Abstract

Within this study, the effect of different cross section dimensions on wood moisture content (MC), time of wetness (ToW), and fungal decay development of Norway spruce (Picea abies Karst.) and Scots pine sapwood (Pinus sylvestris L.) was examined. Specimens with ten different quadratic and rectangular cross sections were exposed horizontally in Hannover, Germany, and monitored for a period of 5 years. MC and temperature were recorded daily and data sets were submitted to a dose–response model based on material climatic data for evaluating the respective decay risk of the different specimen types. After 5 years of outdoor exposure timber dimension was found to be correlated neither with wood MC nor with decay development. However, time of wetness and decay were more severe in pine sapwood compared to spruce. Regarding onset and further development of decay, cracks as well as contact faces turned out to be weak points, but interior rot was observed as well. Brown rot, which occurred predominantly in the specimens, was partly difficult or even impossible to detect from the outside, but caused severe degradation also in small-dimensioned samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The resistance of timber products to wood-destroying organisms is the result of its inherent durability, its ability to take up and release moisture, and the respective exposure conditions. Wood exposed outdoors tends to change its dimensions due to swelling and shrinking with varying moisture. The susceptibility of a wooden component to the formation of cracks is caused by tensions occurring on its surface and its interior parts (e.g. Sandberg 1999). Due to the anisotropy of wood sorption, capillary water uptake and in particular swelling and shrinking are affected by the orientation of the annual rings and have a decisive influence on cracking of wood exposed outdoors (Sandberg 1999, 2005; Müller 2000; Sandberg and Söderström 2006).

The formation of cracks is more pronounced on tangential than on radial surfaces, where latewood and earlywood are alternating and thus shrinkage movements and resulting stresses are buffered (Sandberg 1999; Sandberg et al. 2013). Furthermore, sapwood is usually more susceptible to crack formation than heartwood, because it absorbs more water and therefore undergoes stronger moisture-related movements in wood (Sandberg 2008). In addition to the formation of macroscopically visible cracks, which increase the uptake of liquid and vaporous water (Rapp and Peek 1999; Brischke and Melcher 2015), the wettability of wood increases with proceeding exposure time (Kalnins and Feist 1993) due to micro-cracks and chemical alterations of components on the wood surface. As shown for instance by Müller (2000) the formation of cracks is also influenced by the size of the wooden component and its surface–volume ratio respectively. The risk of crack formation is following the width of a wooden component. Therefore wooden members with small cross section generally show less cracks than bigger sized ones, which is most likely attributed to the occurring shrinkage stresses. It is still controversially discussed to what extent higher wood moisture content (MC) in larger dimensioned components is the result of their lower surface-volume ratio and thus lower re-drying potential (e.g. Meierhofer and Sell 1979; Sell 1980; Müller 2000; Augusta 2007; Meyer et al. 2014). Cracks are potential entry ports for moisture (Adachi et al. 2004), but also for spores of wood-destroying fungi. Cracks have the potential to initiate high MC and consequently increase the risk of decay (Austigard et al. 2014 ). However, formation of cracks does not necessarily lead to fungal infestation, and interior rot can occur as well as rot starting from less durable sapwood portions as shown for split oak fence posts by Brischke and Rolf-Kiel (2010).

Without controversy the dimension of wooden components is affecting the formation of cracks and these are impacting on its moisture performance when exposed to the weather. However, quantitative information to what extent both factors, crack formation and potentially increased MC, are affecting the overall durability of wooden components is still lacking, but essential for service life prediction of timber structures and for durability testing under field conditions. As demonstrated by Meyer et al. (2013, 2014) a wide range of methods for durability field testing of wood exists around the globe, but test results suffer from limited comparability. Beside divergent exposure conditions, the methods vary in terms of specimen size, shape and constitution. While for instance Lap-joint specimens CEN/TS 12037 (CEN 2004) approximately reflect the size of real building components in wooden post construction (Zahora et al. 2013), miniaturized specimen types such as pegs (Cookson et al. 2014) or mini-stakes (Meyer et al. 2013) were designed to accelerate tests, but will not experience moisture-induced stresses as real-size components would do. For interpretation of field test results it is consequently of immanent importance to consider the effect of size and shape and to allow utilizing test data for performance and service life prediction.

This study aimed therefore at examining the effect of different cross section dimensions on the moisture content, time of wetness, crack formation and fungal decay development of wooden specimens made from Norway spruce (Picea abies Karst.) and Scots pine sapwood (Pinus sylvestris L.) exposed horizontally in Hannover, Germany, and monitored for a period of 5 years.

2 Materials and methods

2.1 Specimens and outdoor exposure

Specimens with a length of 500 mm and ten different cross sections were prepared from Scots pine sapwood and Norway spruce, both from central Sweden. Half of the cross sections were quadratic, half were rectangular (Table 1), whereby, apart from the biggest cross sections, specimens were axially matched if possible. For the biggest dimension (100 × 100 mm2) the sapwood portion of the Scots pine specimens was less than one-third of the cross section. For all wood species and cross sections n = 5 replicates were exposed outdoors on test rigs with 1 m height (Fig. 1) on the roof of a faculty building at Leibniz University in Hannover, Germany.

Outdoor exposure of specimens. a Minimized contact area between specimen and bearing through rhombic supports. b Samples mounted with screws and washers. c Side shelter boards. d Set-up overview (Photo: Mehlich 2009)

To reduce the effect of contact with bearings on the decay development, the specimens were exposed on rhombic supports made of Norway spruce. The specimens were exposed with their tangential surfaces upwards. The distance between specimens on the rigs was approximately 10 mm and the margin specimens were sheltered by extra boards to assure homogenous exposure conditions for all test specimens. The initial MC of the specimens was between 10 and 15 %.

2.2 Moisture and temperature recording

Wood MC and temperature were measured daily on n = 3 replicate specimens of each group for a period of 2 years between 12.09.2010 and 12.09.2012. Therefore conductively glued stainless steel electrodes were used for electrical resistance measurements. The measurement system using mini data loggers (Type Materialfox mini, Scanntronik GmbH) has been described in detail by Brischke et al. (2008). Wood temperature measurements and recordings were made in parallel using mini data logger (Type Thermofox mini, Scanntronik GmbH). Temperature data obtained were used to characterize the climatic load and for temperature compensation of the electrical resistance measurements. Wood species-specific resistance characteristics were used for calculating the wood moisture content according to Brischke et al. (2008).

The electrodes were positioned centrally in all directions, i.e. in depth, width, and length, in all specimen groups. Only the groups Q1 and Q2 were equipped with a second pair of electrodes which was glued in approximately 20 mm beneath the upper surface.

2.3 Decay assessment

Fungal decay was assessed annually and rated according to EN 252 (CEN 2015) as described in Table 2. Therefore a pick-test was performed using a knife to determine depth and distribution of decay in terms of softening of the wood substance.

Since the EN 252 rating scheme has been developed for specimens with a cross section of 25 × 50 mm2 only, it was necessary to modify the scheme for the other specimen groups.

Since the maximum depth of decay is determining the minimum remaining cross section at the different rating steps, the latter was used to adopt the rating for the specimens with non-standard cross section. For each specimen group the maximum decay depth was adopted to obtain the same percentage minimum remaining cross section as illustrated in Table 3.

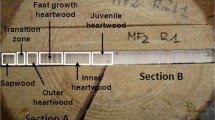

After 5 years of exposure all samples were removed from the test rig and cut perpendicular to the grain 30 and 170 mm from both end-grains as well as in the center of the specimen for inspection. Interior rot––invisible from the outside––was also considered for determining the minimum remaining cross section of the specimens.

2.4 Logistic dose–response performance model (LDR)

The two year data sets were applied to a performance model describing the relationship between the material climate in terms of MC and wood temperature and the corresponding fungal decay. The experimental base for the model was field test results from double layer above ground trials performed at 28 different test sites in Europe as described by Brischke and Rapp (2010).

The impact of a general time variation of moisture content MC and temperature T on the potential for decay can be described by a dose–response function. The total daily dose D is a function of one component D MC dependent on daily average of moisture content MC and one component D T dependent on daily average temperature T.

For n days of exposure the total dose is given by

where T i is the average temperature and MC i is the average moisture content for day i. Decay is initiated when the accumulated dose reaches a critical dose.

As described in detail by Brischke and Rapp (2010), the cardinal points of the parameters wood temperature and MC for fungal growth and decay activity were sought and used to set up polynomial base functions for both dose components (Eqs. 3 and 4). The total dose D is then calculated as a function of D MC and D T according to Eq. 5, where D T was weighted by a factor a.

where D = dose [d], D T = temperature induced dose component [−], D MC = moisture induced dose component [d], MC = daily average moisture content [%], T = daily average wood temperature [°C], T min = minimum wood temperature for the day considered [°C], T max = maximum wood temperature for the day considered [°C], a = temperature weighting factor, e, f, g, h, i, j, k, l, m, n = variables.

The best fit for this model against the available data (Brischke and Rapp 2010) was obtained with the following parameters and the final logistic model function according to Eq. 6. a = 3.2, e = 6.75.10−10, f = 3.50.10−7, g = 7.18.10−5, h = 7.22.10−3, i = 0.34, j = 4.98, k = 1.8.10−6, l = 9.57.10−5, m = 1.55.10−3, n = 4.17.

The total dose over a certain time period is given by Eq. 2 and the decay rating is given by the dose–response function:

where DR = decay rating according to EN 252 (CEN 1990), \( D\left( n \right) \) = total dose for n days of exposure. The effect of temperature is dominating on the total dose. The reason for this is that the empirical data from double layer tests used to fit the model is dominated by observations with continuously high moisture content for pine sapwood. The best fit against these data will therefore primarily reflect the effect of temperature on the decay rating.

The good fit of the dose response function––as indicated through a degree of determination R2 = 0.901––is illustrated for Scots pine sapwood and Douglas fir heartwood in Fig. 2. However, there were different outliers, where decay developed faster than predicted by the accumulated dose. This happened in particular at the South-East European sites Ljubljana and Zagreb, where several specimens had been attacked by brown rot, whereas white and soft rot were dominating at most other sites (Brischke and Rapp 2010).

Relationship between dose and mean decay rating according to EN 252 (CEN 1990) of Scots pine sapwood (black) and Douglas fir heartwood (grey) exposed at 28 different field test sites using a logistic dose–response model (each dot represents the mean decay rating at one exposure site at a certain time of exposure; black line Gompertz smoothing function) (figure modified after Brischke and Rapp 2010)

3 Results and discussion

3.1 Wood moisture content and temperature

The wood MC differed significantly between specimen groups with different dimensions as well as between both wood species. For comparison the average MC and ToW were calculated over the whole measuring period of two years. A summary is given in Table 4.

In general, the average MC was higher in the pine specimens (24.5–36.3 %) than in the spruce specimens (19.0–22.3 %). For a first estimate of the respective moisture induced risk of decay in the different specimen groups the ToW was calculated in terms of the number of days with MC ≥ 25 %, which can be considered as threshold for fungal decay (Schmidt 2006; Brischke and Rapp 2010). As expected, pine sapwood showed higher ToW than spruce. However, no clear tendency was observed between the specimen dimensions and their moisture loads. In contrast, the biggest (Q1) and the smallest (R5) spruce specimens showed almost the same number of wet days (114 days and 115 days). Nevertheless, for both wood species remarkable differences in ToW were observed which ranged between 54 days (R4) and 115 days (R5) for spruce and between 272 days (Q4) and 592 days (Q2) for pine sapwood. To some extent the effect of specimen dimension on MC might be superposed by the fact that MC was measured in the centre of the specimens. Variations in MC were higher in smaller cross sections and the MC amplitude was extenuated with increasing distance between measuring points (in the specimen centre) and specimen surface. This effect became evident when the two measuring points on specimens of group Q1 were compared over time (Fig. 3).

The drastic effects between the measuring points observed for Scots pine are most likely due to heartwood portions in the centre of the specimens, whereas the upper measuring point was located in pure sapwood with higher permeability (Rydell et al. 2005; Metsä-Kortelainen et al. 2006). However, dampening effects on MC also became visible for spruce specimens, where sapwood and heartwood were not distinguishable.

Furthermore, MC and temperature data were submitted to the logistic dose–response performance model (LDR). As shown in Table 4 the temperature induced dose component D T was nearly indifferent between the specimen groups. In contrast, the MC induced dose D MC varied significantly. Consequently, also the total dose D which is a function of both components differed between specimens with different cross sections, i.e. by up to factor 4.4 for pine and factor 4.3 for spruce between specimens with the lowest and those with the highest dose. The respective service life of the various components is therefore expected to vary to the same extent (Brischke et al. 2013, see Eq. 6). In particular with respect to the largest dimension considered (Q1 and Q2) clearly different service lives can be expected depending on the measuring position considered, i.e. service lives are shorter up to a factor of 2.6 when the outer specimen part is regarded.

Further aspects which might influence the moisture performance and thus decay susceptibility of the different specimen groups are the formation of cracks (Rapp and Peek 1999; Brischke and Melcher 2015); staining fungi, which can alter the permeability of wood (Saling 1930; Fojutowski 2005), as well as the onset of decay itself. Therefore, decay development was studied on the different specimen groups over time.

3.2 Decay development

Norway spruce specimens generally decayed slower than Scots pine sapwood specimens (Fig. 4) which corresponds to the generally higher MC in the pine specimens. After 5 years of exposure all pine specimens of the groups Q1-5 and R3-4 had failed due to decay. In contrast, the mean decay rating of most Norway spruce groups was less than 2 (moderate decay) after the same exposure time. Furthermore, the time lag between exposure and onset of decay was approximately one year longer for the Norway spruce samples.

Mean decay ratings according to EN 252 (CEN 2015) and adopted to various cross sections over exposure time of 5 years for Scots pine sapwood (left) and Norway spruce specimens (right)

However, again there was no relationship recognisable between specimen dimension and decay development, neither for pine sapwood nor for Norway spruce. Decay in pine sapwood proceeded very fast in all specimens, so that no significant difference in decay rate became evident. Similarly, the decay rate of the Norway spruce specimen groups with smallest and largest quadratic cross sections was nearly the same. However, distinct differences were found between the specimens groups with respect to the location where they were infested and how decay spread from there. This is exemplarily shown in Fig. 5 for selected Noway spruce specimens that were cut after 5 years of exposure. While deep surface cracks (up to one half of the specimen thickness) served as starting points for decay in Q1 and Q3 specimens, first signs of decay were found in R1 at the contact face between bearing and specimen. Remarkably, all Norway spruce specimens in group R1 showed deep surface cracks, but none of these cracks was infested. So cracks had the potential to initiate high MC and consequently decay (Austigard et al. 2014), but they do not necessarily do, e.g. due to the fact the period of high MC (ToW) is not long enough. How and to what extent water enters into a crack or delamination depends on material, surface treatment, position and size of the crack or delamination (Sandberg 2013). Similar observations were made by Brischke and Rolf-Kiel (2010) on double-split fence posts made from English oak, which had been in ground contact for several decades. Frequently, deep cracks were identified as initiation point of white rot decay, but interior rot was also found. In this study, interior brown rot was found in particular on small cross section specimens, such as within group Q5 (Fig. 5). In these samples only thin and small cracks were observed and no decay was visible from the outside even though more than 80 % of the cross section was severely decayed. A layer of sound wood enclosed the decayed wood portions like a shell. The specimens might have been affected from the end-grain as also suggested for glulam beams by Austigard et al. (2014).

All decayed specimens showed brown rot, only in a few cases pine sapwood samples were also associated with soft rot, but still dominated by brown rot. In other above ground durability studies both wood species, Norway spruce and Scots pine sapwood, frequently showed soft and white rot decay too (Augusta 2007; Welzbacher and Rapp 2007, Brischke and Rapp 2010; Alfredsen et al. 2014), wherefore the above described performance model was also primarily based on the latter rot types. Since the basic requirements for growth and decay of white and brown rot fungi are similar as shown by Huckfeldt and Schmidt 2006; Stienen et al. (2014); Meyer and Brischke (2015), the model might fit for the results obtained. However, to some extent the prominent role of brown rot can explain that the moisture and temperature induced dosage determined in this study does not fully reflect the high decay activity. Furthermore, the moisture load in a single layer set up exposed to strong winds provided high re-drying potential of the specimens. Nevertheless, and to some extent unexpected, even the specimens with the smallest dimension showed severe decay in short time.

These findings stand in contrast to field test results from Sell (1980) which showed a higher decay risk for components with larger dimensions. According to Sell, the low thermal and moisture conductivity of wood leads to high moisture variation close to the surface––as also confirmed within this study. Furthermore, deformation of small-dimensioned specimens and formation of cracks in large-dimensioned components result from hindered swelling and shrinking. Such observations were neither confirmed by Augusta (2007) nor by the results obtained in this study.

4 Conclusion

From the results obtained during 5 years of outdoor exposure no clear effect of the size of the cross section became evident. The specimen dimension was neither correlated with wood MC nor with the decay development. ToW and decay were more severe in pine compared to spruce. Regarding onset and further development of decay cracks as well as contact faces turned out to be weak points, but interior rot was observed as well. Brown rot, which occurred predominantly in the specimens, was partly difficult or even impossible to detect from outside. Likely due to deviating ways of infection brown rot fungi were able to cause severe degradation also in small-dimensioned samples.

With respect to durability field test methodology one might recommend to use specimens with dimensions close to those used for real-life structures even though this cannot be concluded from MC and decay data within this study, but will mimic crack formation as close as possible. To quantify the effect of component dimension on service life further research is needed, whereby the overruling effect of contact faces and further water traps need to be considered carefully.

References

Adachi K, Inoue M, Kawai S (2004) Liquid impregnation into dry wood using a roller-pressing method. II. Effect of specimen size and processing variables on amount of water impregnation. Mokuzai Gakaishi 50:243–247

Alfredsen G, Flæte PO, Kolstad S (2014) Norway spruce. Natural durable timber––field test results. IRG/WP Durability Database. Stockholm: The International Research Group on Wood Protection, IRG/WP/DDB 14-00080

Augusta, U (2007) Untersuchung der natürlichen Dauerhaftigkeit wirtschaftlich bedeutender Holzarten bei verschiedener Beanspruchung im Außenbereich. [Natural durability of European wood species in different use classes]. (In German) Doctoral thesis, University Hamburg, Faculty of Mathematics, Informatics and Natural Sciences, Department Biology, Germany

Austigard, M, Jenssen K, Mattsson J (2014) Decay damages in glulam beams as compared to solid wood logs. In: Wilson P (Ed) Proceedings of the 10th meeting of the Northern European network on wood science and engineering, 13–14th October 2014, Edinburgh, UK:73–78

Brischke C, Melcher E (2015) Performance of wax impregnated timber out of ground contact––results from long-term field testing. Wood Sci Technol 49:189–204

Brischke C, Meyer L, Bornemann T, Bilstein M, Lauenstein B, Lück J-M, Wulf C (2013) Service life of timber structures––prognosis based on 3 years high-frequency monitoring. Eur J Wood Prod 71:79–90

Brischke C, Rapp AO, Bayerbach R (2008) Measurement system for long-term moisture recording with internal conductively glued electrodes. Build Environ 43:1566–1574

Brischke C, Rolf-Kiel H (2010) Durability of European oak (Quercus spp.) in ground contact––A case study on fence posts in service. Eur J Wood Prod 68:129–137

Brischke C, Rapp AO (2010) Service life prediction of wooden components––Part 1: Determination of dose response functions for above ground decay. Stockholm: The International Research Group on Wood Protection, IRG/WP/10-20439

CEN/TS 12037 (2004) CEN/TS 12037 Wood preservatives––field test method for determining the relative protective effectiveness of a wood preservative exposed out of ground contact––Horizontal lap-joint method. CEN (European committee for standardization), Brussels

CEN (1990) EN 252 Durability of wood and wood-based products. Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. CEN (European committee for standardization), Brussels

CEN (2015) EN 252 Durability of wood and wood-based products. Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. CEN (European committee for standardization), Brussels

Cookson LJ, Page D, Singh T (2014) Accelerated aboveground decay testing in Australia and New Zealand. Int Biodeterior Biodegrad 86:210–217

Fojutowski A (2005) The influence of fungi causing blue––stain on absorptiveness of Scotch pine wood. Stockholm: The International Research Group on Wood Protection, IRG/WP/05-10565

Huckfeldt T, Schmidt O (2006) Hausfäule-und Bauholzpilze. [Indoor wood decay fungi]. (In German) Rudolf Müller, Cologne

Kalnins MA, Feist WC (1993) Increase in wettability of wood with weathering. Forest Prod J 43:55–57

Mehlich R-T (2009) Ermittlung der Feuchtebelastung an Holzbauteilen im Außenbereich in Abhängigkeit der Dimension. [Moisture loads of differently sized wooden components exposed outdoors]. (In German) Bachelor thesis, Leibniz University Hannover, Hannover

Meierhofer U, Sell J (1979) Physical phenomena in timber construction elements exposed to weathering. (In German) Holz Roh- Werkst 37:227–234

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170° C, 190° C, 210°C and 230° C. Holz Roh- Werkst 64:192–197

Meyer L, Brischke C (2015) Fungal decay at different moisture levels of selected European-grown wood species. Int Biodeterior Biodegradation 103:23–29

Meyer L, Brischke C, Kasselmann M, Roesmann C (2014) Moisture performance testing of wood––practical experiences. Stockholm: The International Research Group on Wood Protection, IRG/WP/14-20546

Meyer L, Brischke, C, Rieken J (2013) Testing the performance of timber using 27 different field test methods. Stockholm: The International Research Group on Wood Protection, IRG/WP/13-20517

Müller, J (2000) Konstruktiver Holzschutz durch die Gestaltung der Holzoberfläche unter Berücksichtigung der anatomischen Eigenschaften––Machbarkeitsstudie. [Wood protection by design under particular consideration of the wood surface and wood anatomy - A feasibility study] (In German) Final report Az. 08047. Deutsche Bundesstiftung Umwelt, Osnabrück:1–33

Rapp AO, Peek R-D (1999) Melamine resin treated as well as varnish coated and untreated solid wood during 2 years of natural weathering. (In German) Holz Roh- Werkst 57:331–339

Rydell Å, Bergström M, Elowson T (2005) Mass loss and moisture dynamics of Scots pine (Pinus sylvestris L.) exposed outdoors above ground in Sweden. Holzforschung 59:183–189

Saling WM (1930) The effect of blue stain on the penetration and absorption of preservatives. Proc Am Wood Pres Assoc 1930:183–197

Sandberg D (1999) Weathering of radial and tangential wood surfaces of pine and spruce. Holzforschung 53:355–364

Sandberg D (2005) Distortion and visible crack formation in green and seasoned timber: influence of annual ring orientation in the cross section. Holz Roh- Werkst 63:11–18

Sandberg K (2008) Degradation of Norway spruce (Picea abies) heartwood and sapwood during 5.5 years’ above-ground exposure. Wood Mat Sci Eng 3–4:83–93

Sandberg K, Mostolygin K, Hagman O (2013) Effect of lamellas annual-ring orientation on cracking of glulam beams investigated with computer tomography and image processing. Wood Mat Sci Eng 8:166–174

Sandberg D, Söderström O (2006) Crack formation due to weathering of radial and tangential sections of pine and spruce. Wood Mat Sci Eng 1:12–20

Sandberg K (2013) Moisture distribution in glulam beams with natural cracks observed with CT Scanning before and after rain. Stockholm: The International Research Group on Wood Protection, IRG/WP/13-20534

Schmidt O (2006) Wood and tree fungi. Biology, damage, protection, and use. Springer, Berlin, Heidelberg

Sell J (1980) Oberflächenbehandlung von Brettschichtholzträgern: Anforderungen, praktische Erfahrungen und Versuchsergebnisse. [Surface treatment of glulam: Requirements, practical experience and test results] (In German) Holz-Zentralblatt 106:629–630

Stienen T, Schmidt O, Huckfeldt T (2014) Wood decay by indoor basidiomycetes at different moisture and temperature. Holzforschung 68:9–15

Welzbacher CR, Rapp AO (2007) Durability of thermally modified timber from industrial-scale processes in different use classes: results from laboratory and field tests. Wood Mat Sci Eng 2:4–14

Zahora A, Jin L, Preston A (2013) Update on “Sandwich” type above ground field test methods. Stockholm: The International Research Group on Wood Protection, IRG/WP/13-20506

Acknowledgments

The authors are grateful for financial support of WoodWisdom-Net (www.woodwisdom.net) and wood industry partnership in the frame of the WWN project “Durable Timber Bridges DuraTB”. For help with the field trials the authors express their special thanks to Thomas Bornemann, Ralph-Thomas Mehlich, Carola Hesse and Christian Wulf.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brischke, C., Meyer-Veltrup, L. Moisture content and decay of differently sized wooden components during 5 years of outdoor exposure. Eur. J. Wood Prod. 73, 719–728 (2015). https://doi.org/10.1007/s00107-015-0960-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0960-7