Abstract

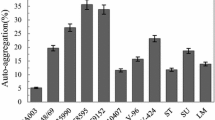

Listeria monocytogenes is one of the most important foodborne pathogens, causing listeriosis, a disease characterized by high mortality rates. This microorganism, commonly found in food production environments and transmitted to humans by consuming contaminated food, has the ability to form biofilms by attaching to a wide variety of surfaces. Traditional hygiene and sanitation procedures are not effective enough to completely remove L. monocytogenes biofilms from food-contact surfaces, which makes them a persistent threat to food safety. Alternative approaches to combating Listeria biofilms are needed, and the use of lactic acid bacteria (LAB) and their antimicrobial compounds shows promise. The present study investigated the effect of Lactobacillus strains, previously isolated from various foods and known to possess antimicrobial properties, on the biofilm formation of L. monocytogenes on three different food-contact surfaces. To study L. monocytogenes IVb ATCC 19115 type, culture was preferred to represent serotype IVb, which is responsible for the vast majority of listeriosis cases. The results demonstrated that cell-free supernatants (CFSs) of LAB strains inhibited biofilm formation by up to 51.57% on polystyrene, 60.96% on stainless steel, and 30.99% on glass surfaces. Moreover, these CFSs were effective in eradicating mature biofilms, with reductions of up to 78.86% on polystyrene, 73.12% on stainless steel, and 72.63% on glass surfaces. The strong inhibition rates of one strain of L. curvatus (P3X) and two strains of L. sakei (8.P1, 28.P2) used in the present study imply that they may provide an alternate technique for managing Listeria biofilms in food production environments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Every year, pathogenic and spoilage microorganisms cause both enormous economic losses in the food industry and threaten human health. The ability of pathogenic microorganisms to withstand adverse conditions impacts their persistence in food production environments. Biofilm formation of microorganisms on surfaces, equipment, and tools in production environments makes them stronger to adverse circumstances and antimicrobial substances. It is known that sessile microorganisms as part of biofilms are more resistant to conventional cleaning and sanitizing agents, in comparison to microorganisms in a planktonic state. As a result of the production of biofilm, combating microorganisms becomes more challenging, and traditional cleaning and disinfection methods are insufficient in this context. Consequently, considerable work is currently being carried out to develop innovative ways to both preventing bacterial adhesion to surfaces which is the initial stage in biofilm production, and eradicating mature biofilm (Chae et al. 2006; Fernández-Gómez et al. 2022).

Listeria monocytogenes, a foodborne pathogen, causes listeriosis in humans. It has 14 different serovars based on variations in its surface antigens. However, in practice, most cases (more than 95%) of listeriosis in humans have been related to three serovars: IVb, 1/2a, and 1/2b. Among these, serovar IVb appears to be the most often associated with major foodborne listeriosis outbreaks (Gasanov et al. 2005; Chae et al. 2006; Ravindhiranet al. 2023). The invasive listeriosis leads to substantial harm, including meningitis, miscarriage, septicemia, encephalitis, and endocarditis since the organism can breach the blood–brain and placental barriers. Approximately 30% of invasive listeriosis cases in susceptible individuals result in death, with the majority requiring hospitalization (Gray et al. 2018; Shamloo et al. 2019).

The primary source of L. monocytogenes infection is the consumption of contaminated food. This microorganism is known to be capable of forming biofilms on 17 different surfaces. It can persist and attach to both biotic surfaces (food) and abiotic surfaces (food processing equipment), where it can grow as biofilms. Up until now, it has been reported that L. monocytogenes forms biofilms on many food industry-related surfaces, including polystyrene, stainless steel, glass, polyester, polytetrafluoroethylene, and wood. In addition, it is also known that this microorganism forms biofilm on equipment used in the food industry like conveyor belts, drain materials, joints, and floor sealers (Doijad et al. 2015; Hossain et al. 2020; Masebe and Thantsha 2022).

To prevent illness caused by L. monocytogenes, controlling the biofilm generation of it is crucial and eradicating mature biofilm residues is critical. The fact that biofilms formed by L. monocytogenes, as in all biofilms, are more resistant to cleaning and sanitizing agents has led researchers to new strategies for the control of Listeria biofilms. Among them, the use of lactic acid bacteria (LAB) to combat L. monocytogenes biofilms has been recognized as an alternative approach that has shown promise and gained attention in recent years (Camargo et al. 2016; Gray et al. 2018). However, there is still limited research on the impact of LAB species on Listeria and their underlying mechanisms. Further studies are needed to figure out the impact of LAB on biofilm formation and inhibition (Camargo et al. 2016; Hossain et al. 2021; Lee et al. 2021). The present investigation seeks to analyze the impact of different Lactobacillus species on L. monocytogenes biofilm formation on polystyrene, stainless steel, and glass surfaces.

Materials and methods

Microorganisms

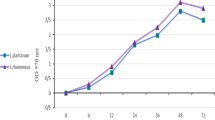

A total of 22 lactic acid bacteria (LAB) strains including 19 Lactobacillus strains isolated from different foods and three commercially available reference probiotic type cultures were used to conduct anti-biofilm activity studies. Isolation and identification of the Lactobacillus strains have been performed at the molecular level in previous studies (Dincer and Kıvanc 2012; Kıvanç and Yapıcı 2015; Kıvanc and Temel 2016). More detailed information about the used strains is given in Table 1. Listeria monocytogenes IVb ATCC 19115 was chosen as an indicator microorganism. Each microorganism was kept in 20% glycerol (v/v) at − 80 °C. LAB strains were cultured in Man, Rogosa, and Sharpe (MRS) broth, while L. monocytogenes were cultured in tryptic soy broth (TSB) at 37 °C under aerobic conditions. Before use, all strains, including L. monocytogenes, were pre-cultivated twice.

Cell-free supernatant (CFS) preparation

Cell-free supernatants (CFSs) of LAB strains were prepared according to the Ben Slama et al. (2013) with minor modification. After strains were incubated for 24 h at 37 °C in MRS broth, they were centrifuged at 12,000 rpm for 5 min at 4 °C, and supernatants were collected. Obtained CFSs were adjusted to pH 6.5 ± 0.02 with 8 M NaOH and 8 M HCl and sterilized using a 0.22 µm pore size syringe filter. The prepared CFSs were used the same day for anti-biofilm analysis to avoid loss of activity.

Inhibition of biofilm formation on the polystyrene surface

The inhibition of the biofilm formation on polystyrene surfaces by LAB was assessed using a previously published method with some modification (Singh et al. 2020). Briefly, 50 µL CFS of each LAB strain were added to a separate well of a 96-well polystyrene microtiter plate. Subsequently, 130 µL of sterile TSB medium and 20 µL of overnight culture of L. monocytogenes in TSB (106 CFU/mL) were added to the wells to initiate the biofilm formation. The well containing 20 µL L. monocytogenes with 50 µL sterile MRS broth (pH 6.5) and 130 µL TSB broth was used as the control. For biofilm formation, the plate was incubated at 37 °C for 48 h. After the incubation, the culture media was discarded, the wells were washed with sterile distilled water three times to remove unattached cells, and left to dry at 60 °C for 45 min to fixate the attached cells. Then 200 µl of 0.1% crystal violet solution was added to the wells and kept for half an hour at room temperature (approximately 25–28 °C) to stain the biofilm. After the crystal violet solution was discarded, the wells were washed again with sterile distilled water three times to remove excess stain. Finally, 200 µl of ethanol was added to the wells. After waiting 15 min at room temperature with gentle shaking to dissolve the absorbed stain, optical density of the biofilm was measured at 600 nm. Results were calculated as % biofilm inhibition percentage (% BIP) with the formula % BIP: [(OD control–OD experimental group)/OD control] × 100.

Eradication of the mature biofilm on polystyrene surface

To ascertain the impact of LAB strains on the mature biofilm on polystyrene surfaces, previously published method was used with some modification (Singh et al. 2020; Masebe and Thantsha 2022). First, biofilm was formed on the 96-well polystyrene microtiter plate. For this purpose, 180 µL sterile TSB medium and 20 µL overnight culture of L. monocytogenes in TSB (106 CFU/mL) were added to wells and cultivated at 37 °C for 48 h. Following cultivation, the culture media was discarded and 200 µL CFS of each LAB strain was added to a separate well and maintained again at 37 °C for 24 h. The well where MRS broth was added instead of CFS was used as the control. Residual biofilm was quantified as described earlier. Results were calculated using the previously mentioned formula as % biofilm eradication percentage (% BEP).

Inhibition of biofilm formation on stainless steel and glass surfaces

The inhibition of biofilm formation on stainless steel and glass surfaces by LAB strains was assessed following the protocol established based on previous studies (Shen et al. 2012; Hossain et al. 2020; Gemmell et al. 2022). To the study, stainless steel (SS) coupons were prepared by cutting AISI 304 (#4) stainless steel into 12 mm in diameter and 1.5 mm thick pieces. Glass coupons were prepared by cutting glass slides 12 × 12 mm dimensions. Prior to use, all coupons (SS or glass coupons) were cleaned and sterilized with the following steps: First, coupons were treated with methanol for 30 min and rinsed with sterile distilled water. Then they were submerged in alkaline detergent (NaOH 1% w/v) for 1 h at 60 °C and again rinsed with sterile distilled water. After all coupons were completely dried, they were autoclaved at 121 °C for 15 min. For the analysis, a SS (or glass) coupon was placed in each well of the sterile polystyrene 24-well plate. Subsequently, 500 µL CFS of each LAB strains were added to a separate well. Then 1.3 mL of sterile TSB medium and 200 µL of overnight culture of L. monocytogenes in TSB (106 CFU/mL) were added to the wells to initiate the biofilm formation. Wells containing 200 µL L. monocytogenes with 500 µL sterile MRS broth (pH 6.5) and 1.3 mL TSB were used as the control. For biofilm formation, the plates were incubated at 37 °C for 48 h. After the incubation, SS (or glass) coupons were taken from the wells under sterile conditions, rinsed gently with sterile distilled water to remove unattached cells without dispersing the biofilm formed on the surface, and transferred to a clean 24-well plate. Then 1 mL of 0.1% crystal violet solution was added to the wells and kept for half an hour at room temperature (approximately 25–28 °C) to stain the biofilm. After SS coupons (or glass coupons) were washed again with sterile distilled water to remove the excess stain, they were transferred again to a clean 24-well plate and 1 ml 95% ethanol was added to each well. After the plates were kept at room temperature for 15 min with gentle shaking to dissolve the absorbed stain, 200 µL samples were taken from the each well and transferred to new microtiter plate, and optical density of the biofilm was measured at 600 nm. Results were calculated using the previously mentioned formula as % BIP.

Eradication of mature biofilm on stainless steel and glass surfaces

To ascertain the impact of LAB strains on the mature biofilm formed on stainless steel and glass surface, first biofilm was formed on these surfaces. For this purpose, SS (or glass) coupons prepared, cleaned, and sterilized as previously described were placed in each well of the sterile polystyrene 24-well plates. 1.8 mL sterile TSB medium and 200 µL overnight culture of L. monocytogenes in TSB (106 CFU/mL) were added to wells, and plates were cultivated at 37 °C for 48 h. Following cultivation, the culture media was discarded and 2 mL CFS of each LAB strain was added to a separate well and maintained again at 37 °C for 24 h. The well where MRS broth was added instead of CFS was used as the control. Residual biofilm was quantified as described earlier. Results were calculated using the previously mentioned formula as % biofilm eradication percentage (% BEP).

Imaging the inhibition of biofilm formation on different surfaces

The impact of LAB strains on L. monocytogenes biofilm formation on polystyrene, stainless steel, and glass surfaces was visualized using scanning electron microscopy. For imaging, LAB strains that had the greatest impact on biofilm formation on all surfaces were initially selected. Then as described earlier, biofilms were developed on the surfaces with and without of CFS of these strains. After biofilm formation, a washing step with phosphate buffered saline (PBS) solutions was performed to remove non-adherent bacteria from the surfaces. Next, fixation was carried out using 2.5% glutaraldehyde at 4 °C for 4 h. After washing with PBS again, biofilms were dehydrated using graded ethanol series: 30, 50, 70, 90, and 100% each step for 10 min (Molham et al. 2021; Qiao et al. 2021). Then dried samples were sputter-coated with gold (5 nm thick layer) and imaged using SEM–EDX (Mira 3, Tescan/Czech Republic) at a voltage of 10 kV.

Statistical analysis

In study, all the assays were performed three times. The data obtained from the study were analyzed using the SPSS 23.0 program. Whether the data were normally distributed was checked with the Shapiro–Wilk test. Comparisons between the two groups were analyzed using the Student’s t test. p values less than 0.05 were considered statistically significant.

Results

According to the findings of the present study, CFSs of strains can inhibit biofilm formation by up to 51.57% on the polystyrene surface, 60.96% on the stainless steel surface, and 30.99% on the glass surface. Furthermore, they can also eradicate mature biofilm by up to 78.86% on the polystyrene surface, 73.12% on the stainless steel surface, and 72.63% on the glass surface. The strain that had the highest inhibition effect on biofilm development on the polystyrene surface in the study was L. brevis (KM1-4), while the strain that had the greatest eradication effect on mature biofilm was L. curvatus (P3X). According to the obtained results, except for a single L. brevis strain (KM2-8), all strains inhibited biofilm formation on stainless steel surface to varying degrees. In addition, in terms of eradicating mature biofilms on stainless steel surface, except for a single L. curvatus strain (P5), all strains were found to be effective. The ability of LAB strains to inhibit biofilm formation on glass surfaces was found to be weak, and only 9 out of the 19 LAB strains tested could inhibit biofilm formation to varying degrees, with 5 strains showing very weak inhibition effects (below 10%). The results were also evaluated by grouping the strains by the species. The biofilm inhibition and mature biofilm eradication potentials of each bacterial group were compared for each surface using the Student’s t test. The detailed results can be seen in Table 2. In addition, in the present study, the biofilm structure formed by L. monocytogenes on all three surfaces and the potential of CFSs to inhibit this structure were visualized using SEM. A comparison of biofilms formed by L. monocytogenes on the three different surfaces utilized in the study revealed that the densest, multilayered, and thick biofilm was produced on the polystyrene and stainless steel surfaces (Fig. 1A1 and B1), while the thinnest biofilm was formed on the glass surface (Fig. 1C1).

Scanning electron micrographs of L. monocytogenes biofilm formation in the absence and presence of LAB. A1: Biofilm formation on polystyrene surface absence of LAB, A2: biofilm formation on polystyrene surface presence of CFS of KM1-4, B1: biofilm formation on stainless steel surface absence of LAB, B2: biofilm formation on stainless steel surface presence of CFS of 8.P1.8, C1: biofilm formation on glass surface absence of LAB, C2: biofilm formation on glass surface presence of CFS of K2-4

Discussion

L. monocytogenes is among the most important food pathogens that threaten human health. Many food-contact surfaces (including glass, polystyrene, and stainless steel) are quite suitable for L. monocytogenes to adhere and develop biofilm. This poses a risk to the safety of the food since it can act as a source of contamination. Therefore, considerable attention is given to research on preventing or reducing the growth of L. monocytogenes biofilms in food manufactured environments (Colagiorgi et al. 2017; Hossain et al. 2021).

Present investigation has been focused on how the CFSs of different LAB strains affected the biofilm that L. monocytogenes developed on various surfaces. Whereby producing antimicrobial compounds especially bacteriocins or biosurfactants, LAB strains have the potential to control the biofilm of various pathogenic microorganisms, including L. monocytogenes. In the food industry, controlling biofilm formation with LAB is recognized as an environmentally friendly and safe alternative strategy that can be used instead of biofilm control with conventional sanitizers and disinfectants (Camargo et al. 2018; Hossain et al. 2021). In the present investigation, the effects of CFSs from 19 LAB strains belonging to five different Lactobacillus species and three probiotic type cultures on both biofilm formation and mature biofilm of L. monocytogenes on polystyrene, stainless steel, and glass surfaces were examined. The obtained results, in line with the literature, showed that the effectiveness of CFSs of LAB strains in biofilm control is a strain-specific feature, and the effectiveness of CFS differed depending on the surface where biofilm formation occurred. The biofilm formation process of L. monocytogenes is complicated and involves a number of variables, including virulence, environmental factors, quorum sensing, and other regulators. Process is affected not only by the strain’s lineage and origin but also by various intrinsic and extrinsic factors present in the environment. As a result, biofilm formation capacity and resistance to anti-biofilm components varies depending on the surface and strains (Reis-Teixeira et al. 2017; Hossain et al. 2021; Lee et al. 2021). For this reason, it is expected result that the degree of effectiveness of the LAB strains used in the study varies depending on the surface.

CFSs of any LAB strains can contain numerous substances with antimicrobial properties affecting L. monocytogenes or components of the biofilm matrix. Bacteriocins or bacteriocin-like inhibitory substances, hydrogen peroxide, exopolysaccharides, and some other chemicals are among them (Lee et al. 2021). Because the pH of the CFSs was adjusted to 6.5 at the beginning of the study, it is known that anti-biofilm activity is not caused by acidity. The antimicrobial activity of the strains used in this study on L. monocytogenes has been previously examined in other studies, and the strains were found to be effective overall (Kıvanç and Yapıcı 2015; Dincer and Kıvanc 2022). The findings of those previous studies indicate that strains can produce bacteriocin or bacteriocin-like metabolites, and also have hydrogen peroxide production abilities. For this reason, it is an expected result that the CFSs of strains have an anti-biofilm effect.

The polystyrene surface is frequently used in studies to detect microbial biofilm development or the effects of various components on these biofilms. Similarly, inhibition of biofilm formation and eradication of mature biofilm on the polystyrene surface were evaluated in the present study. All of the CFSs used in this study inhibited biofilm development to varying degrees (minimum 15.47% and maximum 51.57%). In addition, it was discovered that the CFSs of most strains have the potential to eradicate mature biofilm by 60–70%. As a result, it was concluded that the CFSs used were generally more effective in eradicating mature biofilm. Considering the strains used in the current study in groups based on species, it was observed that the CFSs from all species had a remarkable impact on both the prevention of biofilm formation and the removal of mature biofilm. Similar findings have been reported in the literature for these Lactobacillus species. On the other hand, there are also studies in the literature reporting that LAB strains are more effective in preventing biofilm formation on polystyrene surfaces rather than mature biofilm eradication. The results of the studies vary depending on the LAB strains used and the L. monocytogenes strain they act on. Similar to the current study, it has been reported that CFS of lactobacilli isolated from goat milk both inhibited biofilm formation and dispersed mature biofilm of L. monocytogenes on the polystyrene surface (Singh et al. 2020). Camargo et al. (2016) examined the effects of nine LAB strains, which were previously known as bacteriocin producer, on the biofilm formation capacity of wild strains of L. monocytogenes. The researchers reported that LAB strains were effective in inhibiting biofilm formation, but they did not show any significant effects on mature biofilms. Hossain et al. (2021) demonstrated that previously identified L. curvatus and L. plantarum strains were effective in reducing L. monocytogenes biofilm on various food-contact surfaces and suggested that both strains might be used to control L. monocytogenes biofilm in the food industry. It is known that Lactobacilli such as L. brevis have anti-adhesive properties on pathogen microorganisms through to the bacteriocins and biosurfactants they produce (Gomaa 2013). Similar results to present study, Lee et al. (2021) reported that a L. plantarum strain isolated from Korean fermented kimchi inhibited L. monocytogenes biofilm formation on polystyrene surface by 37.16%. Gómez et al. (2016) found that L. sakei and L. curvatus strains isolated from Brazilian’s foods remarkably inhibited L. monocytogenes biofilm formation on polystyrene surface.

Stainless steel is one of the most used surfaces in the food industry due to its mechanical strength, corrosion resistance, and durability. L. monocytogenes has the ability to adhere stainless steel surface quickly. Therefore, understanding the formation of biofilms on stainless steel surfaces and their removal is of great importance (Hossain et al. 2020). In the current study, the effect of CFSs of LAB strains on the formation of biofilm on stainless steel surfaces was also evaluated in terms of both inhibiting biofilm formation and eradicating mature biofilms. Comparing the inhibition of biofilm formation and the eradication of mature biofilm, it is noteworthy that CFSs were more effective in removing mature biofilms on stainless steel surfaces, similar to polystyrene surfaces. In addition, considering the strains used in the current study in groups based on species, it was observed that CFSs of L. sakei species were more effective than other species in both inhibiting biofilm formation and eradicating mature biofilms. Various studies in the literature support the findings of the present study and show the effectiveness of LAB strains in controlling L. monocytogenes biofilm on stainless steel surfaces. Kıran et al. (2021) revealed that an L. plantarum strain isolated from plant materials (used in the manufacturing of herb cheese) could inhibit biofilm formation on stainless steel surfaces by 78%. The researchers tested the effectiveness of their strain on various surfaces and reported that the bioactive compounds produced by this strain might be used to prevent biofilm formation on food-contact surfaces. Hossain et al. (2020) determined that 6 of 34 LAB strains isolated from kimchi exhibited antimicrobial activity against L. monocytogenes and investigated their effect on L. monocytogenes biofilm on stainless steel surfaces. At the end of the study, the researchers reported that all strains (3 L. plantarum, 1 L. sakei, 1 L. curvatus, and 1 L. mesenteroides) considerably reduced biofilm formation on stainless steel surfaces, with the highest effect observed from the L. curvatus strain. In another research, Masebe and Thantsha (2022) investigated the effect of the potential probiotic strain L. plantarum B411 isolated from a fermented cereal on the biofilm formation of L. monocytogenes on different surfaces. The researchers allowed biofilm growth on the stainless steel surface for 7 days, before testing the effect of the CFS on mature biofilm. As a result, they reported, similar to the current investigation, that LAB strains did not completely destroy the mature biofilm but caused its high dispersion.

L. monocytogenes has the ability to quickly adhere and form biofilms to glass surfaces, as well as many other surfaces (Chae et al. 2006). According to research by Reis-Teixeira et al. (2017), it can adhere to both stainless steel and glass surfaces in just 3 h and reach a density of 106–108 CFU/cm2 within 24 h. Researchers were reported that there was no increase in the sessile cell population even if the incubation period was extended beyond 24 h, and moreover, the planktonic cell count remained constant due to the distributions caused by the biofilm structure. They emphasized that L. monocytogenes can spread from biofilms to the environment and these biofilms have the potential to contaminate food-contact surfaces. In this investigation, the impact of CFSs of LAB strains on biofilm formation and mature biofilm distribution on glass surfaces was detected. The highest effect was shown by the CFS of L. plantarum strain (K2-4) with a 30.99% inhibition rate. On the other hand, when the effects of CFSs on mature biofilms on the glass surface were examined, they were found to be quite effective, similar to polystyrene and stainless steel surfaces. Only one of the CFS was found to be ineffective on mature biofilm, and the majority of the CFSs dispersed the mature biofilm by at least 50% (maximum 72.63%—P3X). According to the literature, similar to the results found in the present investigation, LAB strains can disturb the mature biofilm structure, even if they cannot prevent L. monocytogenes adhesion on the glass surface. Jara et al. (2020) reported that although the LAB strains they used did not reduce L. monocytogenes adhesion, they disrupted the mature biofilm structure by synthesizing extracellular polymeric substances.

Visualization of biofilms can provide information about their structures. For the L. monocytogenes, various diverse biofilm morphologies, such as mushroom-like structure, honeycomb-like structure, dense three-dimensional structure, or knitted chain structure with non-organized and aggregated structure, have previously been identified (Doijad et al. 2015). In this study, to better understand the effect of CFSs of LAB strains on L. monocytogenes biofilm formation, both the biofilm structure formed by only L. monocytogenes on surfaces and the biofilm structure formed in the presence of LABs were visualized using SEM (Fig. 1).

Conclusion

The present study investigated the impact of LAB strains solely through the use of CFS on the biofilm of L. monocytogenes formed on various food-contact surfaces, including polystyrene, stainless steel, and glass. Certain LAB strains used in this study exhibited promising potential in controlling Listeria biofilms, particularly demonstrating notable effectiveness in eradicating mature biofilms on these surfaces. These findings suggest that these strains may hold promise for industrial applications. However, it is crucial to acknowledge that, as the study exclusively utilized CFS without direct co-culture of strain cells with the biofilm, making direct claims about the inhibitory effects of the strains on biofilm formation may not be entirely appropriate. Further research is warranted to delve deeper into the mechanisms underlying the observed effects. Although it is known from previous studies that the strains used in this study show antimicrobial activity against L. monocytogenes, it is necessary to determine the mechanisms by which these strains inhibit biofilm formation and destroy mature biofilms to reach a definitive conclusion. In addition, it is important to note that, while present study demonstrated significant effects in the eradication of mature biofilms using CFS and the absence of a specific cell viability study to confirm these eradication effects. Future investigations incorporating cell viability assays are warranted to further validate and provide a comprehensive understanding of the observed biofilm eradication. This study sets the groundwork for potential future research endeavors exploring the interplay between LAB strains, biofilm formation, and cell viability.

Data availability

Materials and the datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ben Slama R, Kouidhi B, Zmantar T, Chaieb K, Bakhrouf A (2013) Anti-listerial and anti-biofilm activities of potential probiotic Lactobacillus strains isolated from Tunisian traditional fermented food. J Food Safety 33(1):8–16. https://doi.org/10.1111/jfs.12017

Camargo AC, de Paula OAL, Todorov SD, Nero LA (2016) In vitro evaluation of bacteriocins activity against Listeria monocytogenes biofilm formation. App Biochem Biotechnol 178:1239–1251. https://doi.org/10.1007/s12010-015-1941-3

Camargo AC, Todorov SD, Chihib NE, Drider D, Nero LA (2018) Lactic acid bacteria (LAB) and their bacteriocins as alternative biotechnological tools to control Listeria monocytogenes biofilms in food processing facilities. Mol Biotechnol 60:712–726. https://doi.org/10.1007/s12033-018-0108-1

Chae MS, Schraft H, Hansen LT, Mackereth R (2006) Effects of physicochemical surface characteristics of Listeria monocytogenes strains on attachment to glass. Food Microbiol 23(3):250–259. https://doi.org/10.1016/j.fm.2005.04.004

Colagiorgi A, Bruini I, Di Ciccio P, Zanardi E, Ghidini S, Ianier A (2017) Listeria monocytogenes biofilms in the wonderland of food industry. Pathogens 6(3):41. https://doi.org/10.3390/pathogens6030041

Dincer E, Kivanc M (2012) Characterization of lactic acid bacteria from Turkish Pastirma. Ann Microbiol 62:1155–1163. https://doi.org/10.1007/s13213-011-0355-x

Dincer E, Kivanc M (2022) Evaluation of metabolic activities and probiotic characteristics of two Latilactobacillus sakei strains isolated from pastırma. World J Microbiol Biotechnol 38:237. https://doi.org/10.1007/s11274-022-03431-0

Doijad SP, Barbuddhe SB, Garg S, Poharkar KV, Kalorey DR, Kurkure NV, Rawool DB, Chakraborty T (2015) Biofilm-forming abilities of Listeria monocytogenes serotypes isolated from different sources. PLoS ONE. https://doi.org/10.1371/journal.pone.0137046

Fernández-Gómez P, Muro-Fraguas I, Múgica-Vidal R et al (2022) Development and characterization of anti-biofilm coatings applied by Non-Equilibrium Atmospheric Plasma on stainless steel. Food Res Int. https://doi.org/10.1016/j.foodres.2020.109891

Gasanov U, Hughes D, Hansbro PM (2005) Methods for the isolation and identification of Listeria spp. and Listeria monocytogenes: a review. FEMS Microbiol Rev 29(5):851–875. https://doi.org/10.1016/j.femsre.2004.12.002

Gemmell CT, Parreira VR, Farber JM (2022) Controlling Listeria monocytogenes growth and biofilm formation using flavonoids. J Food Prot 85(4):639–646. https://doi.org/10.4315/JFP-21-135

Gomaa EZ (2013) Antimicrobial and anti-adhesive properties of biosurfactant produced by lactobacilli isolates, biofilm formation and aggregation ability. J Gen Appl Microbiol 59(6):425–436. https://doi.org/10.2323/jgam.59.425

Gómez NC, Ramiro JM, Quecan BX, de Melo FB (2016) Use of potential probiotic lactic acid bacteria (LAB) biofilms for the control of Listeria monocytogenes, Salmonella typhimurium, and Escherichia coli O157:H7 biofilms formation. Front Microbiol 7:863. https://doi.org/10.3389/fmicb.2016.00863

Gray JA, Chandry PS, Kaur M, Kocharunchitt C, Bowman JP, Fox EM (2018) Novel biocontrol methods for Listeria monocytogenes biofilms in food production facilities. Front Microbiol 9:605. https://doi.org/10.3389/fmicb.2018.00605

Hossain MI, Mizan MFR, Ashrafudoulla M, Nahar S, Hj J, Jahid IK, Park SH, Kim KS, Ha SD (2020) Inhibitory effects of probiotic potential lactic acid bacteria isolated from kimchi against Listeria monocytogenes biofilm on lettuce, stainless-steel surfaces, and MBEC™ biofilm device. LWT Food Sci Technol. https://doi.org/10.1016/j.lwt.2019.-108864

Hossain MI, Mizan MFR, Roy PK, Nahar S, Toushik SH, Ashrafudoulla M, Jahid IK, Lee J, Ha SD (2021) Listeria monocytogenes biofilm inhibition on food contact surfaces by application of postbiotics from Lactobacillus curvatus B.67 and Lactobacillus plantarum M.2. Food Res Int. https://doi.org/10.1016/j.foodres.2021.110595

Jara J, Pérez-Ramos A, Del Solar G, Rodríguez JM, Fernández L, Orgaz B (2020) Role of Lactobacillus biofilms in Listeria monocytogenes adhesion to glass surfaces. Int J Food Microbiol. https://doi.org/10.1016/j.ijfoodmicro.2020.108804

Kıran F, Akoğlu A, Çakır İ (2021) Control of Listeria monocytogenes biofilm on industrial surfaces by cell-free extracts of Lactobacillus plantarum. J Food Process Pres. https://doi.org/10.1111/jfpp.15042

Kıvanc M, Temel O (2016) Determination of tannase activity of the lactic acid bacteria that isolated from fermented products. J Food 41:395–402

Kıvanç M, Yapıcı E (2015) Kefir as a probiotic dairy beverage: determination lactic acid bacteria and yeast. Int J Food Eng 1(1):55–60

Lee JE, Lee NK, Paik HD (2021) Antimicrobial and anti-biofilm effects of probiotic Lactobacillus plantarum KU200656 isolated from kimchi. Food Sci Biotechnol 30:97–106. https://doi.org/10.1007/s10068-020-00837-0

Masebe RD, Thantsha MS (2022) Anti-biofilm activity of cell free supernatants of selected lactic acid bacteria against Listeria monocytogenes isolated from avocado and cucumber fruits, and from an avocado processing plant. Foods 11(18):2872. https://doi.org/10.3390/foods11182872

Molham F, Khairalla AS, Azmy AF, El-Gebaly E, El-Gendy AO, AbdelGhani S (2021) Anti-proliferative and anti-biofilm potentials of bacteriocins produced by non-pathogenic Enterococcus sp. Probiotics Antimicrob 13:571–585. https://doi.org/10.1007/s12602-020-09711-1

Qiao Z, Zhang L, Wang X, Liu B, Shan Y, Yi Y, Zhou Y, Lü X (2021) Antibiofilm effects of bacteriocin BMP32r on Listeria monocytogenes. Probiotics Antimicrob 14:1067–1076. https://doi.org/10.1007/s12602-021-09863-8

Ravindhiran R, Sivarajan K, Sekar JN, Murugesan R, Dhandapani K (2023) Listeria monocytogenes an emerging pathogen: a comprehensive overview on listeriosis, virulence determinants, detection, and anti-listerial interventions. Microb Ecol 86:2231–2251. https://doi.org/10.1007/s00248-023-02269-9

Reis-Teixeira FBD, Alves VF, Martinis ECPD (2017) Growth, viability and architecture of biofilms of Listeria monocytogenes formed on abiotic surfaces. Braz J Microbiol 48(3):587–591. https://doi.org/10.1016/j.bjm.2017.01.004

Shamloo E, Hosseini H, Moghadam ZA, Larsen MH, Haslberger A, Alebouyeh M (2019) Importance of Listeria monocytogenes in food safety: a review of its prevalence, detection, and antibiotic resistance. Iranian J Vet Res 20(4):241–254

Shen C, Luo Y, Nou X, Bauchan G, Zhou B, Wang Q, Millner P (2012) Enhanced inactivation of Salmonella and Pseudomonas biofilms on stainless steel by use of T-128, a fresh-produce washing aid, in chlorinated wash solutions. App Environ Microbiol 78(19):6789–6798. https://doi.org/10.1128/AEM.01094-12

Singh N, Kaur R, Singh BP, Rokana N, Goel G, Puniva AK, Panwar H (2020) Impairment of Cronobacter sakazakii and Listeria monocytogenes biofilms by cell-free preparations of lactobacilli of goat milk origin. Folia Microbiol 65:185–196. https://doi.org/10.1007/s12223-019-00721-3

Funding

Current investigation has received no funding support from any entity.

Author information

Authors and Affiliations

Contributions

All analyses were performed by Emine Dinçer.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Communicated by Yusuf Akhter.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dinçer, E. Impact of lactic acid bacteria strains against Listeria monocytogenes biofilms on various food-contact surfaces. Arch Microbiol 206, 80 (2024). https://doi.org/10.1007/s00203-023-03811-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00203-023-03811-6