Abstract

In this paper, solid-phase chemical amination was applied to enrich the surface of Geotrichum candidum lipase (GCL) with amino groups. The aminated enzyme was slightly thermostabilized and showed a different activity profile at different pH in relation to the non-aminated enzyme. Furthermore, the chemical modification allowed the enzyme to be rapid and easily immobilized on carboxymethyl and sulfopropyl agarose-based supports. The cationically exchanged derivatives presented higher thermostability and higher stability at alkaline pH than the soluble aminated enzyme. In addition, the carboxymethyl derivative was 5.4-, 8.7- and 9.1- and the sulfopropyl derivative was 6.6-, 11.7- and 10.7-fold more stable than the free aminated enzyme in methanol, propanol and cyclohexane, respectively. The ionic derivatives were applied for fish oil hydrolysis in organic aqueous medium at 37 °C. After 72 h of reaction, Omega-3 production corresponded to 354 and 482 μM using the carboxymethyl and sulfopropyl derivatives, respectively. These derivatives resulted, respectively, in 2.4- and 3.2-fold increased fish oil hydrolysis when compared to the soluble aminated lipase. After the reaction, carboxymethyl derivative presented 6.65 U per gram of support and sulfopropyl derivative showed 7.85 U per gram of support, making them attractive for industrial application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Studies involving lipase-catalyzed hydrolysis aiming to obtain Omega-3 polyunsaturated fatty acids (PUFA) have been in development for approximately 50 years, and it is considered a simple and selective method, which commonly achieves good results [1, 2]. Omega-3 PUFA, composed of two important polyunsaturated fatty acids, eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA), are mainly present in marine fish. There is increasing interest in Omega-3 PUFA production aiming its incorporation into the human diet as preventive and therapeutic tools, since they play important roles in the development of the nervous system, and in the prevention and treatment of cardiovascular diseases, hypertension, diabetes and arthritis [3–6].

To be employed for industrial biotransformations, immobilized lipases should be reused for many reaction cycles and should not be inactivated by the hydrophobic interface present in strongly stirred reactors [7]. Immobilization usually is not easily accomplished, requiring the selection of appropriate support and immobilization conditions [8]. Enzymes only become immobilized on an ion exchanger support when simultaneous enzyme–support attachments are produced; the ionizable groups of the support specifically interact with functional groups of the enzyme thus leading to immobilization [9]. Moreover, the enzyme–support interaction strongly depends on the amount of reactive groups in both support and enzyme [10]. Normally, immobilization is not completely random but requires specific protein orientation. Intrinsic influencing factors such as enzyme physicochemical properties are dependent on microbial source and biotechnological manipulation resulting in enzymes with different surface features [11].

When ionic supports are used to prepare industrial, immobilized biocatalysts, enzymes may undergo desorption during the process, resulting in biocatalyst inactivation and product contamination. Therefore, for an ideal biocatalyst the ionic adsorption should be as strong as possible, implying that the enzyme should only be desorbed after its activity is reduced to ineffective levels [12, 13].

Several studies have shown that different stabilization levels are achieved by following different immobilization protocols. In many cases, this behavior cannot be explained due to problems in determining immobilized enzyme structures [14]. Chemical treatment is a promising tool to improve enzyme properties and can be successfully used to add amine groups on a protein surface, which, in turn, would facilitate and/or strengthen its ionic immobilization [15–17]. The main objectives of chemical amination are to promote enzyme crosslinking, make global changes in the physical characteristics on the enzyme surface, and modify key functional groups [14]. Modification via carboxylic groups reactions, such as Asp and Glu side groups, with ethylenediamine after activation with carbodiimide is a well-described and easily controllable reaction, which may introduce intramolecular crosslinking to enhance enzyme rigidity and, consequently, enzyme stability [13, 18–21]. Chemical amination of lipases previously immobilized on hydrophobic supports, named solid-phase amination, has been reported as a method to simplify the technique [13].

In this research, the lipase from Geotrichum candidum was produced on a medium supplemented with soybean molasses (by-product generated from liquid evaporation during the drying of concentrated soy protein), aminated in solid phase using ethylenediamine and carbodiimide and then immobilized on cationic supports. The derivatives were characterized and further applied to produce omega-3-PUFA from fish oil hydrolysis using biphasic systems (water/immiscible solvents).

Materials and methods

Materials

Octyl-Sepharose 4BCL, carboxymethyl agarose and sulfopropyl agarose supports were obtained from GE Healthcare. Bovine serum albumin (BSA), p-nitrophenylbutyrate (p-NPB), ethylenediamine (EDA), carbodiimide (EDAC), docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA) were obtained from Sigma-Aldrich (St.Louis, MO, USA). Sardine oil was generously donated by BTSA, Biotecnologías Aplicadas, S.L. (Madrid, Spain). Other reagents and solvents were analytical or HPLC grade.

Enzyme production

Geotrichum candidum lipase (GCL) was produced in 250-mL flasks, containing 50 mL of medium supplemented with 200 g/L soybean molasses, pH 3.5, 130 rpm, 24 h, 25 °C, as described by Morais Junior [22].

Lipase activity assay

Lipase activity was determined by measuring the p-nitrophenolate released from the hydrolysis of 50 mM p-nitrophenylbutyrate (p-NPB) at 348 nm as described by Quinn et al. [23] and Bastida et al. [24]. The reaction was initiated with 20 μL of purified lipase [22] dissolved in 2.5 mL of 25 mM sodium phosphate, pH 7.0, at 25 °C. One international activity unit (U) was defined as the amount of enzyme that hydrolyzed 1 μmol of p-NPB per minute under the assay conditions. Protein concentration was determined with the Bradford Reagent at 595 nm, using bovine serum albumin as standard [25].

Amination of Geotrichum candidum lipase immobilized on octyl-Sepharose

Before chemical amination, GCL was immobilized onto the octyl-Sepharose 4 BCL support, as proposed by Fernández-Lorente et al. [13]. For each 25 mL of lipase (12.8 U/mL), 5 g of support were suspended in 25 mL of 5 mM sodium phosphate buffer, pH 7.0, at 25 °C. After 1 h under gentle stirring, the immobilized preparation was filtered and washed with distilled water.

Thereafter, 5 g of the derivative was added to 50 mL of 1 M ethylenediamine, pH 4.5, under continuous stirring. Full modification started with the addition of 10 mM EDAC. After 90 min of gentle stirring at 25 °C, the aminated derivative was filtered, washed five times with 80 mL of distilled water and stored at 4 °C. To release aminated GCL (GCL-A) from the support, 1 g of the derivative was suspended in 10 mL of 2% (v/v) Triton X-100 prepared in 5 mM sodium phosphate buffer, pH 7.0 [26].

Triton X-100 was removed from the lipase solution with chloroform as described by Horikawa & Ogawara [27]. Each 1 mL of the lipase solution containing Triton X-100 was extracted with 1 mL of chloroform followed by vortex agitation for 15 s. After centrifugation (3000 rpm, 30 min), the aqueous phase containing the enzyme was recovered.

Immobilization of GCL-A on carboxymethyl agarose and sulfopropyl agarose

Two grams of carboxymethyl agarose and sulfopropyl agarose supports (previously washed with distilled water) were suspended in 10 mL of GCL-A solution prepared in 10 mL of 5 mM sodium phosphate buffer, pH 7.0, at 25 °C and left under mild stirring. Suspension (soluble enzyme and support/derivative) and supernatant (enzyme solution separated from the support/derivative) samples were taken periodically and enzyme activity was measured. After 1 h, the derivatives were filtered and washed extensively with distilled water. Soluble lipase sample incubated under the same conditions without support was the control.

Biochemical characterization of immobilized lipases

Effect of temperature on enzyme stability

The effect of temperature on lipase activity was evaluated at 30, 40 and 50 °C. Thermal stability was assessed by incubating 0.1 mL of soluble non-aminated and aminated lipase, and 0.1 g of derivative in 50 mM phosphate buffer, pH 7.0, at the given temperatures for 7 h, sampling once per hour. Lipase activity was assayed as previously described, and the residual activities were calculated.

Effect of pH on enzyme stability

The effect of pH on lipase activity was evaluated at pH from 3.0 to 10.0. The soluble non-aminated and aminated lipase (0.1 mL) and derivatives (0.1 g) were suspended in 1.0 mL of each buffer at room temperature. The following 50 mM buffer systems were used: sodium citrate, pH 3.0, 4.0 and 5.0, sodium phosphate, pH 7.0 and 8.0, and sodium bicarbonate, pH 9.0 and 10.0. Lipase activity was assayed as previously described.

Stability on organic solvents

Enzyme stability on organic solvents was evaluated by incubating 10 U/mL of soluble enzyme and 0.1 g of each derivative in 10 mL of 50 mM sodium phosphate, pH 7.0, containing methanol, propanol and cyclohexane at 50% (v/v) final concentration. The incubation in solvents was performed at a 1:1 ratio of each solvent and the enzyme (soluble and derivative suspensions), at 37 °C for 78 h. The first sample was taken after 6 h and then each 12 h thereafter. The lipase activity was determined using the standard assay as previously described and the residual activities were calculated.

Hydrolysis of fish oil

The reaction was performed with the soluble aminated GCL and its ionic derivatives in an aqueous/organic two-phase system with cyclohexane, as proposed by Fernández-Lorente et al. [7]. Hydrolysis reactions were carried out using 10 U of biocatalyst per gram of fish oil, at a 1:1 (v/v) aqueous/organic phase ratio, at 37 °C. The aqueous phase was composed of 5.0 mL of 25 mM phosphate buffer, pH 7.0, and the organic phase was composed of 4.5 mL of cyclohexane and 0.5 mL of fish oil. The organic biphasic medium was prepared in a test tube and pre-incubated at 25 °C for 15 min under magnetic stirring. The reaction was started by the addition of biocatalysts, performed under constant agitation (1500 rpm) to achieve a homogeneous dispersion of phases and finalized after 72 h.

Selectivity was calculated as the ratio between released EPA and DHA; the final activity was expressed in relation to the initial activity, calculated by Eq. 1:

Analysis of free polyunsaturated fatty acids

The analysis of free PUFA was performed as described by Fernández-Lorente et al. [7]. Samples were taken every 12 h and after centrifugation, the organic phase was analyzed by HPLC. The reaction was followed by taking 100 μL of organic phase and dissolving it in 400 μL of acetonitrile. Unsaturated fatty acids were analyzed by HPLC (Spectra Physic SP 100 coupled with an UV detector Spectra System UV1000) using a reverse-phase column (Ultrabase C18, 15 × 0.46 cm, 5 µm). Products were eluted using a 7:3 (v/v) acetonitrile:10 mM acetic acid, pH 3.0, solution as mobile phase at 1.0 mL/min flow rate. Absorbance was read at 215 nm by an UV detector. Retention times for the unsaturated fatty acids were 10.4 and 13.5 min for EPA and DHA, respectively. The PUFA produced during the enzymatic reaction were compared to their corresponding pure commercial standards and yields were calculated from the peak areas.

Residual immobilized enzyme

After reaction, the derivatives were separated from the organic biphasic medium, washed with 25 mM sodium phosphate buffer, pH 7.0, filtrated and the enzymatic activity was measured, as previously described in Sect. 2.3, to evaluate the amount of enzyme that remained bound to the support.

Reproducibility of experiments and statistical analysis

All experiments were performed in triplicate and standard deviation was calculated to confirm the results. Data were treated using STATISTICA 7.0 software (StatSoft).

Results and discussion

Initially, it was verified that even after long-term incubation, the Geotrichum candidum lipase (GCL) could not be immobilized on carboxymethyl and sulfopropyl supports at pH 7.0 and 25 °C. This fact may be attributed to the lack of cationic groups on the enzyme surface, which were not enough to promote any adsorption of the target enzyme on the cationic exchange supports, and have been verified in immobilization attempts of many enzymes [13, 15, 16].

Chemical amination and thermal stability of aminated GCL

To introduce more amino groups on the enzyme surface, thus resulting in higher enzyme reactivity, full chemical amination of the GCL was carried out in solid phase, i.e., the enzyme was chemically treated after adsorption on octyl-Sepharose. In addition to the possibility of using a pre-stabilized enzyme, other advantages of the amination in solid phase are the prevention of enzyme precipitation and the protecting effect of its catalytic site [26]. The enzyme activity of soluble aminated GCL (GCL-A)-immobilized preparations was only mildly affected by the treatment. The activity of GCL-A was 11.5 U/mL, corresponding to 89.8% of the initial activity.

As observed in Fig. 1, amination improved the stability of the soluble enzyme at 30, 40 and 50 °C. After 7-h incubation at 30 °C, the soluble GCL (Fig. 1a) presented 40% inactivation while GCL-A (Fig. 1b) was more stable retaining 80.5% activity; therefore, being 1.3-fold more stable than GCL. At 40 and 50 °C, GCL and GLC-A presented similar deactivation patterns, being GCL-A 10% more stable than GCL. The estimated half-lives of GCL were 10.3, 9.5 and 6.2 h at 30, 40 and 50 °C, respectively, and the estimated half-lives of GCL-A were 13.7, 9.8 and 6.6 h at 30, 40 and 50 °C, respectively.

The activity profiles at different pH for GCL and GCL-A were quite different (not shown). For GCL, high activity was observed in pH from 3.0 to 9.0. GCL-A was 1.2-fold more active than GCL at pH 8.0 and 9.0, and twofold more active at pH 10.0. The activities were similar at pH 4.0, while at pH 6.0 the modified enzyme was nearly 1.5-fold less active than GCL.

The variation in activity profiles at different temperatures and pH indicates changes in physical properties of the enzyme, which may have been greatly altered after surface modification resulting from chemical treatment [28, 29].

The GCL-A presented similar stability profiles with organic solvents when compared to the stability of the GCL (as shown below).

The lipase from Thermomyces lanuginosus was aminated using the solid-phase method and then covalently bound on cyanogen bromide agarose or adsorbed on octyl-Sepharose. The enzyme activity on both derivatives was not affected by the chemical treatment, and the stability of modified lipase during thermal inactivation or inactivation by solvents was not influenced [30]. Godoy et al. [31] applied the same method to modify a mutant Geobacillus thermocatenulatus lipase 2 resulting in a 5% activity decrease and a threefold lower stability when compared to the non-aminated enzyme. Rueda et al. [18] obtained 100% covalent immobilization of the aminated lipases from Candida antarctica B, Thermomyces lanuginosus and Rhizomucor miehei on glyoxyl-octyl agarose after 2 h at pH 9.0, while when using the non-aminated counterparts, an amount of the enzymes was desorbed from the support at pH 10.0.

Immobilization of GCL-A on carboxymethyl and sulfopropyl supports

The chemical amination aims to enrich the enzyme surface with low-pK amino groups that easily react with the ionic groups of the support. Generally, lipases have few lysines resulting in enzyme surfaces with a low amount of amino groups, which consequently hampers enzyme immobilization on cation exchange supports [13].

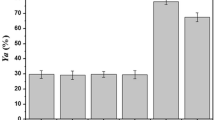

Figure 2 shows the time courses of GCL-A immobilization on cationic supports. In both cases, the aminated enzyme was rapid and easily immobilized, and both processes presented 100% yield after one-hour incubation. The derivatives presented more than 80% expressed activity, which clearly demonstrates an improvement in the immobilization processes by the introduction of positive amine groups on the surface of the lipase previously adsorbed on octyl support.

Immobilization time course of aminated Geotrichum candidum lipase (GCL-A) on a carboxymethyl and b sulfopropyl supports. Immobilization was carried out on 5 mM sodium phosphate buffer, pH 7.0, under gently stirring at 25 °C. Filled circle Control (enzyme solution—without support); open triangle suspension (enzyme solution and support/derivative) and open square supernatant (enzyme solution separated from support/derivative)

Montes et al. [32] observed that the penicillin G acylase was not adsorbed on carboxymethyl and dextran sulfate-coated supports at pH 7.0. Chemical amination of the protein surface, however, allowed its immobilization on both supports. In addition, after the chemical modification, Gómez et al. [33] achieved the immobilization of the invertase from Saccharomyces cerevisiae on sodium alginate-coated chitin support reaching 85% immobilization yield and the immobilized enzyme retained 97% of the initial activity.

Thermal stability of carboxymethyl and sulfopropyl GCL-A derivatives

The stability of the immobilized enzyme on both ionic supports was compared by following inactivation at different temperatures (Fig. 3). Both derivatives were very stable at 30 and 40 °C, retaining 100% activity after 7 h of incubation (Fig. 3.a and 3.b). At 50 °C, the lipase immobilized on sulfopropyl (GCLs) was more stable than on the carboxymethyl support (GCLc). At this temperature, GCLc presented a half-life of 3 h, while GCLs retained 75% activity after 7 h of incubation (Fig. 3.c). This effect may be firstly due to the geometry of the support. In the sulfopropyl support, interactions occur via ion exchange with the enzyme amine groups promoting more resistance to enzyme–support interactions. On the other hand, on the carboxymethyl support the interactions are ligand–ligand type on a plane surface (one group on enzyme surface with one active group from the support). Furthermore, it was observed that the hyperactivation effect was more pronounced with the carboxymethyl than with the sulfopropyl derivative. This is probably because the enzyme catalytic site became more exposed on this support easing the access to the substrate [34].

Thermal of inactivation of non-aminated (GCL) and aminated (GCL-A) Geotrichum candidum lipase immobilized on carboxymethyl and sulfopropyl supports. Incubation was carried out on 25 mM sodium phosphate, pH 7.0, at a 30, b 40 and c 50 °C. Filled square soluble GCL-A; open circle GCLc derivative; open triangle GCLs derivative

The aminated Candida rugosa lipase when immobilized on electrochemical polyaniline activated with glutaraldehyde, at pH 10.0 and 25 °C, had its activity increased by 52% and thermal stability was threefold improved compared to the non-aminated enzyme [35].

Soluble lipase from T. lanuginosus is dramatically hyperactivated by adsorption on sulfopropyl-Sepharose also presenting much higher stability at 25 and 37 °C [36].

Effect of organic solvents on stability of soluble GCL-A and its derivatives

Figure 4 shows the activity of GCL-A and its derivatives after incubation for diverse periods with different solvents. Ionic immobilization highly increased enzyme stability in methanol, propanol and cyclohexane. As presented in Fig. 4a, in medium with methanol, GCL-A was moderately stable presenting a half-life of 6 h and complete inactivation after 48 h. The GCLc derivative showed half-life of 68 h, retaining 42.3% activity after 72 h. The GCLs activity gradually decreased up to 36 h (39%), remaining stabilized in further periods with 44.3% maximum inactivation. This fact can be explained by the stabilizing effect of the solvent on the ionic interactions that promotes conformational changes on immobilized lipolytic enzymes [37]. With propanol (Fig. 4b), GCL-A showed half-life less than 6 h and it was completely inactivated after 48 h, while GCLc showed half-life of 54 h and 41.4% residual activity after 72 h. As with methanol, GCLs also was more stable, presenting 55.5% maximal inactivation, thus being 1.3-fold more stable than GCLc. Figure 4c shows that with cyclohexane, GCL half-life was less than 6 h, and after 36 h no activity was detected. GCLc showed half-life of 60 h and 40% residual activity after 72 h. GCLs was more stable showing a half-life of 66 h, with 40.9% inactivation after 72 h, thus being 1.2-fold more stable than GCLc.

Stability on organic solvents of aminated Geotrichum candidum lipase (GCL-A) and its ionic derivatives. Incubation was carried out at 25 °C with 25 mM sodium phosphate, pH 7.0, containing 50% (v/v) a methanol, b propanol and c cyclohexane. Filled square soluble GCL-A; open circle GCLc derivative; open triangle GCLs derivative

When compared with the carboxymethyl, the superior results obtained with the sulfopropyl derivative in the presence of organic solvents may be explained by the stronger rigidity resulting from the cationic binding of the sulfopropyl to the enzyme surface enriched with amino groups, making it less susceptible to interfacial inactivation by solvents.

Detection of EPA and DHA

To minimize interference by impurities present in the fish oil samples, the wavelength of 215 nm was selected, according to Fernández-Lorente et al. [7]. Different standard solutions at varied EPA and DHA concentrations were prepared in cyclohexane with pure commercial reagents.

For such, 20-μL samples of each standard solution were analyzed by RP-HPLC with UV detection at a 1 mL/min flow rate. Figure 5 shows that integration areas were perfectly proportional to PUFA concentrations. The absorbance of EPA was 50% lower than that from DHA. The hydrolysis rates (EPA/DHA) and the EPA/DHA ratios were easily calculated by comparing UV–HPLC chromatograms of aliquots of the organic phase of the reaction mixture and the corresponding calibration curves.

Crude fish oil presented 18 mM of DHA and 12 mM of EPA, at 215 nm. The retention times in RP-HPLC under isocratic conditions are relatively low due to the polyunsaturated structure of PUFA that makes them less non-polar.

Therefore, a rapid, easy and highly precise analysis of omega-3 fatty acids released by enzymatic fish oil hydrolysis could be designed using an isocratic HPLC elution under the previously mentioned conditions. For instance, when analyzing a sample with 0.1 mM DHA utilizing a 1 mL/min flow rate the peak area was very high (over 4,800,000 ± 10,000 units with a very low baseline noise).

Hydrolysis of fish oil by GCL-A and its derivatives

After immobilizing GCL-A on cationic supports and studying the stability of its derivatives, the soluble aminated enzyme and its derivatives were applied to fish oil hydrolysis (Table 1).

GCLc and GCLs showed similar activity (165 and 170%, respectively) being up to 2.3-fold more active than GCL-A. GCLc produced 354 μM of Omega-3 (2.4-fold more than GCL-A) and the GCLs rendered the highest yield in fish oil hydrolysis, i.e., 482 μM of Omega-3 (3.2-fold more than GCL-A).

Lipase selectivity, given by the EPA/DHA ratio, for the immobilized enzyme, indicated that GCLc and GCLs were, respectively, 3.5- and sevenfold more selective than GCL-A.

Figure 6 presents the RP-HPLC chromatograms of DHA and EPA produced by enzymatic fish oil hydrolysis.

GCL immobilized on cationic supports have more rigid bondings between enzyme and support. Immobilization can cause some distortion of the lipase catalytic site that can be directly related to its specificity [38]. It can be concluded that immobilization on carboxymethyl and sulfopropyl supports alter the enzyme specificity for fish oil hydrolysis, in relation to EPA/DHA. This makes them attractive biocatalysts for industrial application.

EPA and DHA are commonly obtained from fish oil that contains about 30% of Omega-3 PUFAs in combination with different fatty acids, mainly in the form of triglycerides [38, 39]. Moreover, immobilization did not affect the GCL selectivity, in contrast to that observed with soluble GCL-A.

The conversion of fish oil to Omega-3 in the hydrolysis process was up to 15%. Pereira et al. [40] applied the lipase from Hypocrea pseudokoningii stabilized by multipoint covalent immobilization after chemical modification, and applied the derivative to fish oil hydrolysis achieving up to 10% conversion.

Amount of enzyme remained immobilized

After the hydrolysis reaction, the residual lipase activity in each derivative was evaluated.

The carboxymethyl derivative presented 6.65 U per gram of support corresponding to 66.5% of the initial enzyme activity, while the sulfopropyl derivative retained 78.5% activity (7.85 U per gram of support).

These results show that the immobilized ionic derivatives from GCL-A can be effectively used at least for two cycles of substrate hydrolysis.

Conclusion

Chemical amination is an attractive process because it allows the Geotrichum candidum lipase to be efficiently and reversibly immobilized on cationic supports activated with different reactive groups. This modification and mainly the immobilization process improve the enzyme biochemical properties in relation to the thermal stability and stability at more alkaline pH, in comparison to the non-modified free enzyme. In future studies, stability at alkaline pH may facilitate covalent immobilization of this enzyme on glyoxyl or epoxide activated supports.

Concerning the effect of organic solvents on enzyme stability, ionic immobilization improves stability at high concentrations of methanol, propanol and cyclohexane, conferring an interesting property to the biocatalysts, because stability in medium with organic solvents is extremely important for most industrial applications of lipases. During fish oil hydrolysis, both derivatives were more active than the soluble aminated enzyme presenting high specificity (ratio between EPA and DHA).

References

Kahveci D, Xu X (2011) Repeated hydrolysis process is effective for enrichment of omega-3 polyunsaturated fatty acids in salmon oil by Candida rugosa lipase. Food Chem 129:1552–1558

Botino NR, Vandenbu GA, Reiser R (1967) Resistance of certain long-chain polyunsaturated fatty acids of marine oils to pancreatic lipase hydrolysis. Lipids 2:489–493

Carlson S, Neuringer, M (1999) Polyunsaturated fatty acid status and neurodevelopment: A summary and critical analysis of the literature. Lipids 1999 34:171–178.

Ruxton CHS, Calder PC, Reed SC, Simpson MJA (2005) The impact of long-chain n-3 polyunsaturated fatty acids on human health. Nutr Res Rev 18:113–129

Riediger ND, Othman RA, Suh M, Moghadasian MH (2009) A systemic review of the roles of n-3 fatty acids in health and disease. J Am Diet Assoc 109:668–679

Yashodhara BM, Umakanth S, Pappachan JM, Bhat SK, Kamath R, Choo BH (2009) Omega-3 fatty acids: A comprehensive review of their role in health and disease. J Postgrad Med 85:84–90

Fernández-Lorente G, Pizarro C, López-Vela D, Betancor L, Carrascosa AV, Pessela BC, Guisán JM (2011) Hydrolysis of fish oil by lipases immobilized inside porous supports. J Am Oil Chem Soc 88:819–826

Mateo C, Palomo JM, Fernandez-Lorente G, Guisán JM, Fernandez-Lafuente R (2007) Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme Microb Technol 40:1451–1463

Mateo C, Abian O, Ernedo MB, Cuenca E, Fuentes M, Fernandez-Lorente G et al (2005) Some special features of glyoxyl supports to immobilize proteins. Enzyme Microb Technol 37:456–462

Abian O, Grazu V, Hermoso J, Gonzalez R, Garcia JL, Fernandez-Lafuente R et al (2004) Stabilization of penicillin G acylase from Escherichia coli: site-directed mutagenesis of the protein surface to increase multipoint covalent attachment. Appl Environ Microbiol 70:1249–1251

Hernandez K, Fernandez-Lafuente R (2011) Control of protein immobilization: Coupling immobilization and site-directed mutagenesis to improve biocatalyst or biosensor performance. Enzyme Microb Technol 48:107–122

Fuentes M, Maquiese JV, Pessela BCC, Abian O, Fernández-Lafuente R, Mateo C, Guisán JM (2004) New cationic exchanger support for reversible immobilization of proteins. Biotechnol Prog 20:284–288

Fernández-Lorente G, Godoy CA, Mendes AA, Lopez-Gallego F, Grazu V, Rivas B, Palomo JM, Hermoso JM, Fernandez-Lafuente R, Guisán JM (2008) Solid-phase chemical amination of a lipase from Bacillus thermocatenulatus to improve its stabilization via covalent immobilization on highly activated glyoxyl-agarose. Biomacromol 9:2553–2561.

Rueda N, Santos JCS, Ortiz C, Torres R, Barbosa O, Rodrigues RC, Berenguer-Murcia Á, Fernandez-Lafuente R (2016) Chemical modification in the design of immobilized enzyme biocatalysts: drawbacks and opportunities. Chem Rec 16:1436–1455

López-Gallego F, Montes T, Fuentes M, Alonso N, Grazu V, Betancor L et al (2005) Improved stabilization of chemically aminated enzymes via multipoint covalent attachment on glyoxyl supports. J Biotechnol 116:1–10

Perfetti RB, Anderson CD, Hall PL (1976) The chemical modification of papain with 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide. Biochem 15:1735–1743.

Matyash LF, Ogloblina OG, Stepanov VM (1973) Modification of carboxyl groups in pepsin. Eur J Biochem 35:540–545

Rueda, N, Dos Santos, JCS, Ortiz, C, Barbosa, O, Fernandez-Lafuente, R, Torres, R (2016) Chemical amination of lipases improves their immobilization on octyl-glyoxyl agarose beads. Catal Today 259:107–118.

Rodrigues RC, Barbosa O, Ortiz C, Berenguer-Murcia Á, Torres R, Fernandez-Lafuente R (2014) Amination of enzymes to improve biocatalyst performance: coupling genetic modification and physicochemical tools. RSC Adv 4:38350–38374.

Hoare DG, Olson A, Koshland DE Jr (1968) The reaction of hydroxamic acids with water-soluble carbodiimides. A lossen rearrangement. J Am Chem Soc 90:1638–1643

Nakajima N, Ikada Y (1995) Mechanism of amide formation by carbodiimide for bioconjugation in aqueous media. Bioconjug Chem 6:123–130

Morais Júnior WG, Ribeiro EJ, Cardoso VL, Resende MM, Kamimura ES, Pessela BC (2016) Optimization of the production and characterization of lipase from Candida rugosa and Geotrichum candidum in soybean molasses by submerged fermentation. Protein Expr Purif 123:26–34

Quinn DM, Shirai K, Jackson RL, Harmony JAK (1982) Lipoprotein lipase catalyzed hydrolysis of water-soluble p-nitrophenyl esters. Inhibition by apoprotein C-II. Biochem 21:6872–6879.

Bastida A, Sabuquillo P, Armisen P, Fernandez-Lafuente R, Huguet J, Guisán JM (1998) A single step purification, immobilization, and hyperactivation of lipases via interfacial adsorption on strongly hydrophobic supports. Biotechnol Bioeng 58(5):486–493

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principles of protein-dye biding. Anal Biochem 72:248–254

Galvis M, Barbosa O, Torres R, Ortiz C, Fernandez-Lafuente R (2012) Effect of solid phase chemical modification on the features of the lipase from Thermomyces lanuginosus. Process Biochem 47:460–466

Horikawa S, Ogawara H (1979) A simple and rapid procedure for removal of Triton X-100 from protein solution. Anal Biochem 97:116–119.

Palomo JM, Fernandez-Lorente G, Guisan JM, Fernandez-Lafuente R (2007) Modulation of immobilized lipase enantioselectivity via chemical amination. Adv Synth Catal 349:1119–1127

Cabrera Z, Fernandez-Lorente G, Fernandez-Lafuente R, Palomo JM, Guisan JM (2009) Enhancement of Novozym-435 catalytic properties by physical or chemical modification. Process Biochem 44:226–231

Rodrigues RC, Godoy CA, Volpato G, Ayub MAZ, Fernandez-Lafuente R, Guisán JM (2009) Immobilization-stabilization of the lipase from Thermomyces lanuginosus: critical role of chemical amination. Process Biochem 44:963–968

Godoy CA, de las Rivas B, Guisán JM (2014) Site-directing an intense multipoint covalent attachment (MCA) of mutants of the Geobacillus thermocatenulatus lipase 2 (BTL2): genetic and chemical amination plus immobilization on a tailor-made support. Process Biochem 49(8):1324–1331

Montes T, Grazu V, López-Gallego F, Hermoso JA, Guisán JM, Fernandez-Lafuente R (2006) Chemical modification of protein surfaces to improve their reversible enzyme immobilization on ionic exchangers. Biomacromol 7(11):3052–3058

Gómez L, Ramírez HL, Neira-Carrillo A, Villalonga R (2006) Polyelectrolyte complex formation mediated immobilization of chitosan-invertase neoglycoconjugate on pectin-coated chitin. Bioprocess Biosys Eng 28(6):387–395

Palomo J M, Muñoz G, Fernández-Lorente G, Mateo C, Fernández-Lafuente R, Guisán JM (2002) Interfacial adsorption of lipase on very hydrophobic support (octadecyl-Sepabeads): immobilization, hyperactivation and stabilization of the open form of lipases. J Mol Catal B Enzym 19–20:279–286

Bezbradica D, Jugovic B, Gvozdenovic M, Jacovetic S, Knezevic-Jugovic Z (2011) Electrochemically synthesized polyaniline as support for lipase immobilization. J Mol Catal B Enzym 70:55–60

Moreno-Perez S, Ghattas N, Filice M, Guisán JM (2015) Dramatic hyperactivation of lipase of Thermomyces lanuginosus by a cationic support: fixation of the hyperactivated form by adsorption on sulfopropyl-Sepharose. J Mol Catal B Enzym 122:199–203

Betancor L, Lopez-Gallego F, Hidalgo A, Alonso-Morales N, Fuentes M, Fernandez-Lafuente R, Guisán JM (2004) Prevention of interfacial inactivation of enzymes by coating the enzyme surface with dextran-aldehyde. J Biotechnol 110:201–207

Schmitt-Rozieres M, Deyris V, Comeau LC (2000) Enrichment of polyunsaturated fatty acids from fish cannery effluents by enzymatic selective esterification. J Oil Fat Ind 77:329–332

Pérez SM, Martin S, Fernández-Lorente G, Filice M, Guisán JM, Ventosa A, Garcia MT, Mellado E (2011) A novel halophilic lipase, LipBL, with applications in synthesis of eicosapentaenoic acid (EPA). PLoS One 6:1–11

Pereira MG, Facchini FDA, Polizeli AM, Vici AC, Jorge JA, Pessela BC, Fernández-Lorente G, Guisán JM, Polizeli MLTM (2015) Stabilization of lipase of Hypocrea pseudokoningii by multipoint covalent immobilization after chemical modification and application of the biocatalyst in oil hydrolysis. J Mol Catal B Enzym 121:82–89

Acknowledgements

The authors wish to thank CAPES (Brazil) for financial support through the PDSE Program (BEX 14174/13-8) and the “Instituto de Investigación en Ciencia de la Alimentación” (CIAL) for supporting this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

de Morais Júnior, W.G., Terrasan, C.R.F., Fernández-Lorente, G. et al. Solid-phase amination of Geotrichum candidum lipase: ionic immobilization, stabilization and fish oil hydrolysis for the production of Omega-3 polyunsaturated fatty acids. Eur Food Res Technol 243, 1375–1384 (2017). https://doi.org/10.1007/s00217-017-2848-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2848-8