Abstract

Asphalt binder is used to build approximately 80% of roads worldwide in the form of flexible pavement. Many flexible pavements collapse due to surface distress such as potholes, rutting, alligator cracking, raveling, and so on, and a significant amount of maintenance work is required to address these pavement stresses. To reduce building costs, it is required to recycle asphalt pavement. The best method to preserve natural resources and minimize maintenance costs in the building industry is to use recycled asphalt pavement (RAP). However, from the literature review, it has been found that RAP is too stiff when compared to virgin binders, so different oils as a rejuvenator can be added to reduce the stiffness. Consequently, WCO (waste cooking oil) and WEO (waste engine oil) are used to improve the quality of old asphalt. This review paper included an overview of numerous studies on the WEO- and WCO-based rejuvenation of aged asphalt. It has been discovered that using WEO and WCO to rejuvenate asphalt has both positive and negative effects and the WCO produces superior results than the WEO.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Background

The pavements are divided into two groups, such as flexible and rigid pavements, based on their structural behavior. Flexible pavement is that which generally has low or negligible flexural strength, and these layers reflect the bottom layer’s deformation onto the layer’s interface, stiff pavement is that which has notable flexural strength or flexural rigidity, and these layers have slab action that can transmit the load stresses through a wider area below. Flexible pavement is preferred to rigid pavement for several reasons, such as its adaptability to be strengthened and enhanced as traffic volume increases and its lower initial and ongoing maintenance costs. The flexible pavement is made up of base and sub-base courses beneath the surface course of bituminous material. The bituminous substance is usually asphalt, whose viscous nature allows for significant plastic deformation. Depending on the temperature at which it is poured, asphalt can be categorized as hot mix asphalt (HMA), warm mix asphalt, or cold mix asphalt and it is used to construct about 80% of the world’s highways. Due to numerous inherent issues such as potholes, depression, edge cracks, and raveling, many asphalt pavements deteriorate before reaching the desired life. Asphalt waste has been produced due to pavement material degradation, making land filling more challenging. By consuming less virgin asphalt binder, aggregates, and fuels; lowering carbon emissions, and using recycled asphalt material reduce the consumption of non-renewable resources. Reclaimed asphalt pavement, or RAP, is a term used by the Federal Highway Administration to describe asphalt that has been previously used but has been cracked, fractured, or aged. After being fully crushed and screened, RAP is formed of premium, well-graded aggregates that have been coated in the asphalt mix. It is used to create flexible pavement to promote sustainable growth with positive economic and environmental effects.

Recent technological advancements have resulted in the depletion of natural resources, and numerous strategies for the exploitation of solid waste have been adopted. Recent price rises for asphalt surface materials have paved the path for finding cheaper alternatives, such as using recycled asphalt, which also reduces solid waste. Utilizing recycled materials can also cut down on carbon emissions during road building and adding recycled asphalt as an ingredient to hot mix asphalt (HMA) has both financial and environmental advantages.

The different chemical elements that makeup bitumen are divided into four groups: resins, aromatics, saturates, and asphaltenes. The first three groups are frequently referred to as maltenes. Aging causes the polar resins to oxidize, which causes the asphaltenes fraction to rise while the maltenes fraction falls. As asphalt ages, the asphaltenes component increases while the maltenes component decreases, making asphalt binder harder. The quantity of asphaltenes in aged asphalt is reduced using a variety of methods, such as recycling agents, also referred to as rejuvenators. These are frequently added to the RAP to equalize the ratio of maltene to asphaltene in old asphalt, making it more elastic and capable of spreading oil while increasing adhesion.

The two categories of recycling agents are rejuvenators and softeners. The rejuvenators are further divided into oil- and petroleum-based rejuvenators. Recycling agents that are dependent on RAP content are used to minimize fatigue and intermediate temperature cracking. Waste and commercial recycling agents are the two main types of recycling agents. Waste cooking oil (WCO), waste engine oil (WEO), and other types of waste recycling agents are available commercially, along with various commercial rejuvenators such as Pongamia oil and tall oil. In this review paper, we discuss the waste recycling agent which is waste engine oil and waste cooking oil. When choosing a rejuvenator, price is the main factor to consider. Upcoming sections briefly discuss these recycling agents.

1.2 WEO (Waste Engine Oil)

Engine oil also referred to as vehicle oil keeps internal combustion engines cool while they are running and lubricates their moving parts. The recycling of WEO into new engine oil is challenging when an engine is running continuously because the oil’s performance deteriorates over time. Burning WEO will result in contaminants that can damage people’s health and enter their lungs. Numerous studies suggest that using WEO from automobiles could enhance the effectiveness of asphalt [4]. Compared to fresh oil, WEO has different chemical and physical characteristics. In terms of fresh EO, it mostly consists of additives, gasoline, and high levels of heavy metals such as Cd, Fe, Pb, and Cr as well as Zn and Mg. These metals pollute the soil and groundwater when they are discharged onto land. WEO is composed of several chemical compounds having molecular mass under 200 g/mol. Paraffin oil, polyolefin oil, and aromatic solvents, which are like asphalt aromatics, represent the majority of WEO’s chemical components [7] (Table 1).

1.3 WCO (Waste Cooking Oil)

It is gathered from eateries, food producers, and stores that sell disposable items, and recycling facilities. It is also referred to as used cooking oil (UCO), non-edible oil, or waste oil (WEO). A small amount of waste cooking oil is appropriately collected and recycled. A large amount of waste cooking oil is deliberately thrown into dumping sites and waterways, resulting in pollution. Controlling waste cooking oil is a major problem. WCO has lighter oil that is like asphalt, employing it as a rejuvenator is an environmentally beneficial alternative. Research also shows that WCO has greater potential for usage as a rejuvenator [1]. The chemical properties of filtered waste cooking oil are the basic ingredients that determine the behavior of regenerated bitumen. Gas chromatography-mass spectrometry (GCMS) was therefore utilized by the Combinatorial and Catalysis Research Centre (COMBICAT) to assess the chemical composition of spent cooking oil. Consequently, the chemical test results, a common occurrence of chemical constituents in this waste cooking oil were palmitic acid, oleic, and linoleic acid [2] (Table 2).

1.4 Objective

This study intends to evaluate prior research on adding WEO and WCO as a recycling agent to used asphalt in order to ascertain which one is more efficient. In order to lessen WCO environmental issues and WEO harm to human health, respectively, this article examines the feasibility of recycling WEO and the possibilities for employing WCO as a recycling agent for aged bitumen binders. The study summarizes the effects of WEO and WCO on the physical, rheological, and micro-structural characteristics of aged asphalt. The summary was expanded in order to identify which of the two rejuvenators is more efficient.

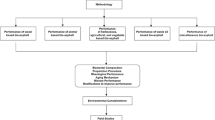

2 Assessment of Rejuvenated Asphalt Properties

2.1 Fundamental Properties of Aging Asphalt Rejuvenated by WEO and WCO

The penetration test (ASTM D5), softening point test (ASTM D36), and ductility test (ASTM D113), as well as other physical characteristics of asphalt binder, are being investigated in this portion.

Consistency is determined by the penetration test, i.e., lower penetration indicates stiffer consistency. Penetration value is the vertical distance traveled or penetrated by the point of a standard needle into the bituminous material in one-tenth of a millimeter under a particular load of 100 g for five seconds at 25 °C. The amount of viscosity in a bituminous substance determines the distance that a needle may move. As a result, viscous bitumen substance has a lower penetration value.

The softening point is used to indicate a material’s ability to flow at high temperatures. The softening point of bitumen is the temperature at which the material softens to a specific degree. According to IS1205-1978, it is the temperature at °C at which a standard ball passes through a bitumen sample in a mold and falls through a height of 2.5 cm when heated under water or glycerin at defined test conditions. The temperature of the bath is raised by 5 °C every minute. Before being used on roads, the binder needs to be sufficiently fluid. By using a ring and ball apparatus, the softening point may be calculated.

Bitumen’s ductility is its ability to extend under traffic pressure without cracking during road building. When a standard briquette sample of the material is split at a specific speed and temperature, the length in cm that it elongates before breaking is used to determine the ductility of the material. A solution of dextrin and glycerin is applied in equal parts to the surface of the brass plate and the internal sides of the briquette mold to prevent the bituminous material from adhering to the surface. The water bath is used to keep the temperature at 27 °C. The sample is pulled until it ruptures at 50 mm per minute. The ductility value is the distance in centimeters to the breaking point. It is generally known that these properties decrease during the life of an asphalt binder.

The effectiveness of using WCO and WEO as rejuvenators with optimal percentages of 3–4% and 5–6% results in a gain in penetration value because the asphaltenes-to-maltenes ratio reduces and the softening value is reduced when compared to virgin binders [3].

As the WCO content increases, penetration increased linearly, resulting in a decrease in aromatic components and an increase in maltene components, while the softening point decreases as the amount of WCO increases, generating a low-temperature susceptibility by adding different Aged Bitumen (AB) such as AB30/40, AB40/50, and AB50/60 [2].

With increases in the proportion of WEO (0–8%), ductility and penetration values rise but the softening point values fall. Asphalt binder with WEO has superior thermal deformation ability because of increased ductility and decreased resistance due to increased penetration value. However, WEO has a better softening effect due to a decrease in softening point. It demonstrates that the asphalt binder containing WEO has a superior capacity for deformation at low temperatures by comparing with Bitumen having penetration grade (PG) of 60/70 and styrene–butadiene–styrene copolymer-modified asphalt (PMB-A) [7].

The penetration value of 5 h aged asphalt with 1% WEO and 1% WCO recovered up to 96.8 and 102.9% as compared to virgin asphalt. It resulted in WCO having more efficiency which must be compared to WEO since it made aged asphalt softer than WEO. The recovery of the 5 h aged asphalt’s softening point value with 1% WEO and 1% WCO was up to 93.8% and 90.7%, respectively. It demonstrated that the WCO has a lower softening effect than WEO. The ductility value at 10 °C of 5 h aged asphalt with 1% WCO and 3% WEO was found to be comparable to that of fresh asphalt as shown in Fig. 1. The optimum amount of WEO and WCO results in enhancing the low-temperature performance [5].

Asphalt with WEO and WCO at 5 h aging time [5]

2.2 Rheological Characteristics of Rejuvenated Asphalt

This section discusses the viscosity and the effectiveness of the bitumen binder at different test temperatures for WEO- and WCO-rejuvenated asphalt. The bending beam rheometer (BBR) test is used to determine the cracking resistance at low temperatures (ASTM D6648), the dynamic shear rheometer (DSR) test (ASTM D7175) is used to measure the fatigue at intermediate temperatures and rutting resistance at high temperatures, and the bending beam rheometer (BBR) test is used to determine the cracking resistance at low temperatures (ASTM D6648). The parameters G*·Sinδ and G*/Sinδ, respectively, control the fatigue and rutting resistance. In general, asphalt performs poorly in terms of elastic recovery when its phase angle is greater. As a result of having a larger complex modulus and a smaller phase angle, asphalt with a higher G*/sin value has superior rutting resistance [7].

When the quantity of WEO increases, the G*/Sinδ and G*·Sinδ decrease, and the temperature rises. It has been observed that 4% WEO reduced the resistance to rutting by 30–40% and 8% WEO reduced the resistance to rutting by 60–70% for all the asphalt binder samples as shown in Fig. 2. Although the addition of WEO significantly affects asphalt rutting resistance, it may improve asphalt fatigue cracking resistance [7].

Rutting and fatigue resistance of asphalt binders [7]

With the addition of 4% WCO to the aged bitumen, the viscosity is brought to a level with the original bitumen. The phase angle rises as the temperature falls, as shown in Fig. 2. Therefore, it can be stated that the rejuvenated bitumen has the same viscosity as the original binder and that the binder should only have a viscous character because of the 90° phase angle that was reached at 65°. When 3% WCO is added, the complex modulus remains the same as that of the original binder as shown in Fig. 3 [2].

A plot between complex shear modulus and phase angle with temperature for different rejuvenated WCO [2]

With the addition of 3–4% WCO, the value of the rutting parameter (G*/Sinδ) would be the same as the original bitumen, and it also showed a lower value of the fatigue parameter (G*·Sinδ), which meant having greater fatigue cracking resistance as shown in Fig. 4. However, adding 5.5% WEO reduced the rutting parameter’s value below that of the original binder, making it more susceptible to rutting and only suitable for low traffic volumes. It had been determined that WEO was less resistant to rutting and fatigue than WCO [3].

DSR results of WCO and WEO [3]

The amount of WEO and WCO (i.e., 0–4%) increases while the viscosity of aged bitumen falls. It proved that the frictional resistance would be enhanced by the WCO and WEO as represented in Fig. 5. However, if the viscosity of old asphalt is too high, it causes segregation, which negatively affects the performance of the asphalt, and if the viscosity is extremely low, it causes the asphalt to be liable to permanent deformation, so the viscosity is appropriate for which the quantity of oil should be sufficient. With an increase in temperature, adding enough WEO and WCO (i.e., 1–4%) caused the rutting parameter to drop as shown in Fig. 6. However, it also showed that WEO and WCO both recovered the performance of asphalt, though the WCO produced the same results with less content [5].

Rejuvenated asphalt after 5 h aging time of VA [5]

Influences of WCO and WEO on rutting resistance factor of rejuvenated asphalt (5 h aging time of VA) [5]

2.3 Micro-structural Properties of Rejuvenated Asphalt

The micro-structural characteristics of asphalt binder are determined using a Fourier transform infrared spectrometer (FTIR). FTIR is the only analytical approach that directly monitors the vibrations of the functional groups that characterize molecule structure at the same time [1]. It is commonly used for qualitative and quantitative investigations of organic materials. The FTIR analyzes the organic group of virgin binder, aged binder, and rejuvenated asphalt binder in order to evaluate the micro-structural characteristics of rejuvenated asphalt [6].

FTIR analysis of the control and aged bitumen as well as the FTIR results of the rejuvenated aged bitumen by both WCO and WEO as shown in Fig. 7. After WEO and WCO were added, the C=C bond in the aged asphalt decreased, potentially lowering the amount of asphaltenes. However, the naphthene aromatic content and carbonyl or ester were increased by both the recycled bitumen, resulting in an increase in maltenes content as shown in Table 3. As a result, the ratio of maltenes to asphaltenes decreases in recycled asphalt but does not regain its original value [3].

FTIR analysis of control, aged bitumen, and rejuvenated aged bitumen by WEO and WCO [3]

The determination of the FTIR spectra for the matrix asphalt and aged asphalt binder using 4 and 8% WEO as rejuvenators. There is no change in the qualitative analysis of the matrix asphalt and the rejuvenated asphalt. Consequently, the matrix asphalt and the rejuvenated asphalt have the same functional group. This demonstrates that the WEO’s functional group and micro-structural characteristics are comparable to those of an original binder [7].

3 Conclusion

According to the above-reviewed literature, it can be inferred that adding enough WEO and WCO causes the ductility and penetration value to increase, and the softening point value to drop, and in addition, it demonstrates that when the temperature rises, the fatigue (G*·Sinδ) and rutting parameter (G*/Sinδ) decrease. It also demonstrated that lesser WCO quantity is needed than WEO to get comparable results. Additionally, it demonstrates that WEOs have lower fatigue and rutting resistance than WCOs because WEOs are more susceptible to rutting. The amount of oil and the proportion of old asphalt in the mix affect the characteristics of WEO and WCO. In general, WCO or WEO was a suitable rejuvenating agent to enhance the performance of aged asphalt. In the field of recycling asphalt pavement, it offered a unique application technique for WEO or WCO that accomplished waste recycling and environmental protection.

References

Ahmed RB, Hossain K (2020) Waste cooking oil as an asphalt rejuvenator: a state-of-the-art review. Constr Build Mater 230:116985. https://doi.org/10.1016/j.conbuildmat.2019.116985

Asli H, et al. (2012) Investigation on physical properties of waste cooking oil—rejuvenated bitumen binder. Constr Build Mater 37:398–405. https://doi.org/10.1016/j.conbuildmat.2012.07.042

El-Shorbagy AM, El-Badawy SM, Gabr AR (2019) Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr Build Mater 220:228–237. https://doi.org/10.1016/j.conbuildmat.2019.05.180

Jia X, et al (2015) Influence of waste engine oil on asphalt mixtures containing reclaimed asphalt pavement. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001292

Li H, et al (2019) Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl Sci (Switzerland) 9(9). https://doi.org/10.3390/app9091767

Li H, et al (2022) Compound reutilization of waste cooking oil and waste engine oil as asphalt rejuvenator: performance evaluation and application. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-22153-2

Liu S, et al (2018) Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr Build Mater 191:1210–1220. https://doi.org/10.1016/j.conbuildmat.2018.10.126

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ritika, Aggarwal, P. (2024). Waste Materials as Rejuvenator—A Review. In: Yadav, K.D., Jariwala, N.D., Kumar, A., Sinha, A. (eds) Recent Advances in Sustainable Waste Management Practices. SWMP 2023. Lecture Notes in Civil Engineering, vol 430. Springer, Singapore. https://doi.org/10.1007/978-981-99-4186-5_5

Download citation

DOI: https://doi.org/10.1007/978-981-99-4186-5_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-4185-8

Online ISBN: 978-981-99-4186-5

eBook Packages: EngineeringEngineering (R0)