Abstract

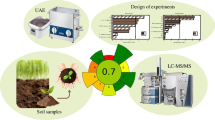

An in-line matrix cleanup method was used for the simultaneous extraction of 15 sulfonamides and two metabolites from manure samples. The ultrasound/microwave-assisted extraction (UMAE) combined with solid–liquid–solid dispersive extraction (SLSDE) procedure provides a simple sample preparation approach for the processing of manure samples, in which the extraction and cleanup are integrated into one step. Ultrasonic irradiation power, extraction temperature, extraction time, and extraction solvent, which could influence the UMAE efficiency, were investigated. C18 was used as the adsorbent to reduce the effects of interfering components during the extraction procedure. The extracts were concentrated, and the analytes were analyzed by liquid chromatography–tandem mass spectrometry (LC–MS/MS) without any further cleanup. The isotopically labeled compounds sulfamethoxazole-d 4, sulfamethazine-d 4, sulfamonomethoxine-d 4, and sulfadimethoxine-d 6 were selected as internal standards to minimize the matrix effect in this method. The recoveries of the antibiotics tested ranged from 71 to 118 % at the three spiking levels examined (20, 200, and 500 μg · kg-1). The limits of detections were 1.2–3.6 μg · kg-1 and the limits of quantification were 4.0–12.3 μg · kg-1 for the sulfonamides and their metabolites. The applicability of the method was demonstrated by analyzing 30 commercial manure samples. The results indicated that UMAE–SLSDE combined with LC–MS/MS is a simple, rapid, and environmentally friendly method for the analysis of sulfonamides and their metabolites in manure, and it could provide the basis for a risk assessment of the antibiotics in agricultural environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Antibiotics are widely used in animals in order to prevent or treat infectious diseases [1, 2]. However, for the therapeutic antibiotics, approximately 30–90 % of the parent compounds are excreted in the urine or feces of the animals and humans [3]. The animals’ urine or feces, which contain bioactive antibiotics and their metabolites, will enter the environment directly either by the spreading of manure or after their collection and storage in the form of sludge, which is used as an organic matter supplement or agricultural fertilizer [3–5].

The antibiotics and their metabolites will be incorporated into the soil environment, where they may accumulate or may be rinsed off into the surface water [4, 6, 7]. The long-term use of manure on fields may result in contamination, which will threaten the health of humans and the environment.

The sulfonamides, as synthetic bacteriostatic antibiotics with a wide spectrum, are the antibiotics most frequently used in animal husbandry in several parts of the world [8–10]. In the published literature, sulfonamides were one of the most frequently detected compounds in manure. In Austria, sulfamethazine (SMZ) was determined in 18 of 30 pig manure samples at concentrations up to 20 mg · kg-1. Sulfadiazine (SDZ) was found in 25 % of chicken dung samples, with the highest concentration being 91 mg · kg-1 [4]. In Canada, the concentration of SMZ in manure is as high as 10 mg · kg-1 [11]. In Turkey, the concentration of SMZ in manure samples ranged from 0.1 to 4 mg · kg-1. The highest concentration of sulfachloropyridazine (SCP) found among animal manure samples was 36 mg · kg-1 [12]. In Shandong province in China, the detection frequencies for sulfonamides in manure samples were 4.8, 0.8, 27.8, 2.4, and 51.6 % for sulfamethoxazole (SMX), sulfathiazole (STZ), sulfamethizole (SMT), sulfadimethoxine (SDM), and SMZ, respectively [13]. The concentrations ranged from 3 to 25 mg · kg-1 for SMZ, from 5 to 19 mg · kg-1 for SDZ, and from 0.6 to 2 mg · kg-1 for SCP in Tianjin, China [14].

Diverse extraction techniques have been used to extract antibiotics in manure samples, including ultrasound-assisted extraction [8, 13–16], accelerated solvent extraction [17], pressurized liquid extraction [18], and microwave-assisted extraction [19, 20]. As the manure of animals contains proteins, carbohydrates, fats, and various inorganic species, complicated purification steps have been applied to reduce the amount of interfering substances [21]. In recent years, purification following the extraction has usually been performed by solid-phase extraction (SPE) [4, 11, 13, 14, 17, 19]. However, these conventional methods are always laborious and use large amounts of organic solvents, giving rise to environmental pollution as a consequence.

Ultrasound/microwave-assisted extraction (UMAE) is usually used as an effective method to extract chemical constituents from plant materials owing to simultaneous irradiation with ultrasound and microwave energy [22–24]. In UMAE, sufficient energy can be supplied to accelerate the extraction process and favor the release of the targets from the matrix in a short time. The solid–liquid–solid dispersive extraction (SLSDE) [25, 26] system consists of two solid phases and one liquid phase. The dispersing sorbent, which is used to adsorb the interfering compounds, and the solid sample matrix are the two solid phases, and the extraction solvent is the liquid phase. During the extraction procedure, when the analytes are dispersed into the extraction solvent, the dispersing sorbent will simultaneously retain the interfering matrix components. In SLSDE, the extraction and cleanup occur in one step, which greatly simplifies the sample preparation procedure. For an in-line matrix cleanup method, the extraction solvent and sorbent type will be the most critical features. The dispersing sorbent needs to retain the maximum interferences, whereas the target analytes should be eluted by the extraction solvent. UMAE combined with SLSDE has been efficiently applied for the determination of organochlorine pesticides in tobacco using a gas chromatograph and an electron capture detector with satisfactory recoveries in the range from 70.2 to 118.2 % [25]. To the best of our knowledge, no articles have reported the analysis of antibiotics in manure samples with UMAE or UMAE–SLSDE. The aim of this work was to develop a simple, fast, and reliable analytical method for the multiresidue determination of 15 sulfonamides and two metabolites in manure by UMAE–SLSDE and liquid chromatography–tandem mass spectrometry (LC–MS/MS), which can provide the basis for a risk assessment of the antibiotics in agricultural environments.

Materials and methods

Reagents and materials

The standards of sulfacetamide, sulfisoxazole, sulfapyridine, sulfamerazine, sulfamethoxypyridazine, sulfamonomethoxine (SMM), sulfameter, sulfadoxine, SDZ, SMX, STZ, SMT, SMZ, SCP, and SDM were purchased from Dr. Ehrenstorfer (Germany). Isotopically labeled compounds SMX-d 4, SMZ-d 4, and SMM-d 4, which were used as internal standards, and the two metabolites N-acetylsulfadiazine (AcSDZ) and N-acetylsulfamethazine (AcSMZ) were purchased from Toronto Research Chemicals (Canada). SDM-d 6 was purchased from Witega (Germany). Chromatography grade acetonitrile and methanol were obtained from Merck (Germany). Ethyl acetate and acetone, both analytical grade, were purchased from Huadong Medicine (China). Silica-based sorbents, including C18 (40-μm particle size) and primary–secondary amine (PSA) (40-μm particle size), were obtained from Agilent (USA). Florisil of 60–100 mesh was purchased from Supelco (USA). Purified water was prepared by using a Milli-Q water purification system (Millipore).

Stock solutions of the standards (0.5 mg · mL-1) were prepared by dissolving each compound in methanol. Working standard solutions were freshly prepared by diluting the stock solutions with methanol on the day of use. The standard solutions were stored in a refrigerator at 4 °C, and were stable for at least 1 month.

Instrumentation and chromatographic conditions

The UMAE experiment was performed with an XH-100A ultrasonic and microwave extracting apparatus (Beijing Xianghu, China). A schematic of the UMAE system is shown in Fig. 1. We used a microwave oven with maximum power of 1,000 W at a frequency of 2,450 MHz, and an ultrasonic transducer with maximum power of 1,500 W at a frequency of 25 KHz.

LC–MS/MS analyses were performed using a TSQ Quantum Discovery mass spectrometer (Thermo Fisher Scientific, USA) equipped with an electrospray interface. The analytes were separated on a Luna C18 column (2.0 mm × 150 mm, 3 μm; Phenomenex, USA) at 30 °C. Mobile phase A was 100 % methanol, and mobile phase B was 2 mM aqueous ammonium acetate (containing 0.1 % formic acid). The flow rate was 0.25 mL · min-1, and the injection volume was 5 μL. For separation of target compounds, the initial mobile phase containing 20 % mobile phase A was increased linearly to 90 % mobile phase A in 5 min, this was held for 11 min before the proportion was decreased to 20 % in 0.5 min, and this was held for an additional 7.5 min. The total time was 24 min.

For mass-spectrometric detection, the instrument was operated in positive-ion mode. The spray voltage was set to 4.0 kV. The capillary temperature was set to 350 °C. Nitrogen was used as the auxiliary gas and the sheath gas. The collision gas was high-purity argon at a pressure at 1.5 × 10−3 Torr in the collision cell. Multiple reaction monitoring was applied, where the parent ions and fragment ions were monitored at quadrupole 1 and quadrupole3, respectively. For each compound, the precursor mass and product ion mass for the multiple reaction monitoring detection and the optimized collision energy are listed in Table 1. Xcalibur 2.0.7 (Thermo Fisher Scientific, USA) was used to process the quantitative data obtained from calibration standards and samples.

Samples

Manure samples were commercially available in Zhejiang province (China). The main component of the commercially available manure product is animal feces, accounting for 70–80 % of the total weight. Other components are wood chips, ash, and slag. In this test, each sample (about 500 g) was ground to a fine powder and sieved through a 40-mesh sieve.

UMAE–SLSDE procedure

An accurately weighed sample (0.5 g) spiked with the internal standards (50 μg · kg-1) and sorbent (C18) was placed in a 100-mL round glass flask. The extraction solvent (30 mL) was added, and then the flask was transferred to the chamber of the apparatus and connected with a condensing tube (see Fig. 1). The parameters of the instrument were set as follows: microwave irradiation power, 200 W; ultrasonic irradiation power, 300 W; extraction temperature, 65 °C; extraction time, 30.0 min. When the extraction was complete, the mixture was transferred to a 50-mL polypropylene tube and centrifuged at 7,000 rpm for 5 min. The supernatant was carefully collected by a straw and evaporated to dryness using a rotary evaporator in a water bath at 40 °C. Then, the residue was dissolved in 1 mL of water–methanol (1:1, v/v). After ultrasonication for 1 min, the solution was filtered through a 0.22-μm Teflon filter and then analyzed by LC–MS/MS.

Method validation

The performance of the method was evaluated through the estimation of the linearity, extraction recoveries, the limit of detection (LOD), and the limit of quantification (LOQ). The quantification was based on linear regression calibration curves constructed with an internal standard approach at concentrations of 1, 10, 100, 250, 500, 750, and 1,000 μg · L-1. Recovery studies were conducted on the basis of the standard addition technique, and they were performed by spiking blank manure samples with three levels of a standard mixture of 17 drugs prior to the extraction procedure. The fortified samples were extracted and analyzed by the UMAE–SLSDE procedure. The LOD and the LOQ were calculated on the basis of the quantitation ion’s signal-to-noise ratio of 3:1 and 10:1, respectively, in the matrix. The LODs and the LOQs were determined six times at a fortification level of 20 μg · kg-1.

The overall precision of the method, which was determined by the intraday repeatability and the interday reproducibility studies, was calculated as the relative standard deviation (RSD). For intraday repeatability, blank samples spiked at 20, 200, and 500 μg · kg-1 were analyzed in quintuplicate on the same day. For reproducibility, blank samples spiked at 20, 200, and 500 μg · kg-1 were analyzed on three different days.

Results and discussion

Mass spectrometry

The sulfonamides show very typical fragmentation patterns. In electrospray ionization, the sulfonamides share the same diagnostic product ions at m/z values of 156, 108, and 92. The possible structures for these common fragment ions are shown in Fig. 2a. The ion at m/z 156 may result from the cleavage of the S–N bond, yielding the stable sulfanilamide moiety [27]. This ion transition shows the highest intensity, except for SMZ. Thus, in our study the ion at m/z 156 was used as the quantitation ion and ws applied for the confirmation of the sulfonamides using the protonated adduct of the sulfonamides, except for SMZ. The most intense ion transition of SMZ is [M + H]+ > m/z 186 (R1NHSO2 +, shown in Fig. 2a), and it was used as the quantitation ion pair. Sulfameter, sulfamethoxypyridazine, and SMM, which have the same molecular mass, could be completely separated on the C18 column, and they would not be mistaken for each other. Similarly, the N-acetylated sulfonamide metabolites and their fragment ions containing the sulfonamide moiety show a number of group-specific product ions. The ions at m/z values of 198 and 134 differ by 42 from the ions at m/z values of 156 and 92, and the fragmentation patterns of the protonated N-acetylated sulfonamide metabolites are the same for all of the sulfonamides. Quantification was performed on the most intense ion transition. Thus, the ions at m/z values of 134 and 108 were chosen as the quantitation ions for AcSDZ and AcSMZ, respectively. The fragmentation patterns of the protonated N-acetylated sulfonamide metabolites are shown in Fig. 2b.

The general structures and fragmentation patterns of 15 sulfonamides. a On the right, for R1, from left to right, the structures of sulfacetamide (SAM), sulfadiazine (SDZ), sulfathiazole (STZ), sulfapyridine (SPD), sulfamerazine (SMR), sulfameter (SME), sulfamethizole (SMT), sulfamethazine (SMZ), sulfamethoxypyridazine (SMP), sulfachloropyridazine (SCP), sulfamethoxazole (SMX), sulfadoxine (SDO), sulfamonomethoxine (SMM), sulfisoxazole (SIZ), and sulfadimethoxine (SDM). b The fragmentation patterns of two metabolites. For N-acetylsulfadiazine (AcSDZ), R2 is H, and for N-acetylsulfamethazine (AcSMZ), R2 is CH3

Optimization of the UMAE parameters

The experimental parameters of the UMAE were optimized using the one-variable-at-a-time method. The optimized parameters include the ultrasonic irradiation power, extraction temperature, and extraction time. All of the optimization experiments were performed at a spiking level of 200 μg · kg-1. Each experiment was performed in triplicate. The recoveries of the target compounds were calculated using matrix-matched calibrations and were evaluated under different conditions.

Selection of the extraction solvent

Because the sulfonamides are amphoteric compounds, they will be liable to be extracted by an organic solvent when they are present in the molecular form. Three solvents—methanol, acetonitrile, and ethyl acetate, which are commercially available and the most commonly used extraction solvents—were tested. The parameters were set as follows: microwave irradiation power, 200 W; ultrasonic irradiation power, 300 W; extraction temperature, 65 °C; extraction time, 30.0 min. The recoveries of the 17 compounds obtained are shown in Fig. 3, which indicates that the recoveries of the target compounds are the highest when methanol is used as the extraction solvent. Methanol, as a polar solvent, has stronger ability to absorb more microwave energy than acetonitrile and ethyl acetate, and that energy will heat the sample system directly, which results in higher recoveries [28]. Hence, methanol was selected as the extraction solvent for the following studies.

Study of the ultrasonic irradiation power

The UMAE of manure samples was performed at different ultrasonic irradiation powers (0, 100, 300, and 500 W). As seen from Fig. 4, increasing the ultrasonic irradiation power from 0 to 300 W resulted in the recoveries of most of the target compounds increasing, and a higher ultrasonic irradiation power of 500 W did not lead to even higher recoveries. Ultrasonic irradiation can enhance the mass transfer phenomenon, which is beneficial for the release and dissolution of the target compounds from the sample to the extraction solvent [29]. Considering that a high ultrasonic irradiation power would result in extraction of many more interfering compounds, we set the optimized ultrasonic irradiation power to 300 W in this experiment.

Study of the extraction temperature

The influence of the extraction temperature on the recoveries of the target compounds was studied with a microwave irradiation power of 200 W. Four different extraction temperatures (25, 45, 55, and 65 °C) were tested. The recoveries of most of the sulfonamides were highest when the extraction temperature was set to 65 °C (see Fig. S1). Generally, the high temperature achieved by microwave irradiation would accelerate the extraction process for the adsorption and desorption of the target compounds from the matrix [25, 29]. Considering that the reflux temperature of methanol is 65 °C, we chose 65 °C as a feasible extraction temperature.

Study of the extraction time

On the basis of these optimal conditions, the influence of the extraction time was also studied. The effect of the extraction time was examined throughout the range from 10 to 40 min in 10-min increments. At the beginning, almost all of the recoveries of the target compounds increased with an increase in extraction time. However, when the extraction time exceeded 30 min, the recoveries of the target compounds did not change significantly. Therefore, 30 min was chosen as the best extraction time for use in further experiments.

Optimization of the dispersing sorbent

Sample purification commonly determines the target object’s analytical signal response; thus, a highly efficient cleanup procedure for the removal of interfering compounds while retaining most of the target compounds is necessary. Therefore, using the optimized solutions and experimental conditions, we tested three sorbents—C18, PSA, and Florisil—to purify the manure samples for the detection of the sulfonamides and their metabolites. The adsorbing capabilities of the sorbents were compared under the same conditions, and the proportion of the sorbent to the sample was 1:1. As seen from Fig. 5, the recoveries of the target compounds are the highest when the sorbent is C18, except for SDM. During the UMAE–SLSDE procedure, the compounds are distributed between the extraction solvent and the dispersing sorbent on the basis of their relative polarities [25]. Also, the interference may compete with the target compounds for adsorption by the sorbent. The adsorption of PSA is nonselective, resulting in its low recoveries. The sulfonamides are moderately polar components and can be retained by Florisil, which preferentially adsorbs polar components [25]. C18 is suitable for adsorbing nonpolar or weakly polar compounds, provided acceptable recoveries, and was chosen as the dispersing sorbent for further studies.

Effect of different dispersing sorbents on recoveries of 17 compounds in the spiking experiment (extraction solvent, methanol; extraction temperature, 65 °C; microwave irradiation power, 200 W; ultrasonic irradiation power, 300 W; extraction time, 30 min; the amount proportion of the sorbent and the sample, 1:1). PSA primary–secondary amine

The influence of the proportion of the amounts of C18 and the sample on the extraction efficiency was studied. The ratios of C18 and the sample studied in this work were 0.5:1, 1:1, 1.5:1, and 2:1. When the amount of sorbent increased, the extraction yields of the target compounds decreased (see Fig. S2). When 500 mg C18 was used, the effect of target adsorption by C18 was a little weaker than that of the desorption by methanol and the competitive interference adsorption by C18, whereas when 750 mg C18 was used, the stronger adsorption effect provided by more C18 exceeded the effect provided by the desorption by methanol and the competitive interference adsorption by C18, and some of the target compounds could be adsorbed. On the basis of the higher extraction yields and the more effective removal of the impurities, a 1:1 ratio of the dispersing sorbent to the sample was adopted.

Performance of the method

The presence of co-extracts in the matrix extracts of the samples causes changes in the baseline of the chromatograms and the responses of the target compounds. The matrix in manure leads to suppression of the signal ions for most of the sulfonamides in our experiments. To improve the quantitative accuracy, the application of isotopically labeled standards is one of the most efficient methods to compensate for matrix effects. The isotopically labeled standards SMX-d 4, SMZ-d 4, SMM-d 4, and SDM-d 6 were selected as internal standards to minimize the matrix effect in this constructed method. In this method, those 17 compounds are divided into four groups. Each group was calculated with an isotopically labeled standard and is shown in Table 1. Good linearity was achieved (r 2 > 0.99) for all of the selected sulfonamides and their metabolites (Table 2). Table 2 shows that the recoveries of the antibiotics tested ranged from 71 to 118 % at the three spiking levels examined. The chromatograms for the 17 compounds spiked at 20 μg · kg-1 in manure and detected by LC–MS/MS are shown in Fig. 6.

For the precision of the method, the RSDs were satisfactory, and are shown in Table 2. The higher RSDs generally observed at the low spiking level were mainly caused by the relative complexity of the matrix.

The LOQs for the test compounds are 4.0–12.3 μg · kg-1 (shown in Table 2). These results confirmed that the LODs and LOQs achieved with the method developed are sufficient to determine the concentrations of the antibiotics in manure samples.

Application to manure samples

To assess the applicability of the proposed method for the detection of these antibiotics and their metabolite residues in manure, 30 real manure samples, including four cow manure samples, two poultry dung samples, two sheep manure samples, seven pig manure samples, and 13 mixed manure samples, were detected. SMZ was detected in 16 samples, and the concentrations ranged from 17.4 to 4,089.0 μg · kg-1. SMM was detected in eight samples, and the concentrations ranged from 47.2 to 2,512.6 μg · kg-1. In the seven pig manure samples, SMZ was detected in three samples, with concentrations ranging from 31.9 to 231.0 μg · kg-1. SDZ and SMM were also found in the pig manure samples. None of these sulfonamides were detected in cow and sheep manure, probably owing to their lower use or their concentrations being lower than the LOD. In the real samples, SMZ and SDZ were detected but their acetylated metabolites (AcSMZ and AcSDZ) were not detected, which may be due to the acetylated metabolites being totally or partially cleaved by bacteria and reverting to the original drug [6] or their concentrations being lower than the LODs.

The performance of the proposed UMAE–SLSDE method was also compared with that of the SPE method developed by Pan et al. [13]. Considering the LOQs of sulfonamides in the aforementioned SPE method were 10–20 μg · kg−1, higher than those in our proposed method, we chose three real samples with SMZ at 17.4 ± 2.3 μg · kg−1, 31.9 ± 3.4 μg · kg−1, and 102.4 ± 6.9 μg · kg−1instead of the samples with SMZ concentrations lower than 20 μg · kg−1 for method comparison. The concentrations of SMZ obtained by the SPE method were 19.2 ± 1.9 μg · kg−1 (n = 3), 34.1 ± 2.8 μg · kg−1 (n = 3), and 107.7 ± 5.3 μg · kg−1 (n = 3). With the t test, no significant difference was found between the results obtained from the SPE method and the results obtained with the proposed method for these three samples.

Conclusion

A procedure using a one-step extraction and cleanup sample preparation combined with LC–MS/MS for the determination of 15 sulfonamides and two metabolites in manure samples was successfully developed and applied for the extraction and determination of sulfonamides and their metabolites in manure samples. The UMAE–SLSDE procedure provides a simple sample preparation approach for the processing of manure samples, with the extraction and cleanup being integrated into one step. Compared with conventional methods, UMAE–SLSDE and LC–MS/MS is a simple and environmentally friendly method for the analysis of sulfonamides and their metabolites in manure. This method can provide the basis for a risk assessment of the antibiotics in agricultural environments.

References

Moreno-Bondi MC, Marazuela MD, Herranz S, Rodriguez E (2009) An overview of sample preparation procedures for LC-MS multiclass antibiotic determination in environmental and food samples. Anal Bioanal Chem 395:921–946

Lu KH, Chen CY, Lee MR (2007) Trace determination of sulfonamides residues in meat with a combination of solid-phase microextraction and liquid chromatography-mass spectrometry. Talanta 72:1082–1087

Alcock RE, Sweetman A, Jones KC (1999) Assessment of organic contaminant fate in wastewater treatment plants I. Selected compounds and physiochemical properties. Chemosphere 38:2247–2262

Martinez-Carballo E, Gonzalez-Barreiro C, Scharf S, Gans O (2007) Environmental monitoring study of selected veterinary antibiotics in animal manure and soils in Austria. Environ Pollut 148:570–579

Hamscher G, Sczesny S, Hoper H, Nau H (2002) Determination of persistent tetracycline residues in soil fertilized with liquid manure by high-performance liquid chromatography with electrospray ionization tandem mass spectrometry. Anal Chem 74:1509–1518

Garcia-Galan MJ, Fromel T, Muller J, Peschka M, Knepper T, Diaz-Cruz S, Barcelo D (2012) Biodegradation studies of N4-acetylsulfapyridine and N4-acetylsulfamethazine in environmental water by applying mass spectrometry techniques. Anal Bioanal Chem 402:2885–2896

Yan CX, Yang Y, Zhou JL, Liu M, Nie MH, Shi H, Gu LJ (2013) Antibiotics in the surface water of the Yangtze Estuary: occurrence, distribution and risk assessment. Environ Pollut 175:22–29

Zhao L, Dong YH, Wang H (2010) Residues of veterinary antibiotics in manures from feedlot livestock in eight provinces of China. Sci Total Environ 408:1069–1075

Dasenaki ME, Thomaidis NS (2010) Multi-residue determination of seventeen sulfonamides and five tetracyclines in fish tissue using a multi-stage LC–ESI–MS/MS approach based on advanced mass spectrometric techniques. Anal Chim Acta 672:93–102

Kumar RR, Lee JT, Cho JY (2012) Fate, occurrence, and toxicity of veterinary antibiotics in environment. J Korean Soc Appl Biol Chem 55:701–709

Aust MO, Godlinski F, Travis GR, Hao X, McAllister TA, Leinweber P, Thiele-Bruhn S (2008) Distribution of sulfamethazine, chlortetracycline and tylosin in manure and soil of Canadian feedlots after subtherapeutic use in cattle. Environ Pollut 156:1243–1251

Karci A, Balcioglu IA (2009) Investigation of the tetracycline, sulfonamide, and fluoroquinolone antimicrobial compounds in animal manure and agricultural soils in Turkey. Sci Total Environ 407:4652–4664

Pan X, Qiang ZM, Ben WW, Chen MX (2011) Residual veterinary antibiotics in swine manure from concentrated animal feeding operations in Shandong province, China. Chemosphere 84:695–700

Hu XG, Yi L, Zhou QX, Xu L (2008) Determination of thirteen antibiotics residues in manure by solid phase extraction and high performance liquid chromatography. Chin J Anal Chem 36:1162–1166 (in Chinese)

Blackwell PA, Holten Lutzhoft HC, Ma HP, Halling-Sorensen B, Boxall ABA, Kay P (2004) Ultrasonic extraction of veterinary antibiotics from soils and pig slurry with SPE clean-up and LC-UV and fluorescence detection. Talanta 64:1058–1064

Haller MY, Müller SR, McArdell CS, Alder AC, Suter MJF (2002) Quantification of veterinary antibiotics (sulfonamides and trimethoprim) in animal manure by liquid chromatography–mass spectrometry. J Chromatogr A 952:111–120

Li YX, Zhang XL, Yang M (2012) Simultaneous determination of fourteen veterinary antibiotics in animal manure using solid phase extraction and liquid chromatography. Chin J Anal Chem 40:213–217 (in Chinese)

Jacobsen AM, Halling-Sorensen B (2006) Multi-component analysis of tetracyclines, sulfonamides and tylosin in swine manure by liquid chromatography-tandem mass spectrometry. Anal Bioanal Chem 384:1164–1174

Hu XG, Luo Y, Zhou QX (2010) Simultaneous analysis of selected typical antibiotics in manure by microwave-assisted extraction and LC–MSn. Chromatographia 71:217–223

Hu XG, Zhou QX, Luo Y (2010) Occurrence and source analysis of typical veterinary antibiotics in manure, soil, vegetables and groundwater from organic vegetable bases, northern China. Environ Pollut 158:2992–2998

Loftin KA, Henny C, Adams CD, Surampali R, Mormile MR (2005) Inhibition of microbial metabolism in anaerobic lagoons by selected sulfonamides, tetracyclines, lincomycin, and tylosin tartrate. Environ Toxicol Chem 24:782–788

Zhang LF, Liu ZL (2008) Optimization and comparison of ultrasound/microwave assisted extraction (UMAE) and ultrasonic assisted extraction (UAE) of lycopene from tomatoes. Ultrason Sonochem 15:731–737

Xiao XH, Si XX, Tong X, Gk L (2012) Ultrasonic microwave-assisted extraction coupled with high-speed counter-current chromatography for the preparation of nigakinones from Picrasma quassioides (D.Don) Benn. Phytochem Anal 23:540–546

Cheng XL, Wan JY, Li P, Qi LW (2011) Ultrasonic/microwave assisted extraction and diagnostic ion filtering strategy by liquid chromatography–quadrupole time-of-flight mass spectrometry for rapid characterization of flavonoids in Spatholobus suberectus. J Chromatogr A 1218:5774–5786

Zhou T, Xiao XH, Li GK (2012) Hybrid field-assisted solid-liquid-solid dispersive extraction for the determination of organochlorine pesticides in tobacco with gas chromatography. Anal Chem 84:420–427

Liao QG, Zhou YM, Luo LG, Wang LB, Feng XH (2014) Determination of twelve herbicides in tobacco by a combination of solid–liquid–solid dispersive extraction using multi-walled carbon nanotubes, dispersive liquid-liquid micro-extraction, and detection by GC with triple quadrupole mass spectrometry. Microchim Acta 181:163–169

Garcia-Galan MJ, Villagrasa M, Diaz-Cruz MS, Barcelo D (2010) LC-QqLIT MS analysis of nine sulfonamides and one of their acetylated metabolites in the Llobregat River basin. Quantitative determination and qualitative evaluation by IDA experiments. Anal Bioanal Chem 397:1325–1334

Eskilsson CS, Bjorklund E (2000) Analytical-scale microwave-assisted extraction. J Chromatogr A 902:227–250

Lou ZX, Wang HX, Zhu S, Zhang M, Gao Y, Ma CY, Wang ZP (2010) Improved extraction and identification by ultra performance liquid chromatography tandem mass spectrometry of phenolic compounds in burdock leaves. J Chromatogr A 1217:2441–2446

Acknowledgments

The authors acknowledge financial support from the Special Fund for Agro-scientific Research in the Public Interest (no. 201303091), the Project of Science and Technology Plan of Zhejiang Province (no. 2013C32026), the National Nature Science Foundation of China (no. 21207118), the Department of Education of Zhejiang Province (Pd2013016), and the Project of Science and Technology Plan of Ningbo (no. 2013C11024).

Author information

Authors and Affiliations

Corresponding author

Additional information

Hui-zhen Wu and Ming-rong Qian contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 26 kb)

Rights and permissions

About this article

Cite this article

Wu, Hz., Qian, Mr., Wang, Jm. et al. Simultaneous determination of sulfonamides and metabolites in manure samples by one-step ultrasound/microwave-assisted solid–liquid–solid dispersive extraction and liquid chromatography–mass spectrometry. Anal Bioanal Chem 407, 3545–3554 (2015). https://doi.org/10.1007/s00216-015-8503-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-015-8503-y