Abstract

The global population spike, rise in industrialization, and highway infrastructure development induce focus on sustainable development. The ever-increasing consumption of non-renewable crude oil and asphalt levies a heavy toll on economic welfare of future generations. This enormous demand of asphalt is due to its wide applicability in flexible pavements. Therefore, the construction industry is exploring the partial substitution of renewable materials in asphalt with a focus on economical, social, and environmental benefits. The current decade has seen a rampant rise of bio-asphalt as an alternative to asphalt. Hence, it is imperative to explore the performance of bio-asphalt for its sustainable applicability. This review comprehensively summarizes the performance of bio-asphalt obtained from various biomass sources. It deals with elemental composition of bio-oil, preparation procedure, rheological performance, mixture performance, and aging mechanism of bio-asphalt along with modification required to improve the performance. The environmental impacts and field application of the bio-asphalts are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The volatility of crude oil market, coupled with the huge consumption of asphalt stresses substitution of asphalt binder, partially or fully, to meet the sustainability goals of modern century. There are more than 250 known applications of asphalt, of which the most popular are paving and roofing. Around 85% of the produced asphalt is used for construction of flexible pavement (Asphalt Institute and Eurobitume 2015). Flexible pavement which consists of asphalt binder is most widely employed due to their less noise, recyclability, excellent rideability, good strength, etc. The share of flexible pavement accounts for 95% of all the world’s roads (Islam 2020). According to a report by Asphalt Institute and Eurobitume (Asphalt Institute and Eurobitume 2015), the global production of asphalt in the year 2015 stood at 87 million tonnes per year. This enormous demand driven by the construction industry takes a heavy toll on earth’s finite resources, compromising the needs of future generations, affecting its quality of life, and leading to ecological imbalance. In addition to the demand, the inventory limitations of crude oil affect the supply and the price of asphalt. Therefore, industries are rigorously looking for alternatives to balance the demand of asphalt binder.

At present, the key alternatives in pursuit are the application of reclaimed asphalt pavement (RAP), recycled materials, and bio-asphalt, which are environmentally responsible, sustainable, and economically viable (Victory 2022; Babalghaith et al. 2022; Jain 2023). Bio-asphalt refers to the partial substitution of asphalt binder with bio-oils, bio-binder, heavy oil, cooking oil, etc. The feedstock for bio-oils is biomass. Bio-binder is a mixture obtained from bio-oil subjected to distillation, oxidation, polymer modification, etc. Biomass is a renewable source which is obtained from woody waste, plant waste, agriculture waste, animal waste, etc. Currently, around the world, biomass is employed for production of high valued liquid fuels. The utilization of biomass for bio-fuel reward incentives by reducing the carbon footprint and dependence on fossil fuels (Mohan et al. 2017). Biomass conversion to bio-oil falls under three broad technologies biochemical, thermochemical, and mechanical extraction (Mohan et al. 2017; Adams et al. 2018). The biochemical process involves applying bacteria and enzymes as catalysts to fragment heavy molecules to smaller molecules through anaerobic digestion and fermentation. Thermochemical conversion consists of combustion, pyrolysis, liquefaction, and gasification. The classification of thermochemical process depends on the amount of oxygen supply. Combustion takes place in excess of oxygen, whereas limited amount of oxygen results in gasification. Pyrolysis, on the other hand, takes place in absence of oxygen. The mechanical extraction involves squeezing of specific woods or seeds of biomass crops by mechanical means to obtain bio-oil. Among all the technologies, pyrolysis is widely applied due to its versatility in operation, handling of wide variety of feedstock, lower catalyst cost, and lesser response time (Ram and Mondal 2022).

The composition of bio-oil is a function of several parameters including the raw material, type of technology applied to process biomass, water content, reactor type, and bed. Bio-oils are a complex mixture of highly oxygenated compounds with high water content and lower heating value. Elementally, bio-oils are composed of mainly five compounds: carbon, hydrogen, oxygen, and nitrogen. This analogous elemental composition of bio-oils has encouraged researchers to substitute it partially or fully in asphalt. However, not all the bio-oils can be substituted directly; some undergo further refining in the form of heating, distillation, extraction, oxidation, or polymer modification to be viable and are commonly referred as bio-binders. In this review bio-oil and bio-binder are used interchangeably.

Application of bio-binders in asphalt can be categorized in three domains: (i) as an asphalt modifier (replacement of asphalt < 10%), (ii) as an asphalt extender (replacement of asphalt between 25–75%), (iii) as a direct alternative (replacement of asphalt 100%). Researches led by (Peralta et al. 2012; Raouf and Williams 2010a, b; Pouget and Loup 2013) explored the possibility of using bio-binders as a total substitution of asphalt. The findings suggest that the existing test methods do not truly reflect the bio-binders performance. Hence, they suggested modification and development of new test methods to viably use the bio-binders. Application of modifiers is quite common practice intended to target specific properties. The potential application of bio-binders lies with extender mode. Therefore, a multitude of research are targeted in this direction.

The paradigm shifts towards environmental sustainability has driven attention towards utilization of renewable sources. Although the introduction of bio-binders results in environmental and economic benefits, it is plagued with several undesirable properties such as compromised high-temperature performance along with increased susceptibility to aging. These variations are dependent on the type of bio-oil, technology conversion procedure, amount of oxygen, and biomass feedstock. Further, in order to promote sustainability and circular economy goals, it is important to understand the performance of bio-asphalt depending on it originating source. Bio-asphalt majorly can be produced from biomass of woody waste, animal waste, herbaceous, agricultural, and municipal, by deriving bio-oil and partially replacing it with asphalt. It is therefore important to compile the existing literature learning categorically to understand the effect of different types of biomass source on the performance of bio-asphalt (Zahoor et al. 2021; Penki and Rout 2021). Thus, this paper comprehensively categorizes the performance based on type of bio-binders for holistic understanding.

This review is summarized in the following sections to comprehensively understand the performance of bio-asphalt: (i) elemental composition of bio-oils, (ii) preparation procedure of bio-asphalt, (iii) rheological performance, (iv) mixture performance, (v) aging mechanism, (vi) modifications to improve the performance, (vii) performance of miscellaneous bio-asphalt, (viii) environmental considerations, (ix) field studies.

Methodology

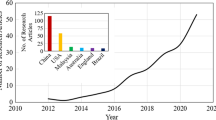

In order to conduct this review, bibliometric databases such as Scopus, web of science, and google scholar were searched for keywords such as “bio-asphalt,” “bio-bitumen,” “bio-binder,” “wood-based bio-binder,” and “animal-based bio-binder.” After initial screening and analysis, the research papers in language other than English were not considered further. Moreover, the scope of this review is limited only to the use of bio-binders as partial or full substitution; therefore, application of bio-oils as rejuvenator were not considered in this study. The framework of the article is shown in Fig. 1.

Elemental composition of bio-oil

The elemental composition of bio-oil varies based on the production procedure, type of feedstock, and moisture content. Figure 2a presents the carbon, hydrogen, nitrogen, and oxygen percentage of bio-oil derived from different wood biomass sources. As evident from Fig. 2a, in comparison to the asphalt binder, the wood-derived bio-oil contains higher oxygen and less carbon. The variable percentage are dependent on the type of biomass conversion process applied and raw materials selected. This variation of chemical composition could alter the physical and chemical properties of bio-asphalt. Thus, there is need to standardize the process of producing bio-oil from a particular biomass source so as to obtain consistent and comparable results. As can be seen in Fig. 2c, the elemental composition of swine manure–based bio-oil varies depending on the method of conversion employed. Compared with the composition of asphalt binder, swine manure–based bio-oil have less fixed carbon, alike amount of hydrogen, high nitrogen content, and oxygen content. The application of thermochemical liquefaction yields similar results whereas pyrolysis technique results in less carbon content and increased oxygen content. The elemental composition of swine manure bio-oils was found to be almost similar to asphalt. In particular, the oxygen content is slightly higher than asphalt but is considerably lower than the various other bio-oils. This peculiarity of swine manure–based bio-oil stands out against the aging resistance.

Elemental composition of bio-oil from various biomass sources (Fini et al. 2011, 2012; Lam et al. 2012; Mills-Beale et al. 2012; Yang et al. 2013, 2014b; Yu et al. 2014; Zhang et al. 2017a, b; Chang et al. 2018; Girimath and Singh 2019; Ingrassia et al. 2019; Hosseinnezhad et al. 2019; Bao et al. 2019; Dong et al. 2020; Zhou et al. 2020a, 2021; Wang et al. 2020a; Sharma et al. 2021)

The elemental composition of bio-oil from the residue of corn processing differs significantly from asphalt in terms of carbon and oxygen content as seen in Fig. 2b. The oxygen content of corn varies from 50 to 60% whereas the carbon content is in range of 30%. Further, the bio-oil from corn contains inorganic impurities. The higher oxygen content of herbaceous, agricultural, and vegetable-based bio-oils would cause a higher affinity towards aging and ultimately will affect its performance. The WEO elemental composition is similar to that of asphalt while the WCO contains a slightly higher amount of oxygen as evident from Fig. 2d. The oxygen content of bio-oil is of prime importance from aging perspective. The higher oxygen content makes the bio-oil susceptible to oxidative aging forming functional groups such as carboxylic, ketons, and sulphoxide. Therefore, comprehensive investigation of elements must be done while choosing a bio-oil for asphalt replacement to ascertain equivalent or improved performance.

Preparation procedure of bio-asphalt

The optimum blending parameters (time, temperature, and speed) are essential from the standpoint of achieving a homogenous mix. From the literature, it was found that the bio-oils are usually blended with high shear mixer into asphalt. The temperature of mixing for wood-based bio-asphalt varies between 120 and 150℃ with of time of blending 10–30 min and speed in the range of 1000–5000 rpm. The presence of large amount of oxygen requires the blending to be done at lower temperature so as to reduce the aging effect imparted by the bio-oils during the mixing. Few researchers recommended heating the bio-oil at temperature of 100–120℃ prior to mixing to remove the moisture and volatile components (Yang et al. 2013, 2014a, b).

As can be seen in Fig. 3, the optimum blending parameters of swine manure–produced bio-oil with asphalt generally range from temperature of 120 to 140℃ at a speed of 3000 rpm with a mixing time of 30 min. The preparation procedure of bio-modified binder from bio-oil obtained through residue of corn processing involves heating bio-oil around 130℃ and blending with asphalt at 135–150℃. Generally, a high shear mixer is employed at a shearing rate of 3000 rpm for 30 min. Apart from the bio-oil of corn residue processing, corn stover–based bio-oil is also used. Corn stover consists of leftover after corn harvesting and is generally referred as stalks, leaves, and cobs (Fini et al. 2015; Hill et al. 2018). Pyrolysis technique is generally adopted to obtain corn stover–based bio-oil. The mixing time and temperature generally remains the same as that of bio-oil from corn processing residue while shearing rate is usually lower. Xi et al. (2015) varied the blending conditions with cottonseed and soybeans bio-modified binder. The mixing temperature varied from 130 to 190℃, with shearing at 500, 1000, 2000, and 3000 rpm, and mixing time of 15, 30, 45, and 60 min. At high blending temperature, it was observed that more aging would take place whereas, with longer blending time, the homogenous blend would be obtained. However, the longer blending would also impart some degree of aging. In summary, researchers are mindful of the fact that higher blending temperature would lead to considerable aging. The blending temperature of plant, herbaceous, and vegetable-based bio-asphalt usually ranges from 120 to 150℃ with a shearing rate range of 1000–3000 rpm and mixing time of 30–60 min. Blending waste engine oil (WEO) with asphalt requires caution due to the potential of harmful emissions. The preparation procedure for WEO and waste cooking oil (WCO) involves blending at 130–160℃ with shearing of 4000–5000 rpm for 40–60 min.

a Shearing rate vs blending time of bio-asphalt. b Mixing temperature of bio-asphalt (Fini et al. 2011, 2012; Lam et al. 2012; Mills-Beale et al. 2012; Wen et al. 2012; Yang et al. 2013, 2014a, b; Lei et al. 2015; He et al. 2017; Zhang et al. 2017b; Liu et al. 2018a, b; Wang et al. 2018, 2020a, b; Girimath and Singh 2019; Ingrassia et al. 2019; Hosseinnezhad et al. 2019; Bao et al. 2019; Dong et al. 2020; Zhou et al. 2020a, 2021)

To sum up, the optimal blending parameters vary depending on different bio-oils. To obtain a homogenous blend, it is critical to choose the blending parameters sensibly.

Rheological performance

Rheological characterization of bio-asphalt is important from the standpoint of permanent deformation characteristics and fatigue resistance. The subsequent section characterizes the performance of bio-asphalt obtained from different biomass source.

Rheological performance of wood-based bio-asphalt

A considerable number of studies are available on effect on bio-oils on rheological performance. These rheological properties are evaluated using dynamic shear rheometer (DSR) which employs a sample sandwiched between parallel plate geometry. The SHRP parameters (rutting and fatigue) are most commonly used to characterize rutting at high temperatures and fatigue within intermediate temperatures. A higher value of G*/sinδ is desirable from the viewpoint of resistance to permanent deformation. A higher value is representation of better elastic response and improved strength, whereas a lower G* sinδ is desired from the fatigue perspective which represents reduction in dissipated energy per loading cycle. Table 1 represents the performance of various wood-derived bio-asphalt on G*/sinδ and G* sinδ in comparison with the control binder. As seen in Table 1, inconsistent results are obtained by various researchers. On the one hand, several researchers believe that the addition of bio-oil improves the rutting resistance while the others believe contrary. This inconsistent permanent deformation resistance of wood-based bio-asphalt could be attributed to source variability, conversion technology, and moisture content of biomass.

Apart from DSR, several researchers have quantified the rutting and fatigue using multiple stress creep-recovery (MSCR) and linear amplitude sweep (LAS). Yang and You (2015) evaluated the high-temperature performance of untreated bio-oil (UTB), treated bio-oil (TB), and polymer-modified bio-oil (PMB) using DSR and MSCR at replacement levels of 5% and 10%. It was found that as the bio-oil content increased, G* increased, δ reduced, and G*/sinδ increased. On the other hand, MSCR yielded increased percent recovery (%R) and decreased non-recoverable creep compliance (Jnr) indicating improved resistance against permanent deformation. The reduction of Jnr at 3.2 kPa for 10% UTB, 10% TB, and 10% PMB was 28.2%, 42.6%, and 22.7% in comparison to the base binder. The authors suggested the use of both the tests for comprehensive results. Similar findings were reported by Yang et al. (2013) where G*/sinδ of original bio-oil-modified asphalt binder (OB), dewatered bio-oil-modified binder (DWB), and polymer bio-oil-modified asphalt (PMB) increased by 6.3%, 0.4%, and 16.8% higher than the control binder. Conversely, the G*sinδ values increased considerably indicating compromised intermediate performance. For instance, G*sinδ of 5% and 10% OB were found to be 164.2% and 253.3% higher than that of control binder. In addition, bending beam rheometer (BBR) test produced lower m-value indicating deteriorated low-temperature performance. Contrasting results were obtained by Girimath and Singh (2019) and Ding et al. (2021). The authors found that increasing percentage of bio-oil negatively affects rutting performance by making the binder soft and in turn improving its fatigue life. Further, they recommend that combination of recycled asphalt pavement (RAP) along with bio-oil would prove beneficial to high-temperature performance. Another study by Girimath and Singh (2019) reported increase in Jnr and reduction in percentage recovery with increasing bio-oil content owing to the softening effect. On the contrary, the fatigue lives increased with increasing dosage.

In summary, the evaluation of rutting and fatigue resistance of wood-based bio-asphalt is a work in progress; conflicting results are found where some researchers align with improved high-temperature performance while others believe that intermediate- and low-temperature performance are improved.

Rheological performance of animal-based bio-asphalt

In terms of high-temperature performance, it is found that the addition of swine-based bio-oil softens the blend at high-temperature compromising its rutting performance. Table 2 represents the effect of animal-based bio-asphalt on rheological parameters. Fini et al. (2011, 2012) replaced asphalt binder with 2, 5, and 10% of swine manure bio-oil extracted through thermochemical liquefaction and found that the addition decreased the complex modulus (G*) and rutting factor (G*/sinδ). Further, the authors recommended the use of PPA and RAP to enhance the high-temperature performance. Similarly, Mills-Beale et al. (2012) and Liu et al. (2020) also found that the addition of swine manure–based bio-oil decreased complex modulus. On the other hand, Wang et al. (2020a) found that pyrolysis temperature and reaction time affect the rheological performance of modified swine manure–modified binders. Swine manure bio-oil was produced at different pyrolysis temperatures of 400℃, 450℃, 500℃, 550℃, and 600℃ with the reaction time of 1 s and 2 s. Initially, as the pyrolysis temperature increased, the rutting performance also increased until 550℃; beyond 550℃, the rutting factor decreased gradually compromising its high-temperature performance.

Conversely, fatigue performance gradually improved as the pyrolysis temperature was increased, whereas deteriorated performance was reported as the reaction time increased. The authors recommended pyrolysis temperature in the range of 550–600℃ and the reaction time of 1 s for improved fatigue performance (Wang et al. 2020a). Researchers have quantified the low-temperature cracking resistance using bending beam rheometer test. Fini et al. (2011, 2012) and Wang et al. (2021b) found that the addition of bio-oil increased m-value. This increment was attributed to the improved stress relaxation property of bio-modified binders resulting in decreased stress accumulation. They also reported decrease in cracking temperature (Tcr) as the percentage of modification increased indicating reduced low-temperature cracking. Mills-Beale et al. (2012) found that the bio-modified binders with 5% bio-oil passed the creep stiffness and m-value requirements at − 18℃ and − 24℃. The researchers believed that this improved low-temperature performance could be due to the interaction of polymer molecules of swine-based bio-oil creating elastic interactions with asphalt leading to decreased stiffness and eventually decreasing the stress accumulation.

To sum up, the addition of swine-based bio-oil in asphalt binder decreased the high-temperature performance while fatigue performance is found to improve. The low-temperature cracking resistance enhanced due to the improved stress relaxation of bio-modified binders.

Rheological performance of herbaceous, agricultural, and vegetable-based bio-asphalt

Researchers are in agreement that adding bio-oil from the residue of corn processing would inherent several negative impacts on the performance. To remedy these defects, researchers introduced modifiers to the blends of bio-asphalt. The commonly used modifiers were Styrene–Butadiene–Styrene block copolymer (SBS), rubber, polyphosphoric acid (PPA), etc. (Dong et al. 2018; Bao et al. 2019; Zhou et al. 2020a; Wang et al. 2021a). The master curve of corn residue bio-modified binder shows that at lower frequency, G* value was higher as compared to base asphalt implying improved high-temperature performance and reduced low-temperature performance. Further, BBR test results confirmed that addition of bio-oil slightly affects low-temperature performance (Dong et al. 2018). Bao et al. (2019) developed a composite of SBS/rubber composite-polymer-modified asphalt with bio-asphalt. The composite was prepared in two steps; first, the bio-oil and asphalt were blended at 150℃ with high shear mixer at a rotation of 1500 rpm for 5 min; secondly, SBS and rubber were added to the prepared mix at 180℃ with 3500 rpm for 30 min. The bio-oil replacement level was 10%, 12%,15%, 18%, and 20% by weight of the binder, whereas the SBS and rubber content was 2% and 10% by weight of the bio-modified binder. The authors found that the composite exhibited excellent anti-cracking performance. Likewise, Wang et al. (2021a) prepared a composite of PPA-modified bio-binder. In view of high- and low-temperature performance, the authors concluded that the optimal content of PPA ranges from 6 to 8% and the bio-modified binder content lies between 10 and 16%.

The corn stover–modified bio-asphalt has a similar performance to that of control asphalt in terms of rutting resistance at unaged conditions, whereas rutting resistance increases as the RTFO aged binders are evaluated (Fini et al. 2016b). Several composite modifications were recommended to evaluate the effectiveness and broader usage of corn stover–based bio-oil. The results by Hill et al. (2018) through BBR at − 12℃ found that the stiffness reduced by 8.9% while m-value increased by 11.3% indicating improved relaxation ability of bio-binder. These results prompted the researchers to evaluate the mixtures with RAP and bio-oil. Likewise, Fini et al. (2016a) evaluated the low-temperature performance and found that the corn stover–modified bio-asphalt exhibited higher dissipated energy ratio (DER). Generally, the higher DER corresponds to better cracking resistance.

Based on the availability, several researches explored the feasibility of using rapeseed, soybeans, sunflower, palm oil, castor oil, date seed oil, and maize oil as bitumen extender and modifier. Most of the binders produced with the above bio-oils results in softer binder indicating an improvement in low-temperature performance (Rusbintardjo et al. 2013; Hainin et al. 2014; Xi et al. 2015; Somé et al. 2016; Portugal et al. 2017; Alamawi et al. 2019).

Rheological performance of waste oil-based bio-asphalt

Liu et al. (2018b) researched the rheological properties and found that as the WEO content increased, the G* decreased and δ increased, indicating poor deformation resistance and elastic recovery. Moreover, the rutting parameter G*/sinδ reduced drastically as the WEO content increased and the reduction for 4% replacement was found to be 30–40%, whereas for 8% the reduction increased up to 60–70%, representing strong influence of WEO on the rutting resistance (Table 3). On the other hand, the fatigue factor decreased as the content of WEO increased signifying improved fatigue cracking resistance (Liu et al. 2018a). Lei et al. (2015) studied the low-temperature performance of 5% refine waste oil–modified binder using BBR. The stiffness value reduced, increasing the crack resistance, whereas m-value increased, suggesting better stress relaxation capability. This investigation was supported by Thermal Stress Restrained Specimen Test (TSRST) on mixtures. Further, the cracking resistance was demonstrated using single-edge notched beam (SENB) test. The fracture resistance increased threefold than the base binder, implying significant low-temperature cracking resistance due to addition of refine waste oil. Wang et al. (2020b) analyzed the MSCR results for permanent deformation characteristics and found that the addition of WEO weakens the elastic recovery and anti-rutting deformation resistance. On the contrary, the compound modification of SBS/WEO-modified binder has a better rutting performance than the control binder.

Wen et al. (2012) attempted replacement of WCO at 10, 30, and 60% by the weight of the base binder. The waste cooking oil was subjected to thermochemical process via polymerization at elevated temperatures. Three base binders were selected viz PG 58–28, PG76-22, and PG 82–16. The addition reduced the PG as shown in Table 4. Based on the PG grading test results, the authors restricted the dosage to 30% for PG 76–22 and PG 82–16. The prepared blends were subjected to monotonic constant shear rate test and MSCR test for evaluation of resistance against fatigue and rutting. The critical strain energy density (CSED) reduced as the WCO dosage increased inferring lowered fatigue performance. Similarly, the rutting resistance also reduced as reflected by increased Jnr values.

Wang et al. (2018) varied the percentage of WCO residue obtained from bio-diesel production. The WCO-modified blends were prepared at a replacement of 5, 10, and 15%. The permanent deformation results from MSCR test found that the unrecoverable strain and non-recoverable creep compliance increased as the WCO content increased. Further, as the stress level increased, the Jnr value doubled for 5% WCO-modified binders. The fatigue life at intermediate temperature under cyclic loading improved but the results of binder yield energy test (BYET) which replicates the monotonic loading showed deteriorated performance. The decreased in yield stress and yield strain could be due to the reduction of tensile strength of the mixtures. The research by Sun et al. (2016) also concluded that the addition reduced the deformation resistance and elastic recovery, while increasing low-temperature performance.

In conclusion, the addition of WEO weakens the high-temperature performance but improves the low-temperature performance. For WCO-based binder, the rutting and fatigue resistance is compromised whereas the low temperature anti-cracking resistance improves drastically.

Mixture performance of bio-asphalt

The study of mixture is undertaken to evaluate the resistance to permanent deformation, fatigue life, moisture resistance, low-temperature resistance, etc. The subsequent section elaborates the mechanical performance of bio-asphalt.

Mixture performance of wood-based bio-asphalt mixtures

Limited studies are available in terms of mechanical performance of wood-based bio-asphalt mixtures. Yang et al. (2013) extended their study from bio-asphalt to bio-asphalt mixtures (Yang et al. 2014b). The bio-modified mixtures were prepared with three different types of bio-oil-modified binders namely original bio-oil-modified asphalt binder (OB), dewatered bio-oil-modified binder (DWB), and polymer bio-oil-modified asphalt (PMB) at replacement levels of 5 and 10%. The original bio-oil-modified asphalt binder (OB) was prepared using the bio-oil obtained after pyrolysis with 15–30% moisture by its weight, whereas dewatered bio-oil which contains 5% moisture was used to produce dewatered bio-oil-modified binder (DWB), and polymer bio-oil-modified asphalt (PMB) contains 4% polyethylene by the weight of bio-oil. The mixtures were subjected to testing against rutting, fatigue, and tensile strength using asphalt pavement analyzer (APA), four-point beam fatigue test, and indirect tensile strength test. The tensile strength of bio-modified mixtures was found to be lower than control mixtures by 16.7%, 18.3%, and 9.3% for OB-, DWB-, and PMB-modified mixtures, respectively. This reduction was attributed to formation of bio-chars during mixing and compaction which leads to agglomeration of asphalt particles. In terms of rut depth, all the bio-modified mixtures exhibited higher values than control mixture indicating increased permanent deformation susceptibility. Additionally, dynamic creep test was employed, the results of which were in agreement with APA results. The flow number of all the bio-modified mixtures was lower than that of control mixture. The fatigue life was evaluated at 200 and 400 micro-strains. The bio-modified mixtures exhibited improved fatigue life at both micro-strains. The authors concluded that the higher fatigue life is due to lower initial dissipated energy and flexural stiffness. Mohammad et al. (2013) subjected bio-modified mixtures to rutting, fatigue, and moisture testing. All the bio-modified mixtures except 50% modification fulfilled the Louisiana rut depth specification of maximum 6 mm at 20,000 passes. Similarly, for moisture resistance, 50% replacement could not meet the minimum requirement of 80% TSR. In terms of low-temperature cracking resistance, bio-modified mixtures performed better than the control mixtures. Ingrassia and Canestrari (2022) characterized the fatigue behavior of bio-modified mixtures under short-term and long-term aging conditions. The short-termed aged bio-modified mixture was found to be more susceptible to cracking than control mixture due to the oxidation caused by exposure to high temperatures during mixing and compaction. However, long termed performed better than control mixture owing to the low conditioning of temperature (85℃). Table 5 summarizes the performance of wood-based bio-asphalt mixtures.

Mixture performance of swine manure–based bio-asphalt mixtures

Very few literature have reported the mixture performance of the swine manure–based bio-binders. Fini et al. (2011) utilized hydrothermal process with temperature of 305℃, pressure of 3.5 MPa, and residence time of 80 min to produce bio-oil using swine manure as biomass source. Nitrogen was used as purge gas in the reactor and the sticky residue obtained was separated using filtration. Bio-modified binders were prepared with 2, 5, and 10% replacement of asphalt binder. Rheological studies found that the addition of bio-oils reduced the complex modulus leading to soft binder at high temperature. To quantify this concern, they employed Hamburg wheel rut test to evaluate the rutting performance of bio-modified mixture. The mixture was produced using 2% replacement. The rut depth progression and rut depth at the end of 20,000 cycles were similar to the base binder. Figure 4 represents the rut depth of base as well as bio-modified mixture. The limitation of the study was that it did not consider the increasing bio-oil percentage effect on mixture’s rutting performance.

Rut depth for control and bio-modified mixture (Fini et al. 2011)

Another study evaluated the low-temperature performance of RAP-modified bio-mixtures at various RAP percentages. The replacement level of RAP was 15 and 45% by the weight of the mixture. The study employed disk-shaped compact tension, indirect tension, and acoustic emissions test to evaluate fracture energy, creep compliance, and embrittlement temperature of the mixture. Bio-modified RAP mixture exhibited enhanced fracture resistance, increased creep compliance, and improved resistance to cracking. The study concluded that bio-modified RAP mixtures display improved low-temperature performance as compared to HMA. Similarly, Mogawer et al. (2011) developed RAP-modified bio-mixture with RAP at 40% replacement. It was found that the addition of bio-oil proved beneficial in reducing stiffness imparted by high replacement level of RAP. Also, the cracking susceptibility of bio-modified RAP mixture reduced.

In conclusion, more studies are needed at mixture’s level to assess the in-depth performance.

Mixture performance of herbaceous, agricultural, and vegetable-based bio-asphalt mixtures

The corn residue bio-oil-modified mixture was subjected to testing for rutting resistance, low-temperature performance, and moisture resistance (Dong et al. 2018). Apart from the bio-modified mixtures (BMM) at 10% and 15% replacement level, base asphalt along with bio-oil was modified with SBS and o-Phthalic anhydride and corresponding mixtures were made. The rutting depth of bio-modified mixture with 10% and 15% bio-oil was similar to base asphalt, whereas the lower rutting depth was observed in case of SBS-modified bio-mixture. Figure 5 represents the rut depth corresponding to each mixture. In comparison among the mixtures, the rut depth of SBS bio-modified mixtures was found to be lowest due to the formation of three-dimensional structure in binder. Overall, the addition of bio-oil improved the rutting resistance of the mixtures except modified with o-Phthalic anhydride. Feng et al. (2023) developed composite mixture containing lignin and waste soybean oil. The dosage of lignin varied from 0, 3, 5, and 7% whereas waste soybean oil replacement stood at 5%. The addition of lignin increased the stiffness of the mixture leading to reduced rut depth while introduction of oil decreased the viscosity leading to higher rut depth. The composite mixture rut depth increased by 5, 10, and 15% as the lignin percentage varied from 3, 5, and 7% with 5% soybean oil addition. The fatigue life of composite mixture increased due to the softening effect imparted by oil.

Rutting depth of mixtures (Dong et al. 2018)

The low-temperature performance was assessed using flexural tensile strain at − 10℃ obtained by bending beam test (Dong et al. 2018). The higher is the flexural tensile strain, the better is the low-temperature performance. The flexural tensile strain of 10% BMM and 15% BMM was found to be lower than that of control asphalt indicating deteriorated low-temperature performance. The SBS-modified bio-mixture performed best while o-Phthalic anhydride mixture resulted in higher flexural tensile strain than bio-modified mixtures. The moisture damage was assessed using the tensile strength ratio (TSR). As evident from Fig. 6, the bio-modified mixtures exhibit worst moisture resistance (Dong et al. 2018). The increase in bio-oil content drastically reduced the water resistance of the bio-modified mixtures due to the presence of low molecular weight compounds. The results suggest that chemically (o-Phthalic anhydride) modified mixture exhibit excellent improvement in terms of resistance while negligible increment was observed in SBS-modified mixture. The SBS-modified mixture and bio-modified mixtures did not meet the minimum criteria laid by Ministry of Transport of the People’s Republic of China, 2004 of 75% TSR. Finally, they concluded that the chemical modification should be adopted to enhance the moisture resistance. Similarly, Zhou et al. (2020a) evaluated the mixtures’ moisture resistance by chemically modifying them with phthalic anhydride (PA), ethylenediaminetetraacetic acid (EDTA), and citric acid (CA) as modifiers and concentrated sulfuric acid was used as catalyst.

Tensile strength ratio of mixtures (Dong et al. 2018)

Mixture performance of waste oil–based bio-asphalt mixtures

Lei et al. (2015) investigated the low-temperature performance of the mixture using thermal stress restrained specimen test (TSRST). The 5% refine waste oil–modified mixtures were prepared using Superpave Gyratory Compactor (SGC). The samples were sawed prismatic beam of size 15 cm × 5 cm × 5 cm. The indicator used here was fracture temperature. The fracture temperature of the oil-modified mixture was found to be lower than control mixture suggesting excellent increase in low-temperature performance of the mixtures. Wen et al. (2012) researched the mixtures produced with high content of WCO. The replacement varied 10, 30, and 60% of the weight of base binder. The mixtures were tested for stiffness, rutting, fatigue, and moisture damage. The stiffness was captured using the dynamic modulus test in asphalt mixture performance tester (AMPT). The dynamic modulus master curves were plotted which depicted reduced stiffness as the content of oil increased. The flow number reduced as the WCO content increased compromising high temperature. The results were consistent with the binder tests as well. In terms of fatigue response, assessed using indirect tensile test as per AASHTO T 322, the addition led to reduced failure strength and critical strain energy density (CSED). Indirect tensile thermal test found promising results, the CSED of mixture increased indicating higher thermal cracking resistance. Furthermore, the moisture resistance of the all the mixes was found to be minimum 80%. Azahar et al. (2017) produced mixture using untreated and treated WCO. The treated WCO was obtained by transesterification. The mixtures prepared using 5% replacement were tested for resilient modulus, dynamic creep, and indirect tension test. The result of resilient modulus at 25℃ and 40℃ for treated WCO mixture was higher than that of control mixture. This increment suggests that treated WCO forms superior chemical bonding with asphalt resulting in stiffer mix. The dynamic creep results found that treated WCO rutting resistance increased by 25% with reference to control mixture. Similarly, the treated WCO mixtures performed superiorly by achieving highest tensile strength. This enhanced tensile strength was attributed to polar group attraction of treated WCO and asphalt binder creating increased adhesion.

To sum up, the results of waste oil bio-modified mixtures are in agreement with binders. The mixtures’ permanent deformation resistance deteriorated as the waste oil dosage increased. Fatigue performance was also affected, while the low-temperature performance improved.

Aging mechanism

The bio-asphalt susceptibility towards aging must be understood thoroughly to achieve durable performance. In this regard, the following section dissects the aging mechanism along with the functional groups present in it.

Aging mechanism of wood-based bio-asphalt

There are some concerns regarding the aging of bio-asphalt because they are subjected to elevated temperatures (Metwally and Williams 2010; Yang et al. 2013). The most commonly and widely adopted technique for identifying functional groups in asphalt is Fourier transform infrared spectroscopy (FTIR). FTIR produces infrared absorption spectrum by identifying the chemical bonds present in molecules. The susceptibility of bio-binder to aging is mainly attributed to loss of volatiles, oxidation, dehydrogenation, and polymerization (Hilten and Das 2010). During mixing and compaction of bio-binders, loss of volatiles takes place due to the presence of low boiling point compounds and large amount of oxygen (Girimath and Singh 2019). Another problem associated with increased mass loss of bio-binders is high emissions (Yang et al. 2014a). Oxidation takes place due to the chemical reaction of bio-binders with atmospheric oxygen (Petersen 2009). Oxidative aging leads to increase in carbonyl and sulfoxides groups. Ingrassia et al. (2019) performed FTIR analysis before and after aging for wood-based bio-oil-modified bio-blends for quantifying sulfoxide and carbonyl index. They found that in unaged conditions, carbonyl index increased as the bio-oil content increased. However, this trend was inverted after aging due to the presence of bio-oil. On the other hand, sulfoxide index reduced slightly as the bio-oil content increased in unaged condition whereas steep rise was noted in short-term and long-term aged bio-blend samples. In addition, lower aromacity and oxidized groups related to esters emerged. Similarly, Yang et al. (2017) evaluated carbonyl and sulfoxide indexes through FTIR for unaged and aged bio-asphalt. For unaged conditions, as the bio-oil content increased, both the indices increased. Furthermore, after RTFO and PAV aging of bio-asphalt, these indices increased indicating bio-asphalt hardening. In another study by Yang et al. (2014a), high replacement of 30% and 70% of asphalt binder with bio-oil was attempted. Carbonyl index corresponding to 1700 cm−1 was found to be higher due to the presence of large amount of oxygen in comparison with asphalt. After subjecting to RTFO aging, carbonyl index of bio-blends were found to be significantly higher. Apart from carbonyl bonds, the concentration of ester, alocohol, and acids increased after aging.

Few researchers modified the aging conditions due to that the fact that bio-binders are subjected to lower temperatures during mixing and compaction temperature. Based on the extensive testing, they recommended few modifications in terms of temperatures and time for RTFOT and PAV. For RTFOT, the temperature should be adjusted to a range of 110–120℃ and duration to 20 min. On the other hand, for long-term aging, PAV should be done at 120℃ for 2.5 h. These temperatures were considered so to replicate the conditions offered by bio-binders during mixing and compaction (Metwally and Williams 2010; Peralta et al. 2012).

Overall, the FTIR spectra confirmed that no new peak was observed for wood-based bio-asphalt, indicating no chemical interaction between asphalt and wood bio-oils (Yang et al. 2014a; Ingrassia et al. 2020). However, the addition of wood-based bio-oils leads to increased percentage of alcohols and acids, whereas percentage of aromatics was not affected (Yang et al. 2014a). In addition, wood-based bio-asphalt have presence of large amount oxygen, acids or esters, aldehydes, acycls, phenols, ketones, alcohols, etc. Presently, there is a need for a detail investigation so as to ascertain the aging behavior of wood-based bio-asphalts.

Aging mechanism of swine manure–based bio-asphalt

Mills-Beale et al. (2012) studied the aging behavior of bio-modified binder in unaged, RTFO, and PAV aged conditions using carbonyl and sulphoxide indices. They found that the FTIR spectra of base and bio-modified blends were similar in terms of shape and symmetry indicating that bio-modified binder behaves as control binder. The carbonyl and sulphoxide index reduced when the bio-modified binders were used. Figure 7 shows aging indices of base binder and bio-modified binders. As evident from Fig. 7, the carbonyl and sulphoxide index decreased with the bio-modified binder imparting lower aging susceptibility. Hosseinnezhad et al. (2019) evaluated the effects the ultraviolet and oxidative aging has on bio-modified binder. They simulated oxidative aging using RTFO and PAV, whereas UV aging was performed using ultraviolet irradiation machine. The results suggest that carbonyl index obtained by UV aging was much higher than that obtained by oxidative aging. This is due to the reactivity of free radicals encouraged by UV light leading to formation C = O bonds. On the other side, sulphoxide index remained unchanged, while oxidative aging showed higher sulfoxide index than UV aged samples. These differential formation rate of carbonyl and sulfoxide indices due to UV and oxidative aging conditions promoted researchers to suggest the incorporation of UV effect in the existing aging methods.

Carbonyl and sulphoxide aging index of base and bio-modified binder (Mills-Beale et al. 2012)

Liu et al. (2020) researched swine manure bio-oil produced using pyrolysis. The FTIR spectra and presence of functional groups of bio-modified binder and neat bitumen were found to be similar indicating good compatibility between them. The bio-modified binder exhibited dominance of alcohol groups due to the presence of retained moisture. They reported reduced aging resistance of bio-modified binder due to the volatilization of light components and conversion of unsaturated alkane groups to saturated alkane groups after short-term aging. On the contrary, Fini et al. (2015) found that bio-oil prepared using thermochemical conversion reduced carbonyl and sulphoxide index. The authors attributed this reduction to molecular interaction of swine manure based bio-oil with asphalt, resulting in lower affinity towards oxygen.

Overall, based on the available literature, it can be concluded that the best anti-aging resistance is offered by swine manure-based bio-asphalt in comparison with other bio-asphalt.

Aging mechanism of herbaceous, agricultural, and vegetable-based bio-asphalt mixtures

The FTIR spectra of corn residue bio-oil confirm the presence of light and soluble compounds (Dong et al. 2018; Bao et al. 2019; Wang et al. 2021a). The presence of these compounds promotes the propensity of moisture damage due to their smaller molecular weight and greater polarity. According to Dong et al. (2018), the bio-oil contains propylene glycol, ethylene glycol, and butane dioic acid which can dissolve in water leading to loss of adhesion. Similarly Bao et al. (2019) also found small molecule water-dissolvable alcohols which would lead to reduction of adhesive property. Further, the addition of bio-oil does not alter the chemical structure of base asphalt implying that the interaction between the bio-oil and asphalt is physical in nature (Wang et al. 2021a). The corn stover–based bio-asphalt show noticeable broad peak at wavelength of 1100–1300 cm−1 representing aromatics and phenolic stretching (Hosseinnezhad et al. 2019). The C = O and S = O indices of corn stover bio-asphalt were consistently higher than the control binder (Fini et al. 2015).

To sum up, the carbonyl and sulfoxide index progression depend on the source of the bio-oil. The variable source leads to formation of bio-oil with differential composition affecting the rate of carbonyl and sulfoxide indices formation. As seen in elemental composition (Fig. 2), the higher amount of oxygen makes the bio-asphalt prone to aging.

Aging mechanism of waste oil–based bio-asphalt

The FTIR spectrum shows that the functional and molecular structures of WEO and asphalt is similar in nature (Liu et al. 2018b; Wang et al. 2020b). The interaction of WEO and asphalt is physical in nature which is ascertained by formation of no new peak (Liu et al. 2018a, b; Wang et al. 2020b). However, Liu and Wang (2021) found a new peak while using a composite of CR/SBS/WEO indicating an possibility of chemical reaction. The changes in functional groups are captured analyzing the peaks at 1700 cm−1 and 1030 cm−1. The variation of these peaks before and after modification are quantified and are referred to as carbonyl and sulfoxide indices. Liu et al. (2018b) calculated the carbonyl and sulfoxide indices for WEO-modified binder and found that as the WEO content increased the carbonyl index reduced. This reduction was due to the breakdown of large molecules of asphalt by WEO resulting in lower carbonyl functional groups. Similarly, the sulfoxide index reduced as the WEO increased. Liu et al. (2019) further analyzed the effects of aging conditions on the WEO/SBS-modified binders. The samples were subjected to short-term, long-term, and a nonstandard double long-term (2-PAV) aging. The results confirm that addition of WEO reduced aging indices due to physical dilution while the introduction of increasing aging time increased these indices because of hydrogenation, condensation, and oxidation.

FTIR analysis confirms the presence of acid, ether, ester, and alcohol with the help of C–O, C = O, and –OH stretch in WCO. The absorbance spectrum shape of WCO-modified binders was found to be similar of base binder (Wang et al. 2018). The spectrum of modified binder did not show any new peak confirming the modification as physical (Sun et al. 2016). The variation in aging indices corresponding varying dosage is presented in Fig. 8. As can be seen, the carbonyl index of WCO-modified binder tend to increase with higher dosages exhibiting increased aging susceptibility. On the other hand, sulfoxide index presented very little variation as compared to control binder (Wang et al. 2018).

Overall, the FTIR spectrum of waste oil–modified binder and asphalt is similar in shape. The waste oil and asphalt were physically blended as there was no new peak observed. The aging indices of WEO-modified binder reduced as the dosage increased. For WCO-modified binder, the carbonyl index increased whereas the sulfoxide index did not increase much.

Modifications to enhance the performance of bio-asphalt

Due to the insufficient high-temperature performance and aging resistance, researches are being carried out to evaluate the synergic effect of additional modifiers along with bio-asphalt. This section lays out the common additional modifiers used and their effect on the performance of bio-asphalt.

Modifications to improve the performance of wood-based bio-asphalt

The common practice among researchers in regard to bio-asphalt is composite modification. The additional modifiers are usually targeted to either negate the targeted drawback or to introduce a certain performance effect.

As can be seen in Table 6, the common modifiers used are SBS, crumb rubber, and PPA. SBS, being thermoplastic elastomer, exhibit good elastic properties and high rutting resistance at elevated temperatures. PPA has been in use since 1973 in asphalt industry aiming to increase asphalt stiffness (Alexander 1972). Crumb rubber addition serves enhanced high temperature, aging, and moisture resistance. Also, utilization of crumb rubber mitigates environmental burden caused by its non-degradable nature. Zhang et al. (2017b) targeted to improve the high-temperature performance of bio-oil obtained from fast pyrolysis. They optimized bio-oil using distilled water to remove the lightweight water-dissolvable compounds responsible for insufficient high-temperature performance and aging. The water–oil mass ratio of 2:1 was found optimum to dissolve polar lightweighted compounds leading to enhanced rutting and aging.

resistance. Gao et al. (2018) prepared composite of SBS-modified asphalt with bio-oil from saw dust. The rutting parameter increased significantly after RTFO aging, thereby improving the high-temperature performance. Similarly, Mousavi et al. (2021) also reported an increase in permanent deformation resistance using composite modification.

To sum up, researches prove that bio-asphalt’s high-temperature performance is insufficient compared to control asphalt binder. Several modifications attempted with accompanying modifiers yield promising results.

Modifications to improve the performance of animal-based bio-binders

Table 7 lists out the combined modification attempted to improve the performance of swine manure based bio-asphalt.

From the literature review, it is evident that the high-temperature performance behavior of swine manure–based bio-binders is driven by the type of process employed for biomass conversion. Swine manure bio-binders produced using the thermochemical liquefaction tend to compromise the high-temperature performance whereas if pyrolysis method was employed contradictory results were obtained (Fini et al. 2011, 2012; Liu et al. 2020; Wang et al. 2020a). Constant efforts are made to negate the impact of bio-oil on high-temperature performance. In this regard, Fini et al. (2012) added 1.5% PPA to the bio-modified binders and found significant increase in complex modulus of the bio-modified binders. They also suggested the use of RAP to counteract the stiffness reduction. Fini et al. (2013) added crumb rubber in the increment of 5% till 15% in bio-modified binder prepared with swine manure bio-oil. The results of bio-modified rubber asphalt binder were comparable to that of crumb rubber–modified binder. Wang et al. (2021b) researched the effects of preparation procedure of swine manure bio-oil–based rubber-modified binder. The outcomes of the study recommended that premixing bio-oil and rubber powder first followed by addition of asphalt binder. Onochie et al. (2013) introduced nanomaterials (nano-clay and nano-silica) to bio-modified binders. The replacement level of nanomaterials stood at 2 and 4% (by weight of base binder), while the bio-modified binder was prepared at 5% replacement of base binder. The addition of nanomaterials proved beneficial in terms of enhanced resistance against permanent deformation and reduced the aging susceptibility.

Overall, the addition of swine manure–based bio-oil to asphalt binder reduces the stiffness and raises concern about its high-temperature performance. Researchers have used various materials ranging from polyphosphoric acid, crumb rubber, RAP, and nanomaterials to counter its softening effect. These materials individual stiffening properties add to the much-needed resistance at high temperature of bio-asphalt.

Modification to improve the performance of herbaceous, agricultural, and vegetable-based bio-asphalt

Table 8 enumerates the materials used in conjunction with herbaceous, agricultural, and vegetable bio-oils to produce bio-composite asphalt blend.

From the literature review, it is found that most of the herbaceous, agricultural, and vegetable-based bio-binders compromise the high-temperature performance; thus, common anti-rutting modifiers are introduced as seen in Table 8. The correct dosage of modifiers along with the bio-binder resulted in elevated high-temperature performance, enhanced aging characteristics, and improved cracking resistance.

Modification to improve the performance of waste oil–based bio-binders

Table 9 summarizes the performance of composite-modified waste oil bio-asphalt.

In summary, from the reviewed literature, it can be inferred that the addition of waste oils in asphalt reduced the high-temperature performance of binder and mixture. In this direction, researches are carried out to negate the softening effect of waste oil on asphalt. The additional modifiers ranged from SBS, CR, PE, and lignin etc. These materials counterbalance the softening effect imparted by waste oils. As can be seen in Table 9, the composite modification enhances the weakened properties and returned comparable performance as base binder.

Performance of miscellaneous material–based bio-asphalt

There are wide variety of materials that are incorporated as partial replacement of asphalt binder.

Most of these miscellaneous materials used are in solid form. Table 10 lists out the varying dosages, rheological effects, and mixture performance of various miscellaneous bio-binders. As can be seen, most of the solid-based materials can only be introduced as modifiers due to the stiffening effect, which increases the viscosity of binder, leading to higher mixing and compaction temperature. In terms of physical properties, the general trend suggest that the addition leads to lower penetration, ductility, and higher softening point. The rheological results found that the stiffer blends exhibit enhanced permanent deformation resistance at high temperature compromising fatigue behavior. Some materials such as lignin, waste coffee grounds, and biochar can offer resistance against aging. The mixtures’ performance is also in agreement with the binders, inferring higher stiffness and reduced rut depth.

Overall, there is a wide variety of materials that are explored in preparation of bio-asphalt. However, the replacement percentage is low since their addition leads to excessive stiffness even at small dosages. Further investigations must be focused on elevating their replacement to extender level.

Environmental considerations

Documentation on bio-asphalt suggest that the utilization of bio-binder derives environmental benefits. However, it is integral to validate the claims using life cycle assessment (LCA). LCA evaluates potential environmental impacts through the service life of the product, right from its production to end-of-life. Samieadel et al. (2018) conducted LCA on swine manure–based bio-modified binder obtained using hydrothermal liquefaction (HTL). The bio-binder was replaced at 10% and a comparative comparison in terms of energy consumption and greenhouse gas emissions with control binder was done. The findings revealed that the gas emissions for conventional asphalt were higher in comparison to bio-modified binder. Similarly, the global warming potential index (GWP) which is a measure of accumulation of greenhouse gases in the atmosphere relative to carbon dioxide recorded lower value for bio-modified binder (23.101) than conventional asphalt (25.051). Figure 9 shows the gases emitted per 50 kg production of each asphalt and bio-modified binder.

GHG emission per 50 kg of bio-asphalt and asphalt (Samieadel et al. 2018)

Similarly, Zhou et al. (2020b) presented LCA on biochar-modified asphalt binder procured from waste wood and pig manure. The results revealed that using biochar-modified asphalt binder yields lower volatile organic compound (VOC) emissions. Further, as the biochar content increased, more prominent environmental benefits emerged in the form of GHG reduction. A plethora of studies are available on lignin-modified asphalt binder (Tokede et al. 2020; Moretti et al. 2022b, a). Tokede et al. (2020) assessed environmental impact of 25% lignin-modified asphalt using cradle-to-gate approach. It was found that the GWP reduced by 5.72% for lignin-modified binder. Finally, in conclusion, the addition of lignin to asphalt could lead to clean and sustainable development reducing dependence on non-renewable resources. Moretti et al. (2022a) researched lignin replacement in top layers of stone matrix asphalt, porous asphalt, and conventional asphalt. The results found that the addition of lignin could reduce the climate change impact in the magnitude of 30 to 75%. Further, Moretti et al. (2022b) found that the environmental impact of lignin-modified asphalt is dependent on the source and production process of lignin applied.

In summary, encouraging results are obtained highlighting lower emissions. More studies are required in this direction to concrete environmental benefits of bio-asphalts from various biomass sources.

Field studies

Field applications are essential to ascertain the laboratory performance of bio-asphalt. Currently, scientific documents are scarce to establish a plausible conclusion regarding their long-term performance. The information presented here regarding field trials are from various news sources and private entities. One of the first reported studies on use of bio-asphalt date back to 2007, where Shell oil company constructed two roads using vegetable oil–based bio-asphalt (Su et al. 2018). In 2011, Christopher Williams of Iowa State University built a bike path 3.048 m wide in Des Moines with oak based bio-asphalt at 5% replacement level (Williams 2011). Recently, a 650-m-long national highway road was constructed using sugarcane molasses in India (NHAI 2022). The conventional binder was replaced with 25% sugarcane molasses to carry a traffic of 200 msa. The authors reported a similar surface finish as conventional asphalt along with no difficulty in production, laying, and compaction. Further, the section is under periodic monitoring to determine the performance. The limited trials insist on narrowing gap between laboratory and field trials to establish long-term performance of bio-asphalt.

Conclusions

This paper presented the performance of bio-asphalt comprehensively. Based on this review, the following conclusions can be drawn:

-

The bio-asphalt are renewable and sustainable alternative to asphalt. Bio-asphalt refers to the mixture of conventional asphalt binder and bio-binder (e.g., bio-oil, heavy oil, cooking oil). The ultimate analysis found that the composition of bio-oil mainly consists of carbon, hydrogen, nitrogen, and oxygen (C, H, N, O).

-

The elemental composition of wood-based bio-oil confirmed the presence of higher proportion of oxygen in comparison to that of asphalt. For preparation of wood-based bio-asphalt, the mixing temperature typically ranges from 120 to 150℃, with a shearing of 1000–5000 rpm for 10–30 min.

-

From rheological and mixture standpoint, the addition of wood-based bio-oil leads to softening effect compromising the high-temperature performance. The FTIR spectra confirmed the blending as physical phenomenon, with a presence of large amount of oxygen, acids, aldehydes, ketones, and alcohols promoting aging susceptibility.

-

The analogous elemental composition of swine manure–based bio-oil proved beneficial in providing much needed aging resistance. The FTIR spectra similarity and symmetry confirmed the physical blending.

-

To develop the swine manure–based bio-asphalt, the mixing temperature varies in the range of 120–140℃ at a shearing rate of 3000 rpm with a blending time of 30 min. The intermediate- and low-temperature performance enhanced due to the addition of swine manure bio-oil.

-

The presence of higher amount of oxygen in herbaceous, agricultural, and vegetable-based bio-oil causes a greater affinity towards aging. Also, the presence of light and water-dissolvable compounds tends to compromise the adhesive property leading to increased propensity towards moisture damage.

-

From production viewpoint, the blending is usually carried out at a temperature range of 120–150℃, with a mixing time of 30–60 min at a shearing rate of 1000–3000 rpm. The softening effect leads to improved cracking resistance implying improved low-temperature performance.

-

The waste oil (waste engine oil, waste cooking oil)–based bio-asphalt is produced at mixing temperature of 130–160℃ with shearing of 4000–5000 rpm for 40–60 min. The replacement of waste oil is generally limited to a maximum of 10% due to the excessive softening effect resulting in weakened permanent deformation characteristics. The anti-cracking resistance on the other hand improves drastically.

-

Due to the similarity in the molecular structure of WEO, the aging resistance increases, while WCO exhibit increased aging susceptibility.

-

The addition of solid-based materials causes excessive stiffening effect restricting their dosage as modifiers.

-

Traditionally, the bio-asphalt have weakened high-temperature performance; additional modifiers such as SBS, crumb rubber, and PPA are introduced to extract the synergic effect.

-

In terms of environmental considerations, the production of bio-asphalt generates lower emissions in comparison with conventional asphalt mixture.

Data availability

Not applicable.

References

Adams P, Bridgwater T, Ross A, Watson I (2018) Biomass conversion technologies. In: Greenhouse gas balances of bioenergy systems, vol 2018. Academic Press, pp 107–139. https://doi.org/10.1016/B978-0-08-101036-5.00008-2

Alamawi MY, Khairuddin FH, Yusoff NIM et al (2019) Investigation on physical, thermal and chemical properties of palm kernel oil polyol bio-based binder as a replacement for bituminous binder. Constr Build Mater 204:122–131. https://doi.org/10.1016/J.CONBUILDMAT.2019.01.144

Alexander S (1972) Method of treating asphalt. Patent. https://patents.google.com/patent/US3751278A/en%0Ahttps://patents.google.com/patent/US3751278

Arabani M, Tahami SA (2017) Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr Build Mater 149:350–358. https://doi.org/10.1016/J.CONBUILDMAT.2017.05.127

Asphalt Institute and Eurobitume (2015) The bitumen industry-a global perspective

Azahar WNAW, Jaya RP, Hainin MR et al (2017) Mechanical performance of asphaltic concrete incorporating untreated and treated waste cooking oil. Constr Build Mater 150:653–663. https://doi.org/10.1016/J.CONBUILDMAT.2017.06.048

Babalghaith AM, Koting S, Sulong NHR et al (2022) A systematic review of the utilization of waste materials as aggregate replacement in stone matrix asphalt mixes. Environ Sci Pollut Res 29:35557–35582. https://doi.org/10.1007/S11356-022-19447-W/TABLES/9

Bao DX, Yu YY, Zhao QM (2019) Evaluation of the chemical composition and rheological properties of bio-asphalt from different biomass sources. Road Mater Pavement Des 21:1829–1843. https://doi.org/10.1080/14680629.2019.1568287

Chang FC, Tsai MJ, Ko CH (2018) Agricultural waste derived fuel from oil meal and waste cooking oil. Environ Sci Pollut Res 25:5223–5230. https://doi.org/10.1007/S11356-017-9119-X/TABLES/3

Ding Y, Shan B, Cao X et al (2021) Development of bio oil and bio asphalt by hydrothermal liquefaction using lignocellulose. J Clean Prod 288:125586. https://doi.org/10.1016/J.JCLEPRO.2020.125586

Dong Z, Zhou T, Luan H et al (2018) Performance evaluation of bio-based asphalt and asphalt mixture and effects of physical and chemical modification. Road Mater Pavement Des 21:1470–1489. https://doi.org/10.1080/14680629.2018.1553732

Dong Jiao Z, Zhou T, Luan H et al (2019) Composite modification mechanism of blended bio-asphalt combining styrene-butadiene-styrene with crumb rubber: a sustainable and environmental-friendly solution for wastes. J Clean Prod 214:593–605. https://doi.org/10.1016/j.jclepro.2019.01.004

Dong Z, Zhou T, Luan H et al (2020) Performance evaluation of bio-based asphalt and asphalt mixture and effects of physical and chemical modification. Road Mater Pavement Des 21:1470–1489. https://doi.org/10.1080/14680629.2018.1553732

Fakhri M, Norouzi MA (2022) Rheological and ageing properties of asphalt bio-binders containing lignin and waste engine oil. Constr Build Mater 321:126364. https://doi.org/10.1016/J.CONBUILDMAT.2022.126364

Feng L, Liu J, Hu L (2023) Rheological behavior of asphalt binder and performances of asphalt mixtures modified by waste soybean oil and lignin. Constr Build Mater 362:129735. https://doi.org/10.1016/j.conbuildmat.2022.129735

Fernandes S, Peralta J, Oliveira JRM (2017) Improving asphalt mixture performance by partially replacing bitumen with waste motor oil and elastomer modifiers. Appl Sci 794(7):794. https://doi.org/10.3390/APP7080794

Fini EH, Kalberer EW, Shahbazi A et al (2011) Chemical characterization of biobinder from swine manure: sustainable modifier for asphalt binder. J Mater Civ Eng 23:1506–1513. https://doi.org/10.1061/(asce)mt.1943-5533.0000237

Fini EH, Al-Qadi IL, You Z et al (2012) Partial replacement of asphalt binder with bio-binder: characterisation and modification. Int J Pavement Eng 13:515–522. https://doi.org/10.1080/10298436.2011.596937

Fini EH, Oldham DJ, Abu-Lebdeh T (2013) Synthesis and characterization of biomodified rubber asphalt: sustainable waste management solution for scrap tire and swine manure. J Environ Eng 139:1454–1461. https://doi.org/10.1061/(asce)ee.1943-7870.0000765

Fini E, Oldham D, Buabeng F, Nezhad S (2015) Investigating the aging susceptibility of bio-modified asphalts. https://doi.org/10.1061/9780784479216.007

Fini EH, Asce M, Khodaii A, Hajikarimi P (2016a) Fractional viscoelastic study of low-temperature characteristics of biomodified asphalt binders. J Mater Civ Eng 28:04016078. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001525

Fini EH, Hosseinnezhad S, Oldham DJ et al (2016b) Source dependency of rheological and surface characteristics of bio-modified asphalts. Road Mater Pavement Des 18:408–424. https://doi.org/10.1080/14680629.2016.1163281

Gao J, Wang H, You Z, Mohd Hasan MR (2018) Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr Build Mater 160:786–793. https://doi.org/10.1016/J.CONBUILDMAT.2018.01.048

Gao J, Wang H, Liu C et al (2020) High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr Build Mater 230:117063. https://doi.org/10.1016/J.CONBUILDMAT.2019.117063

Gaudenzi E, Canestrari F, Lu X, Cardone F (2021) Performance assessment of asphalt mixture produced with a bio-based binder. Materials (basel) 14:1–13. https://doi.org/10.3390/ma14040918

Gaudenzi E, Cardone F, Lu X, Canestrari F (2022) Performance assessment of asphalt mixtures produced with a bio-binder containing 30% of lignin. Mater Struct Constr 55:1–13. https://doi.org/10.1617/s11527-022-02057-w

Girimath S, Singh D (2019) Effects of bio-oil on performance characteristics of base and recycled asphalt pavement binders. Constr Build Mater 227:116684. https://doi.org/10.1016/j.conbuildmat.2019.116684

Hainin MR, Jaya RP, Ali Akbar NA et al (2014) Influence of palm oil fuel ash as a modifier on bitumen to improve aging resistance. J Eng Res 2:34–46

He M, Tu C, Cao DW, Chen YJ (2017) Comparative analysis of bio-binder properties derived from different sources. Int J Pavement Eng 20:792–800. https://doi.org/10.1080/10298436.2017.1347434

Hill B, Oldham D, Behnia B et al (2018) Evaluation of low temperature viscoelastic properties and fracture behavior of bio-asphalt mixtures. Int J Pavement Eng 19:362–369. https://doi.org/10.1080/10298436.2016.1175563

Hilten RN, Das KC (2010) Comparison of three accelerated aging procedures to assess bio-oil stability. Fuel 89:2741–2749. https://doi.org/10.1016/j.fuel.2010.03.033

Hosseinnezhad S, Zadshir M, Yu X et al (2019) Differential effects of ultraviolet radiation and oxidative aging on bio-modified binders. Fuel 251:45–56. https://doi.org/10.1016/j.fuel.2019.04.029

Huang J, Shiva Kumar G, Ren J, et al (2021) Towards the potential usage of eggshell powder as bio-modifier for asphalt binder and mixture: workability and mechanical propertieshttps://doi.org/10.1080/1029843620211905809

Ingrassia LP, Canestrari F (2022) VECD analysis to investigate the performance of long-term aged bio-asphalt mixtures compared to conventional asphalt mixtures. Road Mater Pavement Des 23:2697–2712. https://doi.org/10.1080/14680629.2021.1991839

Ingrassia LP, Lu X, Ferrotti G, Canestrari F (2019) Chemical and rheological investigation on the short- and long-term aging properties of bio-binders for road pavements. Constr Build Mater 217:518–529. https://doi.org/10.1016/J.CONBUILDMAT.2019.05.103

Ingrassia LP, Lu X, Ferrotti G, Canestrari F (2020) Chemical, morphological and rheological characterization of bitumen partially replaced with wood bio-oil: towards more sustainable materials in road pavements. J Traffic Transp Eng 7:192–204. https://doi.org/10.1016/J.JTTE.2019.04.003

Islam MR (2020) Asphalt binders. Civ Eng Mater 175–194. https://doi.org/10.1201/9780429275111-6

Jain S (2023) Chandrappa AK (2023) Critical review on waste cooking oil rejuvenation in asphalt mixture with high recycled asphalt. Environ Sci Pollut Res 3032(30):77981–78003. https://doi.org/10.1007/S11356-023-28098-4

Kumar A, Choudhary R, Narzari R, et al (2018) Evaluation of bio-asphalt binders modified with biochar: a pyrolysis by-product of Mesua ferrea seed cover waste. http://www.editorialmanager.com/cogenteng 5:1–15. https://doi.org/10.1080/23311916.2018.1548534

Lam SS, Russell AD, Lee CL, Chase HA (2012) Microwave-heated pyrolysis of waste automotive engine oil: influence of operation parameters on the yield, composition, and fuel properties of pyrolysis oil. Fuel 92:327–339. https://doi.org/10.1016/J.FUEL.2011.07.027

Lei Z, Bahia H, Yi-Qiu T (2015) Effect of bio-based and refined waste oil modifiers on low temperature performance of asphalt binders. Constr Build Mater 86:95–100. https://doi.org/10.1016/J.CONBUILDMAT.2015.03.106

Lei Y, Wang H, Fini EH et al (2018) Evaluation of the effect of bio-oil on the high-temperature performance of rubber modified asphalt. Constr Build Mater 191:692–701. https://doi.org/10.1016/J.CONBUILDMAT.2018.10.064

Liu C, Wang Q (2021) Enhancing effect of waste engine oil bottom incorporation on the performance of CR+SBS modified bitumen: a sustainable and environmentally-friendly solution for wastes. Sustain 13:12772. https://doi.org/10.3390/SU132212772

Liu S, Meng H, Xu Y, Zhou S (2018a) Evaluation of rheological characteristics of asphalt modified with waste engine oil (WEO) https://doi.org/10.1080/10916466.2018.1430157

Liu S, Peng A, Wu J, Zhou SB (2018b) Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr Build Mater 191:1210–1220. https://doi.org/10.1016/J.CONBUILDMAT.2018.10.126

Liu S, Peng A, Zhou S et al (2019) Evaluation of the ageing behaviour of waste engine oil-modified asphalt binders. Constr Build Mater 223:394–408. https://doi.org/10.1016/J.CONBUILDMAT.2019.07.020

Liu Q, Wang C, Fan Z et al (2020) Feasibility analysis of bio-binder as non-petroleum alternative for bituminous materials. Mater Res Express 6:125115. https://doi.org/10.1088/2053-1591/AB6E28

Luo W, Zhang Y, Cong P (2017) Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr Build Mater 144:13–24. https://doi.org/10.1016/J.CONBUILDMAT.2017.03.105

Luongo A, Kalampokis S, Papamoschou M et al (2022) Investigation of the characteristic properties of lignin-modified bitumen. Civil Eng 3:734–747. https://doi.org/10.3390/CIVILENG3030042

Metwally M, Williams RC (2010) Development of non-petroleum based binders for use in flexible pavements. In: Final Rep to Iowa Department Transportation Rep No TR-594, Iowa Dept Transp Ames, IA. https://scholar.google.com/scholar_lookup?title=Development+of+Non-Petroleum+Based+Binders+for+Use+in+Flexible+Pavements+(Final+Report)&author=Metwally,+M.&author=Williams,+R.C.&publication_year=2010

Mills-Beale J, You Z, Fini E et al (2012) Aging influence on rheology properties of petroleum-based asphalt modified with biobinder. J Mater Civ Eng 26:358–366. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000712

Mogawer WS, Fini EH, Austerman AJ et al (2011) Performance characteristics of high RAP bio-modified asphalt mixtures. In: Transportation Research Board (TRB) 91st Annual Meeting, pp 1–16. https://trid.trb.org/view/1129761

Mohammad LN, Elseifi M, Cooper SB, et al (2013) Laboratory evaluation of asphalt mixtures containing bio-binder technologies. Airf Highw Pavement 2013 Sustain Effic Pavements - Proc 2013 Airf Highw Pavement Conf 128–152. https://doi.org/10.1061/9780784413005.012

Mohan D, Pittman CU, Steele PH (2017) Pyrolysis of wood /biomass for bio-oil. Prog Energy Combust Sci 62:848–889

Moretti C, Corona B, Hoefnagels R, et al (2022a) Kraft lignin as a bio-based ingredient for Dutch asphalts: an attributional LCA. Sci Total Environ 806:. https://doi.org/10.1016/j.scitotenv.2021.150316

Moretti C, Hoefnagels R, van Veen M et al (2022b) Using lignin from local biorefineries for asphalts: LCA case study for the Netherlands. J Clean Prod 343:131063. https://doi.org/10.1016/j.jclepro.2022.131063

Mousavi M, Kabir SF, Fini EH (2021) Polyphosphoric acid’s synergy with bio-modified bituminous composites. Resour Conserv Recycl 168:105310. https://doi.org/10.1016/j.resconrec.2020.105310

NHAI (2022) NHAI constructs one of a kind road stretch made of molasses in Uttar Pradesh. https://www.knocksense.com/kanpur/nhai-constructs-one-of-a-kind-road-stretch-made-of-molasses-in-uttar-pradesh. Accessed 4 May 2023

Onochie A, Agricultural NC, Yang X et al (2013) Rheological characterization of nano-particle based bio-modified binder. https://trid.trb.org/view/1242863

Penki R, Rout SK (2021) Next-generation bitumen: a review on challenges and recent developments in bio-bitumen preparation and usage. Biomass Convers Biorefinery 1–18. https://doi.org/10.1007/S13399-021-01803-4/FIGURES/1

Peralta J, Raouf MA, Tang S, Williams RC (2012) Bio-renewable asphalt modifiers and asphalt substitutes. In: Sustainable bioenergy and bioproducts. Green energy and technology. Springer, London. https://doi.org/10.1007/978-1-4471-2324-8_6

Petersen JC (2009) A review of the fundamentals of asphalt oxidation: chemical, physicochemical, physical property, and durability relationships. Transp Res Circ. https://trid.trb.org/view/902386

Portugal ACX, de Lucena LC, FL, Lucena AE de FL, et al (2017) Rheological properties of asphalt binders prepared with maize oil. Constr Build Mater 152:1015–1026. https://doi.org/10.1016/J.CONBUILDMAT.2017.07.077

Pouget S, Loup F (2013) Thermo-mechanical behaviour of mixtures containing bio-binders. Road Mater Pavement Des 14:212–226. https://doi.org/10.1080/14680629.2013.774758

Ram M, Mondal MK (2022) fuel and chemicals. https://doi.org/10.1016/B978-0-323-85269-2.00008-3

Raouf MA, Williams CR (2010a) General rheological properties of fractionated switchgrass bio-oil as a pavement material. Road Mater Pavement Des 11:325–353. https://doi.org/10.3166/RMPD.11HS.325-353

Raouf MA, Williams RC (2010b) Temperature and shear susceptibility of a nonpetroleum binder as a pavement material. Transp Res Rec 9–18. https://doi.org/10.3141/2180-02

Rusbintardjo G, Hainin MR, Yusoff NIM (2013) Fundamental and rheological properties of oil palm fruit ash modified bitumen. Constr Build Mater 49:702–711. https://doi.org/10.1016/J.CONBUILDMAT.2013.08.056

Saboo N, Sukhija M, Mehta D et al (2023) Use of raw sugarcane molasses as a partial replacement of asphalt binder: an experimental investigation. Constr Build Mater 369:130541. https://doi.org/10.1016/J.CONBUILDMAT.2023.130541

Samieadel A, Schimmel K, Fini EH (2018) Comparative life cycle assessment (LCA) of bio-modified binder and conventional asphalt binder. Clean Technol Environ Policy 20:191–200. https://doi.org/10.1007/s10098-017-1467-1

Sharma P, Usman M, Salama ES et al (2021) Evaluation of various waste cooking oils for biodiesel production: a comprehensive analysis of feedstock. Waste Manag 136:219–229. https://doi.org/10.1016/J.WASMAN.2021.10.022