Abstract

Pasteurised processed cheese spreads of varying chemical composition were developed, using a Myzithra-type cheese, which is a high-moisture and low-fat fresh whey cheese. Nine novel, spreadable processed whey cheese (PWC) samples were prepared comprising only of whey proteins, while guar gum was added as a stabiliser. All samples had a pH value of 5.20, which was obtained with the addition of a starter culture. The effect of chemical composition on the physico-chemical and rheological properties of PWC samples was studied. Due to their texture, two instrumental techniques, lubricated squeezing flow viscometry and texture profile analysis, were considered appropriate for the evaluation of samples. The decrease in protein content or the increase in fat content produced less viscous, consistent and solid samples, which were more spreadable. Protein content was shown to be a better predictor of the texture of PWC samples. Sensory assessments revealed that the majority of PWC samples had good spreadability and flavour and were rated as highly acceptable. Results of sensory and instrumental analyses were highly positively correlated. Results have shown that the choice of the desired formulation could be manipulated for the production of processed whey cheese spreads with specific properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Processed cheese is the product that is normally produced after grating, mixing and melting of one or more natural cheeses, in the presence of emulsifying salts, with the optional addition of other ingredients, until a smooth and homogenous texture of the end product is obtained [1]. The composition of such products largely determines their texture. Almost all natural cheese types can be used for the preparation of processed cheeses. Conventional processed cheeses are produced with the use of natural cheeses as raw materials, where caseins constitute the main proteins [2]. The presence of caseins renders the use of emulsifying salts as additives, necessary in order to solubilise and hydrate the casein network and achieve homogeneity [3].

The processed cheese industry aims at the development of various types of products, via the incorporation of different alternative components in formulations, such as whey proteins and hydrocolloids. The increased interest of the food industry for the utilisation of whey proteins is strengthened because they are considered as a balanced source of proteins of high digestibility and biological value [4]. To date, there have been a number of studies on the preparation of processed cheeses with partial substitution of caseins with whey proteins [5–16]. The effect of added predenatured whey proteins (20 % of total protein content) on the textural properties of model processed cheese spreads has been studied by Lee et al. [16], where it was shown that higher levels of denaturation of whey proteins led to softer and more meltable processed cheeses. Denatured whey proteins were found to be in the form of large aggregates in the cheese matrix, thus possibly disrupting the structure, while native whey proteins increased hardness, since they were incorporated into the matrix. Lee et al. [12] showed that ultrahigh pressure (UHP)-treated whey protein may be used as an ingredient for the production of low-fat processed cheese in order to reduce its firmness. Kaminarides and Stachtiaris [7] included whey protein concentrate and soybean oil in processed cheese. The samples were subjected to sensory analysis and showed differences in flavour, texture, spreadability and appearance. Mleko and Foegeding [8] showed that, in processed cheese products, up to a maximum of 2 % casein could be replaced by whey proteins and that the increasing incorporation of whey proteins in isolated form resulted in a gradual increase in fracture stress of products. Additional work by these researchers, which involved replacement of casein with polymerised whey proteins in a rennet casein-based model processed cheese, showed that replacement of 4 % rennet casein with 2 % whey protein polymers could produce processed cheese analogues of identical texture and meltability [9]. Gupta and Reuter [6] reported that the replacement of 20 % of total solids of processed cheese with whey protein concentrates resulted in products with high acceptability. Nonetheless, there is a lack of literature on the properties of processed cheese prepared using whey cheese. In Greece, one of the most popular whey cheeses is Myzithra, produced from the resulting whey during manufacture of Feta cheese or hard cheeses. It is a protected designation of origin (PDO) cheese, with a maximum permitted moisture content of 70 % and a minimum fat in dry matter content of 50 %. Its production is based on denaturation and coagulation of the proteins present in whey (α-lactalbumin and β-lactoglobulin) when whey is heated at temperatures above 85 °C. Finally, the curd is collected as a surface layer from the coagulating whey system [17]. The coagulated whey is strained and moulded into a moist cheese of sweet and milky flavour.

Polysaccharides have also been incorporated in processed cheese products [11, 18] in order to improve microstructure, bulk properties and stability. Addition of hydrocolloids is gaining popularity in low-fat- and reduced-fat processed cheese products, due to their ability to improve mouthfeel [11]. Some efforts on the replacement of traditional emulsifying salts by hydrocolloids have also been reported [19, 20]. Guar gum, which is a non-gelling neutral polysaccharide composed of a linear (1 → 4)-β-D-mannan backbone with varying amounts of side chains, has been widely used as a food additive due to its high viscosity in aqueous media [21].

Based on the above, the choice of the desired formulation is critical to ensure the production of processed cheese with specific functional properties. The aim of the present work was the development of novel, spreadable processed cheeses with whey proteins as the primary source of proteins, as a means of their utilisation in a product with high added value. In this direction, the spreadable processed cheeses were prepared using a Myzithra-type whey cheese, a cheese base consisting only of whey protein, as well as cream and addition of guar gum as a stabiliser. An extensive study of the effect of chemical composition on the physico-chemical, rheological and sensory properties of the samples was also conducted, as a means to predict the preparation of products with desired characteristics.

Materials and methods

Materials

A high-moisture and low-fat Myzithra-type whey cheese (73.9 % w/w moisture, 1.6 % w/w fat, 13.5 % w/w proteins, pH 5.73) was prepared (without milk, cream or salt addition) and kindly provided by Mevgal Dairy S.A. (Thessaloniki, Greece). This was used as a cheese base for the preparation of spreadable processed whey cheese (PWC) samples. Protein fortification of samples, when needed, was achieved via the addition of quantities of Myzithra-type whey cheese which were lyophilised (1.9 % w/w moisture, 6.0 % w/w fat, 66.1 % w/w proteins), in order to maintain the characteristics and degree of functionality of proteins. Pasteurised, homogenised full cream (46.6 % w/w moisture, 49.0 % w/w fat, 1.42 % w/w proteins, pH 6.72) from bovine milk was purchased from Agno Dairy S.A. (Thessaloniki, Greece). Guar gum and NaCl were obtained from Sigma-Aldrich (Saint Louis, MO, USA). Freeze-dried starter culture of mixed mesophilic lactic strains (FD-DVS Flora-Danica) was purchased from Chr. Hansen’s Dairy Cultures (Hørsholm, Denmark). All reagents used for physico-chemical analyses were of analytical grade (Sigma-Aldrich, USA).

Preparation of processed whey cheeses

All samples were prepared with a UMC 5 Universal Machine jacketed mixer-cooker (Stephan, Germany). Raw materials were added in quantities so that the PWC samples’ texture would vary in a wide range, though all resulting in spreadable-type products. Myzithra-type whey cheese and cream were mixed at ratios varying from 1:1 to 6:1 (w/w), and water was added according to a randomised mixture design. The statistical program aimed at preparing nine randomised samples of chemical composition within specific limits, in order to obtain spreadable products. The raw materials were mixed for 1 min at low speed (1000 rpm). The starter culture (Lactococcus lactis subsp. cremoris, Lactococcus lactis subsp. lactis, Leuconostoc mesenteroides subsp. cremoris and Lactococcus lactis subsp. lactis biovar. diacetylactis) was added to the mixture at a concentration of 0.5 % (v/v) after activation at 30 °C, in order to achieve pH reduction and aroma development. The mixture of raw materials was kept at 30 °C with continuous monitoring of pH, until pH reached the value of 5, which was within 7 h. Guar gum and NaCl were added at concentrations of 0.8 and 1.0 % (w/w), respectively, determined during preliminary experiments. To obtain efficient dissolution of guar gum, appropriate quantities were first allowed to hydrate for 1 h under gentle stirring at room temperature. After removal of air by vacuum, mixtures were heated up to 90 °C, under continuous mixing at 1500 rpm, and then mixing was continued for 5 min, at 2000 rpm, at constant temperature (90 °C). The melted PWC samples were poured into glass jars with metal lids excluding any headspace and inverted and stored under refrigeration (4 °C) for analyses. For rheological measurements, portions of the melted PWC samples were transferred into lubricated moulds (rings), covered with saran cling wrap and stored overnight at 4 °C. For repeatability reasons, the nine samples of varying chemical composition were prepared in duplicate.

Compositional analyses

In raw materials and PWC samples, moisture content, M (% w/w), was determined by drying at 102 ± 2 °C to a constant mass [22]. Fat content, F (% w/w), was determined by the van Gulik method [23] and ash content, A (% w/w), by incineration at 550 °C [24]. Total nitrogen, TN, and non-protein nitrogen, NPN, that is the fraction of TN soluble in 12 % (w/v) trichloroacetic acid, were assayed by the Kjeldahl method. Protein content, P (% w/w), was calculated as 6.38× (TN − NPN). The pH was measured using a pH meter, model ΗΙ 8424 (HANNA Instruments, RI, USA), equipped with a glass, mass intrusion electrode (HI 1230B). Measurements in PWC samples were performed the following day after preparation of each sample. Compositional analyses were conducted in triplicate (one or two repeats per duplicate sample). Fat in dry matter, FDM (% w/w), protein in dry matter, PDM (% w/w), and moisture in non-fat substance, MNFS (% w/w), were also calculated.

Physico-chemical analyses

Colour of PWC samples was determined using a Micro Color colourimeter (Dr. Lange, Germany) on cylindrical samples 10 × 50 mm (height × diameter). The instrument provides the three colour parameters (coordinates) L* (lightness), a* (+redness, −greenness) and b* (+yellowness, −blueness), in accordance with the CIELab system, after having been calibrated with black and white colour calibration tiles. Measurements were conducted in nine repeats (four or five repeats per duplicate sample).

Free oil was also determined in PWC samples using the method described by Kindstedt and Fox [25], which is a quantitative assay that uses centrifugal force to recover free oil from heated samples, hence an accelerated test of oil droplet coalescence. Free oil determinations were performed in triplicate (one or two repeats per duplicate sample).

Rheological measurements

Rheological properties of PWC samples were determined with the aid of the TA.XT.Plus Texture Analyser (Stable Micro Systems Ltd, UK) equipped with a 300-N maximum load force cell. All samples were allowed to equilibrate at room temperature (23 ± 2 °C) for 2 h prior to testing. Since PWC samples were let to set in the respective moulds, the samples were indeed tested practically intact. Measurements were conducted in six repeats (three on each duplicate sample).

Lubricated squeezing flow tests were performed under constant area and displacement rate. Cylindrical specimens of 10 mm height and 100 mm diameter were subjected to compression between two parallel metal discs (Ø = 100 mm), previously lubricated with paraffin oil, with a speed of 6 mm/min, to 80 % deformation. Straight after compression, a stress relaxation test followed for 3 min. The rheological parameters, apparent stress at the end of compression, at 2 mm height, \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}}\), and apparent stress at the end of relaxation, after 3 min, \(\sigma_{{{\text{app}}@ 3 {\text{min}}}}\) [26], were determined. Deformability modulus, E [27], biaxial stress growth coefficient, \(\eta_{E}^{ + }\) [28], and flow behaviour index, n [29], were also calculated.

Texture profile analysis (TPA) was performed on cylindrical specimens of 22 mm height and 22 mm diameter, which were subjected to compression between two metal discs (Ø = 100 mm), with a compression speed of 20 mm/min, up to 80 % deformation. The test comprised of two consequent compression–decompression cycles. The textural properties (hardness 1 and 2, compression work 1 and 2, cohesiveness, adhesiveness, springiness, stringiness and gumminess) [30] were determined.

Sensory evaluation

After equilibration at room temperature (23 ± 2 °C), the nine PWC samples were evaluated by two different taste panels, comprising of members of the Department of Food Technology, conforming to ISO 8586 [31]. The first panel (18 expert sensory assessors) evaluated the intensity of sensory characteristics, using a descriptive intensity rating test, while the second (72 habitual consumers) assessed samples on acceptability, with a hedonic rating test. Evaluations were conducted in a climate-controlled sensory analysis laboratory equipped with individual testing booths with neutral walls and a lighting system that represented illuminant D65. Panellists evaluated all samples, individually presented as cubic specimens and labelled with different and randomised three-digit codes. Each PWC sample was evaluated, according to a randomised balanced block design, balanced for order and carry-over effects, of nine samples with replicates, using 9-point scales [32]. Regarding intensity, sensory attributes, such as yellow colour (white–yellow), fattiness (not fatty–extremely fatty), firmness (extremely soft–extremely firm), spreadability (not spreadable–extremely spreadable), smoothness (extremely rough–extremely smooth) and stickiness (not sticky–extremely sticky) were evaluated. In hedonic evaluations, aroma-flavour, texture and overall acceptability were rated (dislike extremely–like extremely). Each sample was evaluated six times on each sensory attribute for intensity (three repeats per duplicate sample) and twenty-four times for acceptability (twelve repeats per duplicate sample).

Statistical analysis

One-way analysis of variance (ANOVA) was employed on compositional, physico-chemical, rheological and sensory parameters of the developed PWC samples. When significant effects were detected (P < 0.05), the Student–Newman–Keul’s (SNK) multiple range test was applied. Correlation was also employed on all experimental data, in order to reveal relationships between the properties tested. Finally, multiple regression analysis was applied, in order to develop equations which described the physico-chemical, rheological and sensory properties of the developed PWC samples as a function of their chemical composition. In order to select the best regression equation, backward elimination was used. Statistical analyses were performed using Minitab 16 statistical software (Minitab Inc, PA, USA).

Results and discussion

Chemical composition

The chemical composition of PWC samples is shown in Table 1, where samples are coded with numbers with increasing protein content. Chemical composition, such as protein, fat and moisture contents, of samples was in accordance with the expected contents calculated from the mixture design and did not present deviations higher than 10 %. Mean values of compositional parameters have presented coefficients of variation lower than 5 %, indicating a high repeatability of the PWC samples. One-way ANOVA revealed statistically significant differences between the mean values (P < 0.05). Protein ranged from 10.02 to 14.04 % (w/w), moisture from 58.55 to 71.49 % (w/w), fat from 8.00 to 23.17 % (w/w), FDM from 28.07 to 57.76 % (w/w) and ash content from 2.22 to 2.62 % (w/w); thus, the developed processed cheese spreads had a wide range of chemical composition. All samples had equal final pH (5.20 ± 0.02). Strong negative correlations existed between moisture and fat content (r = −0.958), also between protein and fat content (r = −0.881), as well as a strong positive correlation between moisture and protein content (r = 0.764).

Physico-chemical properties

Results of colour determinations are presented in Table 2. Lightness, L*, of around 90 corresponds to samples of off-white colour. All samples had a slight greenish/yellowish colour. Specifically, samples 8 and 9, which had high protein and moisture content, and consequently lower fat content, showed increased values of lightness. Samples of increasing fat content presented increasingly intense yellow colour. Analogous results have been reported for processed cheese [33] and whey protein gels [34]. Green colour, which is characteristic of the colour of whey, has been previously observed in emulsions [35], as well as processed cheeses [36].

Regarding the effect of chemical composition on the values of colour parameters of PWC samples, regression analysis resulted in the following relationship:

The above confirms that the yellowness of PWC samples increased with increasing fat, as well as decreasing MNFS content. Wendin et al. [36] also observed an increase in yellow colour intensity, determined by sensory analysis, in samples of cream cheese with increasing fat content.

Free oil formation, also called oiling off, is the tendency of liquid fat to separate from melted cheese and accumulates as oil pockets and is an indication of fat emulsification in cheese [25]. Free oil was determined in PWC samples since it is a measure of stability during storage of such products. However, since measurements of free oil formation involve accelerated tests of oil droplet coalescence, they have been shown to poorly correlate with the shelf life of products stored under normal ambient conditions [37]. Visual assessment of the developed PWC samples revealed that all were homogeneous, stable, in terms of oil separation, and none exhibited syneresis or other obvious defects. A high concentration of a hydrocolloid such as guar gum increases the viscosity of the continuous phase and restricts the movement of oil droplets and, thus, enhances stability [18, 38]. Figure 1 presents results of free oil formation expressed as per cent (w/w) in PWC sample, where it is shown that chemical composition affected (P < 0.05) free oil formation. Specifically, products with increased fat content, namely products 1 to 6, had higher values of free oil (5.17–9.75 % w/w) and thus weaker emulsification, followed by those with increased protein content (samples 7–9), which had very low free oil values, with some approaching zero (0.01–0.60 % w/w). Sample 6 had the highest value of free oil, possibly due to the combined effect of highest fat content with the lowest MNFS of all other PWC samples. Moreover, sample 6 had a relatively low content of PDM, in relation to samples of similar protein content. The above has been previously shown to enhance free oil formation in pasteurised processed cheese due to the decreased ability of proteins to entrap fat [39]. Hassan et al. [40] reported values of free oil on fat basis under 5 % in samples of reduced-fat (20–22 % w/w) processed cheese. Free oil values from 14 to 19 % have been reported for pasteurised processed cheese [39]. A certain amount of free oil is necessary to prevent localised dehydration of the surface of cheese, with associated browning of the surface during heating. Furthermore, fat globules which partially rupture over time produce a small amount of free oil that may be required for specific cheese functionality, such as enhanced spreadability or meltability [41].

Regarding the relationship between chemical composition and free oil formation, regression analysis produced the following equation:

As shown above, free oil increased with increasing levels of fat or decreasing levels of MNFS and the resulting regression equation could be used to predict the amount of free oil in PWC samples. The above is in agreement with the results of Acharya and Mistry [39].

Furthermore, a positive relationship has been observed between the amount of free oil and the intensity of yellow colour of PWC samples as follows:

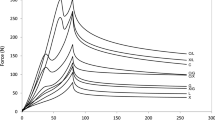

Lubricated squeezing flow viscometry

Typical force–time curves of PWC samples with the lowest (sample 1) and the highest protein content (sample 9) which resulted from the lubricated squeezing flow test are shown in Fig. 2. The compression part is distinguished, from which the rheological parameters \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}}\), E and \(\eta_{\rm E}^{ + }\) were determined, followed by the stress relaxation part, from which the \(\sigma_{{{\text{app}}@ 3 {\text{min}}}}\) was determined. Fracture was not observable in any PWC sample, since curves had smooth profiles, showing no apparent signs of yield points. As shown in Table 3, samples of increasing protein content (1–9) had increasing values of both apparent stresses, \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}}\) and \(\sigma_{{{\text{app}}@ 3 {\text{min}}}}\) (P < 0.05). Values of \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}}\) for the developed PWC samples were in the range of 9.85–37.11 kPa. As this parameter is a measure of specimen’s consistency [26], the important role of proteins on the formation of the structure of PWC samples is evident. Suwonsichon and Peleg [42] reported values of \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}}\) of Ricotta cheese samples ranging from 2.0 to 12.7 kPa, determined by imperfect squeezing flow (6 mm/min compression speed), and the resulting curves were very similar to those of PWC samples. The developed PWC samples had values of \(\sigma_{{{\text{app}}@ 3 {\text{min}}}}\) ranging from 3.51 to 23.84 kPa. Ιn squeezing flow viscometry, the residual unrelaxed stress at a given specimen height, measured after more than a minute at relaxation, expresses the overall “degree of solidity”, and its magnitude is most probably related to the sample’s apparent yield stress [43]. This increasing residual stress for samples 1 to 9 indicated that the protein content led to an increase in the solid character of PWC samples.

Typical force–time curves of processed whey cheese samples during lubricated squeezing flow test: compression up to 80 % deformation with a speed of 6 mm/min and subsequent stress relaxation for 3 min. Curve values are means of six measurements for each sample (solid line sample 1 dashed line sample 9)

In Table 3, deformability modulus, E, was also shown to increase with sample increasing protein content (1 to 9) (P < 0.05). Values of E for the developed PWC samples were in the range of 101.77 to 571.87 Pa. E is a measure of the stiffness of a material, as well as evidence of the existence of a network structure [43]. Stampanoni and Noble [44] observed an increase in values of E and hardness of cheese analogues when the fat content was reduced.

Figure 3 depicts the variation of biaxial stress growth coefficient, \(\eta_{\rm E}^{ + } ,\) of samples, up to 80 % deformation, in relation to the biaxial extensional strain rate, \(\dot{\varepsilon }_{b}\), on logarithmic scales. In all curves, an initial sharp increase in \(\eta_{\rm E}^{ + }\) is evident, which corresponds to the transient flow regime, followed by an approximately linear part, corresponding to the squeezing flow regime, the slope of which is n − 1, where n is the flow behaviour index [29]. Slope was obtained by simple linear regression. The linear parts of curves for samples 1–6, of higher fat content and relatively lower protein content, remained almost horizontal, with \(\eta_{\rm E}^{ + }\) becoming independent of \(\dot{\varepsilon }_{b}\). Therefore, these samples behaved as almost Newtonian fluids during squeezing flow, with n close to unity (n = 0.94 − 1.09) (Table 3). The above also reveal the absence of a dense structural network [45] and an increased spreadability of these products [46]. In the remainder samples 7–9, of lower fat content and relatively higher protein content, the initial rise in \(\eta_{\rm E}^{ + }\) was followed by a decreasing linear part. These samples presented a flow behaviour index lower than unity (n = 0.76 − 0.89) (Table 3) and therefore behaved as pseudoplastic fluids, showing the presence of a structural network. Similar profiles of variation of \(\eta_{\rm E}^{ + }\) with \(\dot{\varepsilon }_{b}\) were reported in the study of Casiraghi et al. [45] on the rheological behaviour of processed cheese spreads during compression under lubricated conditions and similar compression speed (5 mm/min). For comparison among the PWC samples, \(\eta_{\rm E}^{ + }\) values at a selected biaxial extensional strain rate at the end of compression \((\dot{\varepsilon }_{b} = 0.026 s^{ - 1})\) are presented in Table 3. Values of \(\eta_{\rm E}^{ + }\) were in the range of 395.39–1416.02 kPa s. Since \(\eta_{E}^{ + }\) expresses the biaxial extensional (elongational) viscosity, as protein content increased, samples became more viscous. At the same biaxial extensional strain rate, Campanella et al. [46] have found \(\eta_{\rm E}^{ + }\) values from around 50 to 350 kPa s for American processed cheese at 36–62 °C, at a compression speed of 10 mm/min. Casiraghi et al. [45] have studied the rheological behaviour of processed cheese spreads under lubricated conditions and at compression speeds from 0.5 to 50 mm/min. They have found \(\eta_{\rm E}^{ + }\) values of around 350 kPa s (\(\dot{\varepsilon }_{b} = 0.0407 s^{ - 1}\)) and 1400 kPa s (\(\dot{\varepsilon }_{b} = 0.0075 s^{ - 1}\)) at 7 °C. Ak and Gunasekaran [47] have reported \(\eta_{\rm E}^{ + }\) values of around 800 kPa s (\(\dot{\varepsilon }_{b} = 0.015 s^{ - 1}\)) for young Mozzarella cheese at 30 °C, at 5 mm/min compression speed. Raphaelides and Gioldasi [48] reported \(\eta_{\rm E}^{ + }\) values of around 50–250 kPa s (\(\dot{\varepsilon }_{b} = 0.0065 s^{ - 1}\)) measured during lubricated squeezing flow (5 mm/min compression speed) for samples of set yogurt containing caseinates, skim milk powder or carrageenan salts at different levels.

The relationships which resulted between chemical composition and the measured rheological parameters are shown in the following regression equations. These are simple linear regression models which are derived after omission of the statistically non-significant terms:

From the above-mentioned equations, the very important effect of proteins on the rheological parameters of PWC samples was shown, positive on the parameters \(\sigma_{{{\text{app}}@ 2 {\text{mm}}}},\) \(\sigma_{{{\text{app}}@3{ \text{min} }}},\) E and \(\eta_{\rm E}^{ + }\), and negative on flow behaviour index. Furthermore, it was revealed that the increase in fat content in PWC samples had the opposite effect on the above rheological parameters. The effect of proteins was more pronounced than that of fat, which was also observed by Dimitreli and Thomareis [49]. The increase in rheological properties caused by the increase in protein content in PWC samples may be attributed to protein–protein interactions, initiated during the denaturation of proteins with heating, which led to their aggregation and gelation [50]. Therefore, as protein content increases, the formed protein network, providing structure to the product, is denser and stronger [49]. The addition of guar gum to the gel further increased its rheological properties. This may be attributed to segregative interactions, with guar gum promoting aggregation of thermally denatured whey proteins [51]. Indeed, due to their thermodynamic incompatibility, phase separation and excluded volume effects increase the effective concentrations of both biopolymers accounting for their resulting synergism. Specifically, the partial binding of moisture by guar gum favours the approximation of protein molecules and the formation of more protein–protein interactions. Also, guar gum behaves as active filler within the protein network, improving gel strength, by forming a continuous polysaccharide-rich phase of increased viscosity. On the contrary, fat has been shown to act as a lubricant because its increase led to softer processed cheeses [19, 49, 52]. Finally, rheological properties of PWC samples were positively, but not highly, correlated with moisture content. Lee et al. [12] also showed that the firmness of low-fat processed cheese foods with added whey proteins was not closely related to its moisture content, indicating that firmer samples had higher moisture content. Any slight increase in firmness caused by moisture in PWC samples may be due to the hydration of whey protein and guar gum macromolecules, which leads to their swelling and, thus, to the reduction in their mobility.

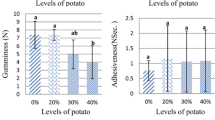

Texture profile analysis

A typical force–time curve of PWC samples which derived from texture profile analysis (TPA) is shown in Fig. 4. The textural properties, such as hardness 1, H1, hardness 2, H2, compression work 1, A1, compression work 2, A2, cohesiveness, A2/A1, adhesiveness, A3, springiness, S1, stringiness, S2 and gumminess, G, of PWC samples, as affected by chemical composition, are given in Table 4. One-way ANOVA showed significant differences (P < 0.05) among the samples for all textural properties. Of all the determined properties, hardness was the property showing major differences among samples. Mean values of H1 ranged from 5.31 to 42.21 N, H2 from 4.76 to 41.44Ν, Α1 from 21.50 to 124.75 mJ, Α2 from 6.25 to 25.60 mJ and A3 from 6.00 to 20.00 mJ. The highest values of H1, H2 and A1 were presented by sample 9, which had the lowest fat content and highest moisture and protein content. Decreasing values of these properties were observed as protein content of samples decreased. Dimitreli and Thomareis [49] observed similar trends in the textural properties of block-type processed cheeses, where a denser network was formed by increasing protein content. Samples 3–6 presented equal values of H1, H2, A1 and A2. Kapoor and Metzger [10] reported that the incorporation of salt whey (up to 9.5 %) as an ingredient in processed cheeses did not adversely affect the products’ quality, producing samples of hardness ranging from 12 N in pasteurised processed cheese spreads to 126 N in pasteurised processed cheeses, as determined by TPA. Furthermore, TPA results on the hardness of commercial samples of pasteurised processed cheese products with added whey proteins reported values ca. 30–40 N [13]. Regarding A3 and G, sample 1 had significantly lower values compared to all other samples which had similar values. Thus, adhesiveness and gumminess did not appear to be good differentiating means of the texture of PWC samples.

Samples of increasing protein content had decreasing values of A2/A1, S1 and S2. Regarding processed cheeses, it has been reported that hardness increased, while cohesiveness and springiness decreased when whey protein concentrate was added to formulations [5]. PWC samples 2–4 showed the highest values of A2/A1, while S1 and S2 were the highest in sample 1, which had low protein and high fat content. An increased stringiness has also been observed in block-type processed cheeses of high fat content [49]. As observed for PWC samples, an increase in fat content has been reported to result in softer and more cohesive cheese analogues [44], as well as in processed cheeses with added guar gum, of decreased hardness and gumminess [21]. The disruption of the continuity of the protein matrix by fat leads to a more soft texture, but the flocculation or partial aggregation of fat droplets could be the cause of an increase in cohesiveness and springiness. The developed PWC samples are considered emulsion gels, as they are protein-based oil-in-water emulsions formulated into soft, solid-like materials by heating and enzyme action and their composite structure is a hybrid network made up of a combination of crosslinked biopolymer molecules and partially aggregated droplets. Moreover, fat droplets have been shown to become an integral part of newly formed structures of emulsion gels, possibly acting as active fillers [37].

The regression equations describing the positive effect of protein content and the negative effect of fat on TPA parameters are described below:

Sensory evaluation

Significant differences were observed (P < 0.05) among the mean scores of intensity ratings of PWC samples’ sensory attributes (Table 5). The PWC samples perceived as having a more intense yellow colour were samples 1 and 6, which had the highest fat content, in relation to the other samples. Fat content and perceived fattiness showed a strong positive correlation (r = 0.788). Increased fattiness was attributed to samples 1–6, which received equal scores, while sample 7 had the lowest score. Sample 7 had a higher fat content than samples 8 and 9, but lower moisture content, which could be the reason of the decreased perception of fattiness by panellists. Sample 9 had the highest score of perceived firmness, while this parameter received lower scores as protein content of PWC samples decreased. Protein content had a strong positive correlation with perceived firmness (r = 0.857) and a strong negative correlation with perceived spreadability (r = −0.765). Samples perceived as fatty were also viewed as spreadable by panellists (r = 0.868). A strong positive correlation was also observed between fat content and perceived spreadability (r = 0.856). Increased spreadability was attributed to samples 1–4, which received equal scores, while as protein increased PWC samples were considered as less spreadable. Samples 1, 2, 5, 6 and 8 received high scores of smoothness. A study by Lee et al. [12] revealed that the addition of UHP-treated whey protein to low-fat processed cheese foods may lead to products with acceptable firmness, but resulted in an undesirable sandy or grainy texture. All the PWC samples received above average scores of smoothness, revealing that any possible inherent whey protein aggregates were not perceived by the panellists. Guar gum addition has been shown to cause the formation of whey protein isolate network with smoother surfaces, attributed to the guar–protein excluded volume effects leading to an increase in protein–protein interactions [53]. Stickiness was more prominent in samples 3–6, as well as 9, which all received equal scores, and was less evident in sample 1, which also had a lower value of adhesiveness, as determined by TPA.

Results on acceptability of PWC samples as affected by chemical composition are also shown in Table 5. The statistically significant differences observed (P < 0.05) showed that PWC samples 2, 5 and 6 had a highly acceptable aroma-flavour. Samples 2–8 were scored as having a highly acceptable texture, while samples 1 and 9 received low scores. Regarding overall acceptability, PWC samples 2–8 were scored as highly acceptable, while samples 1 and 9 were considered as unacceptable. Samples having extreme protein content (1 and 9) were less favourably rated by the panellists. No clear relationship could be established between acceptability of PWC samples and parameters of chemical composition, revealing that the acceptance of the developed processed cheeses was controlled by the balance between fat, moisture and protein content. Brummel and Lee [18] reported that processed cheese spreads with guar gum (1.7 % w/w) had a decreased firmness, good spreadability and good mouth feel. Guar gum addition (2.0 % w/w) to processed cheese spreads produced the most soft and spreadable products, in relation to others with different hydrocolloids added, such as gelatin, carrageenan and locust bean gum [11]. Pinto et al. [14] concluded that whey protein addition up to 4.5 % (w/w) to processed cheese spreads induced better spreadability to end products.

Correlation between methods

Strong correlations were observed between the rheological properties determined with lubricated squeezing flow and TPA, revealing that results of these two methods were in accordance (Table 6). Correlation coefficients between sensory texture parameters (firmness, spreadability) and rheological parameters are listed in Table 7. Sensory and instrumental analyses were highly positively correlated, as was reported in a similar study on the textural and sensory properties of processed cheeses [54]. These authors concluded that the compressive measurements were better able to predict sensory texture than the fundamental rheological tests. In this study, TPA adhesiveness did not correlate with sensory stickiness, which was also observed by Drake et al. [54]. Finally, sensory perception of PWC samples’ yellow colour was in good agreement with the instrumental colour parameter b* (r = 0.788).

Conclusions

Results indicated that the preparation of novel, spreadable processed whey cheeses using a Myzithra-type whey cheese was feasible and all the developed products were stable, in terms of oil separation, and none exhibited syneresis or other obvious defects. Furthermore, the use of guar gum as an additive allowed for the development of PWC samples without the addition of chemical emulsifying salts. These complex emulsion gels had different properties, which were controlled by their chemical composition. A decrease in protein content or an increase in fat content of such products led to samples of decreased hardness and increased spreadability. Protein content was shown to be the better predictor of the texture of PWC samples. Fat was also shown to affect some physico-chemical and sensory properties, such as colour, free oil formation and perceived spreadability. A number of the developed PWC samples were rated as highly acceptable, in terms of aroma-flavour, texture and overall acceptance. Regression analysis elucidated the possibility of manipulating the properties of such complex emulsion gels via specific alterations in their chemical composition.

References

Guinee TP, Carić M, Kaláb M (2004) Cheese chemistry, physics and microbiology, vol 2. Elsevier Academic Press, London

Kapoor R, Metzger LE (2008) Compr Rev Food Sci F 7:194–214

Thomareis AS (1986) PhD Thesis, INPL, Nancy, France

Smithers GW (2008) Int Dairy J 18:695–704

Thapa TB, Gupta VK (1992) Indian J Dairy Sci 45:140–145

Gupta VK, Reuter H (1992) Lait 72:201–212

Kaminarides S, Stachtiaris S (2000) Int J Dairy Technol 53(2):69–74

Mleko S, Foegeding EA (2000) Milchwissenschaft 55:513–516

Mleko S, Foegeding EA (2001) Milchwissenschaft 56:612–615

Kapoor R, Metzger LE (2004) J Dairy Sci 87:1143–1150

Swenson BJ, Wendorff WL, Lindsay RC (2000) J Food Sci 65(5):822–825

Lee W, Clark S, Swanson BG (2006) J Food Process Preserv 30(2):164–179

Lu Y, Shirashoji N, Lucey JA (2007) Int J Dairy Technol 60(2):74–80

Pinto S, Rathour AK, Prajapati JP, Jana AH, Solanky MJ (2007) Nat Prod Rad 6(5):398–401

Lee SK, Anema SG (2009) Food Chem 115:1373–1380

Lee SK, Huss M, Klostermeyer H, Anema SG (2013) Int Dairy J 32:79–88

Dermiki M, Ntzimani A, Badeka A, Savvaidis IN, Kontominas MG (2008) LWT 41:284–294

Brummel SE, Lee K (1990) J Food Sci 55:1290–1307

Černíková M, Buňka F, Pospiech M, Tremlová B, Hladká K, Pavlínek V, Březina P (2010) Int Dairy J 20(5):336–343

Hladká K, Randulová Z, Tremlová B, Ponížil P, Mančík P, Černíková M, Buňka F (2014) LWT 55(2):650–656

Oliveira NM, Dourado FQ, Peres AM, Silva MV, Maia JM, Teixeira JA (2011) Food Bioprocess Technol 4:1414–1421

IDF (2004) IDF Standard 4. International Dairy Federation, Brussels

ISO (2008) Standard 3433. ISO, Geneva

AOAC (2005) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington

Kindstedt PS, Fox PF (1991) J Food Sci 56(4):1115–1116

Corradini MG, Peleg M (2005) J Texture Stud 36:605–629

Johnson EA, Segars RA, Kapsalis JG, Normand MD, Peleg M (1980) J Food Sci 45:1318–1320

Shukla A, Rizvi SSH, Bartsch JA (1995) J Texture Stud 26:313–323

Campanella OH, Peleg M (2002) Crit Rev Food Sci Nutr 42(3):241–264

ISO (2012) Standard 8586. ISO, Geneva

Rousseau B (2004) In: Nollet LML (ed) Handbook of food analysis: physical characterization and nutrient analysis vol. 1, 2nd edn. Marcel Dekker Inc., New York

Bourne MC (2002) Food texture and viscosity: concept and measurement, 2nd edn. Academic Press, New York

Cunha CR, Dias AI, Viotto WH (2010) Food Res Int 43:723–729

Dissanayake M, Kelly AL, Vasiljevic T (2010) J Agric Food Chem 58:6825–6832

McClements DJ, Demetriades K (1998) Crit Rev Food Sci Nutr 38(6):511–536

Wendin K, Langton M, Caous L, Hall G (2000) Food Chem 71:363–378

Dickinson E (2012) Food Hydrocoll 28:224–241

Erçelebi EA, Ibanoğlu E (2009) Eur Food Res Technol 229:281–286

Acharya MR, Mistry VV (2005) J Dairy Sci 88:3037–3043

Hassan AN, Awad S, Mistry VV (2007) J Dairy Sci 90:3604–3612

Everett DW, Auty MAE (2008) Int Dairy J 18:759–773

Suwonsichon T, Peleg M (1999) J Texture Stud 30:89–103

Corradini MG, Peleg M (2000) Food Sci Technol Int 6:339–344

Stampanoni CR, Noble AC (1991) J Texture Stud 22:381–392

Casiraghi EM, Bagley EB, Christianson DD (1985) J Texture Stud 16:281–301

Campanella OH, Popplewell LM, Rosenau JR, Peleg M (1987) J Food Sci 52(5):1249–1251

Ak MM, Gunasekaran S (1995) J Texture Stud 26:695–711

Raphaelides SN, Gioldasi A (2005) J Food Eng 70:538–545

Dimitreli G, Thomareis A (2007) J Food Eng 79:1364–1373

Mleko S (1999) Eur Food Res Technol 209:389–392

Fitzsimons SM, Mulvihill DM, Morris ER (2008) Food Hydrocoll 22:576–586

Dimitreli G, Thomareis A (2008) J Food Eng 84:368–374

Cavallieri ALF, Cunha RL (2009) Food Biophys 4:94–105

Drake MA, Gerard PD, Truong VD, Daubert CR (1999) J Texture Stud 30:451–476

Acknowledgments

The preparation of Myzithra-type whey cheese by Mevgal Dairy S.A. (Thessaloniki, Greece) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animals subjects.

Rights and permissions

About this article

Cite this article

Chatziantoniou, S.E., Thomareis, A.S. & Kontominas, M.G. Effect of chemical composition on physico-chemical, rheological and sensory properties of spreadable processed whey cheese. Eur Food Res Technol 241, 737–748 (2015). https://doi.org/10.1007/s00217-015-2499-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-015-2499-6