Abstract

This paper provides a comprehensive analysis of greenhouse gas (GHG) emissions associated with a wastewater treatment plant in Jiaxing, China. The study calculated scope 1–3 GHG emissions for all stages of the wastewater treatment system. The study evaluated the sources of GHG emissions and identified opportunities for reducing emissions in the wastewater treatment plant. The results show that the carbon emissions of each stage vary based on the power consumption and the associated emission factors. The study recommends the use of renewable energy sources, energy-efficient technologies, and green supply chain management practices to reduce carbon emissions. The study highlights the significance of considering indirect emissions such as scope 2 and scope 3 emissions to provide a more comprehensive estimate of a facility’s carbon footprint. The findings align with previous studies that have emphasized the importance of reducing energy consumption and adopting sustainable practices to improve the sustainability of wastewater treatment plants.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Global warming is a rising concern in the past few decades. China had pledged to reach its CO2 emissions peak before 2030 and attain carbon neutrality by 2060 in order to lessen the effects of climate change. This objective drives the Chinese government’s efforts to find solutions to lower the greenhouse gas (GHG) emissions produced by all sectors of the economy. Urban water systems are responsible for 1–3% of the nation’s GHG emissions [1]. Though the percentage is low, for individual cities with high population, the absolute amount of GHG emission by water system is not to be disregarded [2]. According to the data from National Bureau of Statistics of China (NBS), 575 million people in China lives in urban areas by the year 2020, consuming 581 billion cubic meters of water, and produce 94.6 million tons of CO2, which is approximately equivalent to the total CO2 emissions of Columbia in 2020 [3]. The number is still increasing as the total population grows.

Many different evaluation methods have been reported to estimate the GHG emissions of water systems at all stages. The most commonly agreed methodologies to estimate national GHG emission are the 2006 IPCC guidelines for National Greenhouse Gas Inventories [4]. Besides, the World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD) released the GHG Protocol Corporate Accounting and Reporting Standard to provide guidance on GHG accounting in various industries. It introduced three scopes of GHG emission: scope 1 emissions refer to the direct GHG emissions that result from sources that the entity owns or controls; scope 2 emissions are indirect GHG emissions that result from electricity and heat power that the entity purchases and consumes; scope 3 emissions are all other indirect GHG emissions that result from the entity’s operations but come from sources not owned or controlled by the entity.

According to the previous studies, many factors affecting the GHG emissions of wastewater systems including: energy use (diesel, coal, gas, electricity, solar power, etc.), local electrical grid, treatment process, etc. [2, 5]. Therefore, the reported GHG emissions of wastewater systems of different cities varied greatly worldwide. Saidan et al. [6] presented a baseline assessment of carbon emission in water utilities in Madaba, Jordan using Energy performance and Carbon Emissions Assessment and Monitoring tool (ECAM tool), the result showed that the energy consumed by the entire water system in Madaba releases 28.122 thousand tons of CO2 per year, where the water supply system consumed 89.7% of the energy, whereas the wastewater system consumed only 10.3% of the energy [6]. Racoviceanu et al. [7] estimated the life cycle energy use and GHG emissions for water supply system in Toranto, Canada. It was found that the average carbon emission intensity was 0.144 ~ 0.576 kgCO2/m3, depending on the electrical grid used [7]. Another study by Ma et al. [8] found that the carbon emission of China’s urban water supply system was 0.377 kgCO2/m3. The number was positively related with the economic patterns as it is higher in eastern coastal areas of China than it was in western regions [8]. A study by Zhang et al. [2] reveals that power use is the greatest source of GHG emissions in drinking water services, while in the wastewater system, non-CO2 emissions sometimes can be significant, depending on the various regional contexts and wastewater treatment technology.

This study presents a systematic calculation of the GHG emissions of wastewater treatment plant in Jiaxing, China. The scope 1–3 GHG emissions were calculated for all stages wastewater treatment system. The results of GHG emission were presented using CO2-eq. The study will provide a comprehensive view on the source of GHG emissions associated with wastewater treatment plant, as well as additional guidance on GHG reduction opportunities for the wastewater treatment plant.

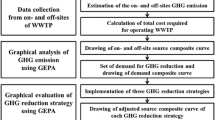

2 Material and Methods

The Jiaxing United Sewage Treatment Co., Ltd. (hereinafter referred to as “United Sewage”) was established in April 2000 and is mainly responsible for the collection, transportation, treatment, and discharge of industrial and domestic wastewater in Jiaxing city (except Tongxiang and Haining). The service area covers more than 1860 km2 and serves a population of about 2.5 million people. The company has one sewage treatment plant with a processing capacity of 600,000 tons/day, 200 km of transmission pipelines, and 20 transmission lift stations.

Carbon emissions of United Sewage mainly include indirect emissions generated by drug consumption, pump stations, and equipment power consumption, and direct emissions generated by wastewater biological treatment. In this study, the carbon emissions and emission efficiency of each process stage were calculated based on the electricity consumption, drug consumption, and effluent quality of each process stage according to the sewage treatment process of the plant. The process flowchart of the United Sewage Treatment Plant is shown in Fig. 1. For convenience of calculation, the treatment process is divided into three stages, namely (1) pretreatment; (2) oxidation ditch + AAO + MBR; (3) deep treatment; (4) sludge treatment.

Wastewater treatment process involves the direct GHG emissions (scope 1), consumption of electricity (scope 2) and chemicals (scope 3). The direct GHG emissions mainly include CH4, N2O, and CO2. The emission of CH4 is usually generated during the anaerobic digestion process, and it can be calculated as follows:

where P is the population which is serviced by the wastewater treatment plant, Ddom the per capita annual BOD discharge; B0 the maximum potential for CH4 production; MCF the modifying factors and R the volume of recovery CH4.

In the aerated zones of wastewater treatment, the nitrogen is removed from the system by both nitrification and denitrification reactions, releasing N2O into the atmosphere. The emission of N2O is difficult to be quantified by stoichiometry, so empirical conversion rate is required to calculate the emission:

where Q is the total inflow of plants, TNe is the total nitrogen of inflow water, []; TNo is the total nitrogen of effluent water, EFNi is the N2O–N emission factor of denitrification process and the \({\text{GWP}}\left( {{\text{N}}_{2} {\text{O}}} \right)\) is the global warming potential of N2O which is taken value as 265 from the 2019 IPCC guidelines.

There are two sources of CO2 emissions in wastewater treatment process, one is generated by aerobic decomposition of organic matter, and the other is caused by the microbial endogenous respiration and metabolism, described as follows:

where Q is the total inflow of plants; \({\text{BOD}}_{{\text{e,a}}}\) is the BOD of inflow water; \({\text{BOD}}_{{\text{o,a}}}\) is the BOD of effluent water; y is proportion of MLVSS in MLSS; \(Y_{{\text{t}}}\) is total sludge yield coefficient, unit kgMLSS/kgBOD5. Q is the total inflow of plants; HRT_a is the hydraulic retention time of aerobic zone; MLVSSa is the MLVSS in the aerobic zone; K0 is the attenuation coefficient. Kd20 is the attenuation coefficient under 20 °C circumstance, and the study takes 0.04; θT is the temperature coefficient, value 1.03; T is the design temperature.

Due to the availability of total sludge yield coefficient, the study use the default value from Wang’s study [3]. What’s more, greenhouse gas emissions caused by this process are caused by biological catabolism, and the organic carbon degraded in this part is not fossil carbon.

During the water treatment process, the indirect GHG emission is caused by both electricity consumption (scope 2) and the chemical consumption (scope 3), expressed as:

where WWM is the carbon emission of water treatment, [M]; P is the consumption of electricity, [W]; Mal is the consumption of alums, [M]; EFal is the carbon emission factor of alums; Mcl is the consumption of chlorine, [M]; EFcl is the carbon emission factor of chlorine; Mpp is the consumption of potassium permanganate, [M]; EFpp is the carbon emission factor of potassium permanganate.

3 Results

In this wastewater treatment plant, the wastewater will be treated by the A2O biological pool, denitrification deep bed filter, and membrane bio-reactor. So the study also calculates the N2O emission of the denitrification and the CO2 emission of aerobic decomposition and microbial endogenous respiration besides the carbon emission of wastewater collection and sludge treatment.

3.1 Wastewater Treatment

Direct carbon emission (scope 1)

The result of direct carbon emissions is calculated according to Eqs. (1–5). The calculated result is given in Table 1. In a word, the total direct carbon emission is 2.66 × 104 tCO2. The carbon emission of aerobic decomposition takes 65.39% of the total carbon emission. The N2O emission accounts for 34.56% of the total emission. The emission of microbial endogenous respiration is least part, taking only 0.05% of total emission.

Indirect carbon emission (Scope 2 and scope 3)

The scope 2 carbon emission includes the consumption of agent and electricity. Firstly, the emission of agent consumption is calculated according to Eq. (7). The consumptions of polymeric ferrit, sodium acetate, polyacrylamide (PAM), polyaluminium (PAC), sodium hypochlorite, citric acid, and sodium hydroxide are 8.20 × 106, 3.38 × 107, 2.84 × 105, 1.79 × 107, 7.90 × 106, 9.03 × 104, and 2.34 × 104 kg according to the record provided by the United Sewage. The calculated results are shown in Fig. 2.

The consumption of various agents has resulted in a total carbon emission of 1.15 × 104 tCO2. Sodium acetate contributes to the majority of this emission, accounting for 44.3% (5.40 × 103 tCO2) due to its extensive use. The emission caused by PAC accounts for 25.16% of the total emission, while the combined emissions of PAM, citric acid, and sodium hydroxide only amount to 0.52% of the total.

Furthermore, indirect carbon emissions arise from electricity consumption. In this study, we obtained data on the electricity consumption of wastewater treatment equipment from a reliable source. Using Eqs. (8–9), the total electricity consumption of 6.19 × 107 kWh is divided by the volume of sewage treated (1.90 × 108m3), resulting in an energy intensity of 0.33kWh/m3. The total amount of CO2 emission is 4.90 × 104 tCO2.

3.2 Sludge Treatment

In the wastewater treatment process, a substantial amount of sludge is generated annually, totaling approximately 1.76 × 105 t per year. The sludge is collected, pumped into a storage tank, dewatered, and then sent to three different refuse incineration plants for disposal. The agent consumption during the sludge dewatering process includes lime (11.4 kg/t), polyacrylamide (0.97 kg/t), and ferric chloride (11.50 kg/t). The total carbon emissions resulting from these processes were calculated to be 5.279 × 103 tCO2-eq, which is equivalent to 29.94 kg CO2-eq per ton of sludge.

The electricity consumption associated with the dewatering process is another important factor to consider. This includes the pumps (5.26 kWh/t) and the centrifuge dewatering machine (5.26 kWh/t). The total carbon emissions resulting from electricity consumption were estimated to be 2.587 × 103 tCO2-eq, or 29.94 kg CO2-eq per ton of sludge.

4 Discussion

Only two levels of headings should be numbered. Lower level headings remain unnumbered; they are formatted as run-in headings.

Table 2 gives the carbon emission of wastewater treatment process at different stages. The findings suggest that there is a significant variation in the carbon emissions of different stages, which can be attributed to the energy consumption and the types of emissions associated with each stage. Our results are consistent with the previous studies that have reported the importance of wastewater treatment processes in reducing carbon emissions and mitigating the impact of climate change [2].

The study examined the carbon emissions and energy consumption of different stages in wastewater treatment plants. The pretreatment stage was found to have the lowest power consumption and carbon emissions, with only 1.96% of total carbon emissions. The low carbon emissions of the pretreatment stage can be attributed to the water inlet pump and agent consumption. These findings are consistent with Svardal and Kroiss’s (2011) study, which reported that the pretreatment stage has low energy requirements and produces fewer greenhouse gas emissions [9].

On the other hand, the oxidation AAO + secondary oxidation stage had the highest carbon emissions due to its high power consumption and large amount of agent consumption. Liao et al. (2020) reported that energy consumption in the biological treatment stage is a significant contributor to carbon emissions [10]. Thus, the optimization of energy consumption in the biological treatment stage can help reduce carbon emissions.

The denitrification + disinfection stage was found to have high scope 2 emissions, consistent with He et al.’s (2018) study. The electricity consumption of the denitrification stage is a significant contributor to indirect carbon emissions. However, alternative processes like biological nitrogen removal through oxygenic denitrification can help reduce energy consumption [11].

The sludge dewatering stage was found to have the highest power consumption, which is consistent with Chen and Kuo’s [12] findings. The authors reported that the sludge dewatering stage is the most energy-intensive process in wastewater treatment plants and significantly contributes to greenhouse gas emissions [12]. Thus, the implementation of energy-efficient technologies and the recovery of energy from sludge can help reduce the carbon emissions of this stage.

5 Conclusion

The wastewater treatment plant emitted 109,031.87 tCO2, with scope 2 emissions being the highest due to electricity consumption, accounting for 35.81%. Sludge dewatering and incineration had the highest carbon emissions per ton at 236.46 kg CO2-eq/t. The carbon emissions of each process were analyzed, with biological treatment in the first and second phases being the highest. The carbon emissions in the first phase were mainly due to drug agents in scope 3, accounting for 52.01%, while electricity consumption accounted for 28.34%. In the second phase, the carbon emissions of AAO were also dominated by scope 3, accounting for 53.12%, while electricity consumption accounted for 33%.

In conclusion, the findings of this study highlight the importance of wastewater treatment processes in reducing carbon emissions and mitigating the impact of climate change. Companies can adopt energy-efficient technologies and renewable energy sources to reduce their carbon emissions and contribute to a sustainable environment. Further research is needed to investigate the potential of carbon capture and utilization technologies in wastewater treatment plants to reduce carbon emissions.

References

Zhang B, Chen ZM, Qiao H, Chen B, Hayat T, Alsaedi A (2015) China’s non-CO2 greenhouse gas emissions: inventory and input–output analysis. Eco Inform 26:101–110

Zhang Q, Smith K, Zhao X, Jin X, Wang S, Shen J, Ren ZJ (2021) Greenhouse gas emissions associated with urban water infrastructure: what we have learnt from China’s practice. WIREs Water 8:e1529

NBS (2021) China statistical yearbook 2021. National Bureau of Statistics of China, Beijing

IPCC (2006) IPCC guidelines for national greenhouse gas inventories. Institute for global environmental stratigies, Japan

Anthony HJ, Tanju K (2013) Calculating the greenhouse gas emissions of water utilities. J (Am Water Works Assoc) 105:E363–E371

Saidan M, Khasawneh HJ, Aboelnga H, Meric S, Kalavrouziotis I, Jasem ASH, Hayek BO, Al-Momany S, Al Malla M, Porro JC (2019) Baseline carbon emission assessment in water utilities in Jordan using ECAM tool. J Water Supply: Res Technol-Aqua 68:460–473

Racoviceanu AI, Karney BW, Kennedy CA, Colombo AF (2007) Life-cycle energy use and greenhouse gas emissions inventory for water treatment systems. J Infrastruct Syst 13:261–270

Ma J, Yin Z, Cai J (2022) Efficiency of urban water supply under carbon emission constraints in China. Sustain Cities Soc 85:104040

Svardal K, Kroiss H (2011) Energy requirements for waste water treatment. Water Sci Technol 64:1355–1361

Liao X, Tian Y, Gan Y, Ji J (2020) Quantifying urban wastewater treatment sector’s greenhouse gas emissions using a hybrid life cycle analysis method—an application on Shenzhen city in China. Sci Total Environ 745:141176

He Z, Feng Y, Zhang S, Wang X, Wu S, Pan X (2018) Oxygenic denitrification for nitrogen removal with less greenhouse gas emissions: microbiology and potential applications. Sci Total Environ 621:453–464

Chen Y-C, Kuo J (2016) Potential of greenhouse gas emissions from sewage sludge management: a case study of Taiwan. J Clean Prod 129:196–201

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wang, S. et al. (2024). Greenhouse Gas Emissions Evaluations of Wastewater Treatment Plant—A Case Study of Jiaxing, China. In: Zhang, Y. (eds) Proceedings of the 5th International Symposium on Water Pollution and Treatment—ISWPT 2022, Bangkok, Thailand. ISWPT 2022. Lecture Notes in Civil Engineering, vol 366. Springer, Singapore. https://doi.org/10.1007/978-981-99-3737-0_8

Download citation

DOI: https://doi.org/10.1007/978-981-99-3737-0_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-3736-3

Online ISBN: 978-981-99-3737-0

eBook Packages: EngineeringEngineering (R0)