Abstract

Global economic development has highlighted the issue of climate change, which is one of the most important environmental issues plaguing human beings. It is widely agreed that excessive greenhouse gas (GHG) emissions are important factors contributing to global warming. Many countries have formulated corresponding GHG emission reduction plans to deal with climate change issues. An important GHG emission source is released from sewage-sludge treatment systems. However, there has not been a comprehensive quantitative GHG emissions evaluation system in the case of sewage-sludge treatment systems, due to multiple emission sources, complex processes, and different standards. In previous studies, the Guidelines for National Greenhouse Gas Inventories (Intergovernmental Panel on Climate Change, IPCC, 2006) and Chinese Greenhouse Gas Inventory (National Center for Climate Change Strategy and International Cooperation, NCSC, 2005) were widely applied to estimate GHG emissions from sewage-sludge treatment. However, IPCC does not consider CO2 emissions from sewage treatment, and NCSC does not consider CO2 emissions from the sewage treatment and N2O emissions from sludge treatment. Therefore, the following have been conducted in this study: (1) A GHG estimation model basing on Life Cycle Thinking (LCT) was constructed, and the research objects were CH4, N2O, and CO2 that were produced by the sewage-sludge treatment system. The estimation model of CO2 and N2O, which were ignored in the IPCC report, were analyzed and discussed. The models of the GHG emission estimation were summarized and improved in the urban sewage-sludge treatment system under the different sewage-sludge treatment process scenarios. (2) The GHG emission load of major urban sewage-sludge treatment processes was analyzed, and the level and key links of environmental impacts generated by different processes were identified. This helps to understand and compare the environmental impacts of different treatment processes and provides suggestions for the sustainable development of wastewater treatment processes. (3) The GHG emission characteristics of nine scenarios of different sewage-sludge treatment processes were analyzed, and the environmental impacts caused by energy consumption and chemicals consumption were studied. Consequently, the sewage-sludge treatment process under low carbonization and low environment impact were proposed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Climate change has become one of the most serious challenges of the twenty-first century. Until the end of 2010, the “Greenhouse Gas Bulletin” published by the World Meteorological Organization (WMO) indicated that the concentration of several major GHGs, such as methane (CH4), nitrous oxide (N2O), and carbon dioxide (CO2) in the global atmosphere reached their highest level, increasing by 38%, 158%, and 19%, respectively, compared with the concentrations during pre-industrial revolution (1750 years ago) (Liu 2010). With an increase in GHG emissions, the global average temperature is predicted to increase by 5 °C in the next 100 years (World Bank, 2010). It is estimated that because of China’s economic development, the atmospheric CO2 concentration will continue to increase, leading to an increase in the average surface temperature of China by 2.2–4.2 °C in 2100 (Chen 2009). Due to rising global temperatures, governments have begun to take measures to reduce GHG emissions to meet climate change targets. In the past 100 years, the Municipal Wastewater Treatment Plants (WWTPs) have developed rapidly in order to solve environmental and health problems due to urban sewage. The traditional sewage treatment process consumes a lot of energy and medicines as well as produces GHG emissions, including CH4, N2O, and CO2. In developed countries, energy consumptions, CO2 emissions, N2O emissions, and CH4 emissions from WWTPs account for 3% (Mo and Zhang 2012), 4% (Martin et al. 2008), 3% (Kampschreur et al. 2009), and 5% (El Fadel et al. 2001) of total consumptions/emissions, respectively.

Meanwhile, the evaluation method of urban sewage treatment process is primarily based on technical and economic analysis to ensure the output quality of WWTPs. This evaluation method is mainly aimed at achieving water quality standards, considering the cost and benefit of different sewage treatment processes from an economic perspective, and analyzing the economic rationality of the treatment process. However, in the face of development challenges of pollutant reduction, energy conservation, and emission reduction, this emphasis on the evaluation of processing technology performance will highlight its shortcomings; thus, a systematic environmental impact analysis should be established. With the development of urbanization in China, energy consumption and GHG emissions of sewage-sludge treatment will become an important aspect of growth. As wastewater treatment is gradually moving towards sustainable development, it is necessary to systematically consider GHG emissions throughout the entire process of sewage-sludge treatment. The LCT can provide a systematic research framework for energy conservation and GHG emission reduction of sewage-sludge treatment systems.

In previous studies, the application of LCA in sewage treatment was mostly to evaluate the environmental impact (EI) of WWTPs or sewage treatment processes and to compare the sewage treatment processes. Mahgoub et al. (2010) evaluated the EI including CO2 emissions from an urban water system in Egypt by using the LCA approach. Rodriguez RM et al. (2016) used the LCA method to compare heterogeneous and homogenous Fenton processes for the treatment of pharmaceutical wastewater. Frijins (2012) mentioned that the accounting boundary should include direct and indirect CO2 from energy consumption, direct CH4 and N2O emissions from treatment processes, and indirect CO2 emissions from production of chemicals used in relevant processes. However, little research has been conducted on the calculation of GHG emissions to account for direct CO2 emissions from sewage treatment processes. In this study, the calculation of direct CO2 emissions from sewage treatment was analyzed based on mass balance.

2 Materials and Methods

2.1 Boundary Definition

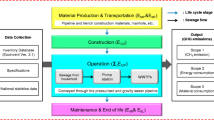

The sewage-sludge treatment system receives domestic sewage as well as discharge treated sewage and sludge. The sewage-sludge treatment is a complex reaction system involved a series of biological treatment. In its Second Assessment Report (1997), the IPCC considers that the carbon in BOD converts only into CH4, whereas in the Fourth Assessment Report (2007), CO2 generated from biomass decay is not considered a part of GHG emissions (IPCC 2007). In the case of GHG emission accounting, some studies state that electric energy consumption should be counted as a part of the energy sector rather than sewage-sludge treatment system. The influent BOD converts into CO2 and biomass, whereas CH4 is generated only during sludge anaerobic digestion. Direct GHG emissions are generated by the treatment of sewage and sludge. Indirect GHG emissions are generated by the consumption of chemicals and electric energy in the treatment process. The evaluation boundaries are shown in Fig. 18.1, wherein the tetragonal broken line refers to boundary of GHG emissions, tetragonal solid line refers to the treatment process, and the oval solid line refers to materials coming in/getting out the boundary.

2.2 Analysis of Different Sewage-Sludge Scenarios

2.2.1 Selection of Sewage Treatment Process

According to the List of National Urban Sewage Treatment Facilities published by the Ministry of Environmental Protection in 2014 (MEPPRC 2015), the statistical results of 4,437 operating WWTPs are shown in Table 18.1. The sewage treatment processes in descending order of quantity were Anaerobic/Anoxic/Oxic (AAO), Oxidation Ditch (OD), Sequencing Batch Reactor (SBR), and Anoxic/Oxic (AO); in descending order of sewage treatment capacity, they include AAO, OD, AO, and SBR. Therefore, three typical sewage treatment processes, namely AAO, OD, and SBR were selected. AO was eliminated as it is similar to AAO. The sum of the three analyzed processes accounted for 71.8% of the total treated water, and the average daily treated water accounted for 74.3% of the total treated water.

2.2.2 Selection of Sludge Treatment Process

According to the Guideline on Best Available Technologies of Pollution Prevention and Control for Treatment and Disposal of Sludge from Municipal Wastewater Treatment Plant (MEPPRC 2010), three typical sludge treatment processes (landfill, composting, and combustion) were analyzed.

2.3 Sources of Estimated Input Data

This study analyzed the theoretical estimation of GHG emissions from sewage-sludge treatment scenarios in China. The estimated input data were obtained from national/industrial standards, different technical guides, and environment assessment reports. Some parameters used in this study were shown in Table 18.2.

A 40,000 m3/day sewage treatment capacity was used to analyze different scenarios, as influent flow rates of small-scale WWTPs (≤40,000 m3/day) (MOHURD 2006) account for 81.1% of the total WWTPs (MEPPRC 2015), which is the mainstream treatment capacity of WWTPs built in China.

The effluent, which reflects the water quality of treated sewage, should be under strict control before being discharged into natural waters, such as rivers and lakes. The highest discharge standard of WWTPs in China, that is 1A-level standard (Table 18.2), was used for GHG emissions calculation.

3 Estimation Procedure of Ghg Emissions from Sewage-Sludge Treatment System

The sewage-sludge treatment system includes a sewage treatment process and a sludge treatment process; furthermore, GHGs can be classified into direct emissions and indirect emissions based on different emission sources. Direct emissions of GHGs include CO2 converted by organic matter in the biotreatment process, CH4 emitted during the anaerobic process and sludge treatment, and N2O emitted during biological nitrogen removal. Indirect emissions of GHGs mainly include electricity consumption of mechanical equipment (such as lifting unit, aeration unit, and sludge treatment unit) and chemicals consumption (such as PAC and PAM) during treatment process.

In this study, estimation method of direct emissions of CO2 and N2O was based on mass balance and active sludge/anaerobic digester model (AS/AD). Indirect GHG emissions from sewage treatment and GHG emissions from sludge treatment were estimated by GHG emission factor method, and the emission factors used are shown in Table 18.3.

3.1 Estimation of CO2 Direct Emissions from Sewage Treatment Process

3.1.1 CO2 Emissions from Aerobic Oxidation of Organic Matter

In the biotreatment process, organic matter is oxidized by microorganisms (biomass) under aerobic conditions to produce CO2. In this study, the organic matter is represented by C10H19O3N (Rittmann 2001), and the oxidation process of C10H19O3N is described as follows:

2 C10H19O3N + 25 O2 → 20 CO2 + 16 H2O + 2 NH3

A conversion factor was 1.1 kg CO2 for every 1 kg O2 produced is obtained. Thus, CO2 emissions from aerobic oxidation of organic matter can be obtained from Eq. (18.1):

3.1.2 CO2 Emissions from Biomass Endogenous Decay

Biomass is represented by C5H7O2N (Rittmann 2001), and the chemical reaction of biomass endogenous decay is described, as follows:

A conversion factor of 1.947 kg of CO2 for every 1 kg of biomass decayed endogenously was obtained. The CO2 emissions arising from endogenous decay can be estimated from Eq. (18.2).

3.1.3 CO2 Emissions from Nitrogen Removal

Biological nitrogen removal process includes nitrification and denitrification. These two processes can be described respectively, as follows:

20 CO2 + 14 NH4+ → 10 NO3− + 4 C5H7O2N + 24 H+ + 2 H2O

C10H19O3N + 0.5 HCO3− + 0.5 NH4+ + 4.8 NO3− + 4.8 H+ → 26 C5H7O2N + 40 CO2 + 2.4 N2 + 7.9 H2O

CO2 is fixed during the nitrification process. However, the CO2 produced during denitrification is not calculated because the CO2 produced is already included in the calculation for C10H19O3N oxidation.

A conversion factor of 4.49 kg CO2 every 1 kg oxidized nitrogen is obtained. The CO2 emissions arising from nitrification can be estimated from Eq. (18.3):

Thus, the estimation of CO2 generation from sewage treatment process can be described by Eq. (18.4).

3.2 Estimation of N2O Direct Emissions from Sewage Treatment Process

The global warming potentials (GWPs) (over 100 years) of CH4 and N2O are 25 times and 298 times that of CO2, respectively (IPCC AR4 2007) (IPCC 2007). The emissions of CH4 and N2O were converted into carbon dioxide equivalents (CO2e) by GWP to estimate GHG emissions in this study.

The N2O emission during the sewage treatment occurred in the biological nitrogen removal process that mainly consisted of nitrification process and denitrification process. (Kampschreur et al. 2009) This study found that N2O was not only generated as an intermediate product in the denitrification process but was also generated as a by-product in the nitrification process (He et al. 2001). The mechanism of N2O production as an intermediate product and by-product is complicated, as it is affected by enzyme inactivation, accumulation of NO2−, and reaction condition (such as pH, DO, and C/N) (Marlies et al. 2009). The N2O emission from sewage treatment was calculated, as shown in Eq. (18.5).

3.3 Estimation of GHGs Indirect Emissions from Sewage Treatment Process

The indirect emission of GHGs mainly include electrical energy consumption of mechanical equipment (such as lifting unit, aeration unit, and sludge treatment unit), and chemicals consumption (such as polyaluminum chloride (PAC) and polymers (PAM)) during treatment process. The consumptions are shown in Tables 18.3 and 18.4. The GHGs indirect emissions from sewage treatment was calculated, as shown in Eq. (18.6).

Thus, GHGs emissions from sewage treatment was calculated, as shown in Eq. (18.7).

3.4 Estimation of GHG Emissions from Sludge Treatment Process

In this study, three types of sludge treatment processes (landfill, composting, and combustion) were considered, because these are the main sludge treatment process. According to the current statistics on all sludge treatment methods, landfill accounts for 60–65%, land use after composting accounts for 10–15%, comprehensive utilization after natural drying accounts for 4–6%, and combustion accounts for 2–3% (Dai 2011). The emission factor method was used to estimate GHG emissions of three sludge treatment processes. The emission factors of different sludge treatments were shown in Table 18.3.

3.4.1 Landfill (Anaerobic Digestion)

The main reaction in the sludge landfill process is anaerobic digestion, where the organic matter slowly releases CH4 under anaerobic conditions. Although N2O emissions are usually small, they still need to be considered because the GWP of N2O is relatively high. The GHG emissions from sludge landfill (anaerobic digestion) are described by Eq. (18.8).

3.4.2 Composting (Aerobic Digestion)

The main reaction in the sludge composting process is aerobic digestion, where the organic matter, which is oxidized, releases CO2 under aerobic conditions. N2O emissions were also considered in this study. The GHG emissions from sludge composting (aerobic digestion) were described by Eq. (18.9).

3.4.3 Combustion

The organic matter was completely oxidation into CO2. Peng J. et al. (Fan et al. 2015) analyzed the GHG (CO2 and N2O) emissions from the sludge combustion process and obtained a conversion value of 0.444 kg CO2e per kg of sludge. The GHG emissions from sludge combustion are described using Eq. (18.10).

where,

- ECO2,ae/de:

-

CO2 emissions rate from organic matter oxidation/endogenous decay, kgCO2e/d;

- ECO2,N:

-

CO2 fixation rate from nitrification, kgCO2e/d;

- ECO2/N2O,sewage:

-

CO2/N2O emission rate from sewage treatment, kgCO2e/d;

- Eindirect,sewage:

-

Indirrect GHG emissions from sewage treatment, kgCO2e/d;

- EGHG,sewage:

-

GHG emissions from sewage treatment, kgCO2e/d;

- EGHG,land. (EGHG,comp./EGHG,comb.):

-

GHGs emission rate from sludge landfill (composting/combustion) treatment process, kgCO2e/d;

- i:

-

The different consumables used in treatment process;

- EFi:

-

GHG emission factors of different consumables; and

- Ci:

-

Consumptions of different consumables

4 Results and Discussions

4.1 GHG Emissions of Different Sewage-Sludge Treatment Scenarios

GHG emissions from different sources for the nine sewage-sludge treatment scenarios (S1–S9) are shown in Table 18.5.

The GHG emission ranges (with different sludge scenarios) of SBR, AAO, and OD are 58–60 ktCO2e/a, 122–127 ktCO2e/a, and 113–125 ktCO2e/a, respectively. The direct GHG emissions of SBR (33.87 ktCO2e/a) are much less than AAO (109.78 ktCO2e/a) and OD (89.86 ktCO2e/a), while the indirect GHG emissions are similar, namely 24.86 ktCO2e/a (SBR), 14.94 ktCO2e/a (AAO), and 30.18 ktCO2e/a (OD). The ratio of direct to total GHG emissions were calculated to be 88% (AAO), 75% (OD), and 58% (SBR). The contribution of GHG emissions from wastewater treatment accounted for many of the total emissions, which were 94.8% for AAO, 85.8% for OD, and 95.6% for SBR.

In the nine sewage-sludge treatment scenarios, SBR-Combustion (S9) scenario had the least amount of GHG emissions, while the AAO-Composting (S2) scenario had the most GHG emissions. The total GHG emissions, in descending order, were S2, S1, S5, S4, S3, S6, S8, S7, and S9. The total emissions of SBR scenario were less than AAO and OD, even under different sludge treatment scenarios.

The ratio of GHG emissions from sludge treatment and total emissions were approximately 5.2% (AAO), 14.2% (OD), and 4.4% (SBR). GHG emissions from different sludge treatment scenarios (same sewage treatment), in descending order, are composting, landfill, and combustion. The reduction rate of GHG emissions under combustion scenario, when compared to landfill were 2.8% for AAO, 7.6% for OD, and 2.4% for SBR; when compared to composting were 3.6% for AAO, 9.6% for OD, and 3.1% for SBR. Therefore, the effect of sludge treatment process selection in reducing GHG emissions is positive, without changing the sewage treatment process.

4.2 GHG Emissions from Different Sources

The GHG emissions of sewage-sludge treatment system were divided into six emission sources among nine different scenarios. The six emission sources were CO2 from sewage treatment, N2O from sewage treatment, chemicals consumption from sewage treatment, electricity consumption from sewage treatment, direct GHG emissions from sludge treatment, and indirect GHG emissions from sludge treatment, as shown in Fig. 18.2.

The contribution of each emission source (in descending order) in the AAO scenario were 80.12-83.12% (N2O), 11.62–12.05% (electricity), 2.66–5.77% (direct emission from sewage treatment), 1.62–1.67% (CO2), 0.004–0.49% (indirect emission from sewage treatment), and less than 0.005% (chemicals).

The contribution of emission source (in descending order) in the OD scenario were 48.52–49.62% (N2O), 23.54–24.07% (electricity), 15.66–17.72% (direct emission from sewage treatment), 10.09–10.31% (CO2), 0.01–0.22% (indirect emission from sewage treatment), and 0.12% (chemicals). S6 scenario showed a different result (OD-combustion): the contribution of CO2 (11.16%) is more than direct GHG emissions from sludge treatment (7.58%), and the contribution of indirect GHG emissions from sludge treatment increased to 1.39%.

The contribution of each emission source in the SBR scenario, in descending order, was 41.62–42.94% (electricity), 36.95–38.11% (N2O), 15.26–16.26% (CO2), 2.25–5.64% (direct emission from sewage treatment), 0.01–0.41% (indirect emission from sewage treatment), and 0.02% (chemicals).

4.3 CO2 Emissions from Sewage Treatment and N2O from Sludge Treatment

The IPCC does not consider the CO2 emissions from sewage treatment, and NCSC does not consider the CO2 emissions from the sewage treatment and the N2O emissions from sludge treatment.

As described in Fig. 18.2, the contribution ranges of GHG emissions from CO2 were 1.62–1.69% for AAO, 10.09–11.16% for OD, and 15.77–16.26% for SBR. Therefore, it is necessary to estimate CO2 emissions from wastewater treatment when estimating GHG emissions, at least in OD and SBR systems.

The direct GHG emissions from sludge treatment account for 2.66–6.62% (AAO), 7.58–17.72% (OD), and 2.25–5.64% (SBR) of total wastewater sludge treatment systems. Moreover, it accounts for more than 95% of the GHG emissions from the sludge system.

5 Summary

In this study, nine scenarios of different sewage-sludge treatment processes were analyzed to estimate the GHG emissions. According to national statistics, the limiting design values of mainstream WWTPs were defined as the limit values in the scenario study. The sewage flow rate was assumed to be 40,000 m3/d, and the 1-A standard was assumed as effluent limit. Results shown that three sources, direct emissions of CO2 and N2O, and indirect emissions of electricity consumption are significant contributors to the GHG emissions of sewage-sludge systems. The total GHG emission ranged from 58-127 ktCO2e per year, with the lowest GHG emissions obtained from the SBR-Combustion scenario and the largest GHG emissions obtained from the AAO-Composting scenario.

N2O emissions and electricity consumption are the primary sources of GHG emissions, and the sum of the contributions of these two sources exceeds 70% in all scenarios. CO2 emissions have not been considered in GHG emissions estimation of IPCC, as it is of the biogenic origin. This study highlights that not considering CO2 emissions in the results of GHG emissions estimation may cause deviations in the results.

According to China’s statistics, total GHG emissions from the wastewater treatment industry in 2005 was 114 million tons of CO2 equivalent (National Development and Reform Commission for responding to climate change 2013), and the ratio of three processes (AAO, OD, and SBR) treatment capacity and the total processing capacity were 37%, 24%, and 13%, respectively (MEPPRC 2015). The result of this study revealed that the contribution of direct CO2 emissions to GHG emissions in three processes were 1.65%, 10.52%, and 15.97%, respectively. Therefore, it can be inferred that in the scenario of calculating direct CO2 emissions from the sewage treatment when calculating GHG emissions, total GHG emissions from the wastewater treatment industry in 2005 should be 150 million tons of CO2 equivalent, an increase of approximately 32% compared to the statistics in 2005.

References

Carr M (2007) Reducing greenhouse gas emissions industrial biotechnology and biorefining. In: 2007 Taiwan international chemical industry forum, Taiwan Chemical Industry Association, Taipei

Chen ZX (2009) Low-carbon economic zone: a test site for China’s economic transformation. China Econ Wkly 41:34–35

Climate Change Division (2014) Average CO2 emission factors of regional electric grids in China during 2011 and 2012. National Development and Reform Commission of People’s Republic of China, Beijing

Dai XH (2011) Current status and opportunities of urban sludge treatment and disposal in China. Constr Sci Technol 19:55–59

De H et al (2008) Greenhouse gas inventories from WWTPs—The trade-off with nutrient removal. In: Sustainability 2008 green practices for the water environment. Water Environment Federation, National Harbor, MD, USA

El Fadel M et al (2001) Methane emissions from wastewater management. Environ Pollut 114(2):177–185

Fan JP et al (2015) Prediction of the effect of fine grit on the MLVSS/MLSS ratio of activated sludge. Bioresour Technol 190:51–56

Foley J et al (2008) Fugitive greenhouse gas emissions from wastewater treatment. Water J Aust Water Assoc 38:6

Foley J et al (2010) Nitrous oxide generation in full-scale biological nutrient removal wastewater treatment plants. Water Res 44(3):831–844

Frijns J (2012) Towards a common carbon footprint assessment methodology for the water sector. Water Environ 26(1):63–69

He Y et al (2001) Nitrous oxide emissions from aerated composting of organic waste. Environ Sci Technol 35(11):2347–2351

Hiatt WC, Grady CP (2008) An updated process model for carbon oxidation, nitrification, and denitrification. Water Environ Res 80(11):2145–2156

IPCC (2007) contribution of working group III to the fourth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA

Kampschreur MJ et al (2009) Nitrous oxide emission during wastewater treatment. Water Res 43(17):4093–4103

Liu Y (2010) Low carbon design: thinking and acting. Modern decoration 2:12–14

Liu HT et al (2013) Life cycle assessment of sludge treatment and disposal process in urban wastewater treatment plant. China Water and Wastewater 29(06):11–13

Mahgoub ME et al (2010) Towards sustainability in urban water: a life cycle analysis of the urban water system of Alexandria City. Egypt Cleaner Prod 18(10):1100–1106

Marlies J et al (2009) Nitrous oxide emission during wastewater treatment. Water Res 43:4093–4103

Martin W et al (2008) Non-energy use and related carbon dioxide emissions in Germany: a carbon flow analysis with the NEAT model for the period of 1990-2003. Res Conserv Recycl 52(11):1252–1265

MEPPRC (2010) Guideline on best available technologies of pollution prevention and control for treatment and disposal of sludge from municipal wastewater treatment plant (on Ttial). Ministry of Environmental Protection of the People’s Republic of China, Beijing

MEPPRC (2015) Announcement on the publication of the list of national urban sewage treatment facilities in 2014. Ministry of Environmental Protection of the People’s Republic of China, Beijing

Metcalf and Eddy (1991) Wastewater engineering: treatment, disposal, reuse, 3rd edn. Toronto, Ontario, Canada, McGraw-Hill

Mo W, Zhang Q (2012) Can municipal wastewater treatment systems be carbon neutral? J Environ Manag 112:360–367

MOHURD (2006) Design scale division table of municipal industry construction project. Ministry of Housing and Urban-Rural Development, Beijing

National Development and Reform Commission for responding to climate change (2013) Second national communication on climate change of the People’s Republic of China. China Economic Publishing House, p 59–62

NBSC (2016) China energy statistical yearbook 2016. China Statistics Press, Beijing

Peng J et al (2013) Analysis on greenhouse gas emissions from different sewage sludge treatments and disposal processes. Chin J Environ Eng 7(6):2285–2290

Rittmann McCarty (2001) Environmental biotechnology: principles and applications. McGraw-Hill, Toronto, Ontario, Canada

Rodríguez R et al (2016) Comparative life cycle assessment (LCA) study of heterogeneous and homogenous Fenton processes for the treatment of pharmaceutical wastewater. Cleaner Prod 124:21–29

Sharaai AH et al (2012) Life cycle impact assessment (LCIA) using the ecological scarcity (ecopoints) method: a potential impact analysis to potable water production. Afr J Biotech 11(6):1391–1402

WEF, ASCE (1998) Design of municipal wastewater treatment plants, 4th edn, Water Environment Federation: Alexandria, Virginia; American Society of Civil Engineers: Reston, Virginia

Acknowledgements

This work were supported by Science Foundation of Shandong Jianzhu University (Grant No. XNBS1824)and Shandong Key Research and Development Program (No. 2019GSF109064).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Liang, Z., Matsumoto, T., Zhang, L., Liu, B. (2021). Study on the Quantitative Evaluation of Greenhouse Gas (GHG) Emissions in Sewage-Sludge Treatment System. In: Kishita, Y., Matsumoto, M., Inoue, M., Fukushige, S. (eds) EcoDesign and Sustainability II. Sustainable Production, Life Cycle Engineering and Management. Springer, Singapore. https://doi.org/10.1007/978-981-15-6775-9_18

Download citation

DOI: https://doi.org/10.1007/978-981-15-6775-9_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6774-2

Online ISBN: 978-981-15-6775-9

eBook Packages: EngineeringEngineering (R0)