Abstract

This paper investigates the long-term tensile properties of laminated veneer lumber (LVL) beech sections coated with cement and exposed to fungal decay. A set of LVL coupon (dog-bone) samples was stored in compost, tested in tension after 6 and 12 months and compared to reference samples stored at 20 °C and 65% relative humidity. Results showed that after 26 weeks of compost exposure, a fungus of the Ascomycota genus was identified in cement-coated samples using a molecular biology polymerase chain reaction (PCR) technique, which analyses the internal transcribed spacer (ITS) region of the ribosomal DNA. However, no visual deterioration was noticed. Still in cement-covered samples and after 12 months of exposure, a common white rot fungus was determined by DNA chip technology, but no fungal wood decay was visible in areas where the applied coating had a thickness of at least 5 mm. Decay in uncoated LVL samples was significant with the samples having an average residual strength equal to 7%. This compares to the tensile strength of coated samples, which only decreased by 65% relative to the reference samples. Strength and stiffness of coated samples did not differ significantly between 6 and 12 months of exposure. Preliminary investigations tend to show that the strength reduction in cement-coated samples is due to an alkaline degradation of the wood. The observed influence of the coating thickness on the visual fungal decay can probably be ascribed to the protection mechanism due to a physical fungal barrier with a high pH.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Foundation problems, soil improvement and slope stabilization measures, temporary as well as permanent, form the basis for many building and infrastructure projects worldwide. Temporary soil nailing systems are often used to stabilize excavation slopes. Steel anchors are therefore drilled into the soil and a reinforced shotcrete layer protects the slope surface. The annulus around the steel rod is filled with cement grout. In addition to nail corrosion protection aspects, the hardened cement body ensures the necessary connection between soil and nail. In the case of temporary soil nailing systems, the construction has a reduced service life of 18 months maximum (EN 14490 2010), compared to permanent constructions with a service life of at least 50 years. After this, the anchors have no structural utility but usually remain in the soil, because it is generally not possible to remove them due to their limited accessibility after installation. In the case of temporary excavation slope stabilization using anchors, neighbouring rights are often impinged because anchors extend into neighbouring land and are an obstacle to later construction activities close to the boundary. Installing anchors close to the boundary may therefore result in high secondary costs (up to 100% of initial installation costs) caused by redemption and easement agreements between the project developer and targeted neighbours. Hence, an innovative approach to temporary soil nailing systems is the use of decomposable nails made of renewable materials, rather than wasting valuable but high primary energy-consuming raw materials such as tempered steel.

The possibility of substituting temporary steel anchors by laminated veneer lumber (LVL) hollow cross sections (Fig. 1) manufactured from European beech (Fagus sylvatica L.) is being investigated in a research project aimed at developing a sustainable temporary soil nailing system. The concept is an innovative approach to combine both the positive and negative material properties of beech (high strength in combination with low durability) to develop a structural pole used for temporary geotechnical anchoring systems. Similar to temporary steel anchors, the hollow cross sections should have a service life of at least 18 months but should subsequently rot practically residue-free in the soil with time. In that case, the remaining thin concrete layer is expected to be an obstacle for later construction activities no more serious than natural gravel or stones in the subsoil.

The geotechnical background for the cross section choice and detailed information about the layer structure is given in Hirschmüller et al. (2018). However, when using beech, because of its excellent peeling performance and its higher strength compared to softwoods, to produce laminated veneer hollow cross sections, the natural low durability of untreated beech against fungal attack may be a decisive factor for the system. However, because of the high-alkaline cement surround, in combination with the low oxygen content within the subsoil, it is anticipated that alkaline degradation is the predominant wood-damaging mechanism rather than possible biological attack caused by fungi.

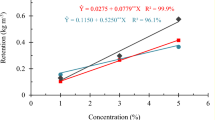

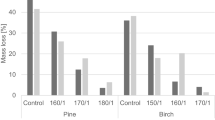

Only few publications have investigated wood embedded in cement and its influence on fungal wood degradation. Goodell et al. (1997) reported an inhibition of fungal colonization on wood particles completely encapsulated in cement and suggested an alteration in wood pH as the primary protection mechanism against fungal degradation. Papadopoulos (2008) evaluated the decay resistance of cement-bonded, oriented strand board against brown (Coniophora puteana) and white rot (Trametes versicolor) as a function of the cement-to-wood ratio (CW) by measuring the weight loss (WL) of boards after 16 weeks of incubation time. Boards made of ring-cut aspen strands (Populus alba) with a CW ratio of 3.0 gained weight instead of losing it. Both of these fungi failed to attack the cement-bonded boards. Furthermore, in-ground field tests compliant with EN 252 (2015) using different soil substrates, inter alia on Scots pine sapwood (Pinus sylvestris L.), Norway spruce (Picea abies Karst.) and European beech (Fagus sylvatica L.), remaining lifetimes significantly increased by a factor of 2.7 and higher if samples were partly embedded in Portland cement (Brischke 2007; Brischke et al. 2007, 2014) compared to uncoated sticks. But, despite a lower degradation of Portland cement-embedded sticks during the first 3 years, the decay rates of those samples increased afterwards. Nevertheless, numerous investigations dealing with wood degradation evaluated the degree of deterioration based on a visual assessment of wood softening and destruction or a measurement of test specimen weight loss caused by fungal attack. Only few publications dealing with wood deterioration relate the level of attack to material strength (especially bending strength) and stiffness determined on degraded test samples (Armstrong and Savory 1959; Boettcher 1985; Baron 2009; Curling et al. 2002; Kleindienst et al. 2016). Generally, a good overview of published work with regard to effects of wood decay on strength is given in Wilcox (1978). This paper reports on the loss of tensile strength (TS) and modulus of elasticity (MOE) of unprotected, as well as cement-covered beech LVL sticks after a 12 months durability test based on a modified ENV 807 (2001) procedure, compared to reference sticks tested after storage in a climate chamber at normal climate NC (20 °C and 65% relative humidity). The main objective is to specify a wood preserving effect of cement embedment against fungal attack to ensure the serviceability of beech LVL soil nails in temporary geotechnical applications for at least 1 year. The paper is focused on the cement-dependent degradation of wood and the influence of tensile properties due to predominant tensile loading of soil nails.

2 Materials and methods

2.1 Wood

All samples were manufactured using 3 mm thick peeled veneers as basic material. The European beech (Fagus sylvatica L.) veneer sheets of dimensions 800 mm by 1400 mm were provided free of charge by ‘Sperrholzwerk Schweitzer GmbH’ of St. Marienkirchen/Polsenz (Austria). The domestically logged beech was steamed prior to peeling. The veneers were visually graded to avoid the influence of natural wood characteristics. Only veneers assigned to EN 635-2 (1995) quality class E were used and mixed to form randomly distributed basic material. 3 mm maximum diameter of knots within veneer sheets was defined. Prior to the final sizing of raw sheets, the veneers were split in the direction of the fibre to ensure the veneer side edges were parallel to the direction of the fibre and to reduce undefined grain deviation in the test samples. Subsequently, the graded veneer sheets were cut into 200 mm wide and 700 mm long (parallel to the direction of the fibre) strips. After storing the pre-sized veneer sheets in normal climate (NC) at 20 °C and 65% relative humidity (RH) until reaching equilibrium moisture content ugl (ugl ≈ 11.3%), the veneer sheets were mixed to avoid a non-random influence of raw-density ρN and other wood characteristics. Therefore, a statistically randomly distributed basic sample of veneer sheets was formed.

2.2 Sample production

BASF Kauramin® 683 melamine formaldehyde resin with Kauramin® 688 hardener was used to produce tubular half-poles, whereby the pressing parameters had been developed in preliminary investigations. To provide realistic geometrical conditions (i.e. to exclude any influence of veneer curvature on fungal attack), hollow cross sections were produced. Unidirectionally adjusted, 6 × 3 mm thick veneers were used to produce tubular half-poles with an outer diameter of 100 mm and a wall thickness of approximately 18 mm. The grain direction of all veneers was adjusted to the tube axis; no transverse layers were used. After the adhesive curing process, all tubular half-poles produced were stored again in NC for 7 days prior to further manipulation. After at least 7 days of storage in NC, all LVL tubular half-poles were sized to a length of 600 mm and subsequently cut into 25 mm wide strips, to ensure tensile tests without geometrical influences. Three 25 mm wide and 15 mm thick strips were obtained from one tubular half-pole (Fig. 2). After that, the samples were symmetrically planed to a similar thickness of 15 mm to avoid the influence of sample size effects on material strength and stiffness. To perform tensile tests parallel to the grain, a dog-bone shaped sample based on D 3500-90 (2003) with 10 mm width in the mid-area was developed in several preliminary tests (Fig. 3). To ensure exactly the same geometry of 10 mm width (b) and 15 mm height (h) within the test length for each sample, a CNC-manufactured model was taken as the basis for milling the specimens. Within the 15 mm high testing cross section at least four 3 mm thick veneers were located with a radial orientation of annual rings due to the peeling process of the veneer sheets (Fig. 4).

2.3 Sampling

The bone-shaped tensile test specimens were randomly mixed and split into four equal lots of n = 45 samples and one lot of n = 39 samples in order to form statistically similarly distributed test batches with regard to ρN and other wood characteristics. Wood moisture content MC was measured immediately after tensile testing by oven drying (EN 322 1993) of at least three randomly selected samples per batch. MC listed in Table 1 presents the average means x̅ of the measured MC within each batch. One batch was used for reference and therefore, stored for 6 months in a climate chamber in NC prior to testing (“Reference NC” batch) without any exposure to fungal attack. Two batches were coated with cement slurry (“6 months CEM” and “12 months CEM” batches) and two batches were left untreated and had no additional wood protection (“6 months exposure” and “12 months exposure” batches).

2.4 Cement coating of tensile test samples

The surface of the bone-shaped CEM batches with a cross-section of 10 mm by 15 mm within the testing length was coated using the cement, CEM II/ A-M (S-L) 42.5 N, with a water-cement ratio (w/c) of 0.6, a common cement composition used in practical soil nailing. The necessary coating thickness and the CW ratio were chosen to suit the intended use of the LVL tubes as geotechnical soil nails, where a slightly higher CW ratio is used to form a pumpable cement suspension without adding plasticisers. In common excavation soil nailing systems, approximately 60–140 mm diameter bores (or larger if necessary) are normally drilled in the soil, depending on the type of soil nail, the drilling procedure and the bore pits. With regard to the dimensions of the tubular LVL poles, a bore diameter of at least 139 mm is necessary to install the LVL nails in the subsoil. For a tubular LVL pole cross-sectional area ALVL of 4636 mm2 and a net cement body cross-sectional area ACEM of 10,538 mm2, the CW ratio is calculated to CW = 2.27. Translated into the bone-shaped tensile test samples with a cross-sectional area ATS of 150 mm2, a cement coating with a net cross-sectional area of ACT = 341 mm2 is necessary.

Commercial formwork with cross-sectional dimensions of 25 mm by 25 mm was used due to the cross-sectional enlargement of the bone-shaped tensile test samples at the clamping area. The formwork was filled with cement slurry and one tensile test sample was subsequently completely embedded in each piece of formwork. The geometrically necessary cross-sectional area of the cement body was therefore slightly higher (ACT = 475 mm2) with a CW ratio of 3.16 (Fig. 5). After one day of initial cement hardening, the formwork was carefully removed and a 600 mm long cement-coated test specimen was produced (Fig. 6). The thin cement coating at the widened cross section (25 mm width and 30 mm width of the formwork) of the bone-shaped test specimens at the clamping area failed immediately after stripping the formwork. The cement coating missing from the enlarged cross-section of the clamping area was replaced using an epoxy resin coating.

2.5 Compost storage

Decomposition tests on cement-coated and unprotected test specimens were conducted according to a modified ENV 807 (2001) process. Untreated and non-sterilized compost, consisting of brush cuttings and garden waste, was filled 600 mm high in two 700 mm wide circular plastic containers (Fig. 7). Both containers were stored for 12 months in the material testing laboratory at Rosenheim University of Applied Sciences with a climate in the range of 22–26 °C and relative humidity between 35 and 45% in the room. Air circulation at the upper surface of the compost was ensured by ventilation openings in the top cover of the box. A drainage opening was located at the bottom of each container. After filling the containers with compost, both were loaded with test specimens in a vertical configuration. Ninety unprotected test samples were placed in container I and 90 cement-coated test samples (after 3 days of cement hardening) in container II (Fig. 8). The top end of each sample was at least 20 mm below the compost surface. Additionally, 12 pieces of solid beech control sticks (100 mm long, 20 mm wide and 10 mm thick) were inserted upright in the compost across the entire surface in each container. Six control sticks were used for moisture control; the remainder was used to control fungal attack (virulence control sticks compliant with ENV 807 2001). Prior to installation of the control sticks, the initial dry weight m0 of each stick was determined by oven drying (EN 322 1993). Moisture control sticks were renewed monthly due to the fungus-induced WL, whereby WL of the wood specimens was calculated compliant with ENV 807 (2001) and EN 113 (1996) as WL of the exposed sticks after oven-drying relative to the initial dry weight.

Subsequently, per container 14 l of potable water with a temperature of approximately 20 °C were added to the soil until a drip discharge appeared at the bottom drainage openings over a period of 5 days. To calculate the amount of water needed, the specific water holding capacity of the compost (WHC = 39% by weight), and the initial compost moisture content (MC = 27% by weight) were specified in preliminary tests compliant with ENV 807 (2001). After 5 days, the maximum WHC of the compost in the containers was reached. To ensure a MC of the test samples as constant as possible, the water content of the compost was increased by up to 100% WHC due to the strong evaporation caused by the dry laboratory climate with low RH. A steady water content of the compost at 100% WHC was simply controlled using the drainage openings at the bottom of the containers (Fig. 7). The seepage through the drainage openings was set to approximately 100 ml per week and water was added to the system during the test period if necessary. Additionally, the pH (pH 7.4) of the compost was determined compliant with EN 15933 (2012). In the first 2 weeks after reaching soil WHC, the MC of the moisture control sticks was controlled daily by determining the exposed weight mE until an equilibrium moisture content of the control sticks compliant with ENV 807 (2001) was reached (MC between 50 ± 5 and 80 ± 5%). Subsequently, the MC of the moisture control sticks was controlled sporadically during the first 6 months of compost storage. After 20 weeks of compost storage, the virulence control sticks were oven-dried and the WL compared to the initial dry weight was determined. WL was controlled for a second time 6 weeks later, when 45 test samples were taken out of each container (“6 months exposure” samples and “6 months CEM”). The remainder of the tensile test samples in both containers was removed after 52 weeks of compost storage (“12 months exposure” samples and “12 months CEM”). After cleaning and carefully removing the cement coating, all samples listed in Table 1 were submerged in potable water at room temperature for at least 2 days until the tensile tests were performed.

2.6 Tensile test

As described previously, 50% of the samples in the containers, as well as the reference batch, were tested in the wet condition (“Reference NC”, “6 months exposure” and “6 months CEM” batches) after 26 weeks of compost storage, as listed in Table 1. The remainder of the samples in the compost containers was removed after 52 weeks of exposure and subsequently tested in the wet condition (“12 months exposure” and “12 months CEM” batches).

All tensile test samples were tested in tension on a Zwick/Roell Z 100 universal testing machine compliant with EN 408 (2012) and a test rate of 3 mm per minute. The sample extension for determining the tensile modulus of elasticity MOE was taken by a machine-integrated extension measurement system. The free length between the clamping points was 448 mm and the distance for extension measurement was 200 mm. After testing, the moisture content of every batch (Table 1) was determined on at least three randomly selected specimens compliant with EN 322 (1993).

2.7 Fungal determination and pH of wood

Immediately after tensile testing, one randomly chosen sample from the “6 months exposure”, “6 months CEM” and “12 months CEM” batches were sent to a molecular diagnostic laboratory (Institut für Holztechnologie gemeinnützige GmbH, Dresden) for fungal determination. Therefore, a 50 mm long sample section of the 10 mm wide and 15 mm high test cross section (Fig. 4) was taken from each batch and ground into wood powder. Subsequently, testing material was mixed and a subsample was taken for analysis. The molecular diagnostic fungal determination of the “12 months CEM” sample was performed using a LCD-Array WDF 1.0 KIT (Chipron GmbH, Berlin) based on the DNA chip technology, which is the laboratory´s regular testing method. Further information about the diagnostic methods and detectable fungi of the LCD-Array 1.0 KIT are available in Rangno and Jacobs (2014) and Rangno et al. (2017). Using DNA chip technology, it was not possible to detect the fungi colonizing the “6 month exposure” sample and the strategy for fungal identification was changed for the “6 months exposure” and “6 months CEM” samples. The internal transcribed spacer (ITS) region of the ribosomal DNA was analysed using a polymerase-chain-reaction (PCR) technique for sequencing for molecular biological identification. The determined sequences were compared to a reference database at the “National Center for Biotechnology Information, NCBI (USA)”.

Additionally, the pH of the cement-coated LVL sticks was determined on four samples from the “12 months CEM” batch. These samples were destroyed during cement removal and were therefore useless for tensile tests. Immediately after compost storage and subsequent removal of the cement coating, the four samples were manually cleaned from cement residues (without water contact) and cut into uniform sticks (10 mm × 15 mm × 100 mm) without visible fungal infestation. Subsequently, the sticks were squeezed in a hydraulic pressing machine at 200 bar to recover cell water. The pH of the press-extracted cell water was measured using a pH electrode (VOLTCRAFT PH-100 ATC).

3 Results and discussion

3.1 Time-dependent moisture content (MC) and weight loss (WL) of control sticks

Monitoring of the control sticks was stopped after an exposure time of 26 weeks due to failure of all virulence control sticks caused by massive deterioration. At a soil moisture content of 100% WHC, the moisture control sticks in both containers reached a more or less constant moisture level (Fig. 9) between (50 ± 5%) and (80 ± 5%) as required in ENV 807 (2001). WL of the six virulence control sticks in container I (KP I_V) and container II (KP II_V) after 20 and 26 weeks exposure time was calculated following Eq. (1). As shown in Fig. 10, the control sticks in both containers had 37% WL after 20 weeks of exposure, which indicates a severe fungal attack.

WL of 45% at the second control measurement after 26 weeks of exposure was moderate compared to WL within the first 20 weeks. Oven drying of the control sticks at a temperature of (103 ± 2) °C after 20 weeks of exposure influenced the fungal activity afterwards and therefore, reduced the rate of WL. Nevertheless, fungal wood deterioration was detected in both containers.

3.2 Tensile strength (TS) and modulus of elasticity (MOE)

A strongly moisture-dependent decrease in mechanical properties beyond the wood fibre saturation point (FSP) has been demonstrated in various publications (Kollmann 1951; Ozyhar et al. 2012a, 2013a, b) and is also incorporated in timber engineering design standards (EN 1995-1-1 2014) using a strength modification factor kmod. Additionally, wood embedment in cement affects a change in wood equilibrium moisture content. In preliminary investigations, three LVL sticks (10 mm × 20 mm × 100 mm) were embedded in cement slurry as described previously. The cement coating was removed after 30 days of hydration time. The sticks were subsequently stored in NC for 6 months in a climate chamber, together with three additional untreated sticks as reference. Subsequently, equilibrium MC of all sticks was determined by oven drying. As a result, LVL sticks with 30 days of cement contact showed a higher equilibrium MC (MC = 13%) compared to MC of untreated sticks (MC = 11%). A continuing increase in equilibrium MC with ongoing cement contact could not be ruled out. Therefore, all tensile tests were conducted in the wet condition after at least 2 days of sample storage underwater at room temperature to avoid the influence on strength and stiffness of different MC between cement-coated and untreated batches. Ozyhar et al. (2012b) reported a slight change in beech material properties at MC far above FSP, but far less than beyond FSP. Therefore, the following results are based on the hypothesis that TS and MOE of beech LVL are constant within the MC range listed in Table 1.

Prior to further evaluation and discussion of results, it must be mentioned that caution must generally be exercised when disseminating the results presented here. As previously discussed, raw material was obtained from one location and the tensile test samples with tubular curved veneers were produced with a defined radius. A statistically reliable extrapolation of results to other raw material or production parameters is not possible. As a general statement, a comprehensive investigation of raw materials with different material origins, log pre-treatment, peeling modalities and radii, as well as thickness variations, would be necessary.

To evaluate the tensile test results, samples that had failed within the clamping area were removed. Hence, 185 samples were evaluated and analysed in total (Table 1). An outlier test by Grubbs at a level of significance of α = 0.05 identified one significant outlier in TS or MOE within each batch, which explains the difference in the number of evaluated samples between TS and MOE (Fig. 11). All material properties were relative to the initial sample cross-section of 10 mm × 15 mm. A visual evaluation of boxplot diagrams gives an overview of statistical values and data distribution. Whiskers mark minimum (Min) and maximum (Max), the lower (Q25) and upper (Q75) quartile are described with a box, a horizontal line describes the median (x̃) and a square in the box the arithmetic mean \({{\overline{\rm x}}}\).

Data were tested on how well they fit to normal or lognormal distribution using a Kolmogorov–Smirnov test at a level of significance of α = 0.05, whereby neither normal nor lognormal distribution of all samples could be rejected. Therefore, TS and MOE of all batches significantly originated from a normal or lognormal distributed population. Subsequently, normal or lognormal distributed data of cement-coated or exposed batches were compared with the reference batch by arithmetic means \({{\overline{\rm x}}}\) using one way analysis of variance (ANOVA) and post hoc Tukey’s multiple comparison tests. Batches with the same exposure period (6–12 months) were compared in pairs by a t test for two independent samples in order to assess the efficiency of cement coating on wood durability. In the case of unequal variances of batches, a Welch-test was applied to recognize significant differences in \({{\overline{\rm x}}}\). Generally, all tests were conducted at a level of significance of α = 0.05. In the case of t tests for independent samples, the test power P was analysed. To achieve a significant difference between the considered batches, P should not be lower than 0.7 (Sachs 1993).

As anticipated, in the case of exposed samples without cement coating, TS and MOE decreased significantly with ongoing exposure, whereby the strength dissipation was higher in the first 6 months of exposure. Contrary to a review given in Wilcox (1978), in case of uncoated samples, TS (82% strength reduction) was found to be more affected by fungal deterioration than MOE (42% stiffness reduction) after 26 weeks of exposure. A decrease in strength was proportionally greater compared to WL, which correlates well with findings published in Curling et al. (2002). However generally, the determined ratio between WL of control specimens after 26 weeks of exposure (WL = 45%) and tensile strength reduction is considerably higher than values for a strength reduction determined in bending tests (Wilcox 1978).

Cement-coated batches also displayed strength loss, but the residual TS and MOE were significantly higher (test power P = 1) compared to exposed batches without cement coating. The strength reduction of cement-coated batches could be traced back to an alkaline degradation of wood. Results of TS and MOE were in good agreement with results of previous investigations, where similar cement-treated beech LVL showed a severe tensile strength and stiffness decrease due to alkaline attack (Hirschmüller et al. 2018). The reduction in TS and MOE was therefore assumed to be predominantly affected by wood hydrolysis due to the high alkalinity of the cement coating and not by fungal degradation. In the cement-coated batches, no significant difference in tensile properties was identified for exposures between 6 and 12 months, neither in TS nor in MOE. Hence, cement coating displayed a positive effect on specimen durability. Coated samples also lost strength, but the decrease in material properties stagnated with time. However, although the statistical comparison between cement-coated batches with 6 and 12 months exposure delivered no significant difference, the low test power (P = 0.10) of the t-test (including a Welch correction due to unequal variances) used to compare the “6 months CEM” batch to the “12 months CEM” batch allowed no direct statement on strength evolution as a function of exposure time. Therefore, a hypothetical sample size of n = 1000 samples would be needed to achieve a test power higher than P = 0.7.

3.3 Wood deterioration, fungal specification and wood pH

3.3.1 6 months exposure sample

Unprotected tensile test samples stored for 26 weeks in active compost (“6 months exposure”) displayed severe wood destruction along the complete length embedded in compost. Both external 3 mm thick veneer layers were completely destroyed, and on both sides of the sample, remaining bond lines were visible. All 44 analysed samples had a similar rate of destruction.

Comparison of the determined ITS sequences with references of the NCBI database delivered a combined infestation consisting of several fungal species. None of the determined sequences achieved full correlation with the database. One sequence, conforming to 90%, indicated an infestation with the Basidiomycota genus Sebacinaceae. The second sequence, conforming to 86%, matched with the Ascomycota genus Chaetomiaceae. A precise fungal definition was not possible due to the 98% level of conformance with the NCBI database required.

3.3.2 6 months CEM sample

All the coated samples had cement cracks along the sample axis due to wood swelling stresses. No fungal deterioration was visible within the testing length (cross-section 10 mm × 15 mm) in any of the samples, neither in regions with cement cracks nor in regions without visible cement cracks. In regions of missing cement coatings at the enlarged cross-section of the clamping area, a dark colouration with initiating wood deterioration was recognized.

The identified ITS sequences were assignable to fungi of the Ascomycota genus Acrostalagmus luteoalbus with a 99% level of conformance. This cosmopolitan, cellulose-degrading fungus is mainly located in dead plants and forests. Therefore, a fungal infestation caused by compost storage cannot be concluded with certainty. Further, an infestation preceding the cement coating is possible due to the natural widespread fungal appearance. Generally, only little fungal DNA was detected on the investigated sample. Although no basidiomycetes were identified, a colonization of other wood degrading fungi could not be excluded due to the selective sample preparation prior to the molecular diagnostic analysis.

3.3.3 12 months exposure sample

All samples displayed massive deterioration throughout their lengths. During compost removal and cleaning, eight samples were destroyed due to the destruction of their complete cross-section (Fig. 12). A molecular diagnostic fungal determination was therefore neglected. It is assumed that these samples were infested by the same fungal species as the 6 months exposed samples due to the sample storage in the same vessel.

3.3.4 12 months CEM sample

After 12 months of compost storage, all samples showed severe destruction in places of the epoxy-resin-covered clamping area. 13 samples were destroyed in the clamping area during compost removal, and in 13 samples, deterioration initiation was recognized in regions with a thin cement coating due to eccentric embedment in the framework during production (Fig. 13). The remainder of the samples had no visible fungal infestation but a fibrous surface caused by rough cement removal in combination with wood degradation caused by the cement, a well-known effect of alkaline wood destruction (Mašura 1982; Glaus et al. 1999; Knill and Kennedy 2003). The pH of the extracted cell water was determined to be 8.99. The molecular diagnostic fungal determination of a randomly selected sample without visible deterioration using DNA chip technology revealed an infestation with Schizophyllum commune, a common white rot fungus.

4 Conclusion

The positive effect of cement coating on the durability of beech LVL sticks was well demonstrated in this study. The tensile tests conducted on bone-shaped wood sticks were an objective way of quantifying the effectiveness of wood preservation by cement coating against fungal attack, whereby the framework requires optimization for future investigations, especially at the enlarged clamping regions. No infestation of the cement-protected sticks by wood-destroying fungi was recognized within the first 26 weeks of exposure. After an exposure time of 1 year, initiating deterioration was recognizable beside unprotected parts of the clamping area, especially in sections with low cement covering. Nevertheless, the strength and stiffness properties of protected sticks remained constant for exposures between 6 and 12 months, while the properties of unprotected sticks decreased steadily. The strength level of cement-protected sticks was dominated by alkaline and not fungal destruction, although after 12 months a fungal infestation was visible in some samples and the DNA of a wood-destroying white rot fungi was detected, whereby an infestation prior to coating and compost exposure cannot be excluded due to the presence of Schizophyllum commune, a common fungus in living trees. Though, additional fungal infestation of other species could not be excluded as using DNA chip technology detects only the most common preselected fungi.

The fungal attack observed in sections with low cement coating thickness and the moderate pH of wood cell water (pH 8.99) measured after 12 months of cement contact (pH 13) led to the assumption that cement coatings work as a physical barrier against fungal infestation, whereby the impact is related to the coating thickness. A possible explanation for this dependence on thickness is the interaction between white rot fungi and cement, because the fungi produce CO2 as a result of their metabolic activity and therefore, increase the carbonisation reaction of cement (Goodell et al. 1997). After a carbonisation-induced decrease of the cement pH, the physical cement barrier may lose its efficiency with subsequently increased fungal deterioration due to easier fungus-induced wood hydrolysis of alkaline-treated beech as reported in Scott et al. (1969).

This study reveals cement coating of wood as a promising wood protection mechanism, but also highlights the necessity for further research. Inter alia, more information is required on possibly increased cement carbonisation due to the presence of fungus, the influence of coating thickness, long term alkaline strength reduction of wood and a protective effect in long-term exposure tests. A detailed investigation of wood–cement–fungal interaction will be part of future research.

References

Armstrong FH, Savory JG (1959) The influence of fungal decay on the properties of timber. Effect of progressive decay by the soft rot fungus, Chaetomium globosum, on the strength of beech. Holzforschung 13(3):84–89. https://doi.org/10.1515/hfsg.1959.13.3.84

Baron T (2009) Untersuchungen an ungeschädigten und durch Pilzbefall geschädigten Nadelholzbauteilen mit ausgewählten Prüfverfahren. (Investigations on undamaged and fungally destroyed softwood with selected testing methods), Dissertation, Technische Universität Dresden

Boettcher P (1985) Untersuchungen zum Tragverhalten von Holzpfahlgründungen in Abhängigkeit von der Holzzerstörung im Untergrund. (Studies on the load bearing behaviour of wooden pilings as a function of the subsoil wood deterioration).Bauforschung. Fraunhofer IRB Verlag, Stuttgart

Brischke C (2007) Untersuchung abbaubestimmender Faktoren zur Vorhersage der Gebrauchsdauer feuchtebeanspruchter Holzbauteile (Studies on decay-influencing factors for service life prediction of timber products subjected to moisture). Dissertation, Universität Hamburg

Brischke C, Rapp AO, Welzbacher CR (2007) The influence of different soil substrates on the service life of Scots pine sapwood and oak heartwood in ground contact. Wood Mater Sci Eng 2(1):15–21. https://doi.org/10.1080/17480270701273015

Brischke C, Meyer L, Olberding S (2014) Durability of wood exposed in ground—comparative field trials with different soil substrates. Int Biodeterior Biodegrad 86:108–114

Curling SF, Clausen CA, Winandy JE (2002) Experimental method to quantify progressive stages of decay of wood by basidiomycete fungi. Int Biodeterior Biodegrad 2002(49):13–19

D 3500–90 (2003) Standard test methods for structural panels in tension. ASTM International, West Conshohocken. http://www.astm.org

EN 113 (1996) Wood preservatives—method of test for determining the protective effectiveness against wood destroying basidiomycetes—determination of the toxic values. European Committee for Standardization, Brussels. Accessed 29 Mar 2016

EN 14490 (2010) Execution of special geotechnical works—soil nailing. European Committee for Standardization, Brussels

EN 15933 (2012) Sludge, treated biowaste and soil—determination of pH. European Committee for Standardization, Brussels

EN 1995-1-1 (2014) Eurocode 5: Design of timber structures—Part 1–1: General—Common rules and rules for buildings. European Committee for Standardization, Brussels. Accessed 21 Apr 2016

EN 252 (2015) Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. European Committee for Standardization, Brussels. Accessed 10 Feb 2016

EN 322 (1993) Wood-based panels—determination of moisture content. European Committee for Standardization, Brussels. Accessed 19 Apr 2016

EN 408 (2012) Timber structures—structural timber and glued laminated timber—determination of some physical and mechanical properties. European Committee for Standardization, Brussels

EN 635-2 (1995) Plywood—classification by surface appearance—Part 2: Hardwood. European Committee for Standardization, Brussels

ENV 807 (2001) Wood preservatives—determination of the effectiveness against soft rotting micro-fungi and other soil inhabiting micro-organisms. European Committee for Standardization, Brussels. Accessed 02 Nov 2015

Glaus MA, van Loon LR, Achatz S, Chodura A, Fischer K (1999) Degradation of cellulosic materials under the alkaline conditions of a cementitious repository for low and intermediate level radioactive waste. Anal Chim Acta 398(1):111–122. https://doi.org/10.1016/S0003-2670(99)00371-2

Goodell B, Daniel G, Liu J, Mott L, Frank R (1997) Decay resistance and microscopic analysis of wood-cement composites. Forest Prod J 47(11/12):75–80

Hirschmüller S, Pravida J, Marte R, Flach M (2018) Long-term material properties of circular hollow laminated veneer lumber sections under water saturation and cement alkaline attack. Wood Mater Sci Eng 81(4):1–15. https://doi.org/10.1080/17480272.2018.1434830

Kleindienst Q, Besserer A, Antoine M-L, Perrin C, Bocquet J-F, Bléron L (2016) Foundation piles: analysis of beech wood decay in service life conditions. In: Proceedings IRG Annual Meeting, Lisbon, pp 1–15

Knill CJ, Kennedy JF (2003) Degradation of cellulose under alkaline conditions. Carbohyd Polym 51(3):281–300. https://doi.org/10.1016/S0144-8617(02)00183-2

Kollmann F (1951) Technologie des Holzes und der Holzwerkstoffe (Technology of wood and wood-based materials). 1. Bd. In: Anatomie und Pathologie, Chemie, Physik, Elastizität und Festigkeit (Volume 1: Anatomy and pathology, chemistry, physics, elasticity and strength), 2nd revised and extended edition. Technology of wood and wood-based materials / Franz Kollmann. Springer, Berlin

Mašura V (1982) Alkaline degradation of spruce and beech wood. Wood Sci Technol 16(2):155–164. https://doi.org/10.1007/BF00351100

Ozyhar T, Hering S, Niemz P (2012a) Moisture-dependent elastic and strength anisotropy of European beech wood in tension. J Mater Sci 47(16):6141–6150. https://doi.org/10.1007/s10853-012-6534-8

Ozyhar T, Jüstrich S, Niemz P (2012b) Tensile, compressive and bending properties of European beech wood at high moisture levels. Ann Warsaw Univ Life Sci 79:135–142

Ozyhar T, Hering S, Niemz P (2013a) Moisture-dependent orthotropic tension-compression asymmetry of wood. Holzforschung 67(4):395–404. https://doi.org/10.1515/hf-2012-0089

Ozyhar T, Hering S, Sanabria SJ, Niemz P (2013b) Determining moisture-dependent elastic characteristics of beech wood by means of ultrasonic waves. Wood Sci Technol 47(2):329–341. https://doi.org/10.1007/s00226-012-0499-2

Papadopoulos AN (2008) Decay Resistance of Cement Bonded Oriented Strand Board. J Inst Wood Sci 18(2):109–111. https://doi.org/10.1179/wsc.2008.18.2.109

Rangno N, Jacobs K (2014) Sequence analysis of the rDNA-ITS region of 27 indoor wood decay fungi for development of DNA chip probes. Holztechnologie 2014(55):33–38

Rangno N, Heiser V, Thiele G, Kath S, Scheiding W (2017) LCD array technology for diagnostics of wood-decay fungi. Part 2: development and validation of DNA macroarrays. Holztechnologie 2017(58):31–35

Sachs L (1993) Statistische Methoden; Planung und Auswertung. (Statistical methods; planning and evaluation), 7th revised edn. Springer-Verlag, Berlin Heidelberg

Scott RW, Millet MA, Hajny GJ (1969) Wood wastes for animal feeding. For Prod J 1969(4):14–18 19

Wilcox WW (1978) Review of literature on the effects of early stages of decay on wood strength. Wood Fiber Sci (9):252–257

Acknowledgements

The authors would like to thank Mr. Alexander Englberger for his great effort in carrying out the tests. This work was supported by the Federal Ministry of Education and Research under Grant 13FH022IX4.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hirschmüller, S., Marte, R., Pravida, J. et al. Inhibited wood degradation of cement-coated beech Laminated Veneer Lumber (LVL) for temporary in-ground applications. Eur. J. Wood Prod. 76, 1483–1494 (2018). https://doi.org/10.1007/s00107-018-1325-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1325-9