Abstract

Anoxybacillus flavithermus subsp. yunnanensis is currently the first species of strictly thermophilic bacteria that is able to tolerate a broad range of solvents. Unlike most of solvent-tolerant mesophilic bacteria, the bacterium does not synthesize unsaturated fatty acids. Our results revealed that in growing cells of A. flavithermus subsp. yunnanensis E13T, ethanol and toluene resulted in an increase in straight-chain fatty acids, mainly C16:0, leading to a more rigid membrane. Moreover, the increase in straight-chain fatty acids caused by ethanol was much higher than that of toluene. High temperature had little effect on the fatty acid composition by itself, whereas the combined conditions of high temperature and ethanol caused the dramatic increase in straight-chain fatty acids (mainly C16:0), that was balanced by decreasing branched fatty acids. The increase was also temperature dependent. The proportion of C16:0 further increased above 60 °C. No similar evidence was found in four other species of Anoxybacillus. The results suggested that A. flavithermus subsp. yunnanesis seems to develop a different response to solvents compared to its mesophilic counterparts, which consist of an increase in the saturated straight/branched ratio.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Organic solvents can be extremely toxic for bacteria because they are able to penetrate cell membranes and disrupt their structure. Organic solvent-tolerant bacteria are considered a subgroup of the extremophiles, which are able to overcome the toxic and destructive effects of organic solvents on account of their unique adaptive mechanisms. Most of the reported and well-studied solvent-tolerant bacteria are mesophilic microorganisms that have an optimal temperature of between 25 and 37 °C, such as Gram-negative species of the genera Pseudomonas (Inoue and Horikoshi 1989), Geobacter (Duldhardt et al. 2010) and Methylococcus (Löffler et al. 2010), and Gram-positive species of Bacillus (Pepi et al. 2008), Rhodococcus (de Carvalho et al. 2004) and Staphylococcus (Kongpol et al. 2009). It is widely accepted that temperature plays an important role in organic solvent inhibition. High temperature causes an increase in membrane fluidity, resulting in an increased disruptive effect of solvent on cell membrane structure (Baer et al. 1987; Georgieva et al. 2007). Because of this reason, only two moderately thermophilic bacteria, Deinococcus geothermalis T27 (Kongpol et al. 2008) and Brevibacillus agri 13 (Kongpol et al. 2009), have been reported to tolerate a broad range of solvents at 45 °C. In the case of low-toxic ethanol, thermophilic bacteria rarely tolerate more than 2 % (% value is in v/v) ethanol (Rani and Seenayya 1999; Burdette et al. 2002). However, several thermophilic bacteria have been reported to tolerate ethanol. For example, Thermoanaerobacter A10, grows optimally at 70 °C and tolerates ethanol concentrations of up to 4.7 % (Georgieva et al. 2007). Furthermore, a mutant strain of T. pseudoethanolicus 39E-H8 is able to grow weakly in up to 8 % ethanol at 60 °C (Burdette et al. 2002). The wild-type strains of Clostridia thermocellum SS21 and SS22 were reported to tolerate to 7.0 and 8.0 % ethanol at 60 °C (Rani and Seenayya 1999), respectively. An ethanol-adapted strain of C. thermocellum was tolerant to 5 % ethanol at 55 °C (Williams et al. 2007). Ethanol tolerance (presumably not with active growth) as high as 10 % at 60 °C has been reported in Geobacillus thermoglucosidasius M10EXG (Fong et al. 2006). Recently, we isolated and classified a novel subspecies of Anoxybacillus flavithermus subsp. yunnanensis from a hot spring. It is a facultatively aerobic, Gram-positive and rod-shaped bacterium that is capable of utilizing a range of carbon sources, such as xylose, arabinose and cellobiose. It is the first strictly thermophilic bacterial species known to tolerate a broad range of solvents at its optimal temperature of 55–60 °C (Dai et al. 2011; Gao et al. 2011). Here we tested whether the subspecies uses any exclusive adaptive mechanisms to acclimatize in the presence of organic solvents at high temperature.

Several mechanisms of solvent tolerance have been found in mesophilic microorganisms (Ramos et al. 2002; Torres et al. 2011). One of the most important adaptive mechanisms is alteration of membrane fatty acid composition and membrane fluidity. Most of these changes, which occur in both Gram-negative and Gram-positive bacteria, are related to changes in unsaturated fatty acids and include (1) the ratio of saturated vs unsaturated fatty acids increasing or decreasing to result in a more rigid or fluid membrane, respectively (Heipieper and de Bont 1994; Ingram 1976; de Carvalho et al. 2005; Duldhardt et al. 2010); (2) the unsaturated fatty acids changing from cis to trans (Heipieper et al. 1992; Löffler et al. 2010); and (3) the conversion of unsaturated fatty acids into cyclopropanes (Pini et al. 2009). Relatively, less information regarding how thermophilic bacteria response to organic solvents is available. Timmons et al. (2009) determined the fatty acid composition from C. thermocellum wild-type and ethanol-adapted (grow in the presence of 5 % ethanol) strains at 55 °C. Unlike mesophilic bacteria, C. thermocellum only synthesizes saturated fatty acids. The ethanol-adapted strain had more fatty acids with chain lengths more than 16:0. They proposed a model that the ethanol tolerance of this strain is due to fatty acid alterations that increase membrane rigidity and counteract the fluidizing effect of ethanol. A. flavithermus subsp. yunnanensis also only synthesizes saturated fatty acids (Dai et al. 2011), but is tolerant higher concentrations of solvents at higher temperature. Therefore, we examined changes in the membrane fatty acid composition of A. flavithermus subsp. yunnanensis E13T grown under thermophilic conditions in the presence of toluene or ethanol. The cells increased the levels of straight-chain fatty acid to counteract the effects of organic solvents, especially when the temperature was above 60 °C. A survey of four other strains of Anoxybacillus, which are unable to tolerate organic solvents, revealed no change in straight-chain fatty acid similar to that of A. flavithermus subsp. yunnanensis E13T.

Materials and methods

Microorganisms and medium

The thermophilic strain A. flavithermus ssp. yunnanensis E13T (Dai et al. 2011) was used in this study. The strain was isolated from a hot spring in China and capable of tolerating high concentrations of organic solvents at high temperature. It was deposited at the China Center for Type Culture Collection (CCTCC, AB2010187T) and the Korean Collection for Type Cultures (KCTC, 13759T). A. flavithermus subsp. flavithermus DSM 2641T and A. pushchinoensis DSM 12423T were obtained from the Deutsche Sammlung von Mikroorganismen und Zellkulturen (DSMZ), and A. eryuanensis KCTC 13720T and A. tengchongensis KCTC 13721T were acquired from the KCTC. A slightly modified Luria–Bertani (LB) medium containing a low NaCl concentration (0.3 % w/v) was used throughout this study.

Culture conditions

Anoxybacillus flavithermus ssp. yunnanensis E13T grown in liquid static culture naturally forms a biofilm (Dai et al. 2011) that increases the ability of the cells to persist in adverse environments, even if there is no environmental stress. Perhaps for this reason, a significantly higher tolerance to solvent was observed in the cells incubated in static cultures when compared with the cells incubated in shaker culture (data not shown). Therefore, all cultures were grown under static culture conditions in strictly sealed 250-ml Balch bottles plugged with butyl rubber stoppers to prevent evaporation of the organic solvents. The head space in the sealed bottles was air.

Strain E13T lives in both biofilm and planktonic forms when the added solvent is below a critical concentration. When the concentration exceeds the critical value, the E13T strain is not grown as planktonic cells, with a discernible increase in turbidity (OD600 nm), but is only grown as a biofilm adhered to the glass surface of bottles (Dai et al. 2011). Because biofilm-grown cells are thought to be more complicated and markedly different from planktonic cells, planktonic E13T cells were harvested throughout this study. The suspended (planktonic) cells that were used for measurements were withdrawn directly from the sealed bottles with long syringe needles after incubation. The critical minimum concentrations that completely inhibited the planktonic growth of the strain E13T, but not the biofilm growth, were used as the highest solvent concentrations in this study. The critical minimum concentrations in the presence of ethanol at 50, 55, 60 and 65 °C were 10.5, 9.0, 8.2 and 7.3 %, respectively.

The E13T strain was initially cultivated overnight in medium without organic solvent at 55 °C to provide an inoculum. The cells were then recovered by centrifugation at 4000×g for 5 min. To standardize the inoculum density, the cell suspension was diluted to an OD600 of 0.20, and then 25-ml aliquots were transferred to Balch bottles (250 ml) with various concentrations of ethanol or toluene. The cultures were grown at a temperature range of 50–65 °C. In all analyses, each set of experiments was performed twice. Three independent replicates were performed for all experimental conditions. The data obtained were subjected to the analysis of variance (ANOVA) procedures. Differences of means were tested by Tukey’s method (HSD).

Cellular fatty acids

Stationary-phase cells were recovered by centrifugation at 8000×g for 10 min at 4 °C and washed three times with distilled water. Lipids from the organism were extracted with a chloroform–methanol–water mixture according to the method of Bligh and Dyer (1959) with minor modifications (Huffer et al. 2011). An internal standard of pentadecanoic acid dissolved in acetic acid was added to each sample at a final concentration of 45 μM. Fatty acid methyl esters were prepared by using extracted lipids and methanol containing 5 % H2SO4 (2 h at 90 °C) applying the method of Voelker and Davies (1994) and extracted with hexane. The final extracts were analyzed by gas chromatography mass spectrometry (GC/MS) in scan mode, using an Agilent 7890 GC/5975 MSD system (Agilent Technologies, Wilmington, DE, USA). The oven temperature was set at 150 °C, followed by an increase to 270 °C at a rate of 5 °C min−1 and cleaning at a final hold at 300 °C for 2 min. Helium was used as a carrier gas at a flow rate of 1 ml min−1. The cellular fatty acids were identified using the mass spectrum library (Wiley Registry 8th Edition/NIST 2005) and quantified by normalizing the peak area of each fatty acid to the peak area of the internal standard.

Results

Effects of ethanol and toluene on the growth of A. flavithermus ssp. yunnanensis E13T

In general, microbial growth decreased with increasing solvent concentration. Growth of A. flavithermus ssp. yunnanensis E13T in the presence of toluene was in agreement with the general rule, while its growth in the presence of ethanol was different (Fig. 1). At 55 °C, the mean generation time for the E13T strain during exponential phase was 8.2 ± 0.4 h. In the presence of 3.0, 6.0 and 9.0 % ethanol, the generation times of the cultures were 3.7 ± 0.3 (standard deviation, n = 6), 9.6 ± 0.5 and 17.6 ± 0.7 h, respectively (Fig. 1a). In the presence of 3.0 % ethanol, the E13T strain not only grew faster but also produced more biomass when compared with cells incubated without ethanol (Fig. 1a). The E13T strain produced a trace amount of ethanol (approximately 0.018 %) but was unable to degrade ethanol (Dai et al. 2011). Therefore, the faster growth and higher biomass were not due to the possibility of it using ethanol as a substrate.

Effects of exogenously added ethanol (a) and toluene (b) on the growth of A. flavithermus ssp. yunnanensis E13T at 55 °C. The cell growth was assessed by measuring OD600 in sealed Balch bottles to avoid the loss of solvent by volatilization. Results are the means of six independent determinations with error bars representing the standard deviation

In the presence of 0.1, 0.2 and 0.3 % toluene, the mean generation times were 8.1 ± 0.4, 6.2 ± 0.4 and 18.2 ± 0.7 h, respectively. Long lag phases of 12 and 24 h were noted in the cultures at 0.2 and 0.3 % toluene, respectively (Fig. 1b). In addition, the cells previously cultivated under solvent stress were used to inoculate new medium with the same solvent concentration. Similar tolerance and long lag phases were observed, which suggested that no solvent-tolerant mutants developed in the lag phases. Because a dependency of the fatty acid composition on growth phase was observed (data not shown), all experiments used membrane fatty acids that were collected from cells during stationary growth phase.

Effects of ethanol and toluene on the fatty acid composition of A. flavithermus ssp. yunnanensis E13T

The main fatty acids of the E13T strain, when grown in liquid LB medium, were iso-C15:0, iso-C16:0, anteiso-C15:0, C16:0 and C17:0, while iso-C14:0, iso-C17:0, C14:0 and C15:0 were present in trace amounts of between 1.4 ± 0.06 and 5.0 ± 0.2 %. Figure 2 depicts the changes in fatty acid composition when the E13T strain was exposed to 3.0, 6.0 and 9.0 % ethanol (Fig. 2a) and 0.1, 0.2 and 0.3 % toluene (Fig. 2b) at 55 °C. Overall, in both cases, the levels of straight-chain fatty acids increased with increasing solvent concentrations, while the levels of branched-chain fatty acids decreased correspondingly. For example, in the 9.0 % ethanol-grown cells, there was a 24.5 ± 0.2 % increase in straight-chain fatty acids that was balanced by a 17.7 ± 0.1 % decrease in iso-branched fatty acids and a 6.8 ± 0.06 % decrease in anteiso-branched C15:0, which resulted in the straight-chain fatty acids representing 63.6 ± 0.3 % of the total fatty acids. The shift in fatty acid composition to more straight-chain fatty acids led to a more rigid membrane that counteracted the fluidity increase caused by the organic solvents.

The effects of ethanol (a) and toluene (b) on the fatty acid composition of A. flavithermus ssp. yunnanensis E13T. The cells were grown to stationary phase in slightly modified LB media at 55 °C. a White bars no solvent; light gray bars 3.0 % ethanol; dark gray bars 6.0 % ethanol; black bars 9.0 % ethanol. b White bars no solvent; light gray bars 0.1 % toluene; dark gray bars 0.2 % toluene; black bars 0.3 % toluene. Results are the means of six independent determinations with error bars representing the standard deviation

Notably, the changes were significantly greater in ethanol than in toluene, and the switch to a fatty acid profile was dominated by the straight-chain C16:0. The higher toxic levels of solvent usually resulted in the slower growth of bacterium. The same toxic levels of ethanol and toluene were roughly estimated by the equal mean generation time of the bacterium. The E13T strain reacted to the presence of 9.0 % ethanol (a generation time of 17.6 ± 0.7 h) with a 2.1-fold increase in the level of C16:0 (from 17.1 ± 0.3 to 36.4 ± 0.6 %), while in the presence of 0.3 % toxically equivalent toluene (a generation time of 18.2 ± 0.7 h), the level of C16:0 increased only 1.3-fold. These results suggested that saturated straight-chain C16:0 probably plays an important role in providing a more rigid membrane for growth under solvent stress, particularly ethanol stress, in thermophilic, solvent-tolerant A. flavithermus ssp. yunnanensis.

In addition, the effect of ethanol and toluene on the fatty acid composition was investigated in the biofilm (Supplementary material). Overall, the results were similar to the planktonic cells.

Ethanol-induced changes in the fatty acid composition of A. flavithermus ssp. yunnanensis E13T at various high temperatures

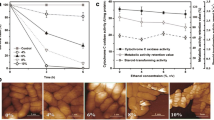

The temperature growth range of the E13T strain was 30 to 66 °C. In addition, the mean generation times at 50, 55, 60 and 65 °C were 11.5 ± 0.6, 8.2 ± 0.4, 8.5 ± 0.6 and 11.9 ± 0.5 h, respectively. It is generally admitted that an increase in the culture temperature induces an increase in the amount of saturated fatty acids and a decrease in the amount of unsaturated fatty acids in the cell membrane, leading to a decrease in membrane fluidity (Teixeira et al. 2002). The fatty acid compositions of the E13T strain grown in the absence of solvent at different temperatures (50, 55, 60 and 65 °C) are shown in Fig. 3a. Although the E13T strain does not possess unsaturated fatty acids, it regulated its fatty acid composition to achieve a slightly low fluidity by slightly increasing its straight-chain/branched-chain ratio of fatty acids.

The fatty acid compositions of A. flavithermus ssp. yunnanensis E13T grown in the absence (a) and presence (b) of ethanol at different temperatures. White bars, 50 °C, 10.5 % ethanol; light gray bars, 55 °C, 9.0 % ethanol; dark gray bars, 60 °C, 8.2 % ethanol; black bars, 65 °C, 7.3 % ethanol. Under these critical minimum concentrations, the E13T strain showed similar mean generation times. Results are the means of six independent determinations with error bars representing the standard deviation

Because ethanol influences the fatty acid composition of membranes more than toluene, ethanol was used to test the changes in fatty acids over the temperature range of 50–65 °C (Fig. 3b). Temperature had a strong impact on the ethanol tolerance of the E13T strain. The critical minimum concentrations in the presence of ethanol at 50, 55, 60 and 65 °C were 10.5, 9.0, 8.2 and 7.3 %, respectively. Under these conditions, the mean generation times of the E13T strain were 18.7 ± 0.8, 17.6 ± 0.7, 17.9 ± 0.6 and 18.1 ± 0.5 h, respectively. The relatively similar mean generation times meant relatively similar ethanol stress.

From 50 to 55 °C, the levels of C16:0 under ethanol stress (Fig. 3b) were twice as high as those of the cells grown in the absence of ethanol. As the temperature further rose to 60 and 65 °C, the C16:0 levels dramatically increased again, and C16:0 became an extremely prominent (56.1 ± 0.5 and 61 ± 0.9 %) component of the fatty acid profile of the E13T strain. At high temperature, especially at 60 and 65 °C, the increase in C16:0 resulted in unusually higher amounts (more than 80 %) of straight-chain fatty acids, versus approximately 44–47 % in cells that were not exposed to ethanol. Such a dramatic rise in the amount of straight-chain fatty acids, mainly C16:0, does not occur in other known organic solvent-tolerant bacteria.

Effect of ethanol on the fatty acid compositions of other Anoxybacillus species

The other members of the Anoxybacillus genus were unable to tolerate high concentrations of organic solvent. The subminimal inhibitory concentrations of ethanol at 55 °C was 1.0 % for A. eryuanensis KCTC 13720T, 3.2 % for A. flavithermus subsp. flavithermus DSM 2641T and A. tengchongensis KCTC 13721T, and 4.4 % for A. pushchinoensis DSM 12423T. The growth of these strains was completely inhibited at ethanol concentrations above these values.

The fatty acid compositions of other Anoxybacillus species are remarkably different from that of A. flavithermus subsp. yunnanensis. These Anoxybacillus species synthesize the branched-chain iso-C15:0, which is the most abundant component (more than 50 % in total), while the levels of C16:0 were lower than 9 % (Dai et al. 2011; Zhang et al. 2011). The effects of ethanol on the fatty acid compositions of four Anoxybacillus species are shown in Table 1. These Anoxybacillus strains had a similar response to ethanol exposure, and the largest percentage change was an increase in iso-C15:0 from 51.8 ± 1.5 to 64.3 ± 1.7 % in cells not exposed to ethanol to 64.1 ± 1.8–74.5 ± 2.4 % in ethanol-grown cells, resulting in a more fluid cellular membrane. There was no significant difference in C16:0 between the two cell samples, which indicates that the four Anoxybacillus species do not fortify the membrane against the fluidizing effects of ethanol.

Discussion

The toxicity of organic solvents appears to, at first instance, dissolve into biological membranes, causing an increase in cell membrane fluidity. The adaptive changes of fatty acid composition in response to organic solvents are observed in a large number of microorganisms, including both solvent-tolerant and non-tolerant bacteria (Huffer et al. 2011; Torres et al. 2011). Microorganisms react to the presence of solvents by increasing or decreasing their membrane fluidity. Although the adaptive changes depend on the type of organism and solvent (de Carvalho et al. 2005; Nielsen et al. 2005) most of the changes are achieved via altered unsaturated fatty acids. Several solvent-tolerant bacteria use a different strategy that utilizes branched-chain saturated fatty acids in response to solvents. Arthrobacter chlorophenolicus reacts to phenols by altering the anteiso/iso ratio of branched-chain fatty acids (Unell et al. 2007), and Staphylococcus haemolyticus reacts to toluene by increasing the amount of anteiso-branched-chain fatty acids and concomitantly decreasing the amount of C20:0 straight-chain fatty acids (Nielsen et al. 2005). Compared to these mesophilic counterparts, the thermophilic solvent-tolerant bacterium A. flavithermus subsp. yunnanensis seems to use neither unsaturated nor branched-chain fatty acids in response to solvents stress. It strengthened its membrane fluidity by significantly increasing the amount of straight-chain fatty acids with a corresponding decrease in the amount of branched chain when grown in solvents. The decrease in iso-fatty acids was approximately proportional to the decrease in anteiso-fatty acids, and only minor changes were observed in the anteiso-/iso-branched fatty acid ratio. For example, the cells grown at 55 °C possessed an anteiso/iso ratio of 0.49, while the cells that were grown in the presence of 9.0 % ethanol or 0.3 % toluene had ratios of 0.57 and 0.46, respectively. Therefore, the alteration in the anteiso-/iso-branched fatty acid ratio contributed little to the solvent tolerance of the E13T strain.

The classical mesophilic solvent-tolerant Pseudomonas putida reacted to ethanol and toluene by undergoing diametrically opposite changes in fatty acid compositions (Heipieper and de Bont 1994). Toluene resulted in an increase in the saturation degree of fatty acids, whereas ethanol led to a decrease in this value. In A. flavithermus subsp. yunnanensis E13T, although the increase in straight-chain fatty acids caused by ethanol was much higher than that caused by toluene, the adjustment strategies of the fatty acids to the toxicities of both compounds were similar. When exposed to increasing concentrations of solvents, the relative amounts of straight-chain fatty acids (mainly C16:0) were increased (Fig. 2); however, the adaptive changes toward 3.0 % ethanol were slightly different: Only a minor decrease in C16:0 was observed. This behavior is probably related to the unusual property of A. flavithermus subsp. yunnanensis E13T in that it grows faster in the presence of low concentrations of ethanol. In addition, because the changes in fatty acids in the presence of toluene were not as drastic as those in the presence of ethanol at toxically equivalent concentrations, other mechanisms might play a significant role during toluene stress.

Studies concerned with changes in fatty acid composition toward thermophilic solvent-tolerant bacteria have been limited. There are only several investigations into ethanol-induced membrane alterations in thermophilic bacteria. T. pseudoethanolicus 39E-H8 produces long-chain (C30) α, ω-dicarboxylic acids under ethanol stress, which would decrease membrane fluidity (Burdette et al. 2002). An ethanol-adapted C. thermocellum strain increased saturated long-chain (>16) fatty acids and 16:0 plasmalogens, meanwhile it decreased C16:0, iso-C16:0 and other short-chain fatty acids, as a response to ethanol adaptation (Timmons et al. 2009). The result of fatty acids changes that increased membrane rigidity in A. flavithermus subsp. yunnanensis was similar to that reported in the two thermophilic bacteria. Thermophiles seem to depend on saturated fatty acids in response to the fluidizing effect of ethanol on the membranes, but the detailed response of fatty acids that are different according to every particular species. The changes in the amount of C16:0 were significant in A. flavithermus subsp. yunnanensis.

The effect of a single high temperature on fatty acid composition was similar to that of toluene; that is, a slight increase in the amount of straight-chain fatty acids with the countervailing branched-chain fatty acids. Many studies show that low growth temperature can offset the disruptive effect of a solvent, but high temperature intensifies the effect (Baer et al. 1987; Georgieva et al. 2007; Unell et al. 2007; Löffler et al. 2010). The results from A. flavithermus subsp. yunnanensis E13T were consistent with this rule, and the combined conditions of high temperature and ethanol caused a dramatic increase in straight-chain fatty acids. However, it was surprising to find that the increase was nonlinearly dependent on temperature. In particular, the amount of C16:0 could further increase quickly and became a major portion of fatty acids when the growth temperature rose from 55 to 60 °C. The difference in the amounts of C16:0 between 60 and 65 °C was much smaller. To our knowledge, these results give the first hint on the synergetic effects of combined high temperature and ethanol on the physical state of the membrane of solvent-tolerant bacteria.

References

Baer SH, Blaschek HP, Smith TL (1987) Effect of butanol challenge and temperature on lipid composition and membrane fluidity of butanol-tolerant Clostridium acetobutylicum. Appl Environ Microb 53:2854–2861

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Burdette DS, Jung SH, Shen GJ, Hollingsworth RI, Zeikus JG (2002) Physiological function of alcohol dehydrogenases and long-chain C (30) fatty acids in alcohol tolerance of Thermoanaerobacter ethanolicus. Appl Environ Microbiol 68:1914–1918

Dai J, Liu Y, Lei Y, Gao Y, Han F, Xiao YZ, Peng H (2011) A new subspecies of Anoxybacillus flavithermus ssp. yunnanensis ssp. nov. with very high ethanol tolerance. FEMS Microbiol Lett 320:72–78. doi:10.1111/j.1574-6968.2011.02294

de Carvalho CCCR, Da Cruz AARL, Pons MN, Pinheiro HMRV, Cabral JMS, da Fonseca MMR, Ferreira BS, Fernandes P (2004) Mycobacterium sp., Rhodococcus erythropolis, and Pseudomonas putida behavior in the presence of organic solvents. Microsc Res Tech 64:215–222. doi:10.1002/jemt.20061

de Carvalho CC, Parreno-Marchante B, Neumann G, da Fonseca MM, Heipieper HJ (2005) Adaptation of Rhodococcus erythropolis DCL14 to growth on n-alkanes, alcohols and terpenes. Appl Microbiol Biotechnol 67:383–388. doi:10.1007/s00253-004-1750-z

Duldhardt I, Gaebel J, Chrzanowski L, Nijenhuis I, Härtig C, Schauer F, Heipieper HJ (2010) Adaptation of anaerobically grown Thauera aromatica, Geobacter sulfurreducens and Desulfococcus multivorans to organic solvents on the level of membrane fatty acid composition. Microb Biotechnol 3:201–209. doi:10.1111/j.1751-7915.2009.00124

Fong JCN, Svenson CJ, Nakasugi K, Leong CTC, Bowman JP, Chen B, Neilan DRGBA, Rogers PL (2006) Isolation and characterization of two novel ethanol-tolerant facultative-anaerobic thermophilic bacteria strains from waste compost. Extremophiles 10:363–372. doi:10.1007/s00792-006-0507-2

Gao Y, Dai J, Peng H, Liu Y, Xu T (2011) Isolation and characterization of a novel organic solvent-tolerant Anoxybacillus sp. PGDY12, a thermophilic Gram-positive bacterium. J Appl Microbiol 110:472–478. doi:10.1111/j.1365-2672.2010.04903

Georgieva TI, Skiadas IV, Ahring BK (2007) Effect of temperature on ethanol tolerance of a thermophilic anaerobic ethanol producer Thermoanaerobacter A10: modeling and simulation. Biotechnol Bioeng 98:1161–1170. doi:10.1002/bit.21536

Heipieper HJ, de Bont JAM (1994) Adaptation of Pseudomonas putida S12 to ethanol and toluene at the level of fatty acid composition of membranes. Appl Environ Microbiol 60:4440–4444

Heipieper HJ, Diefenbach R, Keweloh H (1992) Conversion of cis unsaturated fatty acids to trans, a possible mechanism for the protection of phenol-degrading Pseudomonas putida P8 from substrate toxicity. Appl Environ Microbiol 58:1847–1852

Huffer S, Clark ME, Ning JC, Blanch HW, Clark DS (2011) Role of alcohols in growth, lipid composition, and membrane fluidity of yeasts, bacteria, and archaea. Appl Environ Microbiol 77:6400–6408. doi:10.1128/AEM.00694-11

Ingram LO (1976) Adaptation of membrane lipids to alcohols. J Bacteriol 125:670–678

Inoue A, Horikoshi K (1989) A Psuedomonas thrives in high concentrations of toluene. Nature 338:264–266

Kongpol A, Kato J, Vangnai AS (2008) Isolation and characterization of Deinococcus geothermalis T27, a slightly thermophilic and organic solvent-tolerant bacterium able to survive in the presence of high concentrations of ethyl acetate. FEMS Microbiol Lett 286:227–235. doi:10.1111/j.1574-6968.2008.01273

Kongpol A, Pongtharangkul T, Kato J, Honda K, Ohtake H, Vangnai AS (2009) Characterization of an organic-solvent-tolerant Brevibacillus agri strain 13 able to stabilize solvent/water emulsion. FEMS Microbiol Lett 297:225–233. doi:10.1111/j.1574-6968.2009.01684

Loffler C, Eberlein C, Mausezahl I, Kappelmeyer U, Heipieper HJ (2010) Physiological evidence for the presence of a cis-trans isomerase of unsaturated fatty acids in Methylococcus capsulatus bath to adapt to the presence of toxic organic compounds. FEMS Microbiol Lett 308:68–75. doi:10.1111/j.1574-6968.2010.01993

Nielsen LE, Kadavy DR, Rajagopal S, Drijber R, Nickerson KW (2005) Survey of extreme solvent tolerance in gram-positive cocci: membrane fatty acid changes in Staphylococcus haemolyticus grown in toluene. Appl Environ Microbiol 71:5171–5176. doi:10.1128/AEM.71.9.5171-5176.2005

Pepi M, Heipieper HJ, Fischer J, Ruta M, Volterrani M, Focardi SE (2008) Membrane fatty acids adaptive profile in the simultaneous presence of arsenic and toluene in Bacillus sp. ORAs2 and Pseudomonas sp. ORAs5 strains. Extremophiles 12:343–349. doi:10.1007/s00792-008-0147-9

Pini CV, Bernal P, Godoy P, Ramos JL, Segura A (2009) Cyclopropane fatty acids are involved in organic solvent tolerance but not in acid stress resistance in Pseudomonas putida DOT-T1E. Microb Biotechnol 2:253–261. doi:10.1111/j.1751-7915.2009.00084

Ramos JL, Duque E, Gallegos MT, Godoy P, Ramos-Gonzalez MI, Rojas A, Teran W, Segura A (2002) Mechanisms of solvent tolerance in gram-negative bacteria. Annu Rev Microbiol 56:743–768. doi:10.1146/annurev.micro.56.012302.161038

Rani KS, Seenayya G (1999) High ethanol tolerance of new isolates of Clostridium thermocellum strains SS21 and SS22. World J Microbiol Biotechnol 15:173–178

Teixeira H, Goncalves MG, Rozes N, Ramos A, San Romao MV (2002) Lactobacillus acid accumulation in the plasma membrane of Oenococcus oeni: a response to ethanol stress? Microb Ecol 43:146–153

Timmons MD, Knutson BL, Nokes SE, Strobel HJ, Lynn BC (2009) Analysis of composition and structure of Clostridium thermocellum membranes from wild-type and ethanol-adapted strains. Appl Microbiol Biotechnol 82:929–939. doi:10.1007/s00253-009-1891-1

Torres S, Pandey A, Castro GR (2011) Organic solvent adaptation of Gram positive bacteria: applications and biotechnological potentials. Biotechnol Adv 29:442–452. doi:10.1016/j.biotechadv.2011.04.002

Unell M, Kabelitz N, Jansson JK, Heipieper HJ (2007) Adaptation of the psychrotroph Arthrobacter chlorophenolicus A6 to growth temperature and the presence of phenols by changes in the anteiso/iso ratio of branched fatty acids. FEMS Microbiol Lett 266:138–143. doi:10.1111/j.1574-6968.2006.00502

Voelker TA, Davies HM (1994) Alteration of the specificity and regulation of fatty acid synthesis of Escherichia coli by expression of a plant medium-chain acyl-acyl carrier protein thioesterase. J Bacteriol 176:7320–7327

Williams TI, Combs JC, Lynn BC, Strobel HJ (2007) Proteomic profile changes in membranes of ethanol-tolerant Clostridium thermocellum. Appl Microbiol Biotechnol 74:422–432. doi:10.1007/s00253-006-0689-7

Zhang CM, Huang XW, Pan WZ, Zhang J, Wei KB, Klenk HP, Tang SK, Li WJ, Zhang KQ (2011) Anoxybacillus tengchongensis sp. nov. and Anoxybacillus eryuanensis sp. nov., facultatively anaerobic, alkalitolerant bacteria from hot springs. Int J Syst Evol Microbiol 61:118–122. doi:10.1099/ijs.0.020834-0

Acknowledgments

This work was supported by the National Natural Science Foundation of China (31270081).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Friedrich Widdel.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peng, H., Yi, L., Zhang, X. et al. Changes in the membrane fatty acid composition in Anoxybacillus flavithermus subsp. yunnanensis E13T as response to solvent stress. Arch Microbiol 199, 1–8 (2017). https://doi.org/10.1007/s00203-016-1266-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00203-016-1266-9