Abstract

In this paper, a new hybrid particle swarm optimization (HPSO) based on particle swarm optimization (PSO), evolutionary programming (EP), tabu search (TS), and simulated annealing (SA) is proposed. The aim of merging is to determine the optimal allocation of multi-type flexible AC transmission system (FACTS) controllers for simultaneously maximizing the power transfer capability of power transactions between generators and loads in power systems without violating system constraints. The particular optimal allocation includes optimal types, locations, and parameter settings. Four types of FACTS controllers are included: thyristor-controlled series capacitor, thyristor-controlled phase shifter, static var compensator, and unified power flow controller. Power transfer capability determinations are calculated based on optimal power flow (OPF) technique. Test results on IEEE 118-bus system and Thai Power 160-Bus system indicate that optimally placed OPF with FACTS controllers by the HPSO could enhance the higher power transfer capability more than those from EP, TS, and hybrid TS/SA. Therefore, the installation of FACTS controllers with optimal allocations is beneficial for the further expansion plans.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Electricity consumption tends to increase every year, where demands are driven in accordance with economic growth. Construction of new power plants, electrical power transmission and distribution lines may help to respond these requirements. However, it may take several years from the initial planning and designing throughout construction. Moreover, the pollution control, high cost of installations and operations, and the land acquisitions may be the disadvantages of these utilities. Therefore, to meet those increasing electricity consumption and demand, improving of existing electricity power generation system is much reasonably appropriated and can be applicable for many parts of the world.

It has been reported that Flexible AC Transmission System (FACTS) controllers can improve the efficiency of power transfer capability [1]. The advantages of FACTS controller include less cost of installations and operations, operating with none pollution, and providing flexible control of the existing transmission system [2].

FACTS controllers are power electronics based system and other static equipment that have the capability of controlling various electrical parameters in transmission networks [3]. These parameters can be adjusted to provide adaptability conditions of transmission network [4, 5]. There are many types of FACTS controllers such as thyristor-controlled series capacitor (TCSC), static var compensator (SVC), thyristor-controlled phase shifter (TCPS), and unified power flow controller (UPFC) [6]. These FACTS controllers have been proved to be used for enhancing system controllability resulted in total transfer capability (TTC) enhancement and minimizing power losses in transmission networks [7, 8].

Total transfer capability (TTC) is defined as an amount of electric power that can be transferred over the interconnected transmission network in a reliable manner while meeting all of a set of defined pre- and post-contingency system conditions [9]. TTC can be calculated by several power flow solution methods such as (1) linear ATC (LATC) method [10], (2) continuation power flow (CPF) method [11], (3) repetitive power flow (RPF) method [12], and (4) optimal power flow (OPF) based methods [13, 14].

The maximum performance of using FACTS controllers to increase TTC and minimize system losses should be obtained by choosing the suitable types, locations, and parameter settings [15–18]. The modern heuristics optimization techniques such as genetic algorithm (GA) [19], evolutionary programming (EP) [20, 21], tabu search (TS) [22, 23], simulated annealing (SA) [24, 25], and particle swarm optimization (PSO) [26, 27] are successfully implemented to solve complex problems efficiently and effectively [28, 29]. In [30], OPF using GA is used to consider the optimal allocations of SVC. Test results showed that the purposed method can minimize the overall cost function, including generation costs of power plants and investment costs. In [31], EP is used to determine the optimal allocation of four types of FACTS controllers. Test results indicated that optimally placed OPF with FACTS controllers by EP can enhance the TTC more than OPF without FACTS controllers. In [32] presents Dynamic Economic Dispatch (DED) based on a SA technique for the determination of the global or near global optimum dispatch solution. Numerical results for a sample test system have been presented to demonstrate the performance and applicability of the proposed method. In [33], TS is used to tested and examined with different objectives and different classes of generator cost functions to demonstrate its effectiveness and robustness. The results using the TS approach are compared with evolutionary programming and non-linear programming techniques. It is clear that the TS approach outperforms the classical and evolutionary algorithms. In [34], both GA and PSO are used to optimize the parameters of TCSC. However, there are more advantageous performances of the PSO than that of GA. PSO seems to arrive at its final parameter values in fewer generations than GA. PSO gives a better balanced mechanism and better adaptation to the global and local exploration abilities [35]. Furthermore, it can be applied to solve various optimization problems in electrical power system such as power system stability enhancement and capacitor placement problems [36–38].

On the other hand, these modern heuristic methods have some limitations. First, most of their used control variables give local answer values. Second, these methods use lots of CPU times, in order to find the better answer from the base case, without any additional stop criteria.

Therefore, in this study, the hybrid PSO (HPSO) is developed by merging PSO, EP, TS, and SA and aims to solve those limitations. In additional, multi sub-particle group technique is used. The proposed HPSO is used to determine locations, and parameter settings of four types of FACTS controller which are TCSC, TCPS, SVC, and UPFC to conduct TTC enhancement and minimize power losses are also investigated. The IEEE 118-bus system and practical Thai 160-bus system from Electricity Generating Authority of Thailand (EGAT) are used as the test systems. Test results are compared with those from EP, TS, and hybrid TS/SA [39].

2 Optimal power flow with FACTS controllers problem formulation

To determine the optimal number and allocation of FACTS controllers for TTC enhancement and power losses reduction, the objective function is formulated as maximization of TTC and minimization of power losses represented by Eq. (1). Power transfer capability is defined as TTC value: the sum of real power loads in the load buses at the maximum power transfer. TTC value can be transferred from generators in source buses to load buses in power systems subjected to real and reactive power generations limits, voltage limits, line flow limits, and FACTS controllers operating limits.

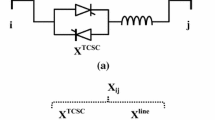

Four types of FACTS controllers include: thyristor-controlled series capacitor (TCSC), thyristor-controlled phase shifter (TCPS), static var compensator (SVC), and unified power flow controller (UPFC). TCSC is modeled by the adjustable series reactance. TCPS and UPFC are modeled using the injected power model [40]. SVC is modeled as shunt-connected static var generator or absorber.

Subject to

where

- \(F\) :

-

objective function,

Input variables

- \(P_{Gi}^{\min }, P_{Gi}^{\max }\) :

-

lower and upper limits of real power generation at bus \(i\),

- \(Q_{Gi}^{\min }, Q_{Gi}^{\max }\) :

-

lower and upper limits of reactive power generation at bus \(i\),

- \(V_i^{\min }, V_i^{\max }, V_j^{\min }, V_j^{\max }\) :

-

lower and upper limits of voltage magnitude at bus \(i\) and bus \(j\)

- \(S_{Li}^{\max }\) :

-

ith line or transformer loading limit,

- \(\delta _{ij}^\mathrm{crit}\) :

-

critical angle difference between bus \(i\) and \(j\),

- \(X_{Si}^{\min }, X_{Si}^{\max }\) :

-

lower and upper limits of TCSC at line \(i\),

- \(\alpha _{Pi}^{\min }, \alpha _{Pi}^{\max }\) :

-

lower and upper limits of TCPS at line \(i\),

- \(V_{Ui}^{\min }, V_{Ui}^{\max }\) :

-

lower and upper voltage limits of UPFC at line \(i\),

- \(\alpha _{Ui}^{\min }, \alpha _{Ui}^{\max }\) :

-

lower and upper angle limits of UPFC at line \(i\),

- \(Q_{Vi}^{\min }, Q_{Vi}^{\max }\) :

-

lower and upper limits of SVC at bus \(i\),

- \(N,\,NL\) :

-

number of buses and branches,

- \(NG\) :

-

number of generator buses,

- \(ND\_SNK\) :

-

number of load buses in a sink area, and

- \(n_{CFk}^{\max }\) :

-

maximum allowable component of FACTS controller type \(k\),

State variables

- \(V_{i},\,V_{j}\) :

-

voltage magnitudes at bus \(i\) and \(j\),

- \(\delta _{i},\,\delta _{j}\) :

-

voltage angles of bus \(i\) and \(j\), and

- \(P_{G1},\,Q_{G1}\) :

-

real and reactive power generations at slack bus,

Output variables

- \(P_{Gi},\,Q_{Gi}\) :

-

real and reactive power generations at bus \(i\),

- \(P_{Di},\,Q_{Di}\) :

-

real and reactive loads at bus \(i\),

- \(P_{Pi}(\alpha _{Pk})\) :

-

injected real power of TCPS at bus \(i\),

- \(Q_{Pi}(\alpha _{Pk})\) :

-

injected reactive power of TCPS at bus \(i\),

- \(P_{Ui}(V_{Uk,}\alpha _{Uk})\) :

-

injected real power of UPFC at bus \(i\),

- \(Q_{Ui}(V_{Uk,}\,\alpha _{Uk})\) :

-

injected reactive power of UPFC at bus \(i\),

- \(Y_{ij}(X_{S}),\,\theta _{ij}(X_{S})\) :

-

magnitude and angle of the ijth element in bus admittance matrix with TCSC included,

- \(m(i)\) :

-

number of injected power from TCPS at bus \(i\),

- \(n(i)\) :

-

number of injected power from UPFC at bus \(i\),

- \({\vert }S_{Li}{\vert }\) :

-

ith line or transformer loading,

- \(VCPI_{i}\) :

-

voltage collapse proximity indicator at bus \(i\),

- \({\vert }\delta _{ij}{\vert }\) :

-

angle difference between bus \(i\) and \(j\),

- \(X_{Si}\) :

-

reactance of TCSC at line \(i\),

- \(\alpha _{Pi}\) :

-

phase shift angle of TCPS at line \(i\),

- \(V_{Ui},\,\alpha _{Ui}\) :

-

voltage magnitude and angle of UPFC at line \(i\),

- \(Q_{Vi}\) :

-

injected reactive power of SVC at bus \(i\),

- \(n_{CFk}\) :

-

integer value of number of FACTS component type \(k\), and

- \(\textit{location}_k\) :

-

integer value of line or bus location of FACTS controller type \(k\).

This paper considers voltage collapse proximity indicator (VCPI), thermal line flow limit, and static angle stability constraint [41–43]. The limits are treated as OPF constraints in Eqs. (7), (8), and (9), respectively. During the optimization, inequality constraints are enforced using a penalty function in Eqs. (17) and (18).

where

- PF :

-

penalty function,

- \(x^{\min },\,x^{\max }\) :

-

lower and upper limits of variable \(x\), and

- \(k_{p},\,k_{q},\,k_{v}\) :

-

penalty coefficients for real power generation at slack bus, reactive power generation of all PV buses and slack bus, and bus voltage magnitude, respectively, and

- \(k_{s},\,k_{d},\,k_{vi}\) :

-

penalty coefficients for line loading, angle difference, and voltage stability index, respectively.

By experiments, the penalty coefficients are set to \(10^{6}\) in all terms since the lower coefficient values result in an oscillation of HPSO solution. The suggested range of penalty coefficient is \(10^{3}-10^{6 }\) [44].

3 Hybrid particle swarm optimization (HPSO)

To improve the heuristics optimization techniques, a new HPSO approach integrating PSO, EP, TS, and SA algorithms is proposed. The flowchart of HPSO is shown as Fig. 1. Special features and merits of HPSO can be described as follows:

-

1.

Multiple sub-particle group searches with various velocity calculating are designed to enhance search diversity and improve particle update. These aims to provide higher quality of solutions than those from single particle group search.

-

2.

Various initializations are used. The represent vector solutions will have various and different initial values.

-

3.

First and second sub-particle group for HPSO speed calculations are the original weight and the temperature value of SA, respectively.

-

4.

Tournament strategy is used for competition between the parent and offspring particle in each sub-particle group.

-

5.

Selection with a probabilistic updating strategy, based on TS and annealing schedule of SA, is applied to avoid dependency on fitness function and to avoid being trapped in local optimal solutions.

-

6.

Crossover strategy is carried out to fuse and exchange the search information of all sub-particle groups. So that premature convergence caused by consistency of particles in a single particle group will be alleviated.

-

7.

In each of all sub-particle groups, the best gBest value will be set as “gBest”, to make the various goal of each particle.

The HPSO is used to simultaneously search for real power generations in a source area. Slack bus, generation bus voltages, real power loads in a sink area, and optimal placement of multi-type FACTS controller for determining maximum TTC value are excluded. HPSO approach can be shown as Fig. 1, which can be explained as follows.

3.1 Representation of solution

Each particle consists of OPF control variables coded by real number. The whole particle group \(P\) is divided into \(M\) sub-particle groups according to the number of mutation operators used. The \(i\)th particle in a particle group is represented by a trial vector in Eq. (19).

There are four types of FACTS controllers with maximum allowable. \(n_{CFk}\) component for each type is assigned as input data. The placement configuration is represented by three parameters: \(n_{CFk}\), \(\textit{location}_{k}\), and \(\textit{parameter}_{k}\) given in Eq. (20). For FACTS controller type, \(k\in \{1,2,3,4\}\) representing placement configuration of TCSC, TCPS, UPFC, and SVC, respectively while the number of FACTS controller type \(k,\,n_{CFk} = 1\). Therefore, locations, and parameters of each type of FACTS controllers are simultaneously searched by the HPSO.

where

- \(S_{p}\) :

-

trial solution vector of the \(p\)th particle,

- \(V_{Gi}\) :

-

voltage magnitude of generator at bus \(i\) including slack bus,

- \(Loc_{k}\) :

-

allocation vector of FACTS controller type \(k\),

- \(n_{CFk}\) :

-

number of FACTS controller, \(n_{CFk} = 1\),

- \(\textit{location}_{k}\) :

-

line or bus location of FACTS controller type \(k\), and

- \(\textit{parameter}_{k}\) :

-

parameter settings of FACTS controller type \(k\).

3.2 Initialization

Each element of the trial vector is initialized randomly within its search space using uniform random number in Eqs. (21) and (22), respectively.

where

- \(x(i)\) :

-

ith element of the particle in a particle group,

- \(x_{\min }\) :

-

lower limit of the \(i\)th element of the particle,

- \(x_{\max }\) :

-

upper limit of the \(i\)th element of the particle, and

- \(x_{random}\) :

-

uniform random number in the interval [0,1].

3.3 Power flow solution

During iterations, a full AC Newton–Raphson (NR) power flow analysis is used to check the feasibility of each particle solution.

3.4 Fitness function

The extended objective function in Eq. (1) is taken as the fitness function of the HPSO approach.

3.5 Cooling schedule procedure

The initial temperature of each sub-particle group is determined in Eq. (23). The temperature is cooled down by the temperature annealing function or cooling schedule in Eq. (24).

where

- \(T_{0,m}\) :

-

initial temperature of the \(m\)th sub-particle group,

- \(F_m^{\min },F_m^{\max }\) :

-

objective value of the worst and the best particles in the \(m\)th sub-particle group,

- \(Pr\) :

-

probability of accepting the worst particle with respect to the best particle,

- \(T_{r,m}\) :

-

annealing temperature of the \(m\)th sub-particle group after the \(r\)th reassignment,

- \(\lambda _r\) :

-

rate of cooling, and iteration counter of reassignment strategy.

3.6 Performing PSO

Different PSO weights are used to create new particles of different sub-particle group, so, many hybrid operators are applied to enhance the search diversity. Two PSO weights including original weight and temperature value of SA are applied. Velocity of each particle can be modified by Eq. (25) [45, 46].

where

- \(v_i^k\) :

-

velocity of particle \(i\)th at iterations \(k\),

- \(w\) :

-

weight function,

- \(c_1\) and \(c_2\) :

-

weighting coefficients both equal to 2,

- \(rand_1\) and \(rand_2\) :

-

random number between 0 and 1,

- \(s_i^k \) :

-

current positions of particle \(i\)th at iteration \(k\),

- \(p_{best_i}\) :

-

best position of particle \(i\)th up to the current iteration, and

- \(g_{best}\) :

-

best overall position found by the particles up to the current iteration.

Weight function of first sub-particle group is given by Eq. (26)

where

- \(w_{\max }\) :

-

max initial weight equal to 0.9,

- \(w_{\min }\) :

-

min weight equal to 0.4,

- \(\textit{iter}_{\max }\) :

-

maximum iteration number, and

- \(iter\) :

-

current iteration number.

Weight function of second sub-particle group is given by Eq. (27).

Each element of the new particle of first and second sub-particle group is calculated in Eq. (28).

where

- \(v_i^{k+1}\) :

-

new velocity of particle \(i\)th at iterations, and

- \(s_i^{k+1}\) :

-

new positions of particle \(i\)th at iteration \(k\)

3.7 Selection strategy

The selection technique utilized is a tournament scheme, which can be computed from Eqs. (29) and (30).

where

- \(w_t\) :

-

weight value of each opponent,

- \(f_{k}\) :

-

fitness value of the \(k\)th particle,

- \(f_{r}\) :

-

fitness of the \(r\)th opponent randomly selected from the combined -particle group based on \(r=\left\lfloor {2*P*u+1} \right\rfloor \),

- \(\left\lfloor x \right\rfloor \) :

-

the greatest integer less than or equal x,

- \(u\) :

-

uniform random in the interval [0,1],

- \(P\) :

-

particle group size,

- \(s_{k}\) :

-

total score of each \(k\)th particle, and

- Nt :

-

number of the opponents.

3.8 Tabu list

Tabu list may be viewed as a “meta-heuristic” superimposed on another heuristic method. It is designed to jump over from local optimal and prevent the cycling movement. It stores movement of solution and forbids backtracking to previous movement [47, 48].

3.9 Aspiration criterion

The aspiration criterion in Eq. (31) adopts a probabilistic acceptance criterion of SA. When the probabilistic acceptance criterion is higher than a uniform randomly generated variable in the interval [0,1], the tabu restriction is overruled.

where

- \(p_{k,m}\) :

-

probabilistic acceptance criterion of the \(k\)th offspring particle within the \(m\)th sub-particle group,

- \(\Delta \) :

-

difference of objective values between the \(k\)th offspring particle and its corresponding parent particle, i.e. the \(k\)th parent particle.

3.10 Termination criteria

There are two termination criteria used in the proposed HPSO approach. It will stop whenever any one of two criteria is met. The first termination criterion is set as the maximum number of iteration. The second termination criterion is no improvement of the best fitness within 20 iterations. In addition, these criteria are applied to all the methods for a fair comparison.

4 Case study and experimental result

The IEEE 118-bus and Thai Power 160-bus systems were used to demonstrate the optimal placement of multi-type FACTS controllers using the HPSO approach. Test results from HPSO were compared to those from EP, TS, and hybrid TS/SA methods.

The reactance limit of TCSC in p.u. was \(0\le X_{si} \le 60\) % of line reactance, phase shifting angle limit of TCPS was \(-\frac{\pi }{4}\le X_{si} \le \frac{\pi }{4}\) radian, voltage limit of UPFC was \(0\le V_{Ui} \le 0.1\) p.u., angle limit of UPFC was \(-\pi \le \alpha _{Ui} \le \pi \) radian, and reactive power injection limit of SVC was \(0\le Q_{Vi} \le 10\) MVAR. Loads were modeled as constant power factor loads. The population sizes of EP, TS and hybrid TS/SA were set to 30. The particle group sizes of each sub-particle group of HPSO were set to 30. The maximum iteration numbers of EP, TS, and hybrid TS/SA were set to 400. The \(\hbox {Gen}_{\max }\) and \(\hbox {L}_{\max }\)of HPO were set to 20.

4.1 The IEEE 118-bus system

The first test system was the IEEE 118-bus system which consisted of 54 generating plants, 64 load buses, and 186 lines. The system data could be found in [49]. Base case TTC of IEEE 118-bus system equaled 1,433.00 MW. Comparisons of TTC results and average CPU times from 20 runs showed in Table 1. The reported CPU time was the total computation time of HPSO algorithm from starting to ending, including the NR power flow of all particles.

Better results on the best, average, and the worst TTC values could be obtained by HPSO than those from the other methods. These effective results by HPSO might be due to the uses of various weight values for each sub-particle group. In addition, the selection mechanism with a probabilistic updating strategy based on TS which aimed to avoid dependency on fitness function, could step over from the local optimal solutions. The allocation of all FACTS controllers were represented in Table 2.

4.2 The Thai power 160-bus system

A practical single line diagram of Thai 230 and 500 kV network consisted of 42 generating plants, 82 load buses, and 185 lines. Base case TTC of Thai Power 160-bus system equaled 11,756.01 MW. The HPSO approach had optimally placed multi-type FACTS controllers (Table 3).

Using HPSO, the best TTC value was 13,530.08 MW, which was 13.11 % increased comparing to the base case without FACTS controllers. In addition, the TTC values were higher than those from EP, TS, and hybrid TS/SA methods. The optimal placements of FACTS controllers showed in Table 4. Test results indicated that TS and hybrid TS/SA cannot evaluate better TTC from the base case value in the large and complex system like this practical test system. Besides, single-population search of EP, TS, and hybrid TS/SA was less effective than multi sub-particle group search of HPSO methods in determining the best, the average and the worst TTC, respectively. Moreover, HPSO had various gBest and various weight values for each sub-particle group which were powerful to step over from local optimal solutions and provided better TTC. In additional, the HPSO required slightly higher computing time for convergence to global optimal.

5 Conclusion

In this paper, new-developed-HPSO with sub-particle group was proposed to determine the optimal allocations of multi-type FACTS controllers. The overall results from both systems indicated that optimally placing OPF with FACTS controllers by HPSO could effectively and successfully enhance the power transfer capability from base case and gave higher TTC than those from EP, TS, and hybrid TS/SA, under normal and contingency conditions. Therefore, the installation of multi-type FACTS controllers with optimal allocation using HPSO are worthwhile and beneficial for the decision making of investment costs and further expansion plans.

References

Song YH, Johns AT (1999) Flexible AC transmission system (FACTS). IEE Power and Energy Series 30

Abdel-Moamen MA, Padhy NP (2003) Optimal power flow incorporating FACTS devices-bibliography and survey. In: IEEE PES transmission and distribution conference and exposition 2003

IEEE Power Engineering Society (1995) FACTS Overview. Cigre 95 TP108

Hingorani NG, Gyugyi L (1999) Understanding FACTS: concepts and technology of flexible AC transmission systems. Wiley, New York

IEEE Power Engineering Society (1995) FACTS Applications

FACTS Terms & Definitions Task Force of the FACTS Working Group of the DC and FACTS Submittee (1997) Proposed terms and definitions for flexible AC transmission system (FACTS). IEEE Trans Power Deliv 12(4)

Ren H, Watts D, Mi Z, Lu J (2009) A review of FACTS’ practical consideration and economic evaluation. In: Power and energy engineering conference (APPEEC 2009)

Chung TS, Shaoyun G (1998) Optimal power flow incorporating FACTS devices and power flow control constraints. In: Proceedings international conference power system technology

Ejebe GC, Waight JG, Manuel SN, Tinney WF (2000) Fast calculation of linear available transfer capability. IEEE Trans Power Syst 15:1112–1116

Ejebe GC (1998) Available transfer capability calculations. IEEE Trans Power Syst 13:1521–1527

Gravener MH, Nwankpa C (1999) Available transfer capability and first order sensitivity. IEEE Trans Power Syst 14:512–518

Ou Y, Singh C (2002) Assessment of available transfer capability and margins. IEEE Trans Power Syst 17:463–468

Dommel HW, Tinney WF (1968) Optimal power flow solutions. IEEE Trans Power Appar Syst 10:1866–1876

Alsac O, Stott B (1974) Optimal load flow with steady-state security. IEEE Trans Power Appar Syst 93:745–751

Feng W, Shrestha GB (2001) Allocation of TCSC devices to optimize total transmission capacity in a competitive power market. In: Proceedings IEEE power engineering society winter meeting

Gerbex S, Cherkaoui R, Germond AJ (2001) Optimal location of multi-type FACTS devices in a power system by means of genetic algorithms. IEEE Trans Power Syst 16:537–544

Ou Y, Singh C (2001) Improvement of total transfer capability using TCSC and SVC. In: Proceedings IEEE power engineering society summer meeting

Xiao Y, Song YH, Liu CC, Sun YZ (2003) Available transfer capability enhancement using FACTS devices. IEEE Trans Power Syst 18:305–312

Goldberg DE (1989) Genetic algorithm in search: optimization and machine learning. Addison Wesley Publishing Company, USA

Fogel LJ, Owens AJ, Walsh MJ (1966) Artificial intelligence thorough simulated evolution. Wiley, Chichester

Yuryevich J, Wong KP (1999) Evolutionary programming based optimal power flow algorithm. IEEE Trans Power Syst 14:1245–1250

Glover F, Laguna M (1993) Tabu search. In: Modern heuristic techniques for combinatorial problems. Wiley

Glover F, Laguna M (1997) Tabu search. Kluwer Academic Publishers, Dordrecht

Kirkpatrick S, Gelett CD, Vecchi MP (1983) Optimization by simulated annealing. Science 220(4598):671–680

Bertsimas D, Tsitsiklis J (1993) Simulated annealing. Stat Sci 8:10–15

Kennedy J, Eberhart R (1995) Particle swarm optimizatio. In: IEEE international conference of neural networks

Abido MA (2002) Optimal power flow using particle swarm optimization. Int J Electr Power Energy Syst 24:563–571

AlRashidi MR, El-Hawary ME (2009) Applications of computational intelligence techniques for solving the revived optimal power flow problem. Electr Power Syst Res 79:694–702

Paliwal P, Patidar NP, Nema RK (2012) A comprehensive survey of optimization techniques used for distributed generator siting and sizing. In: IEEE southeast conference

Metwally MME, Emary AAE, Bendary FME, Mosaad MI (2008) Optimal allocation of FACTS device in power system using genetic algorithm. In: 12th international middle-east power system conference, MEPCON 2008

Ongsakul W, Jirapong P (2005) Optimal allocation of FACTS devices to enhance total transfer capability using evolutionary programming. In: International symposium on circuits and systems

Panigrahi CK, Chattopadhyay PK, Chakrabarti RN, Basu M (2006) Simulated annealing technique for dynamic economic dispatch. Electr Power Compon Syst 34:577–586

Abido MA (2002) Optimal power flow using tabu search algorithm. Electr Power Compon Syst 30:469–483

Panda S, Padhy NP (2008) Comparison of particle swarm optimization and genetic algorithm for FACTS-based controller design. Appl Soft Comput 8:1418–1427

Chansareewittaya S, Jirapong P (2010) Power transfer capability enhancement with multitype FACTS controller using particle swarm optimization. In: TENCON2010

Alrashidi MR, El-Hawary ME (2006) A survey of particle swarm optimization applications in power system operations. Electr Power Compon Syst 34:1349–1357

Al-Awami AT, Abdel-Magid YL, Abido MA (2007) A particle-swarm-based approach of power system stability enhancement with unified power flow controller. Int J Electr Power Energy Syst 29:251–259

Oo NW (2008) A comparision study on particle swarm and evolutionary particle swarm optimization using capacitor placement problem. In: 2nd IEEE international conference on power and energy

Ongsakul W, Bhasaputra P (2002) Optimal power flow with FACTS devices by hybrid TS/SA approach. Int J Electr Power Energy Syst 24:851–857

Bhasaputra P, Ongsakul W (2002) Optimal power flow with multitype FACTS devices by hybrid TS/SA approach. In: IEEE ICIT’02

Chebbo AM, Irving MR, Sterling MJH (1992) Voltage collapse proximity indicator: behaviour and implications. In: Proceeding institute of electrical engineering, generation, transmision and distribution

Canizares CA (2000) Power flow and transient stability models of FACTS controllers for voltage and angle stability studies. In: Proceedings IEEE power engineering society

Yue Y, Kubokawa J, Nagata T, Sasaki H (2003) A solution of dynamic available transfer capability by means of stability constrained optimal power flow. In: Proceedings IEEE Bologna power technology conference

Wood AJ, Wollenberg BF (1996) Power generation, operation, and control, 2nd edn. Wiley, New York

Eberhart R, Kennedy J (1995) A new optimizer using particle swarm theory. In: Proceedings of the sixth international symposium on micro machine and human science

Lee KY, Mohamed AE (2008) Modern heuristics optimizaion techniques. Wiley, New York

Glover F (1989) Tabu search, part I. ORSA J Comput 1:190–206

Glover F (1990) Tabu search, part II. ORSA J Comput 2:4–32

Power Systems Engineering Research Center (PSERC). http://www.eng.nsf.gov/iucrc/

Acknowledgments

This work was supported in part by the Energy Policy and Planning Office (EPPO), Ministry of Energy, Thailand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chansareewittaya, S., Jirapong, P. Power transfer capability enhancement with multitype FACTS controllers using hybrid particle swarm optimization. Electr Eng 97, 119–127 (2015). https://doi.org/10.1007/s00202-014-0317-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-014-0317-y