Abstract

The roasting process plays a key role in hazelnut oil production. The optimal roasting conditions for Delisava and Kara Fındık hazelnut cultivars were studied using response surface methodology (RSM). The maximum oil content and minimum values of peroxide value (PV), conjugated diene (K 232), conjugated triene (K 270) values of Delisava and Kara Fındık hazelnut cultivars were used to estimate the production of high-quality oils. The optimal roasting temperature and time for Delisava and Kara Fındık hazelnuts were 114.24 °C for 27.21 min and 123.43 °C for 22.12 min, respectively. Optimal oils were subjected to accelerated oxidation tests (Schaal oven test at 60 °C) and photooxidation at daylight. Under thermal conditions, Kara Fındık oil possesses higher oxidative stability than Delisava oil according to PV, K 232 and K 270 values. Under photooxidation conditions, an opposite trend was noted when Kara Fındık oil exhibited lower oxidative stability in comparison with Delisava oil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hazelnut is one of the most important agriculture products cultivated in a hilly region along the eastern Black Sea cost of Turkey. The average hazelnut production during the last 5 years in Turkey was approximately 598.000 tons per year. Turkey is by far the world’s biggest exporter for hazelnut that accounted for between 70 and 75 % of the world’s hazelnut production [1]. The hazelnut cultivars could be clustered into three main groups: the round shape, the conic shape and the almond shape. Delisava and Kara Fındık cultivars are a member of the round-shaped cultivars. Another classification of hazelnuts can made based on quality, being the Giresun and the Levant type, wherein Giresun type is accepted as high-quality hazelnut. Hazelnuts have high oil yield with easy processing and good flavor. The other type of hazelnut, Levant, has lower oil yield compared to Giresun type. Delisava and Kara Fındık hazelnut cultivars are assumed as the members of Levant type hazelnuts [2]. Kara Fındık has taken part in high-quality hazelnut cultivars, whereas Delisava cultivar has been exhibited and consumed in domestic market due to its some quality factors such as moderate texture and taste [3].

Hazelnuts are used in confectionery, chocolate, biscuit and pastry manufacture [4]. Besides usage in food products, the other widely consumed product from hazelnuts is hazelnut oil [5]. The oil content of hazelnut is more than 50 % depending on the region, climate, soil and cultivar [6]. Hazelnut oil could be used for different purposes such as cooking, salad dressing, flavoring and cosmetic products [7].

Hazelnut oil is extracted using chemical and physical techniques from hazelnuts without shell. Raw and roasted hazelnuts can be used in oil processing. Hazelnuts are roasted to give products with different aroma and color. The roasted conditions could be changed according to the manufacturer, wherein the roasting temperature and time are generally applied between 100–160 °C and 10–60 min, respectively [8]. Roasting parameters of hazelnuts were previously studied using response surface methodology (RSM). In these works [8, 9], the effect of roasting conditions on the color [8], sensory and physical characteristics [9] of roasted hazelnut were tested.

Hazelnuts are rich in mono- and polyunsaturated fatty acids, especially oleic and linoleic acids. Oxidative stability of hazelnut oils is stronger among vegetable oils including high oleic acid content with tocols and phenolic substances [10]. The investigation of oxidative stabilities in hazelnut oil was carried out using accelerated oxidation experiments such as thermal oxidation (60 °C) and photooxidation [11].

The aim of this work was to optimize the roasting temperature and time for two hazelnut cultivars (Delisava and Kara Fındık) based on oil content, peroxide value (PV) and UV characteristics (K 232 and K 270) using RSM. This information will contribute to the optimization of roasting conditions for hazelnut oil extraction. After the determination of optimum conditions, the extracted oils were subjected to accelerated thermal oxidation and photooxidation. These data could give valuable information about the shelf life of these oils under thermal and photooxidation conditions.

Materials and methods

Material

Two different hazelnut cultivars, Delisava and Kara Fındık, were collected from trees cultivated in Sakarya province of Turkey during the collection season of 2013. After harvesting, the fresh hazelnuts were dried naturally under the sun and separated from leaves. Hazelnuts were kept in a dark room until extraction. Before extraction, the hazelnuts shells were removed.

Methods

Total oil content

Hazelnuts without shell were finely ground using a coffee grinder (Sinbo, Turkey) to 2 µm particle size. The oil of hazelnuts was extracted using n-hexane in a Soxhlet apparatus for 4 h. After the solvent was removed using rotary evaporator, the extract was dried under nitrogen. The extracted oils were kept in brown bottles, flushed with nitrogen and stored at −18 °C until analyses.

Characteristics of oils

Peroxide values (PV) of the oils were determined iodometrically according to the Cd 8–53 method [12]. The oils were analyzed for conjugated diene (K 232) and conjugated triene (K 270) according to the Cd 18–90 method [12].

Experimental design for roasting

The roasting temperatures and times were selected as independent variables used in experimental design created according to a central composite design (CCD). The independent variables, temperature (X1) and time (X2), varied from 110 to 180 °C and from 6 to 34 min, respectively. These ranges in roasting temperature and time reflect the ranges commonly used in conventional roasting. Each independent variable had five levels (−2, −1, 0, +1 and +2). Thirteen combinations were randomly chosen according to a CCD configuration for 2 independent variables. The experimental design of the coded and actual levels of the variables is given in Table 1. The effects of these variables were analyzed on responses (dependent variables) including total oil content, PV, K 232 and K 270 values. The variance in the experimental data of each response depending on the independent variables was explained using a second-order polynomial equation as shown below.

In this equation, β 0 is constant, β 1 and β 2 are linear coefficients, β 11 and β 22 are quadratic coefficients, and β 12 is the interaction coefficient.

Analysis of variance (ANOVA), a partial F test for individual terms, and an analysis of residuals were performed. ANOVA tables were generated, and the effects and regression coefficients of individual linear, quadratic and interaction terms were determined. The degrees of significance of all terms in the polynomial equations were determined statistically by calculating the F value at a probability (p) of 0.001, 0.01, or 0.05. The regression coefficients were used to make statistical calculations to generate surfaces of responses from the regression models. All statistical analyses were performed using a statistical package (Minitab 16.1.1, USA). The hazelnuts were roasted in an air-forced oven at given temperature and time given in Table 1.

Oxidation tests

After optimization of roasting temperature and time for hazelnuts, one sample for each hazelnut cultivar was selected and the hazelnut oil extracted from it. Afterward, the oil samples were stored at thermal conditions (60 °C) and photooxidation conditions. Oxidation was followed by determination of PV, K 232 and K 270 for each experiment condition.

Thermal conditions

Two grams of oil samples was accurately weighed into Petri dishes and closed before being placed in an air-forced oven in the dark and heated to 60 °C. The samples were withdrawn every 2 days for PV, K 232 and K 270 analysis. Each sample in 2 separate Petri dishes was subjected to oxidation.

Photooxidation conditions

Hazelnut oils (2.0 g) were accurately weighed into Petri dishes, closed and placed in a light box (Test 742, Turkey) equipped with two cool-white fluorescent lights. The fluorescent radiation was at 3000 lx. The samples were withdrawn every day for PV, K 232 and K 270 analysis. Each sample in 2 separate Petri dishes was subjected to oxidation.

Results and discussion

Delisava hazelnut oil

The experimental values of PV, K 232 and K 270 for Delisava hazelnut are given in Table 2. The oil content changed between 63.55 % (Run 12) and 65.85 % (Run 7). The primary oxidation indicator, PV, of samples was in the range of 1.44 (Run 12) and 2.98 (Run 7). The K 232 and K 270 values varied from 1.390 to 1.661 and from 0.089 to 0.445, respectively.

The regression coefficients of the second-order polynomial equations are given in Table 3. The linear and quadratic terms were significant for oil yield, PV, K 232 and K 270, whereas the cross product only creates significant difference in K 232 values. The correlation coefficient (R 2) values were 0.98, 0.92, 0.93 and 0.81 for oil yield, PV, K 232 and K 270 from Delisava hazelnut cultivar, respectively. These results indicate that the regression models explained the changes in the responses of interest depending on the roasting conditions well.

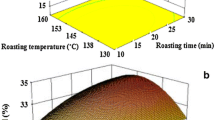

Response surface was used to illustrate the effect of roasting temperature and time on each response. Figures 1, 2, 3 and 4 show the corresponding response surfaces for oil yield, PV, K 232 and K 270, respectively.

The oil yield extracted from Delisava hazelnut cultivar tended to increase with increasing roasting time. At a definite roasting temperature, the oil yield increased with increasing time; afterward, the oil yield almost remained constant with further increases in time up to 30 min (Fig. 1). Another roasting parameter, temperature, also affected the oil yield. In the temperature range from 100 to 150 °C, there was a certain increase in oil yield, but further rise did not create anymore change in this value (Fig. 1). Being coincident with the presented ones, it was previously shown that as roasting temperature and time increased, oil yield was changed depending on the conditions of conventional roasting of hazelnuts [13].

The PV of Delisava hazelnut oil increased slightly with the increase in roasting time when roasting temperature was in between 100 and 150 °C; thereafter, an increase in PV was intensified with increasing temperature up to 175 °C (Fig. 2). The increasing behavior observed in PV with roasting time showed similarity with those results reported by Harhar et al. [14] who emphasized that PV of oils from argan oil increased with increasing roasting time. Roasting temperature was seen to be more effective than time on PV of hazelnut oil. For short roasting durations, the effect of temperature appeared, when it exceeded the value of 150 °C (Fig. 2). On the other hand, an increase in PV was seen with rise throughout the studied temperature range, as roasting time was close to its highest levels (Fig. 2). The similar trend was observed by Özdemir et al. [15] who reported a significant increase in PV after roasting of Giresun hazelnuts at 158 °C.

The effect of roasting temperature and time on K 232 and K 270 values for Delisava hazelnut oil are shown in Figs. 3 and 4, respectively. For short time of roasting, temperature did not show any significant effects on K 232 and K 270 values. However, an increase in time changed this temperature trends wherein sharp increases in K 232 and K 270 values were seen (Figs. 3, 4). Similarly, roasting time was found to cause a slight change in K 232 and K 270 values, when lower levels of temperature were selected. However, there were clear increases in K 232 and K 270 values in case of temperature level higher than 130 °C (Figs. 3, 4). In order to verify the predictive capacity of the model, an optimum condition was determined using the maximum oil content and the minimum PV, K232 and K 270. The experimental values were found to be in agreement with the predicted ones (Table 4).

Kara Fındık hazelnut oil

Yield of oil extracted from Kara Fındık and its PV, K 232 and K 270 values are given in Table 5 for each corresponding run specified in experimental design. Oil yield was found to be changed from 64.7 % (Run 1 and 13) to 66.6 % (Run 11) depending on the process parameters. Quality parameters of oil, PV, K 232 and K 270, were in the range of 1.36 (Run 12) and 8.58 meq O2/kg (Run 3), 1.247 (Run 1) and 1.610 (Run 3), and 0.080 (Run 1) and 0.301 (Run 3), respectively. Experimental data of oil yield and its quality parameters including PV, K 232 and K 270 for Kara Fındık hazelnut cultivar under different roasting conditions of temperature (X1) and exposure time (X2) are given in Table 5.

The regression coefficients of the second-degree polynomial equation are given in Table 6. Model performance parameters (significance of model, R 2 and \(R_{\text{adj}}^{2}\)) indicated that the developed equations for oil yield and PV values were significant (p ≤ 0.05) and they could explain the 79 and 97 % of variations in the corresponding experimental data depending on process conditions, respectively. However, remaining models developed for K 232 and K 270 were nonsignificant (p > 0.05) (Table 6). Thus, further analysis was continued for the models of oil yield and PV.

The changes in yield of oil extracted from Kara Fındık hazelnuts and in corresponding PV values depending on the process conditions are shown in Figs. 5 and 6, respectively. As seen in Fig. 5, oil yield linearly increases with roasting time irrespective of the studied temperature range. Being coincident with the result of regression analysis (temperature terms were nonsignificant), temperature did not show any significant effect on yield (Fig. 5). The highest oil yield was achieved, when time of roasting was selected as the longest one. Similar to the current results, in their studies, Chandrasekara and Shahidi [16] and Amaral et al. [13] have reported the strong relation between oil yield and process conditions.

One significant model was also developed for PV. Using this equation, Fig. 6 is drawn to display its dependence to roasting temperature and time. At lower temperature levels up to 130–135 °C, time did not change PV at its studied range, but its effects were being stronger on PV of oil extracted from Kara Fındık hazelnut roasted at temperature level higher than 130–135 °C (Fig. 6). PV increased from 2.1 to 3.5 meq O2/kg oil with increasing the process time from 6 to 34 min. Another studied process parameter was roasting temperature. Figure 6 displays that PV of hazelnut oil extracted from Kara Fındık increased with roasting temperature, when its level exceeded 140 °C and roasting time was around 6 min. However, this temperature effect on PV values was started with its level around 110 °C and reached its highest level with the highest temperature level of 180 °C in case of 30-min roasting. Additionally, the influence of interaction between temperature and time (getting close to 180 °C and 30 min) on PV is also seen in Fig. 6, which was shown in the regression analysis of the developed model for PV. Similar to the present one, Mariod et al. [17] reported the adverse effect of long-term roasting on quality of safflower oil, where PV of oil was seen to increase when safflower was roasted for long-term process.

Optimal roasting conditions were found to be 123.43 °C and 22.12 min. Oil yield was maximized, as PV was minimized. The responses at these optimal conditions were calculated as 65.5 % and 1.74 meq O2/kg oil for oil yield and PV, respectively. In order to verify the predictive capacity of the model, Kara Fındık hazelnuts were roasted at optimum conditions. The experimental results of yield of oil and its PV were found to be in agreement with the predicted ones (Table 7).

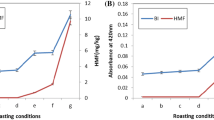

Thermal oxidation of hazelnut oils

After examination of optimum conditions, the oil samples extracted from each hazelnut cultivar were subjected to thermal oxidation. The effect of thermal treatment on PV, K 232 and K 270 values of hazelnut oils during accelerated oxidation is presented in Figs. 7, 8 and 9, respectively. The PV reached up to 48.36 and 28.47 meq O2/kg oil for Delisava and Kara Fındık oil after 14-day storage, respectively (Fig. 7). Generally, PV values of more than 10 meq O2/kg are not considered to be reliable. At the end of storage, K 232 and K 270 values were observed as 6.95, 0.142 and 4.34, 0.092 for Delisava and Karafındık oil, respectively (Figs. 8, 9). These results indicated that although both oil samples from Delisava and Kara Fındık cultivars had high oxidative stabilities, the latter one was higher than the former one. These results were consistent with those reported by Miraliakbari and Shahidi [11], in which solvent-extracted hazelnut oils showed the highest oxidative stability, with the lowest values for PV and conjugated dienes after 12-day storage at 60 °C. Differences in oxidative stabilities among hazelnut oils from Delisava and Kara Fındık could be sourced from the minor components such as tocols at thermal conditions [11].

Photooxidation of hazelnut oils

The effect of photooxidation on PV, K 232 and K 270 values for Delisava and Kara Fındık oil is presented in Figs. 10, 11 and 12. Delisava and Kara Fındık oil had PV of 45.08, 55.04 after 7 days, respectively. At the end of storage, K 232 and K 270 values were found to be 3.25, 0.064 for Delisava oil and 2.92, 0.074 for Kara Fındık oil, respectively.

The results showed similarity with hexane-extracted hazelnut oils having the highest values with conjugated diene levels of 15.910 after 72 h under photooxidation conditions [11]. The differences on oxidation stability of Delisava and Kara Fındık hazelnut oils could be related to pigment transition (mainly carotenoids) [18].

Conclusions

According to the obtained results, the optimal roasting conditions for both hazelnut cultivars were similar, but slight differences were seen. Optimal temperature level for roasting process applied to Kara Fındık cultivar was higher than that for Delisava one, whereas roasting time determined for Kara Fındık hazelnut cultivar was less than that value found for Delisava. The thermal test displaying oxidative stability of oil indicated that sensitivity of Delisava oil against the conditions promoting oxidation was higher than Kara Fındık oil. However, the opposite situation was observed for oxidative stability of these two hazelnut oils under photooxidation conditions. The results from optimization and accelerated oxidation tests could be used as preliminary experiments on roasting conditions which are useful for large-scale manufacturing of hazelnut oil.

References

Gönenc S, Tanrıvermis H, Bülbül M (2006) Economic assessment of hazelnut production and the importance of supply management approaches in Turkey. J Agric Rural Dev Trop 107:19–32

Guney OI (2014) Turkish hazelnut production and export competition. Yüzüncü Yıl Üniversitesi Tarım Bilimleri Dergisi 24:23–29

Dundar MS, Altundag H (2004) Selenium content of Turkish hazelnut varieties: Kara Fındık, Tombul and Delisava. J Food Comp Anal 17:707–712

Özdemir M, Devres O (1999) Turkish hazelnuts: properties and effect of microbiological and chemical changes on quality. Food Rev Int 15:309–333

Stela J, Tihomir M, Krunoslav A, Mate B, Đurđica A, Drago S (2016) Hazelnut oil production using pressing and supercritical CO2 extraction. Hemijska industrija. doi:10.2298/HEMIND150428043J

Ebrahem KS, Richardson D, Tetley R, Mehlenbacher S (1992) Oil content, fatty acid composition, and vitamin E concentration of 17 Hazelnut varieties, compared to other types of nuts and oil seeds. III Int Congr Hazelnut 351:685–692

Alasalvar C, Shahidi F (2008) Tree nuts: composition, phytochemicals, and health effects. CRC Press, Boca Raton

Özdemir M, Devres O (2000) Analysis of color development during roasting of hazelnuts using response surface methodology. J Food Eng 45:17–24

Saklar S, Katnas S, Ungan S (2001) Determination of optimum hazelnut roasting conditions. Inter J Food Sci Technol 36:271–281

Alasalvar C, Shahidi F, Ohshima T, Wanasundara U, Yurttas HC, Liyanapathirana CM, Rodrigues FB (2003) Turkish Tombul hazelnut (Corylus avellana L.). 2. Lipid characteristics and oxidative stability. J Agric Food Chem 51:3797–3805

Miraliakbari H, Shahidi F (2008) Oxidative stability of tree nut oils. J Agric Food Chem 56:4751–4759

AOCS (1997) In: Firestone D (ed) Official methods and recommended practices of the American Oil Chemists’ Society, 4th edn. American Oil Chemists’ Society, Champaign

Amaral JS, Casal S, Seabra RM, Oliveira BP (2006) Effects of roasting on hazelnut lipids. J Agric Food Chem 54:1315–1321

Harhar H, Gharby S, Kartah B, El Monfalouti H, Guillaume D, Charrouf Z (2011) Influence of argan kernel roasting-time on virgin argan oil composition and oxidative stability. Plant Food Hum Nutr 66:163–168

Özdemir M, Açkurt F, Yildiz M, Biringen G, Gürcan T, Löker M (2001) Effect of roasting on some nutrients of hazelnuts (Corylus avellena L.). Food Chem 73:185–190

Chandrasekara N, Shahidi F (2011) Oxidative stability of cashew oils from raw and roasted nuts. J Am Oil Chem Soc 88:1197–1202

Mariod AA, Ahmed SY, Abdelwahab SI, Cheng SF, Eltom AM, Yagoub SO, Gouk SW (2012) Effects of roasting and boiling on the chemical composition, amino acids and oil stability of safflower seeds. Int J Food Sci Technol 47:1737–1743

Abuzaytoun R, Shahidi F (2006) Oxidative stability of algal oils as affected by their minor components. J Agric Food Chem 54:8253–8260

Acknowledgments

We thank scientific research projects fund of Abant Izzet Baysal University (Turkey) for providing fund support of the project under contract Grant Number 2013.09.04.652.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Özkan, G., Kiralan, M., Karacabey, E. et al. Effect of hazelnut roasting on the oil properties and stability under thermal and photooxidation. Eur Food Res Technol 242, 2011–2019 (2016). https://doi.org/10.1007/s00217-016-2699-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2699-8