional food. J Dairy Sci 99:4099–4110

Raveschot C, Cudennec B, Coutte F, Flahaut C, Fremont M, Drider D, Dhulster P (2018) Production of bioactive peptides by Lactobacillus species: from gene to application. Front Microbiol 9:2354

Quist EE, Phillips RD, Saalia FK (2009) Angiotensin converting enzyme inhibitory activity of proteolytic digests of peanut (Arachis hypogaea L.) flour. LWT Food Sci Technol 42:694–699

Rho SJ, Lee JS, Chung YI, Kim YW, Lee HG (2009) Purification and identification of an angiotensin I-converting enzyme inhibitory peptide from fermented soybean extract. Process Biochem 44:490–493

Balti R, Bougatef A, Sila A, Guillochon D, Dhulster P, Nedjar-Arroume N (2015) Nine novel angiotensin I-converting enzyme (ACE) inhibitory peptides from cuttlefish (Sepia officinalis) muscle protein hydrolysates and antihypertensive effect of the potent active peptide in spontaneously hypertensive rats. Food Chem 170:519–525

Xue L, Wang X, Hu Z, Wu Z, Wang L, Wang H, Yang M (2018) Identification and characterization of an angiotensin-converting enzyme inhibitory peptide derived from bovine casein. Peptides 99:161–168

Okamoto K, Nakagawa S, Kanawaku R, Kawamura S (2019) Ethanol production from cheese whey and expired milk by the brown rot fungus Neolentinus lepideus. Fermentation 5:49

Mathai JK, Liu Y, Stein HH (2017) Values for digestible indispensable amino acid scores (DIAAS) for some dairy and plant proteins may better describe protein quality than values calculated using the concept for protein digestibility-corrected amino acid scores (PDCAAS). Br J Nutr 117:490–499

Cushman DW, Cheung HS (1970) Spectrophotometric assay and properties of the angiotensin-converting enzyme of rabbit lung. Biochem Pharmacol 20:1637–1648

Rahimi MH, Shab-Bidar S, Mollahosseini M, Djafarian K (2017) Branched-chain amino acid supplementation and exercise-induced muscle damage in exercise recovery: a meta-analysis of randomized clinical trials. Nutrition 42:30–36

Saito Y, Wanezaki K, Kawato A, Imayasu S (1994) Structure and activity of angiotensin I converting enzyme inhibitory peptides from sake and sake lees. Biosci Biotechnol Biochem 58:1767–1771

Jarmołowska B, Kostyra E, Krawczuk S, Kostyra H (1999) β-Casomorphin-7 isolated from Brie cheese. J Sci Food Agric 79:1788–1792

Singh TK, Fox PF, Healy A (1997) Isolation and identification of further peptides in the diafiltration retentate of the water-soluble fraction of Cheddar cheese. J Dairy Res 64:433–443

Saito T, Nakamura T, Kitazawa H, Kawai Y, Itoh T (2000) Isolation and structural analysis of antihypertensive peptides, that exist naturally in Gouda cheese. J Dairy Sci 83:1434–1440

Pihlanto-Leppälä A, Rokka T, Korhonen H (1998) Angiotensin I converting enzyme inhibitory peptides derived from bovine milk proteins. Int Dairy J 8:325–331

Abubakar A, Saito T, Kitazawa H, Kawai Y, Itoh T (1998) Structural analysis of new antihypertensive peptides derived from cheese whey protein by proteinase K digestion. J Dairy Sci 81:3131–3138

Meisei H (1998) Overview on milk protein-derived peptides. Int Dairy J 8:363–373

den Hengst CD, Curley P, Larsen R, Buist G, Nauta A, van Sinderen D, Kuipers OP, Kok J (2005) Probing direct interactions between CodY and the oppD promoter of Lactococcus lactis. J Bacteriol 187:512–521

Wakai T, Yamamoto N (2013) A novel branched chain amino acids responsive transcriptional regulator, BCARR, negatively acts on the proteolytic system in Lactobacillus helveticus. PLoS ONE 8:e75976

Cheung HS, Wang FL, Ondetti MA, Sabo EF, Cushman DW (1980) Binding of peptide substrates and inhibitors of angiotensin-converting enzyme. J Biol Chem 255:401–407

Cheung LKY, Aluko RE, Cliff MA, Li-Chan ECY (2015) Effects of exopeptidase treatment on antihypertensive activity and taste attributes of enzymatic whey protein hydrolysates. J Funct Foods 13:262–275

Ueno K, Mizuno S, Yamamoto N (2004) Purification and characterization of an endopeptidase that has an important role in the carboxyl terminal processing of antihypertensive peptides in Lactobacillus helveticus CM4. Lett Appl Microbiol 39:313–318

Wakai T, Yamaguchi N, Hatanaka M, Nakamura Y, Yamamoto N (2012) Repressive processing of antihypertensive peptides, Val-Pro-Pro and Ile-Pro-Pro, in Lactobacillus helveticus fermented milk by added peptides. J Biosci Bioeng 114:133–137

Wakai T, Shinoda T, Uchida N, Hattori M, Nakamura Y, Beresford T, Ross RP, Yamamoto N (2013) Comparative analysis of proteolytic enzymes need for processing of antihypertensive peptides between Lactobacillus helveticus CM4 and DPC4571. J Biosci Bioeng 115:246–252

Acknowledgements

This work was supported by the Project of the NARO Bio-oriented Technology Research Advancement Institution (Research program on development of innovative technology) [Grant number 28010A]. We would like to thank Editage (https://www.editage.jp) for English language editing.

Author information

Authors and Affiliations

Contributions

KO conceptualized and designed the study, performed the experiments, drafted the initial manuscript, reviewed the manuscript, and revised the manuscript. SK and MT performed the experiments and analyzed the data. TM contributed to the amino acid analysis, peptide sequencing, and MS analysis. HMZ performed the animal experiments. TN designed animal experiments and reviewed the manuscript. All authors approved the final manuscript as submitted and agree to be accountable for all aspects of the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

The procedures of animal experiments were reviewed and approved by the local committee for animal research at Shimane University. The animal experiments were performed in accordance with relevant guidelines and regulations.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Okamoto, K., Kawamura, S., Tagawa, M. et al. Production of an antihypertensive peptide from milk by the brown rot fungus Neolentinus lepideus. Eur Food Res Technol 246, 1773–1782 (2020). https://doi.org/10.1007/s00217-020-03530-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03530-y