Abstract

This work aimed to evaluate the influence of the impregnation of Pinus sp. veneers with different concentrations of boron compounds on the plywood bond quality, resistance against drywood termites (Cryptotermes brevis) and mold (Penicillium sp.). The panels were produced with veneers (≈ 10% moisture content) impregnated by dipping in the boron compound solutions, for 15 min and bonded with urea–formaldehyde (UF) adhesive. The experiment was performed in a completely randomized design, in a 3 × 3 + 1 factorial scheme, with three compounds (boric acid, borax, and disodium octaborate tetrahydrate—DOT (1.0 boric acid + 1.54 borax ≈ to Polybor or Timbor) and three concentrations (1%, 3%, and 5%) plus the control. The pressure (980 kPa), temperature (140 °C), and curing time (10 min) adopted were adequate to obtain good bond quality on the veneers. The biological resistance against drywood termites and mold was assessed according to a non-choice feeding test and fungal colony growth on the surface of the panels, respectively. Despite the low retention of boron compounds, caused by the low moisture content of the veneers submitted to the dipping (≈ 10%), all tested compounds were effective against the attack of both drywood termites and mold. The boron compounds did not influence the termites’ mortality, but this was evident as the increased solution concentrations. Boric acid at 3% was the most suitable treatment, as it gave the plywood the greatest resistance against the attack of drywood termites and mold.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Planted forests are the most important source of raw material for wood-based industries in Brazil, with 9 million hectares, accounting for a good part of the wood supply. Pinus spp. forests occupy 1.59 million hectares and are concentrated mainly in the Brazilian Southern Region, where the wood is mainly transformed into sawn lumber and panels (plywood, particleboard, oriented strand board, and fiberboard). Plywood production reached 3.4 million m3 in 2021, with 81% exported, as reported by Brazilian Association for Mechanically Processed Timber (ABIMCI 2021) and Brazilian Tree Industry (IBA 2022).

Plywood manufacturers in Brazil have been using pinewood since the early 1990s because of its fast growth, good trunk shape, ease of lamination and bonding, and availability (Almeida et al. 2012; Mendes et al. 2013). Despite these favorable characteristics, pinewood has low natural resistance against the attack of fungi and insects, so the application of chemicals is necessary to increase the life cycle of its products (Ahmed et al. 2013; Mendes et al. 2013; Zabielska-Matejuk et al. 2015).

Regarding plywood the chemicals can be applied to the veneers according to the intended protection level: (i) by dipping or spraying (for stain and mold fungi); (ii) together with the adhesive (for insects), and (iii) by vacuum-pressure (for fungi and insects) (Reinprecht and Kmet’ová 2014).

However, one of the problems related to the use of chemicals in preserving wood composites is the incompatibility of their formulations with industrial adhesives (Jin et al. 2016; Lahiry 2005). Boron compounds are the most investigated products for this purpose because they are less environmentally harmful (compared to those based on arsenic), and have high diffusibility, a broad spectrum of activity against fungi and insects (mainly), low cost, and little effect on the mechanical properties of wood (Chen et al. 2019; LeVan and Tran 1990; Reinprecht and Kmet’ová 2014; Thévenon et al. 2010).

Despite their broad spectrum of activity against xylophagous organisms, boron compounds are only intended for application to wood products used indoors (Cookson 2004). That is because they are easily leached when exposed directly to water, as well as in situations that can cause water steam condensation or ground contact (Thévenon et al. 2010). In this setting, because they are less toxic to humans and other mammals, and promote fire resistance, they can be an alternative for impregnating wood products such as plywood (Cookson 2004; Reinprecht and Kmet’ová 2014; Thévenon et al. 2010; Yalinkilic et al. 1999), mainly those to be used in furniture and internal partitions. However, in these situations, wood products are subject to the attack of drywood termites, and true and false powderpost beetles.

This work aimed to evaluate the influence of the impregnation of Pinus sp. veneers with different concentrations of boron compounds on the plywood bond quality, resistance against drywood termites (Cryptotermes brevis) and mold (Penicillium sp.).

Material and methods

Collection and treatment of veneers

Pinus sp. rotary-peeled veneers with a thickness of 1.5 mm were obtained from a company located in the municipality of Imbituva, state of Paraná, Brazil. According to company information, the veneers were artificially dried to 6% moisture content in an industrial veneer-drying machine and subsequently stored at room temperature. They were transported to Jerônimo Monteiro, state of Espirito Santo, Brazil, and stored under laboratory conditions (25 ± 2 °C and 65 ± 5% relative humidity—RH) for 3 weeks, having reached a moisture content of ≈ 10%, (dry base).

The veneers were visually classified according to the presence of knots and dipped for 15 min in different solutions (50 L of water) of boron compounds (Table 1) stored in polyethylene containers (250 L capacity). Having the control veneers dipping in water for an equal period of time. After dipping, the veneers were air-dried and stored at room temperature until reaching the equilibrium moisture content (≈ 12%).

The concentrations (Table 1) were established based on the literature (Vianez 1993), which stated that for tropical regions, borax should have a concentration of up to 5% in the solution. Above this, precipitation of boron compounds occurs, leading to errors of concentration.

Plywood manufacturing

The plywood panels were manufactured in a laboratory facility using an automatic hydraulic press (SOLAB model SL 12, Piracicaba, Brazil), with two electrically heated horizontal plates at 140 °C, with a useful pressing area of 60 × 60 cm. The pressing time and pressure were 10 min and 980 kPa, respectively. This curing time is one of the most used in research for the production, on a laboratory scale, of panels glued with adhesive based on urea formaldehyde and castor bean polyurethane resins (Brito et al. 2018, 2020; Furtini et al. 2021; Oliveira Júnior et al. 2023), for ensuring good adhesion between the veneers, wood particles and other lignocellulosic materials (Martins et al. 2020), such as residues from agricultural and forestry activities.

The plywood panels were manufactured with three veneers (1.5 mm) and were intended for interior use. Liquid urea–formaldehyde (UF) adhesive was used, catalyzed with 24% ammonium sulfate [(NH4)2SO4], calculated at 2% of the solids content of the adhesive, and wheat flour as a binder. The UF used had density: 1.28 g cm3; pH: 8.1; viscosity: 600 Cp; solids content: 64.8%; gel time: 64 s (Martins et al. 2020). The time and pressures used were able to produce plywood with good union between the veneers (Nunes 2017). The glue was formulated at a ratio of 100:40:40 (adhesive:binder:water) and each glue line had 340 g m−2.

Five panels (Final thickness ≈ 4 mm) were produced for each treatment (Table 1) along with the control (untreated), resulting in 50 panels (Following the manufacturing, the panels were stored in a climatic room (25 ± 2 °C and 65 ± 5% RH) until reaching the equilibrium moisture content (≈ 12%). For the mechanical property evaluation, four panels (five veneers each, Final thickness ≈ 7 mm) were produced for each treatment (Table 1), along with the control (untreated), resulting in 40 manufactured panels. They were produced and stored under the same mentioned conditions.

In order to evaluate the quality of the plywood bonded joint, the shear test was conducted in according to European Committee for Standardization, European Standard EN 314-1 (CEN 2004), with 12 specimens (≈ 7 mm thickness × 25 mm width × 150 mm length) per treatment, three per panel. The specimens were immersed in distilled water for 24 h and then tested in universal testing machine (EMIC, DL 10000, São José dos Pinhais, Brazil) with load capacity of 100 kN, using a loading speed of 4 mm min−1. The shearing area was 25 mm × 25 mm. After the test, the specimens were classified according to the percentage of apparent cohesive wood failure by comparison. Finally, the plywood was classified regarding bonding quality according to EN 314-2 (CEN 1993) and EN 314-1 (CEN 2004).

Retention assessment in the plywood

Twenty specimens (± 2 g) per treatment (four/panel) were used to evaluate the retention of boron. This was determined according to the method described by Wischer (1976), cited by (Paes et al. 2014), in five steps: (i) determination of the oven-dry volume of specimens (at 103 ± 2 °C) by immersion in mercury; incineration of specimens in a muffle furnace at 500–550 °C until ash formation; (ii) addition of 3 mL of a mixture containing sulfuric, perchloric and nitric acids (7:2:1) to the ash; (iii) accelerated digestion of the ash by heating the acid-ash solution on a hot plate until reaching a clear color; (iv) diluting the resulting solution in distilled water at fixed volumes; 50 mL) reading the diluted solutions with an atomic absorption spectrophotometer (Bel Photonics, SP 2000 UV, Monza, Italy).

Based on the spectrophotometer readings (420 nm) and the anhydrous volume of each specimen, the mean retention of boric acid equivalent—BAE or boron trioxide (kg of H3BO3 or B2O3 per cubic meter of wood) was calculated for each treatment (Paes et al. 2014), using Eq. (1)

Where R: retention (kg m−3); F: stoichiometric factor for transformation of element boron (B) to boric acid (B × 5.72 = H3BO3) or to boron trioxide (B × 6.44 = B2O3); S: spectrophotometer reading (mg l−1); DF: dilution factor (10 for 1%, 20 for 3% and 40 for 5% concentration); V: anhydrous volume of specimen (cm3).

Non-choice feeding test with drywood termites

The efficiency of preservative solutions on the resistance of plywood against drywood termites (Cryptotermes brevis Walker) was tested according to Institute of Technological Research of the State of São Paulo-method (IPT 1980), similar to the described by (Maistrello 2018). Ten specimens per treatment (two/panel) of 20 × 4.5 × 70 mm (width × thickness × length) were paired, forming five sets per treatment for testing. A polyvinyl acetate (PVA) pipe (35 mm internal diameter × 40 mm high) was attached with paraffin to each set, filled with 40 drywood termites (two soldiers and 38 workers) and placed in a Petri dish, and a piece of filo fabric was placed over the PVA pipes to prevent termite prey (Pinto 2020).

The test was carried out in a climate-controlled room (27 ± 2 °C and 65 ± 5% RH) for 45 days. In the end, we evaluated the termites’ mortality (%), the visual damage scoring and the number of holes that ran through the surfaces of the samples. The damage scoring was classified as: 0—sound, surface nibbles permitted, 1—light attack, 2—moderate, penetration, 3—heavy, and 4—deep damage or failure. Additionally, the mass loss (%) was calculated according to the American Wood Protection Association standard (AWPA 2016a).

Mold test

The efficiency of preservative solutions on the resistance of plywood against Penicillium sp. mold was carried out according to the American Society for Testing and Materials (ASTM 2019). Ten specimens per treatment (two/panel), with dimensions of 20 × 4.5 × 70 mm (width × thickness × length) were paired, forming five sets per treatment for testing.

The mold was indirectly isolated according to (AWPA 2016b), where pinewood veneers naturally mold-infected (indirect isolation) were used as a source of mold inoculum, similar to search by (Ahmed et al. 2013), and then cultured in Petri plates. The spore solution used for inoculation in the samples was prepared by mixing the cultures of two Petri dishes in 300 mL of sterile distilled water. For homogenization, the solution was magnetically stirred (30 rpm for 40 min) at room temperature (25–30 °C).

The test was carried out in a climate-controlled room (27 ± 2 °C and 65 ± 5% RH) for 4 weeks, in four steps: (i) placing layers of absorbent paper in Petri dishes, moistened with sterile distilled water, to keep humidity high (≈ 70%); (ii) laying glass slides on the paper, in adaptation to (ASTM 2019), to avoid direct contact of the specimens with the moistened paper; (iii) laying the paired specimens on the glass slides, and (iv) pipetting 0.25 mL of spore solution on the surface of the specimens.

The evaluation of the results was based on visual analysis of mold growth on a scale from zero (lowest growth) to five (highest growth). Subsequently, the growth percentage was calculated (Eq. 2) considering the mean scores given by five evaluators for each treatment concerning the control.

Analysis of results

The experiment was carried out in a completely randomized design in a 3 × 3 + 1 factorial arrangement (boron compounds × concentrations, plus control), totaling 10 treatments. Data were subjected to statistical assumption tests (Cochran; normality and Shapiro–Wilk; homogeneity of variance), and then submitted to analysis of variance (ANOVA) with the F-test (p < 0.05).

For the evaluation of the retention of boron compounds in the plywood, we considered only the factorial scheme, excluding the control. In situations where there was a significant effect of the type of boron compound, the Tukey test (p < 0.05) was applied to compare the means; in cases where there was a significant effect of the concentration, analysis of regression was applied, using the technique of orthogonal polynomials with decomposition in linear and quadratic effects.

For the evaluation of the tests of veneers bond quality, drywood termites (mortality percentage, mass loss, and damage scoring) and mold (growth percentage), the same analyses as the retention test were performed, with the same assumptions. However, in addition, the means of each treatment were compared to the control using the Dunnett’s test (p < 0.05).

Results and discussion

Retention of boron element, boric acid, and boron trioxide in plywood

The interaction between the factors boron compound and concentration was significant (Fc = 4.17; p < 0.01) for retention of the element boron, boric acid equivalent or boron trioxide (kg m−3) in the nine treatments, which demonstrated their synergistic effect. The comparison of retention means (kg m−3) among the different boron compounds for each concentration is given in Table 2.

There was a significant difference among retention means (kg m−3) only in solutions formulated with 5% concentration, with the higher mean for disodium octaborate tetrahydrate—DOT (Na2B8O13·4H2O), which was 27% higher than the general mean (Table 2). This behavior is in agreement with the literature, where the solubility of DOT (also known by Polybor or Timbor), obtained by the mixture of 1.0 boric acid (H3BO3) and 1.54 borax (Na2B4O7·10H2O) as in (Freeman et al. 2009; Richardson 1993), had greater solubility than when they were used separately (Freeman et al. 2009; Richardson 1993), which provides more diffusibility in wood. It is worth noting that the veneers had a moisture content of ≈ 10% when they were dipped in the boron compound solution (Table 1). The same procedure was performed for the control, which in this case were dipped in water. This may have negatively influenced the diffusion of boron compounds in the wood, reflecting a lower retention and effectiveness against the xylophagous organisms tested.

During the preparation of solutions, no problems of dilution were noted, even at 5% concentration, as reported in the literature (Cookson 2004; Willerding and Vianez 2003). The lower retention values of samples treated with boric acid and borax at 5% concentration may be explained by the lower solubility of these compounds at concentrations higher than 4% (Cookson 2004), and consequently their lower diffusibility in the veneers.

None of the retentions obtained reached the minimum of 3.89 kg m−3 for Timbor® (Jorge et al. 2004) to protect southern yellow pine wood from subterranean termites in field testing. This is because the diffusibility obtained by the dipping method is more effective in freshly sawn wood (high moisture content), which facilitates the diffusion process of boron compounds. As the veneers were previously dried (≈ 10%), their low moisture content hampered the diffusion of boron compounds. However, that retention is recommended as the minimum to protect treated wood against subterranean termites above ground in field tests, which is a drastic condition of wood exposure.

However, values for various xylophagous organisms, including Basidiomycetes (brown-rot fungi) and insects (wood-boring beetles), where retentions as low as 0.5 kg m−3 (BAE equivalent) inhibited the development of Coniophora puteana and Serpula lacrymans fungi in oak (Quercus sp.) wood are cited in the literature (Freeman et al. 2009). In the same article, it is mentioned that retentions between 0.2 and 0.4 kg m−3 (BAE equivalent) prevented the attack of Anobium sp. in radiata pine (Pinus radiata) treated wood and larval survival of Anobium sp. and Hylotrupes sp. (Cerambycidae) in corsican pine (Pinus nigra) in treated wood sawdust. Thus, the retention obtained for the solution with 5% DOT (Table 2) is expected to be efficient against drywood termites and molds.

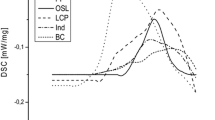

The effect of solution concentration on boron retention for each boron compound (Table 2) was performed by regression analysis, whose estimated equations are shown in Fig. 1. All boron compounds had a positive and linear relationship between concentration and retention, and all adjusted equations were significant (F; p < 0.01).

For boric acid and borax solutions (Fig. 1), higher retention increases occurred from 1 to 3%, corresponding to 91% and 158%, respectively. In contrast, for boric acid + borax (DOT, Polybor or Timbor) solutions, the greatest retention increase occurred from 3 to 5%, corresponding to 94%.

The effect of the concentration of boron on retention (Fig. 1) is related to their solubility and diffusion in the veneers. Higher retentions, obtained with increasing concentrations of boron suggest greater efficiency against xylophagous organisms (Freeman et al. 2009), including false and true powderpost beetles (e.g., Dinoderus sp. and Lyctus sp.), where retentions of 0.8–1.0 kg of BAE m−3 of wood are required, for the prevention of its attack. For drywood termites (Incisitermes minor), (Kartal et al. 2020) reported that retention of 0.533 kg DOT. m−3 of wood provided 25% of termite mortality. Nevertheless, to achieve 80% or more termite mortality, retention greater than 6.8 kg m−3 would be required. DOT in the concentration levels of 1% did not completely inhibit mold growth in Cryptomeria japonica-treated sapwood (Kartal et al. 2020).

Bond joint quality of the plywood

The means of shear strength (MPa) and bond line failure (%) of the treatments were compared to the control (1.37 MPa and 30.8%), horizontal line (Figs. 2, 3), respectively. For shear strength, the treatments containing boric acid at 1% and 3% (better than control), and DOT at 1% did not differ (p > 0.05) from the control (no impregnated veneers). For the other treatments, the effect of boron impregnation was negative and lower than the control results. This can cause less adhesion between the veneers and facilitate access drywood termites or coleoborers (Coleoptera) to the core of the plywood, mainly when the retention of boron compounds was low or not effective to prevent the attack of these insects.

When testing shear strength, the aim is to get more failures in the veneers (Fig. 3) than in the glue line, which means efficient bonding. The treatments containing boric acid at 1% and 3%, 1% borax, and DOT at 1% did not differ (p > 0.05) from the control (no impregnated veneers). But, no treatment showed better results than the control. The treatments (boric acid, borax and DOT at 1%; boric acid at 3% and DOT at 3% and 5%) met the shear strength requirements (> 1.0 MPa) (CEN 1993), independently of the percentage of bond line failure (Fig. 3).

An overall analysis indicates that boron compounds had a negative effect on bond quality, except at the 1% concentration. Boron compounds have no effect on practical bonding quality, but tend to reduce shear strength (Özçifçi 2008). On the other hand, they improve the efficiency of plywood against drywood termites and borers.

Drywood termites test

The interaction between the factors boron compound and concentration was not significant (Fc = 0.85; p > 0.05) for the termite mortality. The effect of the factor boron compound alone was also not significant (Fc = 0.52; p > 0.05). On the other hand, the effect of the concentration was significant (p < 0.01) according to the regression analysis. The adjusted regression equation is shown in Fig. 4.

These results (Fig. 4) are consistent with the literature because the effectiveness of boron solutions against xylophagous depends solely on the amount of boron applied to wood, regardless of the compound used (Freeman et al. 2009). Nevertheless, for the same concentration, there is a difference in the efficiency of the compounds used, which is related to retention into wood (Table 2).

According to the Dunnett’s test (Table 3), there was a significant difference between the mean mortality and damage but not for mass loss (DOT to 1% and 3%) caused by the treated samples compared to the control. All treatments were effective against drywood termites, resulting in higher mortality when compared to the control.

There was no significant interaction between the factors for the damage scoring (Fc = 0.73; p > 0.05). However, the factors had significant effect when analyzed separately, with Fc = 3.28 (p < 0.05) and 9.85 (p < 0.01), respectively, for boron compounds and concentration. On the other hand, there was a significant (p < 0.01) decrease of damage scoring (Ŷ) with increasing concentration of boron compounds (X), with means of 1.79, 1.24, and 1.09, respectively, for 1%, 3%, and 5%. The adjusted equation was significant (Ŷ = 1.18991 − 0.1750*X, R2 = 90.7%, p < 0.01).

Similarly, to the damage scoring, there was no significant interaction between the factors boron compounds and concentration (Fc = 0.43; p > 0.05). However, the factors had significant effect when analyzed separately, with Fc = 19.81 (p < 0.01) and 17.70 (p < 0.01), respectively, for boron compounds and concentration. As the mass losses provided by boric acid were equal to zero, only the other two boron compounds were considered for the statistical analysis.

There was a significant (p < 0.01) decrease of mass loss (Ŷ) with increasing concentration of boron compounds (X), with means of 0.35%, 0.25%, and 0.18%, respectively, for 1%, 3%, and 5%. The adjusted equation was significant (Ŷ = 0.3891 − 0.0424*X, R2 = 97.9%, p < 0.01).

The mean mortality rates were 68.0%, 84.7% and 84.2%, respectively, for concentrations of 1%, 3%, and 5% (Table 3). The highest increase in mortality compared to the increase in the concentration of boron compounds occurred from 1 to 3%, reaching 16.7%, and then stabilized up to 5% concentration. (Kartal et al. 2020) reported that higher retention levels (> 6.8 kg DOT.m−3) were needed to reach up to 80% or more mortality for drywood termites (Incisitermes minor) in contact with Cryptomeria japonica treated sapwood. Thus, Cryptotermes brevis were more sensitive to boron compounds when compared to Incisitermes minor, since DOT retentions as low as 0.511 kg m−3, calculated as BAE, were sufficient for mortality of more than 84% of termites.

By separately assessing the effect of the factor concentration on retention results, there was a relationship between mortality increase and retention when comparing different concentrations. Similarly, the largest retention increase (122%) occurred when increasing the concentration from 1 to 3%. Thus, considering the economics of the process and the efficacy against drywood termites (Cryptotermes brevis), the use of solutions formulated at 3% concentration is recommended, since the result of this concentration was better than the others.

DOT at 3% concentration caused the highest absolute mortality (86.5%), which was twice that of the control. Boric acid at 1% caused the lowest absolute mortality (64.5%), but it was still 1.5 times higher than the control. Considering the mortality imparted by the different treatments, we recommend the use of DOT at 3% concentration to protect plywood against drywood termites.

Overall, the damage scoring (Table 3) were less than 2, representing moderate attack (IPT 1980; Maistrello 2018). Boric acid had the lowest absolute mean (1.13), which differed significantly from borax, which had the highest absolute mean (1.53). The samples treated with DOT had an intermediate mean (1.45) and did not differ significantly from the others. Thus, according to the damage scoring, the boron compounds were effective against drywood termites. The lower absolute mean achieved by boric acid indicated higher efficacy of this compound compared to the others.

According to the Dunnett’s test, there was a significant difference between the damage scoring of the treated samples compared to the control (Table 3), which indicated the efficiency of boron compounds against the attack of drywood termites. The mean damage scoring (3.02) of the control was classified as deep or failure attack (IPT 1980; Maistrello 2018).

There is little information on the relationship between the feeding behavior of termites in tests with treated wood with boron compounds. According to (Campora and Grace 2007), the exposure of termites to wood treated with these compounds causes a gradual response of insect rejection when feeding.

Boric acid at 3% concentration had the lowest absolute mean damage score, which was 3.5 times lower than the control score, and was classified as light attack-lower than 1.0 (IPT 1980; Maistrello 2018). In contrast, borax with 1% concentration had the highest absolute mean damage scoring, but even so, it was 1.5 times lower than the control. This treatment was classified as moderate attack—slightly higher than 2.0 (IPT 1980; Maistrello 2018).

Mean mass losses were lower than 0.50% (Table 3), where DOT had the highest mean (0.43%), followed by borax (0.10%). Besides the preservative treatment, low mass losses for plywood may be related to the type of adhesive used in its production, since no holes were observed in the specimens. Regarding plywood resistance against the drywood termite Cryptotermes brevis, (Ribeiro 2011) reported that urea–formaldehyde (UF) was effective against termite attack. Nevertheless, drywood termites may attack the plywood without directly crossing the glue line; this may occur through cracks in plywood structure, or after UF evaporation, as is observed in the home furniture, flat wooden doors, and partitions and thus cause great damage or economic losses.

In agreement with the results of the damage scoring, there was an inverse relationship between concentration and mass loss. The efficiency of boron compounds in wood treatment is related to the amount of boron (concentration and retention), regardless of the type of compound (Freeman et al. 2009). There was a greater increase in efficiency with increasing concentration from 1 to 3% than from 3 to 5%, corroborating the literature, as reported by (Kartal et al. 2020) and the results are presented in Fig. 1, where the largest increase in retention of boron also occurred under these conditions.

According to the Dunnett’s test (Table 3), there was a significant difference between the mass losses of the majority of the treatments and the control (p < 0.01). Only the means of 1% and 3% DOT did not differ significantly from the control. For all the concentrations of boric acid, there was no mass loss detected by weighing (0.01 g), although damage scores were attributed to these treatments. Differences between the results of mass loss and damage scoring are common, especially in the case of lower density wood, as was the case of the plywood studied (0.46 g cm−3–0.55 g cm−3). It is necessary to remove more volume of material caused by scarification of termites to represent a significant mass loss (Sousa et al. 2019). The mass loss could have been detected if a scale with an accuracy of 0.0001 g was used.

Although the mass loss of all treatments was low (> 1%), we highlight the conditions of the (IPT 1980) test, where the termites (40 insects) are trapped for 45 days in a cylinder (3.5 mm of internal diameter) of 962 mm2, what corresponds to contact with 69% of the total surface area of the samples (1400 mm2). A higher mass loss can be achieved with the method described by (Maistrello 2018), which lasts longer (84 days) and uses more termites (50 days); however, it demands further studies.

Other causes for the small mass loss are the total area of the samples and their density, as mentioned by (Sousa et al. 2019), in which the termites would need to remove a large amount of material to cause significant mass loss. Similar results using the IPT/DIMAD method were found in the literature (Brocco et al. 2017; Gonçalves et al. 2021; Martinez Lopez et al. 2020; Oliveira and Paes 2019).

Regarding the control (untreated), the mortality was moderate, 43.0%, the damage scoring was 3.02, the mass loss was 0.73% (Table 3), and no holes were crossing the samples or the glue line. Then, we suggest that the adhesive (UF) contributed to the improvement of the Pinus sp. wood resistance against the termites’ activity. This is in agreement with (Ribeiro 2011), who stated that the UF acted against the drywood termites Cryptotermes brevis attack. The results were also similar to those reported in literature (Brocco et al. 2017) for control samples of Pinus elliottii, who obtained mass loss of 1.76%, damage scoring of 2.28 and mortality of 44.50%. The mortality of termites may also be associated with wood extractives, such as terpenes and terpenoids (Oliveira and Paes 2019).

Mold test

The effect of the factor’s boron compounds (Fc = 2.91; p > 0.05) and concentration (Fc = 0.87; p > 0.05), as well as their interaction (Fc = 1.01; p > 0.05), was not significant for mold growth percentage. However, preservative treatments were effective because the mold colonized only the control samples (Table 4).

Although there was no significant difference between the boron compounds, the highest scores, and hence the highest growth percentages, were observed in the samples treated with borax at the three concentrations. Considering the absolute means (Table 4), increased concentration tended to slow the mold development only for borax. When used alone, borax had limited effectiveness against mold and was more effective at high concentrations (Micales-Glaeser et al. 2004). Little has been reported about the efficiency of boron compounds against molds, however, is reported that DOT in highest retention level tested (1.0 kg DOT.m−3) was not able to completely inhibit mold growth on the surfaces of Cryptomeria japonica treated sapwood (Kartal et al. 2020). These compounds are more effective against staining and rot fungi in higher pH media (Richardson 1993; Scheffer and Lindgren 1940), and also to blue stain fungi (Lesar and Humar 2009).

As reported by (Freeman et al. 2009), retention of 0.7 kg BAE.m−3 was able to inhibit the growth of several brown-rot fungi, as Poria vaporaria (accepted name: Antrodia sinuosa), Coniophora cerebella, Coniophora puteana, Serpula lacrymans, and Lentinus lepideus (currently called Neolentinus lepideus). (Lesar and Humar 2009) reported that retentions from 0.8 to 1.0 kg of boric acid (BA).m−3 were effective against Gloeophyllum trabeum, Antrodia vaillantii and Serpula lacrymans (brown-rot fungi), and Trametes versicolor, Hypoxylon fragiforme and Pleurotus ostreatus (white-rot fungi), after 12 weeks of the test. They also reported 100% growth retardation of two blue stain fungi (Aureobasidium pullulans and Sclerophoma pythiophila) at a boric acid concentration of 200 mg L−1.

Conclusions

Despite the low retention achieved by the veneers impregnated by dipping, caused by their low moisture content (≈ 10%) when dipping in solutions of boron compounds, at concentrations of 1%, 3%, and 5% were effective against the attack of drywood termites (Cryptotermes brevis) and mold (Penicillium sp.). The pressure, temperature and curing time adopted in the plywood production were able to cause good bond adhesion between the veneers. The type of boron compound did not influence the mortality of drywood termites. Nevertheless, considering damage scoring and mass loss, boric acid was more efficient than borax and DOT. In general, increased concentration (retention) resulted in higher mortality, decreased damage scoring, and consequently reduced the mass loss caused by the attack of the drywood termites. Regarding the mold Penicillium sp., all boron compounds and concentrations were efficient, and 3% boric acid produced the best results.

References

ABIMCI (2021) Brazilian association for mechanically processed timber. Estudo setorial 2022. Ano base 2021. https://abimci.com.br/wp-content/uploads/2022/09/Estudo-Setorial-2022.pdf

Ahmed SA, Yang Q, Sehlstedt-Persson M, Morén T (2013) Accelerated mold test on dried pine sapwood boards: Impact of contact heat treatment. J Wood Chem Technol 33(3):174–187. https://doi.org/10.1080/02773813.2013.773041

Almeida NF, Bortoletto Júnior G, Mendes RF, Surdi PG (2012) Avaliação da madeira de Pinus elliottii var. elliottii x Pinus caribaea var. hondurensis para produção de compensados. Sci For 40(96):435–443

ASTM (2019) American Society for Testing and Materials. D4445-10: standard test method for fungicides for controlling sapstain and mold on unseasoned lumber (laboratory method). West Conshohocken, PA, pp 1–4

AWPA (2016a) American Wood Protection Association. E 30-16: standard method for evaluating natural decay resistance of woods using laboratory decay tests. AWPA Book of Standards, Birmingham, pp 494–498

AWPA (2016b) American Wood Protection Association E10-16: laboratory method for evaluating the decay resistance of wood-based materials against pure basidiomycete cultures: soil/block test. AWPA Book of Standards, Birmingham, pp 406–417

Brito FMS, Bortoletto Júnior G, Paes JB, Belini UL, Tomazello-Filho M (2020) Technological characterization of particleboards made with sugarcane bagasse and bamboo culm particles. Constr Build Mater 262:120501. https://doi.org/10.1016/j.conbuildmat.2020.120501

Brito FMS, Paes JB, da Oliveira Silva JT, Arantes MDC, Vidaurre GB, Brocco VF (2018) Physico-mechanical characterization of heat-treated glued laminated bamboo. Constr Build Mater 190:719–727. https://doi.org/10.1016/j.conbuildmat.2018.09.057

Brocco VF, Paes JB, da Costa LG, Brazolin S, Arantes MDC (2017) Potential of teak heartwood extracts as a natural wood preservative. J Clean Prod 142(4):2093–2099

Campora CE, Grace JK (2007) Foraging behavior of the formosan subterranean termite (Isoptera: Rhinotermitidae) in response to borate treated wood. International Research Group on Wood Preservation, Stockholm (Doc. IRG/WP 07-10605)

CEN (1993) European Committee for Standardization. EN 314-2: plywood. Bonding quality-requirements. Brussels, pp 1–12

CEN (2004) European Committee for Standardization. EN 314-1: plywood. Bonding quality-test methods. Brussels, pp 1–20

Chen X, Li J, Gao M, Yue L, Zhou X (2019) Fire protection properties of wood in waterborne epoxy coating containing functionalized graphene oxide. J Wood Chem Technol 39(5):313–328. https://doi.org/10.1080/02773813.2019.1601740

Cookson LJ (2004) Treatment methods for the protection of hardwood sapwood from lyctine borers. Australian Government, Forest and Wood Products Research and Development Corporation, Melbourne

Freeman MH, McIntyre CR, Jackson D (2009) Critical and comprehensive review of boron in wood preservation. In: Proceedings of the 105th annual meeting of the American Wood Protection Association, pp 279–294

Furtini ACC, Aparecida dos Santos C, Venâncio Silva Garcia H, Maria Silva Brito F, Paula dos Santos T, Marin Mendes L, Benedito Guimarães Júnior J (2021) Performance of cross laminated timber panels made of Pinus oocarpa and Coffea arabica waste. Coffee Sci 16:1–12. https://doi.org/10.25186/.v16i.1854

Gonçalves FG, Paes JB, Martinez Lopez Y, de Alcântara Segundinho PG, de Oliveira RGE, Fassarella MV, Brito AS, Chaves ILS, Martins RSF (2021) Resistance of particleboards produced with ligno-cellulosic agro-industrial wastes to fungi and termites. Int Biodeterior Biodegradation 157:105159. https://doi.org/10.1016/j.ibiod.2020.105159

IBA (2022) Brazilian tree industry. Relatório Anual Ibá. https://www.iba.org/datafiles/publicacoes/relatorios/relatorio-anual-iba2022-compactado.pdf

IPT (1980) Instituto de Pesquisas Tecnológicas de São Paulo, Brazil. DIMAD D-2: ensaio acelerado da resistência natural ou de madeira preservada ao ataque de térmitas do gênero Cryptotermes (Fam. Kalotermitidae). IPT, São Paulo. (Publicação 1157)

Jin J, Wang J, Qin D, Luo N, Niu H (2016) Effects of veneer treatment with copper-based preservatives on the decay resistance and mechanical properties of poplar LVL. J Wood Chem Technol 36(5):329–338. https://doi.org/10.1080/02773813.2016.1148167

Jorge FC, Nunes L, Botelho C (2004) Boron in wood preservation: problems, challenges and proposed solutions—an overview on recent research. Rev Da Fac De Ciênc e Tecnol 1:1–15

Kartal SN, Terzi E, Yoshimura T (2020) Performance of fluoride and boron compounds against drywood and subterranean termites and decay and mold fungi. J For Res 31(4):1425–1434. https://doi.org/10.1007/s11676-019-00939-4

Lahiry AK (2005) Non–pressure treatability of plywood by CCA, CCB and boron. IRG/WP/05–40295

Lesar B, Humar M (2009) Re-evaluation of fungicidal properties of boric acid. Eur J Wood Wood Prod 67(4):483. https://doi.org/10.1007/s00107-009-0342-0

LeVan SL, Tran HC (1990) The role of boron in flame-retardant treatments. In: M. Hamel, D. Robertson (Eds) First international conference on wood protection with diffusible preservatives. In: Proceedings 47355, Forest Products Research Society, Madison, WI/USA, pp 39–41. https://www.fs.usda.gov/research/treesearch/5831

Maistrello L (2018) Termites and standard norms in wood protection: a proposal targeting drywood termites. In: Khan MA, Ahmad W (eds) Termites and sustainable management: economic losses and management, 2nd edn. Springer International Publishing, Cham, pp 261–287

Martinez Lopez Y, Gonçalves FG, Paes JB, Gustave D, Theodoro Nantet AC, Sales TJ (2020) Resistance of wood plastic composite produced by compression to termites Nasutitermes corniger (Motsch) and Cryptotermes brevis (Walker). Int Biodeterior Biodegrad 152:104998. https://doi.org/10.1016/j.ibiod.2020.104998

Martins RSF, Gonçalves FG, Lelis RCC, Segundinho PGA, Nunes AM, Vidaurre GB, Chaves ILS, Santiago SB (2020) Physical properties and formaldehyde emission in particleboards of Eucalyptus sp. and lignocellulosic agro-industrial waste. Sci For 48(125):e-2926. https://doi.org/10.18671/scifor.v48n125.13

Mendes RF, Bortoletto Júnior G, Vidal JM, Almeida NF, Pontes IJ (2013) Efeito do tratamento preservativo de painéis compensados sobre as suas propriedades físico-mecânicas. Sci For 41(100):507–513

Micales-Glaeser JA, Lloyd JD, Woods TL (2004) Efficacy of didecyl dimethyl ammonium chloride (DDAC), disodium octaborate tetrahydrate (DOT), and chlorothalonil (CTL) against common mold fungi. International Research Group on Wood Preservation: Stockholm (Doc. IRG/WP 04-30338)

Nunes AM (2017) Influência do tratamento de lâminas de Pinus sp. com sais de boro nas propriedades dos compensados. Federal University of Espírito Santo, Vitória

Oliveira JTS, Paes JB (2019) Biological resistance of two reforestation woods to dry wood termites. Floresta e Ambiente. https://doi.org/10.1590/2179-8087.055817

Oliveira Júnior JN, Lopes FPD, Simonassi NT, Oliveira MP, Gonçalves FG, Vieira CMF (2023) Evaluation of hot pressing processing by physical properties of ecofriendly composites reinforced by Eucalyptus sawdust and chamotte residues. Polymers 15(8):1931. https://doi.org/10.3390/polym15081931

Özçifçi A (2008) Impacts of impregnation with boron compounds on the bonding strength of wood materials. Constr Build Mater 22(4):541–545. https://doi.org/10.1016/j.conbuildmat.2006.11.006

Paes JB, Lopes DJV, Gonçalves FG, Brito FMS, Lombardi LR (2014) Efeito da concentração na ascensão de soluções preservativas preparadas com CCB em moirões de Eucalyptus. Floresta e Ambiente 21(3):384–393. https://doi.org/10.1590/2179-8087.036913

Pinto JA (2020) Medidas profiláticas para proteger madeiras à ação de insetos xilófagos. Federal University of Espírito Santo, Vitória

Reinprecht L, Kmet’ová L (2014) Fungal resistance and physical–mechanical properties of beech plywood having durable veneers or fungicides in surfaces. Eur J Wood Wood Prod 72(4):433–443. https://doi.org/10.1007/s00107-014-0788-6

Ribeiro MX (2011) Resistência de Painéis Aglomerados a Cupins de Madeira Seca (Cryptotermes brevis). Tesis (Master’s degree), Federal Univesity of Lavras, Lavras

Richardson BA (1993) Wood preservation, 2nd edn. E & FN Spon, London

Scheffer TC, Lindgren RM (1940) Stains of sapwood and sapwood products and their control. Technical bulletin, 714. United States Department of Agriculture, Washington, DC

Sousa SF, Paes JB, Arantes MDC, Lopes Junior DV, Nicácio MA (2019) Efficiency of vegetable oils in wood resistance to Cryptotermes brevis termites. Floresta e Ambiente 26(2):e20170780. https://doi.org/10.1590/2179-8087.078017

Thévenon M-F, Tondi G, Pizzi A (2010) Environmentally friendly wood preservative system based on polymerized tannin resin-boric acid for outdoors applications. Maderas Cienc y Tecnol 12(3):253–257. https://doi.org/10.4067/S0718-221X2010000300009

Vianez BF (1993) Aspects of boron diffusion through hardwoods. University of Wales, Wales

Willerding AL, Vianez BF (2003) Utilização de bórax por difusão no tratamento de preservação de lâminas de sumaúma (Ceiba pentantra (L.) Gaertn.). Rev Árvore 27(3):321–326. https://doi.org/10.1590/S0100-67622003000300007

Yalinkilic MK, Imamura Y, Takahashi M, Yalinkilic AC (1999) In situ polymerization of vinyl monomers during compressive deformation of wood treated with boric acid to delay boron leaching. For Prod J 49(2):43–51

Zabielska-Matejuk J, Stangierska A, Kot M (2015) New ammonium- and 1,2,4-triazolium-based ionic liquids for wood preservation. J Wood Chem Technol 35(3):178–192. https://doi.org/10.1080/02773813.2014.909852

Acknowledgements

The authors would like to thank the company Compensados Galli Ltda. (Brazil) for donating the veneers and the company Fibria Celulose S.A. (Brazil) for granting a scholarship to the first author, the Espírito Santo Research and Innovation Foundation (FAPES), and the National Council for Scientific and Technological Development (CNPq), Brazil for Research support grant.

Author information

Authors and Affiliations

Contributions

The article was written through the contributions of all authors and all of them have approved the final version of the article. D.C.B., J.B.P., and F.G.G. proposed experimental solutions, and validated the initial objectives of the project. A.M.N. prepared the boron compound solutions, treated the veneers, produced the plywoods, and analyzed the preliminary results. A. J. R. assisted in statistical analysis and discussion of results. A.M.N. wrote the original draft. A. T. S. A. contributed on production of illustrations and critical reading of the text. D.C.B., J.B.P., and F.G.G. helped for reviewing, editing, and correcting both spelling and grammar errors.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest is reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nunes, A.M., Regazzi, A.J., Gonçalves, F.G. et al. Resistance to biodeterioration of plywood manufactured with veneers treated with boron compounds. J Indian Acad Wood Sci 20, 138–148 (2023). https://doi.org/10.1007/s13196-023-00322-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-023-00322-1