Abstract

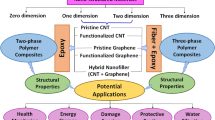

Hybrid nanocomposites have appealing chemical and physical properties and are used on a large scale worldwide. Graphene-nanoparticles (G-NP) hybrid fillers and their composites have particularly gained attention among researchers in recent times, as the incorporation of nanoparticles (NP) into the chemically derived graphene (G) in hybrid fillers open for new applications. This is as a result of the synergetic properties of the obtained materials, such as biodegradability, low density, physical and chemical structure, etc. The novelty of this chapter is to present a review of the recent studies of G-NP hybrid filler’s characteristics and their composites using the most fundamental characterization techniques. Our literature review examines various published findings regarding, among others, surface, mechanical and thermal properties in order to determine the performance of the fillers. Therefore, we briefly reviewed their basic structure and surface modifications of G-NP hybrid fillers and nanocomposites. The main output is to study and review techniques frequently reported in the literature to examine their structure and properties, we exemplified and discussed in this chapter key results collected from SEM, AFM, TEM, HRTEM, FTIR, UV-vis, Raman, XRD, XPS, SEM, TGA-DTA, DMA and tensile analyses. To help the readers, this chapter is subdivided into three sections covering a state-of-the-art of the most recent hybrid fillers, their preparation and characterization. The overall objective of this chapter is to dress a relationship between their structure and property to provide key indicators and future directions for their efficient large-scale production of G-NP hybrid nanocomposite with unique characteristics for different applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

Research on nanomaterials characteristics and properties has seen a strong increase thanks to the ever-increasing industrial needs [1], and the limited performance of conventional materials [2, 3]. The hybridization of different materials at the nanometer scale has been shown to bring about new and improved materials properties [4]. Among those, graphene (G) with its derivatives (graphene oxide (GO), reduced graphene oxide (rGO) and graphene oxide nanosheets (GON)) combined with nanoparticles (NP) have been developed as novel hybrid nanomaterials with excellent properties [5, 6].

Since its discovery, G is at the forefront of research in various fields of application because of its excellent chemical, electrical, optical and mechanical properties. It was proposed for applications such as a nanofiller in hybrid nanocomposites [7, 8], consisting of functional inorganic nanoparticles or aggregates incorporated in a polymer matrix. These materials exhibit several distinctive properties that are not achievable with organic polymers or inorganic materials individually. The G-NP based polymeric composites have excellent properties like mechanical, thermal, optical, and structural which are not observed in bulk materials [9,10,11]. Additionally, the performance of hybrid polymer nanocomposite is dependent on the characteristics of hybrid nanofillers, the filler dispersion in the matrix, the interlinkages linking the matrix and the arrangement of fillers within the matrix [12,13,14]. In recently published works, it has been demonstrated that G-NP based hybrid composite nanomaterials are ideal for use in different applications, such as food packaging, energy storage, sensors technology, water treatment, and transparent-flexible electrodes [15,16,17].

Hence, there is a need to understand the characteristics of the different G-NP hybrids like their morphology, the choice to incorporate organic or inorganic materials dispersed in the polymer matrix, which can lead to several changes in properties of the neat material. Therefore, in order to facilitate a better understanding of the characteristics of the G-NP based materials, for the first time, this chapter reviewed and classified the G-NP hybrids into five categories: (1) G-metal and metal oxide, (2) G-metal alloy, (3) G-carbon nanotubes, (4) G-nanocellulose and v) G-nanoclays.

Metal or metal oxide nanoparticles are commonly used to produce the G-based hybrid nanofillers [18]. G hybrids incorporated with different metal nanoparticles have been reported like, for example, G-Au [19], G-Ag [20], G-Cu [18], G-Ni [21], G-Pd [22], G-Zn [23], etc. Besides, there are numerous G-metal and G-metal-oxide nanohybrid synthesis methods. Similarly, various nanometal alloys were integrated by appropriate synthetic approaches on the G surface to ensure a high degree of morphological and structural properties and minimizing the possibility of their fragmentation and agglomeration in the matrix [18, 24, 25]. Currently, researchers have developed different synthetic methods for the preparation of the G-metal alloy nanohybrids, such as reduction, solvothermal, microwave-assisted, electrochemical and chemical vapor deposition [25,26,27,28].

Recently, carbon nanomaterials, such as carbon nanotubes (CNT), were introduced to the carbon family. Carbon nanotubes (both single- and multi-walled CNT) with G are commonly used as nanofillers of polymer composite materials [29, 30]. Various processes including chemical vapor deposition, physical vapor deposition, chemical processing, pyrolysis, 3D printing and more assembly-based techniques were developed to produce 3D G-CNT materials [10, 31,32,33]. G and CNT have remarkable mechanical strength, high thermal and chemical stability and wide surface area, and are therefore used for the production of hybrid composite materials [32, 34,35,36].

A fourth category of NP is cellulose nanomaterials. They are derived from abundant renewable organic biomaterials, and have been attracting much interest because of their high crystallinity, chemical versatility, low density and renewable ‘green’ nature [2, 3, 37], and in particular for the fabrication of hybrid G-nanocellulose nanocomposite [38,39,40].

The last category of nanoparticles depicts nanoclays (NC). These are some of the most abundant nanosized materials, normally available in hundreds of tons and broadly used in different applications [41]. NC are organically modified layered silicates with applications as a reinforcement filler in hybrid nanocomposite [12, 42]. In the preparation of hybrid nanocomposites, many NC (montmorillonite, kaolin, halloysite and bentonite) along with silica and GO nanoparticles are used.

In this chapter, key findings of the characterization techniques for hybrid nanocomposites, whereby G and NP are distributed into a matrix, are reviewed. This chapter also explains that the synthesis of these nanocomposites varies depending on the nanofillers’ properties; i.e., the G and NP, its dispersion and alignment as reinforcements within the polymer matrix, as well as the interaction of the polymer matrix with the reinforcement. Examples of morphology, structure and property, including the relationship between structure and property, are explored upon characterization. This perspective on the properties of G-NP hybrid materials will provide a detailed view of the current stage of characterization techniques, highlighting the obstacles and new directions for the future production of G-NP hybrid materials.

2 Hybrid Nanocomposite Based on Graphene and Nanoparticles as Advanced Materials

2.1 Graphene and Nanoparticles as Hybrid Nanomaterials

2.1.1 Graphene-Metal and Metal Oxide

G and its derivatives could be obtained by following a top-down (mechanical cleavage or liquid phase exfoliation) or a bottom-up (such as chemical vapor deposition, arc-discharge, chemical conversion, unzipping carbon nanotubes, and epitaxial growth on SiC) preparation method [43].

G-metal and metal oxide hybrids have excellent properties, with promising applications in electronics, sensors, solar cells, batteries, and supercapacitors [11, 19, 20]. Their synthesis could be achieved by using various preparation methods based on microwave-assisted synthesis, thermal evaporation, chemical reduction, photochemical synthesis and electroless metallization [13, 44, 45].

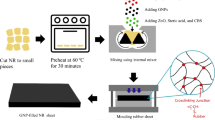

In the case of metals, nanoparticles precursors, i.e. metal salts, are generally reduced in a solvent containing GO and rGO [47]. Due to the weak van der Walls interactions, these graphene derivatives tend then to aggregate and even stack to form graphite in the solution [47]. Hence, by attaching metal NP, it is, in fact, possible to prepare individual G sheets and to reduce their agglomeration [47]. In many instances, researchers use this direct chemical reduction approach in order to prepare a large variety of G-metal nanohybrids by combining metal precursors with G or its derivatives, GO and rGO [20, 22, 48]. Among the many deposition approaches of G-NP fillers onto polymers, G and metal hybrid nanostructures are some of the most effective platforms for various applications [9, 45, 49]. For instance, in order to obtain a homogeneous suspension of exfoliated GO, Feng et al. prepared G-TiO2 by dispersing GO in an ethanol solution under ultrasonication and by adding then Ti(OPr)4 [46]. The resulting solution was then moved to an autoclave and placed in the oven for 12 h at 150 °C [46]. The desired product was thus isolated by centrifugation, thoroughly rinsed with deionized water and ethanol prior to be vacuum-dried [46]. The development procedure as shown in Fig. 1 resulted in a G-TiO2 hybrid in the form of black, gray powder [46]. The G-TiO2 hybrids (2 wt%) was used as filler for PVC films, with a glass transition temperature that increased by 3.5 °C and a storage modulus that increased by 50% relative to a pure PVC film [46].

G-TiO2 hybrid preparation and structure schematic presentation [46]

2.1.2 Graphene-Metal Alloy

Owing to the great synergetic performance and long-term working stability of hybrids, the G hybridization with nanometal alloys has shown high potential for various applications [25, 50]. Synthetic methods have integrated various metal alloys on the G surface to reach a perfect control of their morphological and structural properties, by enhancing the adhesion and by limiting the possibility of their dissolution and aggregation [22, 28, 50]. To date, numerous novel metal alloy nanostructures integrated on G nanosheets have been widely produced simply by changing the conditions of the reaction, such as the concentration of the precursor, the temperature of the reaction and introduction of the dispersion agent. The nanohybrids obtained displayed very interesting morphologies that were compatible with unique chemical and physical properties [25, 27, 28]. For example, in order to produce G-nanoalloy (Palladium-Copper) hybrid, precursors (Na2PdCl4 and CuSO4 of molar ratio 1:3) were mixed together with a suspension containing G. As shown in in Fig. 2, during this preparation method, metal ions from precursors such as \({\text{PdCl}}_{4}^{2 - }\) and Cu2+ were adsorbed onto the surface of G nanosheet thanks to a coordination effect between its remaining oxygen moieties and each ion [28].

Hybrid processing design of 3D G-nano alloy (G-PdCu) [28]

2.1.3 Graphene-Carbon Nanotubes

In recent years, carbon-based nanofillers such as G and carbon nanotubes (CNT) in nanocomposites have been shown to have better structure and functional properties and a broad range of applications [51, 52]. CNT are prepared using various process techniques including chemical vapor deposition, laser ablation, arc evaporation, electrolysis, flame synthesis, etc. [53, 54]. The CNT are generally used as a filler due to their excellent filler properties including a high conductivity and a superior aspect ratio and tensile strength. G fillers have also the potential to adjust or fine-tune the properties of targeted materials, which attracted various interests of several scientists working in different research fields [55,56,57]. Furthermore, a homogenous dispersion could be achieved during the early stages of processing of nanocomposites by incorporating CNT into the polymeric matrix limiting in fact their aggregation [30, 58]. For this reason, several research groups reported on the successful preparation and utilization of G-CNT hybrid fillers in diverse applications such as energy storage, sensing, water treatment, capacitors, etc. [34, 59,60,61].

The characteristics of G, CNT or hybrid fillers depend upon many parameters such as the type of CNT, the type of G, the purity, the size of CNT, the aspect ratio of the nanotubes, the loading, the interactions, the alignment, and the anti-agglomeration of G and CNT [63]. Three techniques are used for processing G-CNT hybrids: solution mixing, chemical vapor deposition and in situ polymerization [64,65,66]. In a study by Kong et al., a two-stage method for G-CNT hybrid synthesis was developed. This is shown in Fig. 3 [62], where it was reported that the CNT growth uniformly on the G surface followed that of the modification agent, resulting in the creation of a complex interface driven by a covalent C–C bonding connection between the G and CNT [62]. Similar observations were made by various studies on G-CNT hybrid [67,68,69].

Schematic diagram of the G-CNT hybrid synthetic method [62]

2.1.4 Graphene-Nanocelluloses

Nanocellulose, an organic compound extracted from natural resources, is biodegradable, biocompatible, and can demonstrate interesting properties when used as a filler in composites [70, 71]. Nanocellulose has unique characteristics including a large aspect ratio, good mechanical properties, good flexibility and hydrophilicity, explaining why it is therefore used as a filler to form nanocomposite [72]. The hierarchical structure and the presence of rigid chains on its molecular structure allow the formation of composite containing nanocellulose with flexible substrates and other materials [73]. Nanocellulose is found in the form of crystals (CNC) or fibrils (CNF), which can be dispersed and self-assembled easily in a solution under the ultrasonication process [72, 74]. Graphene, on the other hand, is a two-dimensional carbon nanostructure that has drawn considerable attention in the development of composites because of its excellent thermal properties, large surface area, high strength and young's modulus [75]. However, due to the presence of strong intermolecular π-π stacking attraction forces and van der Waals interaction, G has the tendency to aggregate irreversibly even in water or in organic solutions [75].

Researchers have suggested a new strategy to hybridize G with amphipathic nanocellulose during GO reduction, acting as a stabilizer or a supporting agent [15, 38, 40]. Depending on the G-nanocellulose ratio, the resulting hybrid material is made up of G layers surrounded by nanocellulose to a greater or lesser limit [76]. The G-nanocellulose hybrid was demonstrated to have a covalent chemical structure and an excellent aqueous suspension stability, which greatly facilitated G dispersion [77]. Studies have reported that the abundance of oxygen-containing groups decorated with G can combine with nanocellulose hydroxyl groups and oxygen atoms, which are advantageous for the homogeneous dispersion of G and nanocellulose in the shaped hybrid nanofiller [40, 76, 78]. Hence, the preparation of covalent cross-linked G-nanocellulose hybrids was realized by esterification between hydroxyl groups [79].

Montes et al. prepared fillers based on G-CNC by assisting the graphite exfoliation in a liquid-phase containing CNC. By following this novel approach, graphene flakes seem to be stabilized in aqueous dispersions [80]. Similarly, as shown in Fig. 4, Wang et al. produced rGO-CNF hybrid with rGO and CNF aqueous suspension by using a one-step synthesis combining a chemical reduction and an induced materials assembly, which was facilitated by the addition of the tannic acid [76]. Due to the functional catechol chemistry of tannic acid, the interfacial interactions between rGO nanosheets and CNF (which includes π-π and hydrogen bonding) improved; this created a strong adherent coating acting as a capping layer to stabilize and decorate the obtained rGO-CNF hybrid [76].

Schematic diagram and nanohybrid structure of rGO-CNF [76]

2.1.5 Graphene-Nanoclays

Natural occurring nanoclays (NC) like montmorillonite, bentonite, laponite, halloysite and kaolin were used as nanofillers for the production of composites in a variety of industrial applications [81]. The NC platelet structure allows it to form a protective barrier once a high degree of exfoliation with a good dispersion has been achieved, resulting in an improved mechanical performance of materials [82]. Similarly, G is a member of the family of monolayer carbon atoms, fully compacted into a 2D honeycomb network, which acts as a fundamental structural block for graphite-based materials [83,84,85,86]. A high-performance material is thus obtained by producing, a hybrid composed of GO and NC [82, 83, 86].

In different studies, GO hybrids reduced by halloysite nanotubes were prepared by simultaneous reduction and hybridization of GO with halloysite nanotubes [84, 87, 88]. It was observed that the hybrids had a perfect coverage structure and that the intercalation of halloysite nanotubes within the GO sheet interlayers was likely due to the excellent compatibility between G and halloysite nanotubes [87]. Research on GO-montmorillonite hybrid has shown that the hybrid material’s d-spacing is observed between that of the GO-montmorillonite and the structure of the GO flake-pillared montmorillonite [89].

NC’s role in the manufacture of G-based hybrids was thus explored due to its high chemical stability, specific swelling capability and ability to exchange ions [41]. As seen in the Fig. 5, the scattered nanoclay particles are physically or chemically absorbed at the ionized sites of the G layers in the hybrid [90]. The particles of NC do not attract or interact with the sites of radicalized G as they are effectively surrounded by the radicals of hydrogen [90]. The distributed radicalized G has a high affinity with H and CH2-CN radicals and generates, as a result, G-NC hybrid pyridinic and pyrrolic systems [90].

Proposed framework for G-NC hybrid formation [90]

2.2 Hybrid Nanocomposites Based on Graphene and Nanoparticles

2.2.1 Hybrid Polymer Nanocomposites Based on Graphene and Metal/metal Oxide

Hybrid G-nanometal polymer composite materials is a subject that gained much attention recently [6, 91, 92]. In particular the design and preparation methods of polymer nanocomposites reinforced by G-nanometal have become common practice, since these hybrid fillers provide unique properties to the polymer matrix [92, 93]. The hybrid G-nanometal/metal oxide in the polymer matrix has the advantage that the G sheets serve as a loader for regulated metal NP production and can prevent the self-assembly of small metal NP during the preparation of the composite nanomaterials [6, 18, 94]. Metal oxides play here a significant role in improving the polymer's immobilization and thus the enzyme stability [95].

For instance, the polyvinyl chloride (PVC's) glass transition temperature reinforced with G-TiO2 hybrid increased from 71.3 to 74.8 °C compared with neat PVC, indicating that the segmental chain mobility is limited by the intense interfacial interactions between the nanohybrids and the polymer matrix [46]. Kumar et al. prepared a multifunctional biodegradable material where hybrid graphene-silver (rGO-Ag) nanoparticles were used to enhance poly-caprolactone (PCL) matrix, as demonstrated in Fig. 6 [6]. Comparing with rGO or Ag nanoparticles alone, rGO-Ag hybrid nanoparticles were found to be well dispersed in the polymer matrix due to enhanced exfoliation [6]. In addition, it was noted that uniformly scattered rGO-Ag hybrid nanoparticles resulted in a 77% increase in the PCL Youngs’ modulus at 5 wt% filler, which exceeded significantly the improvements achieved with the addition of rGO or Ag nanoparticles alone in the PCL [6]. Other improved properties include conductivity, stiffness, antibacterial property and cytocompatibility [6]. Likewise, by adding 0.25 phr rGO—Fe2O3 in the epoxy matrix, tensile strength, flexural strength and impact strength improved by 56%, 81% and 112% respectively [92].

Schema polymer nanocomposite incorporated with rGO-Ag hybrid [6]

2.2.2 Hybrid Polymer Nanocomposites Based on Graphene and Metal Alloy

Metals’ scarcity, mass interaction and stability have become the critical limiting factors that hinder the commercial applications of metal-based materials, in recent years [96, 97]. A number of strategies have been adapted to enhance those properties, two of which are: i. reducing the size of metals to a nanoscale, which can provide more active sites and increases the use of metals per mass, ii. alloying with earth-abundant transition metals (Cu, Zn, Ni, and Fe), which may improve the metal-based hybrid's mass activity and stability due to the synergetic effects resulting from changes in the nano-alloy surface physical and chemical natures [26]. These approaches and others have helped the rapid advancement of G-based nanocomposites, highlighting the nanometal alloys strong mechanical reinforcement strength, large specific surface area, excellent biocompatibility and good thermal properties [48, 98, 99].

Hong et al. prepared poly(methyl methacrylate) (PMMA) nanocomposite as shown in Fig. 7, reinforced by rGO-NiAl hybrid, using a simple solution blending method, in order to investigate its effect on increasing the composite’s thermal stability [48]. It was observed in the thermal studies that a greater residue of 3.7 wt% was obtained, which was attributable to the combination of the physical barrier effect of rGO and the NiAl alloy nanoparticles, hence confirming enhanced thermal stability of the PMMA hybrid nanocomposite [48]. Physical characterization demonstrated that poly (triazine imide) (PTI) nanosheets hindered G nanosheets restacking and allowed the even-scattering of the 2.5 nm PtSn alloy nanoparticles on the PTI graphene support materials [99].

Schema of the formation of poly(methyl methacrylate) composite reinforced with rGO/NiAl-layered double hydroxide hybrid (presented as rGO-LDH) [48]

2.2.3 Hybrid Polymer Nanocomposites Based on Graphene and Carbon Nanotubes

The improvement of the nanocomposite materials properties could be achieved by using CNT as fillers since the CNT have a high Young’s modulus, a high tensile strength, a high aspect ratio, a low density, etc. [29, 100]. These exceptional properties make CNT ideal as a reinforcement additive in hybrid nanocomposites. On the other side, G and its derivatives can be used to modify the inherent properties or induce new properties to the matrix [101, 102]. G based-polymer composites show improved mechanical, thermal, and barrier properties compared to the neat polymeric materials [103]. However, difficulties lie in transforming or imparting the unique properties of G or CNT alone to the polymer [104, 105]. The homogeneous dispersion of the filler in the matrix is crucial in ensuring a good interfacial interaction and adhesion between the phases [106].

The incorporation of the G-CNT hybrid filler to the polymer matrix has more attractive properties compared to the neat polymer [108]. Hybrid polymer nanocomposite based on G and CNT can be used for diverse applications like conduction, coating and films, electromagnetic interference shielding materials for electronic devices, thermal interface materials, etc. [35, 36, 64]. As an illustration, Liu et al. prepared hybrid polyethylene polymer composites based on graphene and carbon nanotubes [109]. They demonstrated an impressive synergetic effect between the G and CNT leading to a clear improvement of the interfacial mechanical properties of the polyethylene matrix [109]. Furthermore, they showed that the reinforcement effect on the covalent bond of the G-CNT hybrid is directly related to the CNT length and radius, and also to the choice of CNT as the use of multi-walled CNT seems to lead to more efficient materials than those made using single-walled CNT [109]. By the addition of GO-CNT hybrid charges to the polymer matrix, it was observed that the composite's storage modulus was the main thermal response speed factor [63]. This observation could be attributed by the presence of specific molecular interactions occurring within the G-CNT hybrid and the polymeric structure.

In another study, Bagotia et al. successfully prepared polycarbonate/ethylene methyl acrylate nanocomposites by following a melt-blending method using different ratios of the G-CNT hybrid filler, as shown in Fig. 8 [107]. Among the tested materials, hybrid filler composites with 10 phr loading (G:CNT ratio 1:3) have a highest tensile strength and tensile modulus than G or CNT based composites at the same loading [107]. In summary, the G-CNT hybrid nanostructure exhibited a synergistic effect improving thus the structural, mechanical and thermal properties of the composite even by selecting a large variety of polymeric matrix, like, exemplified using the poly(vinylidene fluoride) [67], epoxy [63], poly(methyl methacrylate) [110], poly(ether sulfone) [32], poly(vinyl alcohol) [69, 111], poly(dimethylsiloxane) [62], poly(ether-ether-ketone) [112], poly(styrene-b-butadiene-b-styrene) [112], etc.

Graphical description for manufacturing of G-CNT hybrid reinforced polymer composite [107]

2.2.4 Hybrid Polymer Nanocomposites Based on Graphene and Nanocelluloses

Nanocellulose (CNC or CNF) was used individually as an efficient reinforcing fillers on many kinds of polymers [73, 113]. Driven by unique properties (high specific strength, biocompatibility, biodegradability, low weight, abundance, barrier properties and capacity for reinforcement) nanocellulose is recognized as an ideal candidate for the development of polymer nanocomposites [71, 114]. On the other hand, G and its derivatives are also well-known to be potentially the best options leading to high enhancement of polymeric nanomaterials due to their favorable scalability, high mechanical/thermal conductivity, and chemical flexibility [103]. However, as with most nanocomposites, several crucial challenges, such as incomplete G exfoliation, uneven dispersion of fillers, high hydrophilicity of nanocellulose and weak G-matrix adhesion, present limited the full functionality of most described nanomaterials containing G or nanocellulose alone [78, 103, 115].

The development of sustainable and biodegradable nanocellulose aligns with an environmentally friendly approach to mediate G dispersion in aqueous media and its integrated morphology in polymeric matrices such as polyvinyl alcohol [15, 79, 80], polyethylene [40], poly-lactic [38, 78], polyphenol [76], rubber [77], etc. Recent studies have therefore explored the use of sustainable carbohydrate polymers (i.e. cellulose), as they are biocompatible and environmentally friendly, thus achieving the functionalized biopolymer G-nanocellulose hybrids to reinforce the nanocomposites [40]. The obtained G-nanocellulose hybrids have excellent aqueous suspension stability, which greatly facilitated their dispersion into polymer matrix [15].

In many cases, it was noted that the G-cellulose nanohybrids are selectively located in the interfaces between the polymer microspheres and are assembled into a 3D hierarchical conductive network structure during co-coagulation [77, 79, 116]. Interestingly, the use of G-nanocellulose hybrid was considered a simple approach not only to prevent the use of chemicals modifying agents, but also to enhance the conductivity and mechanical properties of G-based composites prepared with randomly scattered G, through traditional production procedures [39, 77, 79].

For instance, the G-CNC hybrid was combined with poly(vinyl alcohol) (PVA) aqueous solutions to prepare PVA-based nanocomposites (PVA/G-CNC), using a simple and environmentally friendly casting process [80]. It was stated that the synergistic reinforcing effect of G-CNC was obtained through the presence of strong H-bonds between -OH groups of the PVA and CNC enhancing thus their interfacial interaction. This was also achieved thanks to the presence of CNG, promoting the dispersion of graphene in the PVA matrix, as shown in Fig. 9 [80]. Similarly, owing to the synergistic reinforcement of G-CNC, it was noticed that Young’s modulus, tensile strength and resilience of the PVA nanocomposite containing 5 wt% hybrid nanofiller (G:CNC ratio 1:2) increased substantially by 320%, 124% and 159% respectively; and the break elongation remained substantial compared to the pure PVA matrix [15].

Schematic presentation of poly (vinyl alcohol) nanocomposites with G-CNC hybrid [80]

2.2.5 Hybrid Polymer Nanocomposites Based on Graphene and Nanoclays

Nanocomposites made of clay-based polymers have gained significant interest from the scientific community over the past decade [81]. Researchers studied particularly the potential for reinforcement of polymeric matrix with modified nanoclays (montmorillonite, bentonite, laponite, halloysite and kaolin), so as to improve its properties such as thermal, barrier, mechanical and resistance to flammability [84, 117, 118]. Compatibilizers such as G are also used in the preparation of nanocomposites as well as modifying the nanoclays (NC) to enhance the dispersion of the filler particles [86]. Hence, the synergetic effect of dispersion and flame retardancy was the key element to the introduction of G-NC hybrid fillers in the polymer matrix [119].

In addition to flame retardants, G-NC hybrids have been used in various polymer matrices for various other applications such as nylon thermomechanical properties enhancement [82], supercapacitors electrode materials [41, 85], superabsorbent [88], water treatment [84, 118], thermoplastics manufacture [120], etc.

Figure 10 shows graphene oxide-halloysite nanotubes hybrids (HRGO) prepared by simultaneous reduction and hybridization of GO with halloysite nanotubes. The HRGO have been integrated into an epoxy matrix to improve its thermal and the mechanical properties [87]. In fact, the Halloysite nanotubes effectively impeded the accumulation of GO sheets in the epoxy matrix [87]. Similarly, the epoxy nanocomposites showed improvements of 36, 16, 27 and 19% in Young’s modulus, tensile power, critical stress intensity factor (KIC) and critical energy release rate (GIC) were achieved using GO-attapulgite hybrids, respectively [121]. In a different study where hybrids with different montmorillonite/GO ratios were examined, the 5:1 mass-ratio hybrid offered better dispersibility and more effectively, while the mechanical strength of epoxy-based composites was enhanced [89].

Schematic overview of GO-halloysite nanotubes hybrid (HRGO) preparations and HRGO-reinforced epoxy composites [87]

3 Characterization Techniques

In materials science, material properties are fundamentally linked to microstructure, which necessitates knowledge of the recent characterization approaches [122, 123]. This is because materials such as thermoplastics, composites and hybrid films have several elementary constituents dispersed in more than one process of fabrication. Characterization is, otherwise, essential for the systematic production of these different materials and for determining their functionality in practical uses. Several commercially available techniques are used to study materials, e.g., microscopy, spectroscopy, and thermal analysis. Each of these techniques is typically used for a define type of materials or for the retrieval specific information. This presents a technical challenge in choosing the adequate characterization technique when dealing with a specific sample. Researchers or engineers must therefore specify which information is required to thoroughly describe each substance and use that data to understand its behavior, create new and advanced materials, minimize costs, or comply with regulatory standards. The following sub-chapter provides all the contexts required to understand the, as characterization technologies of graphene-based nanohybrid and its composite materials, with particular attention to the current and most commonly used techniques as presented in Fig. 11.

3.1 Microscopy-Based Characterization

3.1.1 Scanning Electron Microscope, SEM

Roughness, morphology, size and state of dispersion of particles in a material can be measured using several microscopy techniques at various length scales. Scanning electron microscopy (SEM), transmission electron microscopy (TEM) and atomic force microscopy (AFM) can provide a straightforward way of observing and analyzing the dispersion of particles at various lengths qualitatively [124]. SEM used a focused electron beam to scan a surface and subsequently present an image [125]. SEM has been used in several works in order to study the dispersion of the graphene-based hybrid nanofillers and examine the surfaces of their composites [23, 32, 45, 80, 126].

With the help of SEM images it was possible to confirm that SnO2 nanocrystals are attached to the surface of rGO sheets, where the presence of SnO2 nanocrystals proved that GO and SnCl4 hydrothermal treatment is an effective preparation method of the rGO-SnO2 hybrid [127]. Similarly, the GO-TiO2 hybrid SEM images proved that dense TiO2 nanocrystals were tightly attached to GO sheets and did not separate under sonication [128]. Furthermore, from the analysis of the SEM images of the GO-TiO2 hybrid, it was possible to conclude that the coating of TiO2 nanocrystals on graphene is denser with increasing the Ti (BuO)4/GO feed ratio [128]. Further analysis of the dispersion of nanoparticles in the hybrids shows that the SEM images (Fig. 12a) exhibit the presence of individually large Cu or copper oxide particles in the hybrid rGO-Cu (ratio: 1–2) [21]. The rGO-Cu hybrid SEM image (ratio: 1–1) shown in Fig. 12b also clearly indicates the size of the non-uniform nanoparticles in the hybrid [21]. An increase of the mass ratio of rGO-Cu to 2:1 leads to highly dispersed metallic Cu nanoparticles with a small size distribution of 50–100 nm within the GO structure, as shown by SEM image in Fig. 12c. Further increase of the mass ratio of GO-Cu to 5:1 leads to even smaller Cu nanoparticles on the surface of rGO nanosheets with a size distribution of 5–15 nm, as shown in Fig. 12d [21].

SEM images of rGO-Cu hybrid at different ratios [21]

SEM analysis was also used to investigate the fracture surfaces of epoxy composites reinforced with G-CNT nanofillers [106]. For the composite with the G-CNT hybrid filler structure, the dispersion of the CNT within the matrix is improved with no rich CNT domains on the surface [106]. The analysis showed that a small amount of G has greatly modified the dispersion and state of aggregation of CNT. In fact, there were no voids or gaps found on the surface of the fracture [106]. Yang et al. demonstrated that the SEM images demonstrated a better dispersion and homogeneity of G and CNT within the epoxy matrix for composites which contain the G-CNT hybrid nanofillers [126]. The SEM images proved that adding CNT significantly affected the dispersion of graphene and the state of aggregation in the epoxy matrix [126], and confirmed the impact that the synergetic effects that CNT and G have on the mechanical properties and composite thermal conductivity [126].

The SEM images (Fig. 13) of the cryogenically broken cross-section of the nanocomposite films obtained in the polyimide (PI) matrix brings to light details of these nanofillers [129]. For example, many of the GO nanosheets were aggregated together in the PI/GO nanocomposites (Fig. 13a), aside from some scattered GO nanosheets. In addition, the zone magnified in Fig. 13b suggests that the GO nanosheets were poorly compatible with the PI matrix and formed an extreme aggregation, resulting from the wide surface area of GO, which easily stacks to form agglomerates [129]. The GO agglomeration decreases the area of interaction between GO and PI, leading to low-efficiency GO-reinforcing. Figure 13c, d show the PI nanocomposites packed with the GO-CNT hybrid. It is seen that the introduction of CNT prevents the aggregation of nanosheets of GO and increases the area of interaction between matrix GO and PI. For PI nanocomposites filled with the GO-CNT hybrid (shown in Fig. 13e, f), GO is firmly embedded in the PI matrix, which suggests an excellent stability of hybrid GO-CNT nanofillers in the PI matrix, due to the creation of hybrid nanostructure bound by the hydrogen bond interaction [129]. Additionally, 3D hybrid networks were formed between GO and CNT and well distributed in the PI matrix containing GO-crosslinked and oxidized CNT nanofillers (Fig. 13g, h), which is regarded to be of great advantage in increasing the performance of PI matrix [129].

SEM observations of hybrid polyimide (PI) polymer nanocomposites based on GO-CNT fillers [129]. The yellow arrows indicate the GO nanosheets and the red arrows indicate the CNT

3.1.2 Transmission Electron Microscopy, TEM

Besides SEM analysis, TEM is a technique that also uses an electron beam to image a sample, offering a much better resolution than light- imaging techniques [130]. TEM is the best tool for calculating the scale of the NP, the grain scale, the size distribution and the morphology of hybrid nanofillers [129]. For example, analysis of the TEM images allows the confirmation of the morphology structure of nanohybrid based on exfoliated G and CNF [131]. Using a TEM image of the G-CNF hybrid, it was observed that graphene had a crumpled geometry and that CNF were found on the G surface [131]. The selected area electron diffraction pattern (SAED) from the TEM analysis showed that standard six-fold symmetry diffraction spots with the outer hexagon spots appear slightly weaker than those of the inner hexagon, which also confirms the obtained monolayer graphene, as shown in Fig. 14.

a TEM images and b SAED pattern of graphene-chitin nanofibers (G-CNF) hybrid nanomaterial [131]

TEM images were also used by Taj et al. to confirm the existence of gold nanostructures on the 2D layer of a G hybrid [132]. The images demonstrated that it is possible to obtain a uniform distribution of gold nanostructures (2–8 nm diameters) anchored on nanosheets of G by in-situ synthesis [132]. Besides, the corrugated structure of the G sheets was possible to demonstrate [132], and it was observed that approximately 75% of the particle size distribution was with a dimension of 2–4 ± 1.2 nm, while the remainder occurs within a range of 4–8 nm [132]. Similarly, typical G-PtAu hybrid TEM images were obtained with various magnifications, showing that PtAu bimetallic nanoparticles with an average diameter of 3.3 nm are spread evenly on G nanosheets [50]. Furthermore, Taj et al. confirmed that the results of microscopy obtained by SEM and TEM are in agreement and define the novel morphology of the hybrid G-NP [132].

Yue et al. analyzed TEM images of microtomed samples at an average filler concentration of 0.1 wt% in order to examine the filler dispersion in the epoxy composites with G-CNT hybrid nanofillers [106]. For the nanohybrid epoxy composite network, the dispersion of the filler significantly increased [106]. The nanoplatelets of 2D graphene were intercalated between the nanotubes of 1D carbon, which could contribute to the creation of a network of 3D fillers, and lead to better mechanical and electrical properties [106].

Through TEM analysis, the rGO-CNT hybrid has shown a good dispersion in the rubber matrix [133]. Song et al. confirmed the introduction of CNT bridges into the isolated rGO nanosheets, which resulted in reduced interfacial thermal resistance from the filler-filler interface and the filler/rubber interface (Fig. 15a) [133]. Thus, the ultimate thermal energy of the rubber composites is transferred to strictly defined 3D channels, as demonstrated with the normal red arrows in the model shown in Fig. 15b.

TEM images of the styrene-butadiene rubber composites containing 3% rGO-CNT. a The red lines illustrate the pathways of heat transfer. b Schematic diagram of the proposed thermal conduction [133]

3.1.3 High-Resolution Transmission Electron Microscopy

In the same way as TEM analysis technique, HRTEM is a developed transmission electron microscope imaging mode that allows direct imagery of the graphene-based nanohybrid material’s atomic structure [11, 48, 62, 134]. For instance, Chouhan et al. obtained the high resolution transmission electron microscopy (HRTEM) image of GO-Laponite nanohybrid, which indicated that the GO and Laponite layers are overlapped with each other [134]. The overlapping is a clear indicator of the interactions between the GO and Laponite layers at nanoscale [134]. The hexagonal sequence of bright spots in the selected region electron diffraction (SAED) pattern, obtained from the HRTEM analysis, showed a bright spot, identifying the group of {1100} plane perpendicular to the basal plane (0001). This indicates clearly the presence of GO sheets. Whereas in the SAED pattern, the amorphous ring pattern suggest the existence of Laponite [134].

Similarly, Fig. 16 displays TEM, HRTEM images of a silica and G-silica nanohybrid, as well as the associated select area electron diffraction (SAED) patterns [135]. It is seen that the size of the silica particles is very uniform (Fig. 16a) [135], and that the silica aerogel sample is primarily composed of amorphous and disordered structures, as disclosed in the HRTEM image in Fig. 16b [135]. Furthermore, the silica aerogel SAED pattern (Fig. 16c) reveals diffraction rings without any diffraction dots, which validates the existence of an amorphous structure of the silica aerogel [135]. Figure 16d shows a TEM image of a G-silica nanohybrid, in which many small-layered graphene layers wrinkled on a silica aerogel can be identified [135]. The HRTEM image of G-silica nanohybrid analysis revealed that thin walls as shown in Fig. 16e, usually consist of just a certain layer of graphene sheets formed from silica aerogel. As further confirmation, selected area electron diffraction (SAED) was used to uncover the crystal structure of G on silica, as can be seen in Fig. 16f [135].

TEM images of a silica, and d G-silica hybrids, HRTEM images of b silica, and e G-silica nanohybrids and equivalent SAED patterns of c silica, and f G-silica hybrids [135]

3.1.4 Atomic Force Microscopy

AFM is another advanced micro-based technology used to analyze a surface in its complete, three-dimensional space, down to the nanometer size [37, 71]. The AFM techniques have been commonly used to study the G-based hybrid filler structure's physical behavior and its effect on a polymer matrix [15, 129, 136, 137]. Illustratively, AFM studies were used to investigate the morphology and measurements of the nanomaterials GO, CNC and their hybrid nanofillers GO-CNC [15]. For CNC, the AFM image demonstrated that there were needle-like nanoparticles for the as-extracted CNC, indicating that their isolation from the treated sugarcane bagasse was productive [15]. On the other hand, the GO's AFM images showed the presence of individual irregularly shaped nanosheets with identical thicknesses and different lateral sizes [15]. AFM characterization of the GO-CNC nanofiller hybrid (GO: CNC-1:2) revealed that the GO surface had become fully and densely covered with randomly arranged CNC [15].

In another study (Fig. 17), the AFM morphology of GO-CNF and rGO-CNF revealed an ultrathin GO surface (∼1.0 nm thickness, ∼0.6 μm size) [76]. As shown in Fig. 17a, the CNF nanofibers were partially absorbed on the GO surface; the thinness of GO-CNF hybrids was approximately 2.42 nm [76]. In comparison, the thickness of rGO-CNF nanohybrid layer was about 5.245 nm (Fig. 17b), which was much thicker than the GO-CNF specimen [76]. Xiong et al. noted that the AFM images analyses helped realize that the combination of cellulose nanofibers CNF and GO nanosheets resulted in the spontaneous creation of stable 2D hybrid nanostructures with planar GO nanosheets uniformly encapsulated in a dense network of 1D nanofibers [138]. Furthermore, it was also noticed the thick CNF coating renders them extended from the sides of GO, like long hairs produced around the sides of GO [138].

AFM images of a GO-CNF hybrid, and b rGO-CNF hybrid [76]

AFM was also utilized to investigate the surface morphology of the polyimide reinforced with hybrid GO-CNT [129]. It was noted that the surface roughness of the polyimide matrix increased considerably with the addition of either GO or CNT compared to that of pure PI [129]. Compared to all other polyimide-based nanocomposites, the surface roughness value decreased when incorporating the hybrid GO-CNT, and almost identical to that of neat polyimide [129].

For further illustration, Fig. 18 portrays AFM 3D topography images of pure polysulfone (PSf) and composite membranes filled with CNT, rGO and rGO-CNT nanofiller hybrids [136]. The pure PSf film micrograph was found to be coarser with a roughness of 19.89 nm, which showed that an amorphous network is built on the surface [136], While the PSf reinforced with the CNT film exhibited a roughness of 18.12 nm, it addressed improved compatibility of CNT within the PSf matrix. This is illustrated in the topographic image, which shows homogeneously scattered bright patches on the surface [136]. The PSf-rGO film micrograph showed, on the other hand, the presence of a thicker area with a layered and firmer structure, with a roughness of 21.5 nm [136]. The hybrid composite film AFM micrograph showed the presence of several convex hills and walls on the surface with a roughness of 22.86 nm, which is higher than for the matrix reinforced with G and CNT alone [136].

AFM 3D composite samples topographical micrographs [136]

3.2 Spectroscopy-Based Characterization

Spectroscopy characterization is the study of the interaction between material and electromagnetic radiation by means of electron and atomic energy [139,140,141,142]. Many such interactions include spectroscopy of absorption, elastic, resonance, emission and inelastic scattering [143,144,145]. Spectroscopic studies were essential to the development of nanohybrids and composites based on G [15, 46, 80]. There are several types of spectroscopy, though the most common types used for GF-NP based hybrid composite analysis include Fourier transform infrared spectroscopy, ultraviolet and visible spectroscopy and Raman spectroscopy.

3.2.1 Fourier Transform Infrared Spectroscopy

Fourier Transform Infrared Spectroscopy (FTIR) spectroscopy is used to demonstrate what kinds of bonds are present in a composite material by measuring at various frequencies different forms of interatomic bond vibrations [70, 146]. The FTIR spectra create a sample profile, a distinctive molecular fingerprint that can be used for screening and scanning nanofiller samples for different components based on G [12]. From an analytical point of view, by measuring the impact of molecular vibrations at the polymer and nanofiller interaction, the fraction of the interfacial polymer composite can be determined via FTIR spectroscopy [18, 147].

For instance, Pu et al. observed the characteristic FTIR spectra of GO and GO-TiO2 nanohybrids (shown in Fig. 19) [148]. Both GO and GO-TiO2 displayed spectra that have a large peak above 3000 cm−1, resulting from the OH stretching vibrations of the H2O and the C–OH groups [148]. GO displays the peaks for C=O at 1110 cm−1, C–O–C at 1250 cm−1, C–H at 1387 cm−1, and C=O at 1720 cm−1 [148]. As for the hybrid GO-TiO2 nanohybrid, the spectra for C=O disappeared completely, confirming the decomposition of partial oxygen comprising functional groups under microwave irradiation [148]. In addition, it was observed that the absorption edge of GO-TiO2, relative to pure TiO2, displayed an apparent shift [148]. This result indicated the narrowing of TiO2’s bandgap, which also supports the development of Ti–O–C bonds between GO and TiO2 [148].

FTIR spectra of raw GO and GO-TiO2 nanohybrid [148]

Figure 20 displays FTIR results for the main GO-SiO2 hybrid filler (Fig. 20a) and the hybrid PLA composites (Fig. 20b) [12]. In addition to the predicted FTIR peaks for each filler in Fig. 20a, it was predicted that the peak at approximately 1420 cm−1 in the GO-SiO2 nanohybrid originates from the -COOSi-group, which confirmed the desired connection between GO and silica [12]. Terzopoulou et al. used the FTIR results to compare a poly-lactic acid (PLA) composite structure when filled with hybrid fillers based on graphene and silica nanoparticles [12]. Figure 20b, particularly the spectra around 1750 cm−1, provided interesting information regarding the interactions between the polymer-fillers. The key sources of the peaks are the stretching and vibration of the PLA free carbonyl –C=O groups. The peak was clearly absent in the smooth GO and SiO2 hybrid spectra (Fig. 20a), which affirms the polymer-filler interaction [12].

Comparative FTIR spectra for a hybrid fillers GO-SiO2 and b hybrid filler-based PLA composites. The major molecular vibrating groups leading to the spectra are colored grey [12]

3.2.2 Ultraviolet-Visible Spectroscopy

In the same manner, as FTIR, Ultraviolet–visible spectroscopy (UV-Vis) technique applies to spectroscopy of absorption and reflectance within the section of the ultraviolet and the complete, adjacent visible spectral region [149]. UV-vis-spectrophotometry was used as a function of light wavelength for determining light transmittance through graphene-based hybrid nanocomposite films [44, 150]. Furthermore, UV spectroscopy is an important method for the quantitative detection of various analytes in G based hybrid materials, such as transition metal ions (Cu, Au, Ag, Pb, Fe, Zn etc.) and conjugated organic compounds [22, 24, 151]. Such in the case of Wang et al. who analyzed the UV vis-à-vis spectra of rGO-TiO2, rGO-Ag–TiO2 and rGO-Pt–TiO2 hybrids and found that all had a wide absorption range of 300–350 nm due to the TiO2 absorption [151]. It was reported that the absorption in the rGO-Ag–TiO2 nanohybrid spectrum at around 431 nm resulted from the excitation of a surface plasmon in noble metal nanoparticles and further confirmed the formation of Ag particles on the rGO-TiO2 surface [151]. No apparent surface plasmon absorption was observed for the rGO-Pt–TiO2 nanohybrid in the visible area [151].

UV-Vis spectrometry analysis was performed to investigate the electronic interaction of the G and nanometals (silver (Au) and gold (Ag)) [24]. Compared to the G spectra, additional peaks were observed for all the hybrids due to metal nanoparticles insertion [24]. Characteristic peaks at 545 and 410 nm were attributed respectively to Au and Ag surface plasmon resonance (SPR) [24], indicated the presence of Ag and Au nanoparticles on the surfaces of graphene. The G-AuAg’s UV-Vis spectrum showed a strong absorption peak at 477 nm, which is noticeably different from G-Ag and G-Au hybrids peaks positions [24]. In order to study the conjugated structure of exfoliated graphene in G-CNF hybrid nanomaterials, UV-vis absorption spectra were analyzed for GO, rGO, and G-CNF [131]. As illustrated in Fig. 21, The UV-vis hybrid spectrum shows a high absorption peak of about 267 nm, close to that of rGO, whose conjugated graphic structure has been restored by chemical reduction, relative to that of GO [131].

UV-vis spectra of GO, rGO, G-CNF and exfoliated graphene obtained in N-Methyl-2-pyrrolidone (NMP) or in Sodium dodecyl sulfate (SDS) aqueous solution (presented in the graph as GO, RGO, GE (NMP) and GE (SDS), respectively) [131]

UV-Visible spectrometry measured the anti-UV properties of polylactic acid (PLA) and nanocomposite films [44]. The pure PLA film absorbed strongly ultraviolet light (200–400 nm) and visible light (400–800 nm), by 92% transmittance [44]. Because of the combination of GO and ZnO nanoparticles, which increases the light absorption spectrum, the film displayed good anti-UV safety and good transmission of visible light when combined with GO-ZnO nanohybrid [44]. It was noticed that when the GO-ZnO content increases, the nanocomposite films obtain excellent absorption properties both in the UV region and in the visible region [44]. Similarly, in a study, Patole et al. presented UV-visible spectra of the polystyrene (PS) hybrid nanocomposite at wavelengths from 200 to 800 nm as shown in Fig. 22. PS spectra displayed peaks from lower to higher at approx. 200–400 nm led by associative interactions between the phenyl groups [35]. Similar peaks, less intense, appeared in the hybrid nanocomposite caused by addition of G-CNT hybrid, where the PS chains get tangled and trigger a screen effect limiting the absorption of the light beam [35].

UV-visible spectrum of neat and hybrid polystyrene (PS) nanocomposite [35]

3.2.3 Raman Spectroscopy

Raman spectroscopy is a valuable tool for performing carbon nanomaterials characterization, especially for identifying the order of graphene particles layers [75, 152]. Raman Spectroscopy was done to analyze the efficiency of the graphene nanosheets before and after a hybrid nanocomposite preparation [59]. Much information like grain boundaries, edge, disorder, doping, thickness, thermal conductivity and strain of graphene, can be obtained from the Raman spectrum and its characteristic s under various physical conditions [62, 68].

Considering the example in Fig. 23, Raman characterization that showed D band intensity ratios to G band (ID/IG) of GO, rGO, and G-CNT hybrid, which was around 0.97, 0.82, and 1.10, respectively [62]. These results confirmed that the amorphous carbon layer is formed during the CNT growth process [62]. In a different study, Das et al. analyzed the G-CNT hybrid’s Raman spectrum, where all the typical carbon nanostructure bands (G, D, and 2D/2 G) were shown [153]. The full-width half maxima (FWHM) of 2D band were 30 for mono and bilayer graphene and 69.14 for G-CNT [153]. It has been noted that the 2D peak enlargement can be attributed to the layer increase in the G architecture [153]. Likewise, the blue shift in the G-CNT hybrid band positions also suggested a relatively stronger bond between the G and CNT [153].

Raman spectra of GO, RGO and G-CNT hybrid [62]

Xu et al. reported that G-metal contact, together with physisorption and chemisorption, cause the deviations of the G-band responses and the shifts of 2D-band frequency [154]. Furthermore, it was noted that the Cr, Ag and Al's interaction with G lead to a blueshift of the G peak, while Ni and Ti result in a redshift for the G peak [154]. The interactions of G and electrode metals like Ni, Ti, Al, Cr, and Ag introduced shifts in the peak G and the peak 2D [154]. Ni and Ti contributed to the peak G redshifts. Raman spectroscopy was reported to be an effective method for graphene studies, even if it interacts strongly with transition nanometal surfaces [154].

In another study, Raman analysis spectrum of GO displayed a D band at 1359 cm−1 as well as a G band at 1602 cm−1, while the rGO-Co3O4 nanohybrid D and G bands were at 1330 cm−1 and 1596 cm−1, respectively [9]. It was further noted that the redshift of the G band from 1602 to 1596 cm−1 for the rGO-Co3O4 nanohybrid was attributable to the recovery of the carbon atom's hexagonal network [9]. The nanohybrid rGO-Co3O4 exhibited a comparatively higher D-to-G-band intensity ratio (1.16) compared to the GO (0.96) [9]. Similarly, with regards to pure graphene D-to-G intensity ratio (0.497), the graphene-titanium dioxide hybrid D-to-G intensity ratio increased by 1.5 times (0.7) [155]. These results confirmed that after the chemical reduction of GO, there was the creation of a new graphitic domain [9, 155].

Research has been done using Raman spectroscopy to study the poly(pyronin Y) and the impact of rGO-silver (Ag) nanohybrid on the polymer [20]. It was observed that the rGO-Ag nanohybrid Raman spectrum resembles that of rGO sheet [20]. Furthermore, it was noticed that the ID/IG ratio for the rGO-Ag nanohybrid was 0.91, which was lower than that the rGO sheet, which may be an indication of Ag nanoparticles doping by filling the gaps left after extracting oxygen and iodine molecules, decreasing the defect density [20]. Moreover, it was noted that for the poly(pyronin Y)/rGO-Ag hybrid nanocomposite Raman spectrum was considerably different than that of the fillers, due to the presence of poly (pyronin Y) as a matrix [20].

Raman spectroscopy was also performed for hybrid composites based on poly (trimethylene terephthalate-block-poly (Tetramethylene oxide) (PTT-PTMO) and G-CNT nanofillers as shown in Fig. 24 [68]. It was noted that the Raman spectrum corresponding to the hybrid nanocomposite with G-CNT hybrid nanofiller was almost similar to the nanocomposite with the CNT filler alone [68]. Therefore, CNT were proposed to be an indicator in deciding the properties of the hybrid nanocomposites [68]. In a different study, the structural study of the rGO, CNT, G-CNT, Polymethyl-methacrylate (PMMA), and PMMA/G-CNT hybrid composite was performed using Raman spectroscopy [16]. It was noted that PMMA Raman spectra display all of the typical PMMA peaks, except D and G bands [16]. After the G-CNT nanohybrid filler was integrated into the PMMA polymer matrix, D and G bands began to appear [16]. Furthermore, it was found that as the content of the G-CNT nanofiller increased, the intensity of the bands increased and showed a slight shift in peak position of the D and G bands, independent of the PMMA polymer peaks. This was related to chemical interactions between the PMMA polymer particles and the G-CNT nanohybrid filler particles [16].

Raman spectra of pure and hybrid PTT-PTMO [68]

3.3 X-Ray-Related Characterization

3.3.1 X-Ray Diffraction

X-ray methods are instrumental in providing data on the chemical composition and crystalline and amorphous structures of materials [40]. The X-ray Diffraction (XRD) and X-ray photoelectron spectroscopy (XPS) analysis are the most commonly used methods for characterizing composite hybrid materials [19, 151, 156]. XRD operates on the concept of diffraction from various planes of the atom generating a pattern of diffraction (diffractogram), that contains data of the atomic structure of the crystal. XRD is also used to detect a polymorph phase and determine the abundance of a phase to classify the hybrids and compare the compositional efficiency of composites [12, 151, 155].

Using XRD analysis of rGO-CNC nanohybrid, it was possible to confirm that the CNC were decorated on the rGO surface [40]. It was confirmed by noticing that after reduction, the strong (002) GO diffraction peak at 2θ = 11.8° disappeared in the rGO and rGO-CNC hybrid [40]. Four defined diffraction peaks at 14.9, 16.6, 22.7 and 34.5° were reported, related to the presence of the crystalline region in the CNC and rGO-CNC nanohybrid, which suggests that the rGO-CNC crystalline structure is undamaged after GO reduction [40].

In another example, XRD was used to analyze and characterize the crystal structure patterns of the GO, rGO, Ni–Al alloy nanoparticles and an rGO-Ni–Al hybrid nanofiller (Fig. 25) [48]. It was observed that the GO's XRD pattern (Fig. 25) displayed a sharp peak at 10.48, suggesting the interplanar spacing of the (002) is around 0.85 nm, which is explained by the turbostratic structure of the stacked graphene plates [48]. The diffraction peaks (Fig. 25) of 11.48°, 23.18°, 35.28°, 39.38° and 46.58° correspond to the respective planes (003), (006), (012), (015) and (018), which is typical for a Ni–Al alloy hydrotalcite [48]. Furthermore, the XRD pattern of rGO-Ni–Al hybrid nanofiller is almost similar to that of pure Ni–Al alloy, and no characteristic peaks of the rGO are observed. These findings suggested that the Ni–Al alloy nanoparticles were well anchored on the rGO nanosheets, effectively preventing the graphene from being restacked [48].

XRD patterns of the obtained GO, rGO, Ni–Al layered double hydroxide and rGO-Ni–Al (rGO-LDH) [48]

In order to investigate the impact of integrating rGO and CNC on the crystallinity of the polylactic acid (PLA) matrix, the structure of CNC, the rGO filler and the neat PLA and rGO-CNC reinforced PLA nanocomposite were characterized by broad angle XRD analysis [78]. A broad diffraction band at 2θ = 16.5° was depicted from the XRD spectra of the neat PLA polymer, suggesting a PLA’s XRD-amorphous structure [78]. The XRD curves of the nanocomposite reinforced with rGO-CNC showed no peak of CNC and rGO at low filler contents, other than the wide prominent peak at 2θ = 16.5°, confirming a typical amorphous material [78].

In a different study, a polymer hybrid nanocomposite in its amorphous (melt-quenched) and semicrystalline (annealed) structures were investigated. Figure 26a displays the XRD spectrometers for the fillers separately and (Fig. 26b, c) for the nanocomposite [12]. Compared to the stuck-formed GO, it was confirmed that the complete exfoliation of the hybrid GO-SiO2 was achieved [12]. This was confirmed by the absence of XRD peaks in the nanohybrid GO-SiO2 at 2θ ∼ 10° in Fig. 26a. [12]. For the polymer hybrid nanocomposites, the XRD findings from Fig. 26b, c showed no observable alternations between the polymer matrix and the polymer hybrid nanocomposites in the reported XRD spectra [12]. Therefore, no significant alteration is observed in the crystalline structure of the neat polymer, nor in the polymer hybrid nanocomposites [12].

XRD spectra for a the nanofiller particles (GO and SiO2), and b, c pure polylactic acid (PLA) and PLA hybrid nanocomposite b amorphous and c semicrystalline nanocomposites [12]

3.3.2 X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) is another method for the study of composite material's surface chemistry [157, 158]. The basic XPS principle is to irradiate the surface of the studied material with X-rays to eject electrons from its surface [158]. The energy of these electrons, which is used to determine the surface chemical composition, is then measured [158]. XPS was used to analyze the elementary composition and the chemical state of a wide variety of solid samples from hybrids to composite materials [19, 49]. Besides, XPS was used in this study to determine the oxidation states of metal atoms, and the nitrogen bonding configuration of a G-MnCo2O4 nanohybrid [49]. It has been demonstrated that the observed characteristic peaks suggested that the hybrids contain carbon (C 1 s peak), oxygen (O 1 s peak), nitrogen (N 1 s peak), cobalt (Co 2p peak) and manganese (Mn 2p peak) elements and that the Co-to-Mn ratio is approximately 2 which was a close match to the modeled ratio [49]. Similarly, the chemical composition of rGO and rGO-Au nanohybrid was analyzed using XPS spectra of C1s and O1s [19]. XPS spectra of C1s and O1s, which confirmed the effective chemical reduction of GO and Au nanoparticles were present in the rGO-Au nanohybrid [19].

The XPS measurements confirmed the efficiency of the surface functionalization and the reduction of the hybrid nanofiller rGO-CNF [76]. Figure 27 shows that the intensity of the oxygen-containing group peaks for C1s binding region of rGO-CNF clearly decreased compared with that of the GO-CNF nanohybrid, indicating an efficient GO reduction [76].

Full XPS spectra a GO, CNFs, GO-CNFs and rGO-CNFs [76]

Similarly, the surface chemical composition of the soy protein (SPI) hybrid nanocomposite films reinforced with GO-CNF and rGO-CNF were surveyed by XPS measurements [76]. The effective application of tannic acid coating on the SPI/GO-CNF structure was demonstrated in the SPI/rGO-CNF nanocomposite film spectrum by an increase in C1s and O1s peaks [76]. In addition, it was noted that the peak corresponding to the C=OH groups with rGO-CNF integration was significantly increased in the SPI/rGO-CNF nanocomposite film, which indicated the reaction potential of rGO-CNF with SPI matrix [76].

3.4 Thermal Analysis

3.4.1 Thermal Stability Analysis

Thermal analysis techniques are essential for a wide range of materials such as polymers, composites, pharmaceutical products, food packaging, fuels, energy, chemicals, and many more [70, 72]. These techniques, such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), usually measure heat transfer, weight loss, difference in size, or mechanical properties, as a function of change in temperature [156]. The thermogravimetric analysis (TGA) or derivative thermogravimetry (DTG) is an important laboratory tool used for the characterization of composite material. It measures the mass of material as temperature changes over time [159]. The TGA/DTG technique was used through the desired temperature range to provide insight into mass changes of G-NP hybrid and its nanocomposites [12, 31, 48, 159, 160]. In the case of the GO-CNT-CNF hybrid's, thermal stability was evaluated and two weight-loss mechanisms were demonstrated using TGA analysis [160]. It was found that a weight loss occurred in the temperature range 144−226 °C, due to the removal of oxygen-containing groups from the GO nanosheets [160]. Moreover, another weight loss was observed over the temperature range 233 − 413 °C, which agreed with the decomposition of the CNF in the GO-CNT-CNF hybrid [160]. In comparison, it was noted that in the TGA study of the rGO-CNT-CNF hybrid, there was only one weight loss phase, and it was correlated with the CNF decomposition. Such findings led to the interpretation that a successful reduction of the GO nanosheets to rGO [160].

Similarly, Tajik et al. examined the G-silica nanohybrid using TGA and DTG. They showed that there existed three thermally stable regions [159]. Due to its high percentage of silica phase, an effective thermal stability can be observed up to 549.06 °C at the first region [159]. Then, the second region was relevant to the abrupt reduction of sample weight from 549.06 to 629.78 °C likening it to the complete loss of G [159]. Therefore, the amount of G in the G-silica nanohybrid was roughly evaluated by the TGA and DTG analysis and was determined to be 16 wt% [159]. Hence, the TGA and DTG measurements have approved the formation of G nanosheet in the nanohybrid [159].

The TGA analysis was also used to characterize the thermal properties of the neat PVA film and the G-CNT hybrid nanofiller-reinforced PVA films at different hybrid filler ratio [31]. Both the neat PVA and the PVA hybrid composite films have been found to decompose through a two-step process [31]. First, a weight loss phase resulting from a thermal decomposition of PVA was estimated to take place at around 220–350 °C and a second step related to the thermal decomposition of the residue was considered to be at around 400–500 °C [31]. The TGA curve of the PVA hybrid nanocomposite film was shifted to a slightly higher temperature in comparison with that of the pure PVA film [31]. The PVA hybrid nanocomposite film peak temperatures at 314.4 and 440.3 °C, were approximately at 19.8 and 7.4 °C slightly higher than those of the neat PVA, which suggested to be due to enhanced compatibility between the PVA and the G-CNT hybrid nanofillers [31]. Similar findings were reported for the G-CNT as a hybrid reinforcement of poly(ether-ether-ketone) and poly(styrene-b-butadiene-b-styrene) [35, 112, 161].

TGA has further been used to analyze the effect of a rGO-Ni–Al hybrid on the thermal stability of the polymethyl methacrylate (PMMA) matrix as shown in the Table 1 [48]. Neat PMMA’s thermal degradation demonstrated a single phase, and no residues were left [48]. It was remarked when rGO was added in the polymer matrix, the T−5% (defined as the temperature where 5% of weight loss occurs) decreased by 12 °C because of the high thermal conductivity of rGO [48]. It was found that the maximum rate of decomposition decreases significantly, with the little residue possibly remaining because of the rGO that prevents the final thermal degradation of the polymer PMMA [48]. In the case of PMMA polymer reinforced with Ni–Al alloy, more char residue (2.2 wt%) remained, due to the catalytic carbonization effect of layered double hydroxide [48]. An improved thermal resilience of the PMMA polymer was achieved as demonstrated by a higher residue of 3.7 wt%, attributable to the combination of the rGO’s physical barrier effect and the Ni–Al alloy’s catalytic carbonization [48]. The TGA summary data of the PMMA neat polymer and the PMMA hybrid nanocomposite are given in Table 1.

3.4.2 Differential Scanning Analysis

Differential Scanning Calorimetry (DSC) is another thermal analysis method in which the heat flow in or out of a material is determined as a variable of temperature or time. In contrast, the material is exposed to a temperature-regulated system [35, 112]. DSC analysis was performed to evaluate the degree of crystallinity (Xc), the fusion heat (∆Hf) and the melting temperature (Tm) of graphene based nanohybrid composites [12, 15, 35, 40]. The degree of crystallinity (χc) is determined as follows: χc = ΔHm/ΔH0 where ΔHm is the evaluated melting enthalpy from DSC curves, and ΔH0 is the 100% crystalline melting enthalpy. In a study by Patole et al., DSC analysis were done to examined the impact of G-CNT hybrid filler in the thermal transformation of a segmental motion of the polystyrene (PS) polymeric chain [35]. It was observed that the existence of such a carbonaceous kind of filler enhanced thermal effect since the temperature needed to modify the behavior of the PS chains in hybrid nanocomposite from the glassy to the rubbery state was raised by 70 °C in comparison with the pure PS [35]. Furthermore, a high shoulder peak between 150 and 170 °C was also observed [35]. It was proposed that the thermal transformation started to become flexible from 150 °C due to the PS polymer chain at the edge of G, which was not fully covered by the carbonaceous fillers [35]. The shielding effect was caused by the presence of CNT, which is sandwiched between two graphene flakes and surrounded by the polymer chain PS [35].

Similarly, DSC analysis was used to evaluate the temperature of the glass transition (Tg) of pure PVA and its nanocomposite film, as summarized in Table 2 [31]. It was noted that PVA with 1 wt% G-CNT composite film exhibited 81.5 °C higher Tg than the pure PVA film (77.3 °C) [31]. The rise in Tg showed that PVA’s successful attachment to graphene nanosheets limited the PVA chains’ segmental motion [31]. It was further noted that there is a strong interfacial interaction between the G-CNT matrix and the PVA matrix, which benefits the successful transfer of load [31]. Correspondingly, For the GO-CNC hybrid nanofiller containing the high amount of GO (GO:CNC-2:1), the impact of nanofillers on the PVA’s glass transition (Tg) and melting (Tm) temperatures from DSC is more significant because the (PVA-GO:CNC-2:1) exhibited a higher Tg and Tm compared to (PVA-GO:CNC-1:1) and (PVA-GO:CNC-1:2) [15].

3.5 Mechanical Characterization

3.5.1 Tensile Analysis

Polymer composites’ mechanical properties rely on their structure at the nano- and micro-scales [31, 33, 109]. Generally, a good dispersion and a strong interfacial interaction between particles and the selected polymeric matrix induce superior mechanical properties of the polymer composite materials [30, 33, 106]. This was well attested by comparing the tensile stress–strain curves, highlighting that the compressive strength, Young’s modulus and breaking elongation of well-dispersed G-NP hybrid composites are significantly higher than those observed for composites based on G or NP alone [11, 112, 161].

For instance, Fig. 28 demonstrates the tensile strength and the Young’s modulus of polyvinyl chloride (PVC) film. It was noted that the Young’s modulus with rGO-ZnO fillers varying from 5 to 20 wt% and PVC films with G-Zno hybrid fillers [11]. Indeed, because of the poor interaction and aggregation of fillers, the tensile strength of PVC with G-ZnO fillers decreased with the increase of the filler material [11]. In comparison, it was found that PVC's tensile strength was obviously enhanced by adding rGO-ZnO hybrids, even at a high fillers content (20 wt%) [11]. It was also observed that the addition of G-ZnO hybrid particles had a negligible impact on the PVC’s young modulus [11]. These results suggested that strong interfacial interaction occurred between rGO-ZnO hybrid particles and PVC chains but the interfacial interaction between G-ZnO hybrid particles and PVC chains were weak [11].

a Tensile strength and b Young modulus of polyvinyl chloride (PVC) film incorporated with the specific ratio of G-ZnO and rGO-ZnO fillers [11]

Several studies show that mechanical properties increased after reaching a critical GO-CNT content added into hybrid nanocomposites [129, 133]. Better mechanical properties could be achieved by using a homogenous dispersion and alignment, preventing the particles agglomeration and a better load transfer to filler material. For example, a uniaxial tensile measurement was used to investigate the mechanical properties of neat polyimide and its nanocomposites [129]. The tensile strength, Young modulus, toughness of fracture and strain at break of pure PI were found to be 74.3 MPa, 2.47 GPa, 12.71 MPa and 21.4%, respectively [129]. The strength and Young’s modulus of the polyimide matrix were increased with the addition of GO, while the resilience of the strain at break and fracture significantly decreased [129]. However, by adding a small amount of CNT, the reinforcing efficiency of GO on polyimide was enhanced by 86%, 56%, 220% and 78% on the tensile strength, modulus, toughness and strain at break respectively, compared with those of the neat polyimide [129].

3.5.2 Dynamic Mechanical Analysis

Dynamic mechanical analysis (DMA) is the most useful tool for studying the viscoelastic condition of polymers and their composites [21, 30]. DMA analysis is defined as a function of temperature by the bending elastic modulus and damping properties of the G-NP based hybrid composites. DMA analysis was used to study mechanical behaviors of polymers with different hybrid nanofillers such as G-CNT [161], G-SiC [162], G-TiO2 [46], GO-CNT [112], rGO-CNC [38], etc. As a function of temperature in tensile mode, the dynamic mechanical behavior of the produced polylactic acid (PLA) hybrid nanocomposite films was calculated by DMA in terms of storage modulus (E′) and loss modulus (E′′) as shown in Fig. 29 [38]. By adding modified rGO-CNC hybrid in the PLA, it was observed that the E′ values were enhanced by approximately 1.6 times for rGO-CNC based PLA compared to the neat PLA at 28 °C [38]. It was noted that the increase in E′ values with increasing CNC concentration in the rGO-CNC hybrid could be related to the cross-related structure formation, enhancement of crystallinity (more organized regions formed) and better dispersion of rGO-CNC in the PLA matrix, resulting in improved adhesion between hybrid and polymer [38].

E′ and E′′ values obtained for the fabricated hybrid films obtained by DMA ( Sample A: pure PLA and Sample B-E: PLA nanocomposite with G-CNC hybrid filler with ratio of 1:2, 1:4, 1:6 and 1:10 respectively) [38]

Similarly, the E′ and loss factor (tanδ) of the studied G and CNC based natural rubber composites were investigated using DMA as a function of temperature (−30 to 80 °C) [39]. It was observed that the natural rubber composite filled with G, displayed the highest E′ when the temperature was lower than the temperature of the glass transition [39]. It was also noted that natural rubber composites filled with CNC displayed a similar storage modules above the glass transition temperature (Tg) in comparison with the pure natural rubber [39]. It was concluded that the addition of G-CNC hybrid had no influence on the composites’ glass transition temperature [39].

In other research works, the DMA findings showed a major enhancement of the E′ and Tg in the GO-ZnO based poly-lactic acid (PLA) hybrid nanocomposite films [44]. The tanδ specified as the ratio of the loss module to the storage module displayed a peak around 60–80 °C corresponding to the glass transition of the PLA polymer chains [44]. The Tg values for pure PLA increased from 65.45 to 70.90 °C for the PLA nanocomposite reinforced with 0.5 wt% GO-ZnO filler [44]. Furthermore, it was reported that this effect was caused by the large specific surface area of the GO sheets and the reinforcement effect of loaded ZnO nanoparticles on the GO surfaces, strong interfacial action was effectively created and the mobility of PLA chains was reduced [44].

4 Conclusion

The characterization of hybrid nanocomposites is fundamental to obtain important information on these materials, such as: (1) the hybrid filler distribution in the polymer matrix, (2) the effect of the filler surface modification on the filler dispersion and composite properties, (3) interactions of the hybrid filler with the polymer chains, (4) changes in the process parameters on the resulting morphology and properties, (5) broad range of properties to establish potential applications of nanocomposites. This chapter has provided the advances on recent characterization techniques for the nanocomposites specifically prepared by the incorporation of G-NP as hybrid fillers.

Major categories of hybrid fillers and nanocomposites based on G and NP were also briefly summarized in their preparation and proposed chemical structures. The exceptional morphological, chemical, thermal, and mechanical properties demonstrated for hybrids of G-NP make of them an excellent candidate for strengthening nanocomposites. It is also worth noting that different G-NP hybrid fillers influence high specific properties such as mechanical and thermal properties of the polymeric matrix, but how effective the influence is based solely on their degree of dispersion within the matrix because agglomeration of the hybrid nanofillers significantly reduces or causes more detrimental impact on the hybrid nanocomposite.

The most significant characterization techniques in this field of research were reviewed and the relevant literature existing for G-NP based polymer nanocomposites was highlighted. Hence, attention was given to the numerous methods of analysis in the available literature such as the microscopy techniques SEM, TEM, HRTEM and AFM, spectroscope technologies (FTIR, UV-vis and Raman), X-ray related analysis (XRD and XPS), Thermal analysis (TGA/DTG and DSC) and mechanical characterization methods.