Abstract

Electric power systems, around the globe, are changing in terms of structure, operation, management, and ownership due to technical, financial, and ideological reasons. Recent trend involves augmentation of power systems in terms of geographical area, assets additions, and penetration of new technologies in generation, transmission, and distribution sectors. In this regard, flexible alternative current transmission system (FACTS) devices play a key role in enhancing controllability and increasing power transfer capability of the network. Thyristor-controlled series compensator (TCSC) is an emerging FACTS device designated to achieve this objective. The conventional methods in solving optimization problems in power systems suffer from several limitations due to necessities of derivative existence, providing suboptimal solutions, etc. Computational intelligence plays an important role in determining the optimal solutions for multiobjective functions. A combinatorial analysis problem in power systems can be solved by modern heuristic methods in finding optimal solution. Thus, in this paper, particle swarm optimization (PSO), a wing of evolutionary computation (EC) encapsulated with heuristic approach, has proposed for finding optimal location of TCSC. An IEEE standard 5-bus and 14-bus systems have been considered to test the credibility of the proposed algorithm. The simulation result proved the efficiency of the proposed approach by optimal placement of the FACTS device to minimize the losses and to improve the power transfer in a power system network.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Computational intelligence

- Particle swarm optimization (PSO)

- Flexible alternative current transmission system (FACTS)

- Thyristor-controlled series compensator (TCSC)

- Loss reduction

- Power transfer capability

1 Introduction

Electric power systems have forced to operate to almost their full capacities due to the environmental and/or economic constraints to build new generating plants and transmission lines. The amount of electric power that can transmit between two locations through a transmission network is limited by security and stability constraints. Power flow in the lines and transformers should not be allowed to increase to a level where a random event could cause the network collapse because of angular instability, voltage instability, or cascaded outages [1]. Hence, economic operation of power system along with the assurance of refined quality of power supply to consumers is a challenging task. Due to the introduction of deregulation in electricity market, installation of flexible alternative current transmission system (FACTS) devices has become inevitable [3]. Because of the economic considerations, installation of FACTS controllers in all the buses or the lines in a system is not feasible. There are several sensitivity-based methods for finding optimal locations of FACTS devices in power systems described [4]. However, it is required to find the optimal location of FACTS devices by heuristic method to overcome both economical and technical barriers in accomplishing the objective. The use of thyristor-controlled series compensator (TCSC) which is a FACTS device gives a number of benefits for the user of the grid, all contributing to increase the power transmission capability of new as well as existing transmission lines. These benefits include improvement in system stability, voltage regulation, reactive power balance, load sharing between parallel lines, and reduction in transmission losses [2]. Optimal location of TCSC is a task assigned to particle swarm optimization (PSO) where PSO is an approach to find optimal solutions for search problems through application of the principles of swarm intelligence technique [4]. The sensitivity analysis has been carried out for the location of the different FACTS devices for the solution of optimal power flow [5]. System load ability can be increased using evolutionary strategies that use different types of FACTS controllers have been discussed [6]. The application of PSO method for location of FACTS devices to achieve maximum system load ability with minimum cost of installation of FACTS devices has been evaluated [7].

This paper has focused on loss reduction and to increase the power transfer capability of the transmission line by optimal location of TCSC using PSO technique in a power system. An overview of modeling of TCSC and brief description of PSO are presented in Sects. 2 and 3.1, respectively. Optimal location of TCSC using PSO has explained in Sect. 4.1.2, which elaborates the traits of an IEEE 5-bus and 14-bus systems under consideration. It also reveals the results obtained on applying the evolutionary strategy to solve the optimization problem. Finally, the conclusion of the paper is described in Sect. 5.

2 Thyristor-Controlled Series Compensator Modeling

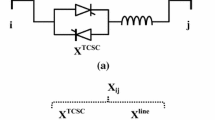

The IEEE TCSC is a capacitive reactance compensator, which consists of three main components: capacitor bank C, bypass inductor L, and bidirectional thyristors SCR1 and SCR2 [8]. Series capacitive compensation has used to increase line power transfer as well as to enhance system stability. Figure 1 shows the main circuit of a TCSC.

The firing angles of the thyristors are controlled to adjust the TCSC reactance according to the system control algorithm, normally in response to some system parameter variations. According to the variation in the firing angle, this process can modeled as a fast switch between corresponding reactance offered to the power system. Assuming that the total current passing through the TCSC is sinusoidal, the equivalent reactance at the fundamental frequency can represented as a variable reactance \( \mathop X\nolimits_{\text{TCSC}} \).

The TCSC can control to work in either the capacitive or the inductive zones avoiding steady-state resonance [8]. There exists a steady-state relationship between the firing angle α and the reactance \( \mathop X\nolimits_{\text{TCSC}} \), as described by the following equation [8]:

where,

where α is the firing angle, X L is the reactance of inductor, and X l is the effective reactance of inductor at firing angle [8].

A model of transmission line with a TCSC connected between bus i and bus j is shown in Fig. 2. During the steady state, the TCSC has considered as a static reactance −jx c . The controllable reactance x c is directly used as a control variable in the power flow equations.

The real power injections at bus i(P ic ) and bus j(p jc ) are given by the following equations [2]:

Similarly, the reactive power injections at bus i(Q ic ) and bus j(Q jc ) can be expressed as follows:

where

where ∆G ij and ∆B ij are the changes in conductance and susceptance of the line i and line j, respectively.

This model of TCSC is used to properly modify the parameters of transmission lines with TCSC for optimal location.

3 Proposed Method

3.1 Particle Swarm Optimization

The inherent rule adhered by the members of birds and fishes in the swarm enables them to move and synchronize, without colliding, resulting in an amazing choreography, which was the basic idea of PSO technique. PSO is similar to evolutionary computation (EC) techniques in which a population of potential solutions to the problem under consideration has used to probe the search space. The major difference between the EC techniques and swarm intelligent (SI) techniques is that EC technique uses genetic operators, whereas SI techniques use the physical movements of the individuals in the swarm. PSO has developed through simulation of bird flocking in two-dimensional space. The position of each agent is represented in X–Y plane with position (Sx, Sy), Vx (velocity along X-axis), and Vy (velocity along Y-axis). Modification of the agent position has realized by the position and velocity information. Bird flocking optimizes a certain objective function. Each agent knows its best value so far, called ‘Pbest’, which contains the information on position and velocities. This information is the analogy of personal experience of each agent. Moreover, each agent knows the best value so far in the group, ‘Gbest’ among all ‘Pbest’. This information is the analogy of knowledge, how the other neighboring agents have performed. Each agent tries to modify its position by considering current positions (Sx, Sy), current velocities (Vx, Vy), the individual intelligence (Pbest), and the group intelligence (Gbest).

The following equations are utilized, in computing the position and velocities, in the X–Y plane:

where

- \( \mathop {v_{i} }\nolimits^{k + 1} \) :

-

Velocity of ith individual at (k + 1)th iteration;

- \( \mathop {v_{i} }\nolimits^{k} \) :

-

Velocity of ith individual at kth iteration;

- W :

-

Inertial weight;

- C 1, C 2 :

-

Positive constants both equal to 2;

- rand1 :

-

Random number selected between 0 and 1;

- rand2 :

-

Random number selected between 0 and 1;

- Pbesti :

-

Best position of the ith individual;

- Gbest :

-

Best position among the individuals (group best);

- \( \mathop {s_{i} }\nolimits^{k} \) :

-

Position of ith individual at kth iteration;

The velocity of each agent has modified according to (9), and the position has modified according to (10). The inertia weight ‘W’ is modified using (11), to enable quick convergence.

where

- W max :

-

Initial value of inertia weight;

- W min :

-

Final value of inertia weight;

- Iter:

-

Current iteration number;

- Itermax :

-

Maximum iteration number

3.2 Problem Formulation Equations

Equations that considered for optimization to reduce the losses are given below.

-

\( P_{gi} ,Q_{gi} \) are the real and reactive power generation at bus i.

-

\( P_{di} ,Q_{di} \) are the real and reactive power demands at bus i.

-

\( V_{i} ,\delta_{i} \) are voltage and angles at bus i.

-

\( P_{gi,\hbox{min} } ,P_{gi,\hbox{max} } \) real power minimum and maximum generation limits at bus i.

-

\( Q_{gi,\hbox{min} } ,Q_{gi,\hbox{max} } \) reactive power minimum and maximum generation limits at bus i.

-

\( P_{di,\hbox{min} } ,P_{di,\hbox{max} } \) real power minimum and maximum demand limits at bus i.

-

\( Q_{di,\hbox{min} } ,Q_{di,\hbox{max} } \) reactive power minimum and maximum demand limits at bus i.

-

In the objective function, \( C_{Gi} (P_{Gi} ) \) is cost function for generating real power \( P_{Gi} \) at bus i, and \( B_{Di} (P_{Di} ) \) is the demand function.

-

N number of lines

-

V voltage at the bus

3.3 Proposed Algorithm for Location of TCSC

The algorithm steps for the proposed optimal placement of TCSC device with PSO are as follows:

-

Step 1:

Initialize the line and bus parameters, particle size, and maximum number of iterations.

-

Step 2:

The initial population of individuals is created satisfying the FACTS device constraints given by (17), and it has verified that only one device is placed in each line individually.

-

Step 3:

Using initial parameters, run load flow to find losses using Newton–Raphson method.

-

Step 4:

Populate the dependent variable, that is, voltage between its limits with the number of populations mentioned.

-

Step 5:

Calculate the power loss using dependent variables.

-

Step 6:

The minimum power loss and its position are taken as the P best(position) and fP best(power loss)

-

Step 7:

Update each population with the new population and run load flow with modified admittance matrix, which reflects the reactive power injected variation.

-

Step 8:

Iteration starts from this point.

-

Step 9:

Process from Step 4 and Step 5 repeated until the stopping criterion, which is the total number of iteration, reached.

-

Step 10:

The P best value becomes the best for the 1st iteration.

-

Step 11:

From the 2nd iteration, the new P best compared with the Gbest, that is, update and interchanges for the lower power loss.

-

Step 12:

Check whether the final best individual obtained satisfies the above equations, which means that the load voltage magnitude deviations and real power losses are minimum.

-

Step 13:

After the final iteration, the G best value and its position are taken to find the placement of TCSC.

-

Step 14:

Stop the process.

4 Simulation Result

4.1 Case Study of IEEE 5-bus System

One line diagram of the above system has shown in Fig. 3. The system consists of 5 buses, 7 branches, and generators connected to buses 1, 2, and 3. The range of TCSC is taken as −0.8 to +0.2 % from line reactance, and the power flow has carried out before and after placing the TCSC to determine their benefits.

4.1.1 Line Flow for 5-bus System

The load flow analysis by Newton–Raphson method has been carried out using MATLAB, and the results are tabulated as shown in Table 1.

4.1.2 Optimal Location of TCSC Found by the PSO Method

Proposed PSO methodology has applied to the IEEE 5-bus system. In this paper, reactance of TCSC has considered as variable parameter. From the simulation results, we can infer that TCSC has been optimally located in one of the seven branches where minimum loss occurs rather than locating all the branches, which in turn reduces the cost. The location of TCSC and the corresponding reactance with PSO method have tabulated in Table 2.

It has noticed that the insertion of the TCSC found by PSO method into the system has resulted in:

-

Total P loss reduces, real power flow increases, reactive flow changes, and optimal location of TCSC is in 4th branch.

-

Graph of line loss verses branch shown in Fig. 4 and graph of power flow verses branch shown in Fig. 5.

4.2 Case Study of IEEE 14-bus System

The data of the IEEE 14-bus system are given in Fig. 6. The system consists of 14 buses, 20 branches, and generators connected to buses 1 and 2. The reactive power sources connected to buses 3, 6, and 8.

Data: S base = 100 MVA, V max = 1.06 p.u, V min = 0.94 p.u, P max gen. at bus 1 = 250 MW, P max gen .at bus 2 = 50 MW, Q max gen. at bus 1 = 10 MVAr, Q max gen. at bus 2 = 50 MVAr, Q max gen. at bus 3 = 40 MVAr, Q max gen. at bus 6 = 24 MVAr, Q max gen. at bus 8 = 24 MVAr, Q min gen. at bus 1 = 0 MVAr, Q min gen. at bus 2 = −40 MVAr, Q min gen. at bus 3 = 0 MVAr, Q min gen. at bus 6 = −6 MVAr, Q min gen. at bus 8 = −6 MVAr.

4.2.1 Line Flow for 14-bus System

The line losses and power generation as per Newton–Raphson method have given in Table 3.

4.2.2 Optimal Location of TCSC Found by the PSO Method

Proposed PSO methodology has been applied to IEEE 14-bus systems. The location of TCSC and the corresponding reactance with PSO method have been tabulated in Table 4.

PSO method into the system has resulted in:

-

Total P loss reduces, real power flow increases, change in reactive flow, and optimal location of TCSC is in 17th branch.

-

Graph of line loss verses branch shown in Fig. 7 and graph of power flow verses branch shown in Fig. 8.

4.3 Summary of the Results

5-bus system | 14-bus system | |||

|---|---|---|---|---|

Parameter | Without PSO | With PSO | Without PSO | With PSO |

Real power flow in MW | 18.221 (Line 2–4) | 34.531 | 9.932 (Line 9–14) | 12.345 |

Total loss | 3.055 MW | 3.0 MW | 14.288 MW | 14.283 MW |

Degree of compensations | 5 % | 5 % | ||

5 Conclusion

It can be observed from the results that using PSO method, TCSC has been optimally placed in a weak line of the system and resulted in loss reduction in the lines. The total loss effectively reduces and resulted in a loss reduction, and it increases the power transfer capability of the line. Hence, this method can be extended to any practical systems with more number of buses. Further, the same method can also be effectively applied to shunt FACTS devices to enhance the voltage stability.

References

Ramasubramanianl P, Uma Prasana G, Sumathi K (2012) Optimal location of FACTS devices by evolutionary programming based OPF in deregulated power systems. Br J Math Comput Sci 2(1):21–30

Rajalakshmi L et al (2011) Congestion management in deregulated power system by locating series FACTS devices. IJCA 13(8)

Kodsi SKM, Cañizares CA (2003) Modelling and simulation of IEEE 14 bus system with FACTS controllers. IEEE benchmark technical report

Venayagamoorthy GK, Harleyl RG (2007) Swarm intelligence for transmission system control. 1-4244-1298- 6/07/IEEE 2007

Chandrasekarn K et al (2005–2009) A new method to incorporate FACTS devices in optimal power flow using particle swarm optimization. J Theor Appl Inf Technol 67–74

Santiago-Luna M, Cedeno-Maldonado JR (2006) Optimal placement of facts controllers in power systems via evolution strategies. PES transmission and distribution conference and exposition Latin America, Venezuela, IEEE

Saravanan M et al (2005) Application of PSO technique for optimal location of facts devices considering system loadability and cost of installation

Samimi A, Naderi P (2012) A new method for optimal placement of TCSC based on sensitivity analysis for congestion management. Smart Grid Renew Energy 3:10–16

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer India

About this paper

Cite this paper

Surendra, U., Parthasarathy, S.S. (2014). Optimal Location of Series FACTS Device Using PSO Technique to Reduce the Losses and to Enhance Power Transfer Capability in a Power System. In: Sridhar, V., Sheshadri, H., Padma, M. (eds) Emerging Research in Electronics, Computer Science and Technology. Lecture Notes in Electrical Engineering, vol 248. Springer, New Delhi. https://doi.org/10.1007/978-81-322-1157-0_87

Download citation

DOI: https://doi.org/10.1007/978-81-322-1157-0_87

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-1156-3

Online ISBN: 978-81-322-1157-0

eBook Packages: EngineeringEngineering (R0)