Abstract

The reliability-based design optimization (RBDO) has been widely recognized as a powerful optimization tool under probabilistic constraints, through appropriate modeling of uncertainties. However, the drawback of RBDO is that it does not reflect the ability of the structure to comply with large data variations, unforeseen actions or deterioration mechanisms. On the other hand, the robust design optimization (RDO) reduces the variability of the structural performance, in addition to its mean level. However, RDO does not take direct advantage of the interaction between controllable (product design values) and noise variables (environmental random values), and the obtained results do not accurately indicate what parameter has the highest effect on the performance characteristics. The purpose of this paper is to propose a robust formulation for reliability-based design optimization (RRBDO) that combines the advantages of both optimization procedures and overcomes their weaknesses. The optimization model proposed overcomes the limitations of the existing models without compromising the reliability level, by considering a robust convex objective function and a performance variation constraint. The proposed formulation can consider the total cost of structures and can control structural parameter variations. It takes into account uncertainty and variability in the same mathematical formulation. A numerical solution procedure is also developed, for which results are analyzed and compared with RBDO for several examples of concrete and steel structures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The early design methods proposed by regulations were based on the principle of allowable stresses. Given the scattered nature of data, designers started using in the 1960’s a semi-probabilistic approach based on partial safety factors that are supposed to deal with variability. This approach is nowadays used in many codes of practice, as it allows one to cover a large range of uncertainties. The use of these factors often leads to over-design, and does not award the engineer who hold more information and more representative models which naturally allows the designer to be more confident in the results he gets. The probabilistic methods constitute an alternative to safety factor approaches and allow for effective cost optimization. In order to point out the difference between the existing optimization methods, a distinction is to be highlighted between the terms ‘variability’ and ‘uncertainty’. In this paper, the Van Belle’s terminology (Van Belle, 2011) is considered, where ‘variability’ refers to natural or intrinsic variation in some quantity, whereas ‘uncertainty’ refers to the degree of precision with which a quantity is measured. Usually, uncertainty can be probabilistically modeled, whereas variability cannot without specific assumptions; other methodologies, such as fuzzy sets and interval algebra could be appropriate for modeling variability. In structural design, the Deterministic Design Optimization (DDO) is known as the first mathematical formulation to be applied in engineering (Arora, 1989), where the safety factors are assumed to cover the uncertainties related to design variables, material properties and loads. However, as uncertainties can have large impact on structural performance, the probabilistic constraint formulations have been developed since the 1980 (Madsen & Krenk, 1986). Although the Reliability-Based Design Optimization (RBDO) takes into account the uncertainty in the analysis, it does not reflect the ability of the structure to adapt to variability, unforeseen actions or to deterioration mechanisms. A design that is less sensitive to changes in the variable parameters can sustain greater excursions from the assumed design conditions before failing (Sandgren & Cameron, 2002). The Robust Design Optimization (RDO) implies that the objective function becomes less sensitive to random variations by reducing the variability of the structural performance while increasing its mean level. The conventional formulation of robust engineering design was proposed by Taguchi (Taguchi & Rafanelli, 1994) with the aim of enhancing the quality of a product or process not only by achieving the performance target, but also by minimizing the performance variation without removing the cause of variations. Later on, the limitations of Taguchi methods are clarified by Parks (Parks, 2001). It has been proven in many studies that reliability-based and robust design has advantages over deterministic design; e.g. (Sandgren & Cameron, 2002; Taguchi & Rafanelli, 1994; Parks, 2001; Lee & Park, 2001; Doltsinis et al., 2005; Saydam & Frangopol, 2011). However, there are still ambiguities regarding the links between the two approaches, and the domain of application in which RBDO or RDO can be recommended. Although the former uses the reliability theory and the latter uses deterministic models (Beck & de Santana Gomes, 2012), the engineer is seeking for a consistent and adapted decision-making methodology whatever the applied procedure. In order to combine the advantages of both optimization methods, the present paper proposes a robust formulation for Reliability-Based Design Optimization (RRBDO). Some work in literature integrates the robustness into the reliability-based design (Youn et al., 2005; Lee et al., 2008; Rathod et al., 2013; Shahraki & Noorossana, 2014), by keeping a robust objective function, and adding a reliability constraint on the performance variation. However, these formulations presents the same pitfalls of RBDO. The solution of theses formulations can be very sensitive to the choice of the reliability target and the probabilistic input parameters. Moreover, considering a target failure probability as a constraint without tolerating small amount of variation may lead to highly conservative solutions. Also, the probabilistic constraint may not always be active. Moreover, these formulations cannot take into account the variations in the system parameters related to external and internal variabilities.

The major development in this paper is the formulation of a design optimization that can take account for uncertainty and variability in the same mathematical formulation, while minimizing the response variation and guaranteeing the desired reliability level. This is done by considering a robust convex objective function and a performance variation constraint. Another development is the consideration of the total cost of structures, which allows balancing the dispersion of the failure cost expectance, including failure cost and failure probability. Also, a solution procedure is developed, through the application of an efficient computational technique to facilitate the assessments of both robustness and reliability characteristics in searching the optimal solution.

The benefits of the proposed RRBDO is demonstrated through several applications on concrete and steel structures. The RRBDO formulation provides a general framework in which the link between RBDO and RDO is well established, through the definition of the application domain for each method and the appropriate setting of the optimization constraints. The advantage of the proposed RRBDO over the existing formulations is demonstrated from both conceptual and numerical points of view.

2 Total Design Cost

The total design cost of a structure has been widely studied in the literature; e.g. (Aoues & Chateauneuf, 2008; Aoues & Chateauneuf, 2010; Saad et al., 2016). This cost does not consider only the initial cost (i.e. design, manufacturing, transport, construction, etc.), but also the expected failure cost (i.e. operation loss, structural failure, damage to facilities, etc.). It is to note that maintenance cost is out of the scope of the present paper, which is focused on structural design stage. The total cost C T can be formulated as:

where C 0 is the initial cost and C F is the expected failure cost. The initial cost covers the costs of design, material and workmanship. It includes all the costs of buying the physical asset and bringing it to operation. Let the limit state function g j represent the structural condition that preserves the operation, away from the critical performance level; the subscript j makes reference to a given failure scenario. The failure probability P fj is the probability of having negative limit state function (i.e. failed condition):

The expected failure cost can be estimated by:

where P fj (T) is the cumulative failure probability for the j th limit state (i.e., probability that failure occurs anytime between the construction and the time T), m is the number of independent limit state functions, and C fj is the failure cost associated with the occurrence of the j th limit state.

If all aspects and consequences of a decision concerning a structure can be converted to monetary terms, then an optimal decision will be met by minimizing the life-cycle cost (Val & Stewart, 2003).

3 Reliability-based design optimization

As the uncertainties in the design variables can lead to large changes in performance, a probabilistic model should be considered. The probabilistic constraint formulation, described by Madsen et al. (Madsen & Krenk, 1986), defines the design optimization under probabilistic constraints as follows:

where X and d are the vectors of random and design variables respectively, E[f(X, d)] is the mathematical expectation of the cost function f(X, d), P j is the probability of failure for the limit state function g j , d L and d U are respectively the lower and upper bounds of the design variables, m is the number of independent limit state functions, and \( {P}_f^T \) is the admissible failure probability. The optimality conditions for the RBDO problem are as following:

where k j is the Lagrange multiplier for the j th constraint. Each one of the second system of equation means that either the multiplier is nil (i.e. inactive constraint) or the constraint is nil (i.e. active constraint). These optimality conditions indicate that the rate of decrease of the expected cost is balanced by the increase rate of the weighted probability sum for active constraints. The intricate part in RBDO applications is the assessment of the probability of failure. Standard Monte-Carlo simulations and classical reliability methods have been widely used, but suffer from high computation costs.

The reliability constraint in RBDO formulation allows one to take into account the uncertainties related to structural parameters. As mentioned in the above introduction, the terms ‘variability’ and ‘uncertainty’ are used herein for intrinsic variation and for knowledge precision, respectively, according to Van Belle’s terminology (Van Belle, 2011). Similarly, Guedri et al. (Guedri et al., 2012) defined two types of uncertainties that are encountered in practice, namely aleatory and epistemic uncertainties. Aleatory uncertainties are generally considered to be irreducible and results from variations in the physical properties of components and interfaces. Epistemic uncertainties are due to a lack of knowledge concerning the physical laws governing the behavior of a component and can generally be reduced with more thorough modeling and experimental studies. Epistemic uncertainties can be difficult to illustrate due to simplifications in geometric and material field properties, and as such are rarely taken into account in reliability analysis. In general, mainly aleatory uncertainties are covered by structural design approaches. These uncertainties are defined as “non-cognitive” by Pendola et al. (Pendola et al., 2000), “inherent uncertainties” by Tovo (Tovo, 2001), and “variability” by Van Belle (Van Belle, 2011). Variability may be either controllable in case of geometrical and material parameters to be set by engineers, or uncontrollable in case of environmental parameters and deterioration-related mechanisms. The transmitted variation from uncontrollable variability to the objective function can result in the deterioration of product quality and can compromise design feasibility. The effect of variability on the objective function can be generally reduced by adjusting the design values. Therefore, there are needs to define the values of controllable settings (such as cross-section dimensions of a bridge girder) which minimize the negative effects of the uncontrollable phenomena (such as humidity and corrosion rate). In this context, the Robust Design Optimization (RDO) aims at finding the optimal settings to minimize cost by minimizing the response variation, where more consistent design meets better quality.

4 Robust Design Optimization Formulation

Robust design is an engineering procedure for optimal design of products, in order to make them less sensitive to system variations (Kang, 2005; Tsompanakis et al., 2008). Robustness is also defined as the ability of a structure to sustain damage without uneven consequences (Kagho-Gouadjio et al., 2015). Robust product design is defined as reducing the variation of a product without eliminating the causes of variations. This variation can come from a variety of factors and can be classified into three main types: internal variation, external variation, and unit-to-unit variation. Internal variation is due to deterioration such as the aging of materials. External variation comes from factor related to environmental and loading conditions such as temperature, load, humidity and dust. Unit-to-Unit variation is the difference between parts due to scatter of materials, processes and equipment. The goal of robust design is to come up with a way to make the final product consistent when its development is subject to variability. This can be done through a variety of experimental approaches.

There is no agreement on a simple measure to quantify the robustness of structures. De et al. (De et al., 1989) defined robustness as the ability of the system to still carry some load after the brittle fracture of one or more critical components. An approach to robustness has been proposed by Saydam and Frangopol (Lee & Park, 2001) by the ratio of the failure probability of the intact structure to the failure probability of the damaged structure, for each damage case. Casas and Chambi (Casas, 2014) defined a robustness coefficient which modifies a typical condition rating obtained with standard inspection procedures, to take into account structural type and configuration, based on redundancy measures. A robustness index is also proposed to measure the influence of deterioration propagation on the loss of performance. The above mentioned robustness insight is generally accompanied by redundancy insight. System redundancy is defined as the ability of a structural system to redistribute the applied load after reaching the ultimate capacity of its main load-carrying members (Frangopol & Curley, 1987). In this study, robust design refers to a design that is less sensitive to changes in the variable parameters and that can sustain greater throw from the assumed design conditions before failing (Sandgren & Cameron, 2002).

Lee and Park (Lee & Park, 2001) proposed a mathematical formulation for robust design by defining the robustness of the objective and the constraint functions as follows:

where f(.) is the original objective function, \( \overset{\sim }{f}(.) \) is the desirability robustness objective, d is the design variable, μf and σ f are respectively the mean and the standard deviation of the objective function, μ f * and σ f * are normalization factors denoting the mean value and the standard deviation of the objective function, respectively, m is the number of limit state functions, α is the weighting factor and λ j is the penalty factor. The value of the weighting factor α can be set to specify the relative weights to put on the different objective functions and therefore enables the user to investigate the trade-off between the objectives in an easy manner. To include the variations of the constraint, the revised constraint \( \overset{\sim }{g_j}(.) \) is defined by Sundaresan et al. (Sundaresan et al., 1995). The penalty factors λ j are determined by the designer. The low sensitivity of the objective function to system variations is enhanced by decreasing the weighting factor α, while the low sensitivity of constraint to system variations is enhanced by increasing the penalty factor λ j . Most of the researchers, e.g. (Lee & Park, 2001), take into account only the variations of the design variables, while the variability of the other parameters including loads are not accounted for in the formulation. Doltsinis et al. (Doltsinis et al., 2005) used the same objective function as in (Taguchi & Rafanelli, 1994), but developed a different constraint formulation which is able to deal with variations in both design and system parameters:

In this formulation, the designer has a choice of weights that will eventually define how far from the failure surface should the average optimum lie. The optimality conditions for the above RDO problem are as following:

In these optimality conditions, the weighted mean and standard deviation are balanced at the optimal solution. In addition to the Lagrange multiplier k j , the penalty factor λ j plays a significant role in the optimal design solution, as it controls the coefficient of variation of the constraint function g j (d). In general, the RDO optimization allows one to minimize the performance variation but cannot guarantee the desired reliability level. Moreover, the mean and variance modeling approach of robust design does not take direct advantage of the interactions between controllable and uncontrollable variables. Another disadvantage is that the obtained results do not exactly indicate what parameter has the highest effect on the performance characteristic value. In addition, this method is not appropriate for a dynamically changing and time-variant processes (Rizzuti et al., 2009). For this reason, a reliable optimization procedure that can overcome the above disadvantages is developed in the present work. But first, let us observe the behavior of reliability based design optimization.

5 Behavior of RBDO formulation

Let us consider the following RBDO formulation applied to the expected total cost:

where d, P f , d L , d U and \( {P}_f^T \) are defined in section 2. In this formulation, the reliability constraint is not always active, as the optimal solutions may be found with failure probabilities lower than the admissible one. Depending on the considered problem, there may be conflicting requirements between the objective function minimization and the failure probability constraint. When the admissible failure probability \( {P}_f^T \) increases, the initial cost C 0(d) decreases but the expected failure cost C f P f (d) increases, and vice-versa, leading to the convex shape of the cost function, as shown in Fig. 1. Let C T,RBDO be the optimal cost found by the application of the above RBDO formulation, and \( {C_T}_{min}^{\ast } \) be the optimal cost corresponding to the unconstrained formulation. In fact, the constraint on the failure probability is not active beyond a certain value P f (d ∗) corresponding to the unconstrained minimum cost \( {C_T}_{min}^{\ast } \), as shown in Fig. 1.

When the expected value of performance exceeds the level corresponding to the target (i.e. \( {P}_f\left({\boldsymbol{d}}^{\ast}\right)<{P}_f^T \)), the RBDO becomes insensitive to the reliability constraint. The drawback in this situation is that the wrong or large setting of the admissible failure probability, will lead to non-robust solution as it mostly corresponds to large variability. In other words, the obtained solution will satisfy the optimality conditions and the reliability constraints, but not the robustness requirements. This drawback makes the solution very sensitive to the choice of the reliability target and the probabilistic input parameters, and therefore inappropriate for practical engineering use.

Another drawback of the RBDO appears when the expected total cost function is narrow as shown in Fig. 2; this situation is frequently observed when the failure cost is high. A narrow cost function is very sensitive to the failure probability; i.e. large cost points are clustered closely around the optimum \( {C_T}_{min}^{\ast } \). In this case, inquiring the optimal solutions may be skipped when applying the RBDO, since a less costly solution can be found without degrading neither the structural performance nor the safety level, if a small variation is allowed for \( {P}_f^T \). Therefore, considering a target failure probability as a constraint without tolerating small amount of variation may lead to highly conservative solutions. By setting the constraint on \( {P}_f^T \), the RBDO finds a solution that costs much more than the unconstrained one \( {C_T}_{min}^{\ast } \). Knowing the various levels of uncertainties in engineering systems, this over-cost cannot be properly justified when the admissible failure probability \( {P}_f^T \) is close to the one corresponding to the unconstrained minimum cost P f (d ∗). In this case, a better solution can be found with much less cost than for the crude RBDO solution, without compromising significantly the structural reliability.

The above two situations, either inappropriate setting of reliability target or narrow expected cost function, show clearly that the crude RBDO is not sufficient to provide robust solutions, especially that large amount of uncertainties cannot be predicted and identified in engineering practice. Among these uncertainties, we can mention the direct and indirect failure costs which are often very difficult to estimate precisely, and the admissible failure probability which is a conventional measure depending on the precision of the input data and the involved physical and probabilistic models. It is therefore necessary to develop a more consistent methodology for optimal decision-making under uncertainties.

Some authors proposed reliability-based formulations for robust optimization by keeping the robust objective function in eq. 7, and adding a reliability constraint on the performance variation (Youn et al., 2005; Lee et al., 2008; Rathod et al., 2013; Shahraki & Noorossana, 2014). However, these formulations cannot take account for the variations in the system parameters. Moreover, they suffer from the same limitations explained herein, which are mainly caused by the fixed value of the reliability target.

It is worth to note that unconstraint formulations of robust and reliability optimization procedures were compared by Beck et al. (Beck et al., 2015). The unconstraint risk formulation was found in their study to outperform robust formulation, mainly due to the non-convex shape of the robust objective function which leads to optimal designs determined by the variable bounds.

The available methods in the literature still need to be improved, in order to properly handle both variability and uncertainty, affecting structural performance and parameters. The main difficulties are related to the consistency of reliability and robustness objective function and constraints, on one hand, and to the arbitrary choice of the constraint bounds, on the other hand. According to the above discussion, the inconsistency of setting the reliability target in accordance with the problem context is believed to be the key feature for combining effectively the reliability and robustness considerations. In this framework, the optimization model proposed in the next section overcomes the above limitations without compromising the reliability level, by considering a robust convex objective function and a performance variation constraint.

6 Robust Reliability-based design optimization

As mentioned in the above sections, the RBDO solution leads to reliable design, but does not consider the performance variation. On the opposite, the RDO can minimize the performance variation, but cannot guarantee the desired reliability level. A formulation that combines the benefits of robust and reliability design is proposed herein, by considering both: the objective function robustness and the reliability level. This method allows one to overcome the previously discussed weaknesses of both optimization procedures. The proposed Robust Reliability-Based Design Optimization RRBDO applied to the total cost is formulated as following:

As can be seen, the mean value of the limit state functions g j appears in the objective function as well as in the constraint function. Consequently, the increase in the mean value that is usually observed in robust design is limited in this formulation. The advantages of the proposed RRBDO method are as following:

-

The low sensitivity of the objective function is emphasized,

-

The effect of uncontrollable random variables on the structural performance is minimized,

-

The tolerance to comply with unforeseen actions or to deterioration mechanisms is quantified and controlled,

-

The prescribed reliability level is ensured.

The optimality conditions for the above RRBDO problem are as following:

These optimality conditions aim at balancing, not only the cost function mean and standard deviation, but also the dispersion of the failure cost expectance, including failure cost and failure probability. In addition to random variable considerations, the obtained solution takes into account the possible variations in the design variables d, through their effects on both the limit state functions and the failure probabilities. As a consequence, it is expected to get more stable solution with less sensitivity to variations than in the classical formulations. This can be seen from the optimality conditions where the derivatives of the standard deviations are to be lowered. Beside the failure costs C fj , the final solution is governed by two types of control parameters: the weighting factor ∝ and the penalty factor λ j specified for each constraint.

Let z* refer to the optimal solution of the problem, C T * is the optimal total cost of the structure, μ fj and σ fj are respectively the mean and standard deviation of the failure probability, \( {\mu}_{g_j} \) and \( {\sigma}_{g_j} \) are respectively the mean and standard deviations of the limit state function g j (X, d).

For each failure scenario (i.e. limit state function), the mean and standard deviation of the failure probability are given by:

where \( {f}_{Pf_j\left(\boldsymbol{X},\boldsymbol{d}\right)} \) is the probability density function of \( {P}_{f_j}\left(\boldsymbol{X},\boldsymbol{d}\right) \) . The mean and standard deviation of the limit state function g j are given by:

where \( {f}_{g_j\left(\boldsymbol{X},\boldsymbol{d}\right)} \) is the probability density function of g j (X, d).

These parameters can be estimated by either Monte Carlo simulations or by first order approximations.

The above formulation can be extended to time-variant problems if the limit state can be expressed as function of time g j (X, d, T). This is particularly useful for structures subjected to performance degradation due to aging. A discount rate is thus attributed to the failure cost, in order to get its equivalent present value. For practical reasons, the time integration over the structure life can be discretized in terms of the years in service, leading to the expected total cost expression:

where P[g j (X, d, τ) ≤ 0] is the annual probability of failure for the j th limit state at the τ th year (i.e. probability that failure occurs during the year τ, with 1 ≤ τ ≤ T), and ν is the discount rate. The above time-variant extension is made possible by the use of probabilistic degradation models, based on either explicit or numerical procedures to evaluate the failure probability of complex nonlinear problems.

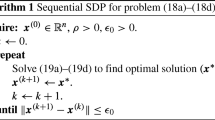

7 Solution procedure

When robustness is considered, the solution procedure should be defined such that practical engineering problems can be handled in a reasonable computation time. This procedure can also be used for comparison between RRBDO and RBDO. As shown in Fig. 3, the proposed procedure is divided into the following steps:

-

Step 1:

The limit state functions g j are evaluated.

-

Step 2:

The failure probability \( {P}_{f_j} \) associated with the limit state function g j is evaluated. For this purpose, the First Order Reliability Method (FORM), or any other numerical procedure, can be applied to give an approximation of \( {P}_{f_j} \). The uncertainties in the problem-related parameters are accounted for through their corresponding probability distributions.

-

Step 3:

Monte Carlo simulations (MCS) are performed on the reliability analysis results (e.g. FORM results) in order to evaluate the mean and standard deviation of the failure probability (μ Pfj and σ Pfj ).

-

Step 4:

The same Monte-Carlo simulations can be used to evaluate the mean and the standard deviation of the limit state functions g j (\( {\mu}_{g_j} \) and \( {\sigma}_{g_j} \)); in this way, no additional computation cost is considered to compute these quantities.

-

Step 5:

Having the mean values and standard deviations of the limit state and failure probability functions, the RRBDO can be solved using classical optimization procedures.

-

Step 6:

When comparison between RBDO and RDO is required, the RBDO is performed using the solution of RRBDO as initial values for the design variables. In addition, the admissible failure probability used in the RBDO constraint is taken equal to the failure probability when the design variables take the values given by RRBDO solution. This procedure allows one to obtain the results of RRBDO and RBDO for the same reliability level, and thus allowing for comparison between the two optimization procedures.

The different runs of the RRBDO correspond to different values of the constraint λ j , such as \( {\mu}_{g_j}/{\sigma}_{g_j}\le -{\lambda}_j \). In fact, λ j is a constraint on the coefficient of variation of the limit state function.

The above procedure allows one to insure the reliability level while minimizing the effect of variability on the design objectives. However, several computational challenges have to be faced: (1) FORM has to be applied herein to evaluate the reliability index in the space of random variables, leading to two nested optimization problems (Aoues & Chateauneuf, 2010). The outer problem searches for the design variables minimizing the cost function, while the inner one searches for the most probable failure point in the space of random variables; when the limit state function is highly non-linear, the convergence of FORM cannot be guaranteed. (2) MCS are applied for both the limit state function and the failure probability (obtained herein by FORM analysis), in order to determine their mean values and coefficients of variation. MCS requires a large number of samples to give stable results, which is very time consuming, and cannot be always feasible, especially with FORM results. It is important to note that, although the FORM algorithm is used in our applications, any other reliability procedure (e.g. Monte-Carlo simulations, response surfaces, stochastic expansions, etc.) can be applied to compute the failure probability. The main criteria to consider when choosing a method are the precision and the computation cost.

In order to cater for the above problems, a polynomial approximation is adopted herein to compute μ Pf , σ Pf , μ g and σ g as functions of the design variables, using least square regression on a reduced number of MCS samples. Gomez and Beck (Beck & de Santana Gomes, 2012) proposed a design space root finding method for efficient risk based optimization computation (corresponding to the herein RBDO formulation (10)). Their method can be extended to the above described sequence in order to overcome the computational burden of the nested optimization and reliability loops. Other authors also proposed approached based on decoupling the reliability loop from the optimization loop (Spence et al., 2015).This formulation is still in need of more accurate and performant numerical estimation methods; however, the solution procedures are beyond the scope of the present paper, although the reader can check the work of Aoues and Chateauneuf (Aoues & Chateauneuf, 2010) for comprehensive discussion about this issue.

8 Application

Four applications are considered hereafter in order to investigate the performance of the proposed RRBDO formulation and to compare it with Reliability-Based Design Optimization. The first example aims at illustrating in details the proposed procedure, and at describing the behavior of reliability-based design. In the second application, the role of time in the RRBDO formulation of a time-variant process is investigated. The third example shows the interest of RRBDO framework for system analysis, through the design of overhanged beam with variable cantilever depth. The fourth application investigates the effect of robustness objective regarding the structural topology, where several failure modes are considered. The structural applications are chosen to have different structural properties and modes of failure, in order to show the applicability of the proposed methodology on a large range of engineering problems (i.e. structural topology, number of failure modes, time-invariant and time-variant, component and system reliability, etc.).

8.1 Plane truss

This application, drawn from Beck and Gomes (Beck & de Santana Gomes, 2012), aims at finding the optimal height and thickness of a plane truss structure, considering the yielding of steel cross-section as shown in Fig. 4. The span is fixed to 2B = 6 m. Table 1 summarizes the data and distributions of the system variables. The considered limit state function accounts for cross-section yielding, and takes the form:

where σ is the compressive stress in the tubes, B and H are respectively the truss half-span and height, d and t are respectively the cross-section diameter and thickness, P is the applied load, and f y is the yield stress. The initial cost is composed of a fixed cost of labor (taken equal to 10 cost units), plus a term proportional to material cost:

where C s is the cost of steel per unit weight and ρ is the material density. The expected total cost C T is written as:

In Table 1, the design variables are represented by the vector d = [t H]. The uncertainties, represented by the vector X = [P, E, f y ], are characterized by their probability distributions, mean values, coefficients of variation.

The RBDO problem of the plane truss is:

where the admissible failure probability \( {P}_f^T \) is taken equal to 10−4 and P f (d) is approximated using the first order reliability method FORM .The RBDO is applied for different values of C f leading to results in Table 2. The amplification of the failure cost C f does not lead to significant variations in the optimal design. A rise of C f from 10C 0 to 10 6 C 0 induces an increase of only 16% in the optimal thickness and 31% in the optimal cost.

As a matter of fact, for all failure costs below 10 4 C 0 , the reliability constraint of 10 −4 is active, as shown in Fig. 5. Therefore the optimal results correspond to a failure probability equal to \( {P}_f^T \), with optimal cost higher than for the unconstrained case. For C f higher than 10 4 C 0 , the reliability limit of 10 −4 is not active, and the minimum cost is equal to \( {C_T}_{min}^{\ast } \) .

The robust formulation for reliability-based design optimization (RRBDO) applied to the plane truss example is written as:

where \( {\mu}_{C_T}^{\ast } \), \( {\sigma}_{C_T}^{\ast } \), α, λ, d L and d U are defined in section 3. The normalization factors \( {\mu}_{C_T}^{\ast } \) and \( {\sigma}_{C_T}^{\ast } \) are taken equal to the mean and the standard deviation of C T (X, d) when the design variables take the initial values d 0 = [2.4m; 0.018m] . The lower and upper limits are respectively d L = [1; 0.01] and d U = [3; 0.03]. Fig. 6 shows the mean values of the initial cost, the failure cost and the total cost, for decreasing values of the penalty factors λ from 5 to 0.5, with α equal to 0.5 and C f equal to 10 4 C 0 . A larger value of λ generally requires the corresponding performance to be more robust regarding the system variability. A decrease of the penalty factor corresponds to an increase in μ Pf , leading to an increase in the mean failure cost and a decrease in the mean initial cost. This behavior is foreseen because the penalty factor is a measure of the inverse of the coefficient of variation of the limit state, and the failure probability (thus the expected failure cost) increases when σ g increases. In this RRBDO formulation, the objective function is directly related to the constraint function by the mean of P[g < 0]. Therefore, the increase of mean objective function that is usually seen in RDO studies is limited in the suggested RRBDO formulation.

As explained above, the reliability constraint in RBDO is not active when \( {P}_f^T \) exceeds P f (d ∗) corresponding to the unconstrained minimum cost \( {C_T}_{min}^{\ast } \). Therefore, the optimal cost found by the use of RBDO is independent of the reliability constraint when \( {P}_f^T \) exceeds P f (d ∗). Fig. 7 shows the optimal costs found by the RBDO and the RRBDO for increasing values of \( {P}_f^T \), when \( {P}_f^T<{P}_f\left({\boldsymbol{d}}^{\ast}\right) \), the RRBDO solution costs 7% less than the RBDO for the same reliability level. On the opposite, when \( {P}_f^T>{P}_f\left({\boldsymbol{d}}^{\ast}\right) \), the reliability constraint in the RBDO is not active, although the RRBDO continues to perform reasonably when \( {P}_f^T \) is greater than P f (d ∗) because the optimal cost increases with the failure probability.

The optimal design parameters are shown in Fig. 8, in terms of the admissible failure probability \( {P}_f^T \). For low admissible failure probability (\( {P}_f^T<{P}_f\left({\boldsymbol{d}}^{\ast}\right) \)), both procedures tend to decrease the optimal thickness and maintain a constant optimal height. For higher failure probabilities (\( {P}_f^T>{P}_f\left({\boldsymbol{d}}^{\ast}\right) \)), the RRBDO tends to increase the optimal thickness by 10% and decrease the optimal height by 20% in order to maintain a certain level of reliability while minimizing the total cost. However, the optimal design of RBDO becomes independent of the failure probability beyond P f (d ∗).

As a result, the proposed RRBDO has better behavior than the RBDO for all reliability targets, since it provides more robust and less costly optimal solutions for high reliability levels, and it continues to perform properly for low reliability levels.

8.2 Bridge girder

This application aims at finding the optimal longitudinal steel area and concrete depth of a reinforced concrete girder, considering degradation with time due to corrosion and fatigue. The coupled corrosion and fatigue deterioration process is formulated by Bastidas-Arteaga et al. (Bastidas-Arteaga et al., 2009), and was divided into three stages. The first stage is corrosion initiation and pit nucleation. The time to corrosion initiation τ ini is given by Thoft-Christensen (Thoft-Christensen, 1998), and the time to pit nucleation τ pn is given by Stewart (Stewart, 2004). The second stage is pit-to-crack transition τ pt obtained by equating the pit growth rate to the equivalent crack growth rate, as defined by Val et al. (Val & Melchers, 1997; Val et al., 1998). The third stage is the crack growth, τ cg , which is reached when the crack size induces cross-section failure. The reduction of the steel reinforcement cross-section which is caused by the coupled effect of corrosion and fatigue starts after the time-to-corrosion initiation τ ini . This reduction is estimated by considering pitting corrosion from τ ini till τ pt . After the pit to crack transition, the new crack size is calculated by integrating the fatigue crack growth rate. For full description of the degradation model, the reader is invited to see the papers (Bastidas-Arteaga et al., 2009; Stewart, 2004; Val & Melchers, 1997; Val et al., 1998; El Hassan et al., 2010). The limit state considered herein is related to girder bending capacity:

where M r is the resisting moment and M a is the applied bending moment, d and X are the vectors of design and random variables, respectively, and t is the time. The initial cost is:

where C c , C reinf and C form are respectively the costs of concrete, reinforcement and formwork per unit weight and ρ is the material density. The cost of failure is considered as C f = 10C 0 . Table 3 summarizes the values and distributions of different variables in this problem (Bastidas-Arteaga et al., 2009; El Hassan et al., 2010).

The RBDO problem is given by:

The RRBDO formulation applied to the bridge girder is:

The weighting factor α is taken equal to 0.5, and the normalization factors \( {\mu}_{C_T}^{\ast } \) and \( {\sigma}_{C_T}^{\ast } \) correspond to the steel area of 44 cm2 and a beam depth of 0.9 m Different values are assigned to the penalty factor λ in order to parametrically study the problem (from 0.5 to 5).

Figure 9 shows the optimal costs and steel areas found by RBDO and RRBDO as functions of \( {P}_f^T \). The optimal height is constant for a fixed point in time in both optimization formulations and for all reliability levels. The procedure described in section 6 is applied for a reference period of 10 years. In this example, the value of P f (d ∗) is 10 −4 as shown in Fig. 9. The reliability constraint of RBDO is not active when \( {P}_f^T>{P}_f\left({\boldsymbol{d}}^{\ast}\right) \) corresponding to the unconstrained minimum cost \( {C_T}_{min}^{\ast } \) of 585 cost units. The optimal solution found by RBDO is constant when \( {P}_f^T \) exceeds P f (d ∗), with optimum reinforcement area of 48 cm2 for all reliability constraints higher than 10−4. Nevertheless, the RRBDO continues to perform properly when \( {P}_f^T \) is greater than P f (d ∗), i.e. although the optimal costs increases by 17%, the optimal reinforcement area (and therefore the initial cost) decreases by 18% when the admissible failure probability increases from 10−5 to 10−3. In fact, the increase of the admissible probability of failure \( {P}_f^T \) leads to decrease the penalty factor λ which increases the coefficient of variation of the limit state function. It is thus normal to have a larger optimal cost when there is more variation in the limit state function. Therefore, a more robust design with a constraint on the coefficient of variation leads to a structure that can better adapt to unforeseen variations.

In this application, the solution procedure is executed for different points in time in order to observe the influence of time on the optimal solution. Although the optimal RRBDO cost increases by 4.5% if the time span increases by 10 years, a very interesting RRBDO behavior is deducted from the results. When time increases, the RRBDO increases the beam depth h ∗ in the aim of reducing the steel area \( {A}_s^{\ast } \). This behavior is not present in the RBDO runs for different times. In fact, most of the degradation uncertainties are related to the steel area that becomes more corroded with time. Therefore, the RRBDO is able to find the solutions that are less sensitive to the highest variations, while keeping the same reliability level as the RBDO. This is achieved by the performance variation constraint in the RRBDO formulation.

8.3 Overhanged beam

This third application, drawn from Aoues and Chateauneuf (Aoues & Chateauneuf, 2008), aims at finding the optimal thicknesses of a reinforced concrete overhanged beam structure with variable depths (Fig. 10), considering the bending due to uniformly distributed load and concentrated end forces. The beam is defined by the middle-span depth d 1 and the cantilever end depth d 2 . In this example the middle span and the cantilever are considered as two perfectly correlated components of the system. The span is L = 8 m and the cantilever length is L c = 3 m. The beam is subjected to the distributed loads q and q/8 as illustrated in Fig. 10. In order to reduce the negative moments, two tension rods are acting at the cantilever ends, with tensile force P. Table 4 summarizes the data and distributions of the problem variables. Under nominal conditions, the maximum moments are M1 = 90 kNm and M2 = −11.25 kNm.

For a given cross-section j, the limit state function is written as:

The reinforcement area is chosen as A s1 = 12 cm 2 and A s2 = 6 cm 2, leading to the following nominal values of the limit state functions:

The initial costs C 0 and the failure costs C f are computed as in the previous example, and the design variables are d 1 and d 2 .

The results show that when applying the RBDO, the constraint \( \left(P\left[{g}_1\le 0\right]\le {P}_{f1}^T\right) \) is not active when it is greater than 6 × 10−3, which is the value of \( {P}_f\left({d}_1^{\ast}\right) \), for the limit state g 1 . Therefore the RBDO optimal solutions for d 1 are constant beyond \( {P}_f\left({d}_1^{\ast}\right) \). The optimal solution found for d 2 through the use of RRBDO and RBDO are the same, because \( {P}_f\left({d}_2^{\ast}\right) \) for the limit state g 2 is not reached by the RBDO constraint \( {P}_{f2}^T \) (which is equal to the RRBDO solution \( {\mu}_{Pf_2} \) as explained in section 6). Therefore, the initial cost is similar for both optimization procedures until \( {P}_f\left({d}_1^{\ast}\right) \), after which the use of RBDO does not affect d 1 and the use of RRBDO provides solutions that reduce the initial cost by continuously reducing d 1 . Since the RBDO does not allow the failure probability to exceed \( {P}_f\left({d}_1^{\ast}\right)=6\times {10}^{-3} \), the failure costs using RBDO are also irreducible even when a greater probability of failure is allowed. The proposed formulation is therefore able to decrease the depth where cost is involved (mid-span) without compromising the structural safety of the components, as long as the performance variability limit is respected. d 1 is reduced by 3.7% for an admissible probability of failure of 10−2.

It is interesting to note that Aoues and Chateauneuf (Aoues & Chateauneuf, 2008) proposed a scheme for consistent RBDO of structural systems, where the component target safety is adapted in order to fulfill the overall system target. They considered the overhanged beam example to investigate the adaptive target approach. The adaptive target approach reduced d 1 by 4.7% for a reliability index of 1.645. The comparison with this result shows that the proposed RRBDO is able to handle properly the system effect in the structural optimization framework.

8.4 A Built-up column

This application, drawn from Beck and Gomes (Beck & de Santana Gomes, 2012), aims at finding the optimum width and topology of a steel column formed of U and L cross-sections (Fig. 11), subject to local and global buckling due to axial load. The impact of robust design on the topology of the structure is also observed in this application. The column is made of U-section struts (U200 × 75 × 2.65 mm), with L-section braces and battens (L30 × 2.25 mm). The total length is L and the column is subject to a load P. The optimization variables are the width b and the number of braces and battens (N = L/d). The input data are summarized in Table 5. The limit state functions are related to local and global buckling. Local buckling of the U-shaped struts is given by:

where I U is the moment of inertia of the U-section. Global column buckling is given by:

where I G is the moment of inertia of the column cross-section, given by:

\( {I}_G=2\ \Big({I}_U+{A}_U\ {\left(\frac{b}{2}\right)}^2 \)) (31).

One unit of braces and battens is considered as one horizontal and one diagonal L-shape. The total length of a brace-batten unit is:

The material cost C mat is:

where C S is the cost of steel material per unit weight and ρ is the material density. Considering a fixed reference cost of C ref = 150 C S , the construction cost C const contains a setup cost, a material cost, and a cost due to the number of brace-batten units:

The initial cost is:

The probabilities of local and global failures are respectively:

The cost of global failure is considered as C SFG = 100C ref , and the cost of local failure is considered as C SFL = 10C ref . The total cost takes the form:

As shown in Table 6, the optimal number of braces and battens increases when the structural robustness increases (i.e. λ increases), which means that additional members help in improving the structural robustness. A robust design increases the initial cost by increasing the number of members N and the width b, but decreases the failure cost by decreasing the failure probability. The optimum configuration found by the RRBDO has 5 brace-batten units (N = 5), b = 13.5 cm, a system failure probability of 1.45 × 10−4, and an optimal cost of 28,580 unit cost. In addition, it is interesting to note that the RRBDO favors the increase of the number of members over the amplification of the width. Between the two extents of the penalty constraint values, the RRBDO solution increases the number of members by 72% and the member widths by 31% to meet the most stringent penalty function. It can be concluded for this example that the topology plays a higher role in robustness than the member widths.

The RBDO constraint P f T is not active beyond P f (d ∗) = 2.09 × 10−5. Therefore, the RBDO optimal solutions for N and for the optimal cost are constant after P f (d ∗). whereas by the use of RRBDO, b, N and the optimal cost continue on decreasing when the constraint λ is loosen, as shown in Table 6. Therefore, the RRBDO formulation delivers less costly results while satisfying the performance variability limit and without compromising the targeted safety level. Moreover, it can give solutions that are consistent with all reliability targets. The RRBDO formulation clearly outperforms the RBDO formulation for this example.

9 Conclusion

The proposed formulation for robust reliability-based design optimization (RRBDO) considers the total cost of structure and controls the variations in the structural parameters. The reliability-based design optimization (RBDO) is known to be sensitive to the input data and their possible variation, regarding the assumed or initial conditions. Meanwhile, a more robust structure is less likely to fail, which is particularly important for optimized systems, as no additional margin is available. A robust design may increase the mean initial cost by increasing the design variables in order to reduce the variability, leading to decrease the probability of failure. In this scope, the proposed RRBDO is able to find an optimal solution that reduces the variability of the structure. A comparison between the RBDO and the RRBDO procedures is carried out for the design of two structural concrete and two structural steel problems. It is shown in this study that the proposed RRBDO behaves better than the RBDO for all reliability values, since it provides more robust optimal solutions for high reliability levels, and it continues to perform properly for low reliability levels. The scope of work of the RRBDO is wider than the RBDO and the DDO because more information and better assumptions can be handled by the application of RRBDO.

References

Aoues Y, Chateauneuf A (2008) Reliability-based optimization of structural systems by adaptive target safety–Application to RC frames. Struct Saf 30(2):144–161

Aoues Y, Chateauneuf A (2010) Benchmark study of numerical methods for reliability-based design optimization. Struct Multidiscip Optim 41(2):277–294

Arora JS (1989) Introduction to Optimum Design. McGraw-Hill, Inc., New York

Bastidas-Arteaga E, Bressolette P, Chateauneuf A, Sánchez-Silva M (2009) Probabilistic lifetime assessment of RC structures under coupled corrosion–fatigue deterioration processes. Struct Saf 31(1):84–96

Beck AT, de Santana Gomes WJ (2012) A comparison of deterministic, reliability-based and risk-based structural optimization under uncertainty. Prob Eng Mech 28:18–29

Beck AT, Gomes WJS, Lopez RH, Miguel LF (2015) A comparison between robust and risk-based optimization under uncertainty. Struct Multidiscip Optim 52:479

Casas JR (2014) Robustness and life-cycle analysis (LCA) of structures and infrastructures. Proceedings of the 46th ESReDA seminar, Torino, May 29–30

De R S, Karamchandani A, Cornell C A (1989) Study of redundancy in near-ideal parallel structural systems. Structural safety and reliability, ASCE, 975–982

Doltsinis I, Kang Z, Cheng G (2005) Robust design of non-linear structures using optimization methods. Comput Methods Appl Mech Eng 194(12):1779–1795

El Hassan J, Bressolette P, Chateauneuf A, El Tawil K (2010) Reliability-based assessment of the effect of climatic conditions on the corrosion of RC structures subject to chloride ingress. Eng Struct 32(10):3279–3287

Frangopol DM, Curley JP (1987) Effects of damage and redundancy on structural reliability. J Struct Eng 113(7):1533–1549

Guedri M, Cogan S, Bouhaddi N (2012) Robustness of structural reliability analyses to epistemic uncertainties. Mech Syst Signal Process 28:458–469

Kagho-Gouadjio N, Orcesi A, Cremona C, Marcotte C (2015) Quantification of structural robustness: application to the study of a prestressed concrete beam. Mech Ind 16(1):104

Kang Z (2005) Robust design optimization of structures under uncertainties. PhD.-Institute of Statics and Dynamics of Aerospace Structures, Stuttgart

Lee K, Park G (2001) Robust optimization considering tolerances of design variables. Comput Struct 79(1):77–86

Lee I, Choi K, Du L, Gorsich D (2008) Dimension reduction method for reliability-based robust design optimization. Comput Struct 86(13):1550–1562

Madsen H, Krenk L S (1986) Methods of structural safety. Englewood Cliff, Dover publications, United States

Parks J (2001) On stochastic optimization: Taguchi Methods™ demystified; its limitations and fallacy clarified. Prob Eng Mech 16(1):87–101

Pendola M, Mohamed A, Lemaire M, Hornet P (2000) Combination of finite element and reliability methods in nonlinear fracture mechanics. Reliab Eng Syst Saf 70(1):15–27

Rathod V, Yadav OP, Rathore A, Jain R (2013) Optimizing reliability-based robust design model using multi-objective genetic algorithm. Comput Ind Eng 66(2):301–310

Rizzuti S, De Napoli L, Giampà F, Lofranco F (2009) Axiomatic design as a means to find contradiction in an integrated approach for product design. Fifth International Conference on Axiomatic Design, ICAD, 25–27

Saad L, Aissani A, Chateauneuf A, Raphael W (2016) Reliability-based optimization of direct and indirect LCC of RC bridge elements under coupled fatigue-corrosion deterioration processes. Eng Fail Anal 58:570–587

Sandgren E, Cameron T (2002) Robust design optimization of structures through consideration of variation. Comput Struct 80(20):1605–1613

Saydam D, Frangopol DM (2011) Time-dependent performance indicators of damaged bridge superstructures. Eng Struct 33(9):2458–2471

Shahraki AF, Noorossana R (2014) Reliability-based robust design optimization: A general methodology using genetic algorithm. Comput Ind Eng 74:199–207

Spence S M, Gioffrè M, Kareem A (2015) An efficient framework for the reliability-based design optimization of large-scale uncertain and stochastic linear systems. Prob Eng Mech

Stewart MG (2004) Spatial variability of pitting corrosion and its influence on structural fragility and reliability of RC beams in flexure. Struct Saf 26(4):453–470

Sundaresan S, Ishii K, Houser DR (1995) A robust optimization procedure with variations on design variables and constraints. Eng Opt A35 24(2):101–117

Taguchi G, Rafanelli A J (1994) Taguchi on robust technology development: bringing quality engineering upstream

Thoft-Christensen P (1998) Assessment of the reliability profiles for concrete bridges. Eng Struct 20(11):1004–1009

Tovo R (2001) On the fatigue reliability evaluation of structural components under service loading. Int J Fatigue 23(7):587–598

Tsompanakis Y, Lagaros N D, Papadrakakis M (2008) Structural Design Optimization Considering Uncertainties: Structures & Infrastructures Book, Vol. 1, Series, Series Editor: Dan M. Frangopol. CRC Press

Val DV, Melchers RE (1997) Reliability of deteriorating RC slab bridges. J Struct Eng 123(12):1638–1644

Val DV, Stewart MG (2003) Life-cycle cost analysis of reinforced concrete structures in marine environments. Struct Saf 25(4):343–362

Val DV, Stewart MG, Melchers RE (1998) Effect of reinforcement corrosion on reliability of highway bridges. Eng Struct 20(11):1010–1019

Van Belle G (2011) Statistical rules of thumb. Wiley

Youn BD, Choi KK, Yi K (2005) Performance moment integration (PMI) method for quality assessment in reliability-based robust design optimization. Mech Based Des Struct Mach 33(2):185–213

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saad, L., Chateauneuf, A. & Raphael, W. Robust formulation for Reliability-based design optimization of structures. Struct Multidisc Optim 57, 2233–2248 (2018). https://doi.org/10.1007/s00158-017-1853-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-017-1853-7