Abstract

This paper evaluates the exergy of an integrated two-stage humidification dehumidification (HDH) desalination with the cooling system. The exergy analysis was carried out for the experimental data generated from a laboratory level experimental setup. The experimental results were developed by varying hot water flow rate and its temperature to the humidifiers and air preheaters. The exergetic efficiency, exergy destruction of each component and desalinated water and gained out ratio (GOR) of the system are evaluated for different experimental conditions. The system performance was evaluated with hot water is supplied at 100,125,150,200 L per hour to humidifiers at different inlet temperatures. Atmospheric air is supplied at a flow rate of 15 cubic metre per hour and maintained it constant throughout the experiments. The desalination yield increases with an increase in water flow rate and its temperature, whereas the cooling effect is observed a decreasing trend. The exergy efficiency in air preheaters, humidifiers and dehumidifiers was observed to be 20–30%, 70–90%, and 30–60%, respectively. Total desalinated water yield of 1.2–1.9 kg per hour is obtained with a GOR of 0.7–1.6 is from the integrated system. Air cooling of 0.1–0.25 kW is observed from the system for the mentioned flow rate of air and hot saline water.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The scarcity of fresh water due to natural and unnatural actions is imminent. Water is a primary resource which is used in occupations of huge and varying spectrum. Water is a necessary resource for humans and is taken for granted since Earth seems to have it in excess. Desalination is a process of removing the salts and certain minerals from the sea water making the product of the process usable. There are different methods of performing desalination. Here, the principle of humidification and dehumidification is used to obtain desalinated water. This project aims on conducting an exergy analysis on two-stage HDH desalination system with an integrated cooling system.

The irreversibility analysis is applied to HDH desalination system to identify the irreversibility prone areas. This observation was further used to improve cycles and components individually. The system can lead to peak performance by diminishing the specific irreversibility [1]. Thermodynamic studies by applying second law to evaluate minimum work requirement for dehumidification process in HDH desalination cycle assuming the dead state as dry ambient and final state as to be saturated air. At constant air temperature, rise in relative humidity by 10% can lead to increment in work by 2.4–32% based on the air temperatures. Similarly, at constant relative humidity, as the air temperature rises, minimum work required to condense the humid air increases [2]. The effect of different operating conditions and design parameters on HDH desalination system operating with solar water heater was studied and identified that the productivity rises with mass flow rate of air up to an optimal value then drops. The study depicts that double pass heater is better than single pass solar air heater and effect the performance of system as it increased the productivity of system by 10%. Rate of airflow also affects the productivity of system, with the increase in flow rate by 200% productivity rises to 400% increment [3]. The characteristics of HDH desalination system as a function of flow rate of water and air, temperature of hot water and temperature of cooling water were studied [4]. The study reveals water temperature plays a major role in output water production and high water yield can be achieved by increase of air flow rate and reduced cooling fluid temperature. A source and sink HDH desalination model to identify the exergy losses was developed by [5]. Study reveals that the highest irreversibility was determined in the heater, further the investigation tells that for a HDH process, exergy destruction of system is not affected by phenomena of mass transfer. Higher temperature part of system plays an immense role in exergy destruction.

A two-stage HDH desalination system with cooling system integration was designed, developed and carried out experiments by [6,7,8,9,10,11]. They carried out thermodynamic, simulation and experimental studies for the maximization of energy utilization. Studies reveal that the degree of humidification depends on the effectiveness humidifier, first law efficiency and hot water inlet temperature. Desalinated water yield depends on the temperature of cooling water circulated in dehumidifier. Approximately 1.5 LPH of fresh water and 150–200 W of cooling effect with an EUF of 0.33 and 0.58 was observed for plant and cycle respectively. Exergy analysis on solar multi-effect HDH desalination process was carried out by [12] and studies reveal that the solar collector has minimum exergy efficiency. To enhance fresh water output, the energy and exergy efficiency should be improved and rejected water should be reused to obtain fresh water. Thermodynamic analysis of various psychrometric processes was carried out and was concluded that second law efficiency is a function of mass flow rate, temperature and relative humidity of air [13]. Experimental studies were carried out to enhance the productivity of desalinated water by using various type of inserts in the air pre heater and different packing materials in the humidifier. Energy and exergy analysis was conducted to determine the EUF and compare the various changes been made in components. The improved system was able to develop 45% increase in water yield when compared to conventional system. It was observed that exergy efficiency increases with higher turbulence. Using twisted tape in air heater and gunny bags in the humidifier resulted in maximum obtained efficiency. In the modified system energy efficiency jumped from 20 to 44% and exergy efficiency from 15 to 38% [14].

The effect of various operating conditions on the performance of solar HDH desalination system was investigated experimentally. The results that by increasing the feed water mass flow rate, productivity of the system can be increased. However, air mass flow rate does not have any major effect on the productivity of the system and double pass solar air heater plays a key role and productivity was decreased by 15% without solar air heater [15]. Energy and exergy analysis was carried out on a HDH solar desalination system and found that maximum energy and exergy efficiency was obtained as 31.54% and 1.87% respectively with fresh water production of 1.11 kg/h [16]. Various methods of exploiting exergy as an influential tool for the generation of better energy strategy for various applications were described [17]. Different thermodynamic studies on HDH cycle was studied to improve the performance. These include vapour compression cycles, multi-extraction cycles and multi-pressure cycles. On the basis of study, the use of novel air heater to increase the efficiency and usage of vacuum operations was recommended [18].

Exergy analysis is generally carried out to make the thermal system more economic in terms of available energy. The losses in exergy flow also known as exergy destruction is responsible for irreversibility occurrence associated with heat addition processes and finite temperature variations. Thus, this analysis of available energy or exergy plays an inevitable role in determination of losses in energy system and later in refining the outputs in components.

2 Methodology

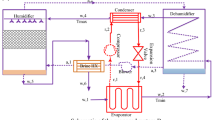

The line diagram of the proposed integrated plant with different components is shown in Fig. 1. A rotameter is provided at the inlets of the components to verify the flowrate is near the supposed value or not. Rotameter is used to measure the flowrates of hot water to air preheater (APH)s, circulating water and chilled water to dehumidifiers and constant flow rates of 1150, 300 and 125 L/h is maintained to the respective devices. Similarly, air flow rate was kept constant at 15 m3/h. As this a study for determining the variation in the exergetic and performance parameters with respect to varying hot water supply rate as well as inlet water temperature to the humidifiers in the systems, rotameters were utilized to maintain the flow rates at 100, 125, 150 and 200 L/h at different instances of time to humidifiers. The inlet temperatures considered are at 46, 48 and 51 ˚C.

Figure 1 emphasizes on the experimental setup. The water is heated using solar flat plate collector. The heated water is supplied to APHs and humidifier for obvious purposes. The heated water flow rate for both the preheaters are kept constant and is kept variable for both the humidifiers. The air from the atmosphere is passed to APH with the help of a blower in order to maintain a constant air flow rate. The air flowing through preheater undergoes sensible heating i.e. rise in temperature of air without any changes in specific humidity. This decreases the heating load for humidifier. The hot water is sprayed from the top side of the humidifier while preheated air enters from below. This increases the humidity of air. The humidified air is then passed through water cooled dehumidifier. This leads to the end of first stage of the HDH system. Similar procedure is followed as above in second stage except it uses chilled water from a water cooler. After going through the second dehumidifier, distilled water is obtained at the bottom of dehumidifier and the chilled air can be used for centralized air conditioning in hotter environment.

The following formulae were used to evaluate different parameters. Mass of dry air is to be considered for exergy balancing of components. The estimation of mass of dry air can be done by the following equation:

The air flows through the annular tube heat exchanger APH and gains heat via conduction and forced convection from the hot water coming heated up by solar flat plat collector but there is mass exchange involved in this process as it is indirect heat exchanging process. So, inlet and outlet mass flow rate of dry air in the APH is similar.

The mass of water vapour absorbed in the humidifiers by the air stream is as follows:

The addition of water vapour leads to change in the humidity ratio of the air stream passing out of the humidifier as well as the mass of the stream.

The above equations are used to obtain the mass of condensate in each stage. The motive of preheater is to increase the absorption capacity of air before undergoing the humidification. The air stream undergoes only sensible heating, hence there is no change in the humidity ratio of the air leaving the preheater.

The above equations signify the heat transferred by the hot stream from the collector to the atmospheric air passing through the APHs.

The heating of air in humidifiers can be negligible. The cooling offered by the cooling water in respective dehumidifiers can be given below.

Exergy is the maximum amount of usable energy in a stream with reference to the environment as the dead state, that is, available energy. The specific exergy of a stream at a given point, neglecting the mechanical and chemical oriented terms can be expressed as below:

The following equations are used in determining the irreversibility of each component from each stage of the desalination system:

Exergy Efficiency is an entity that can be used to demonstrate the degree of efficiency of a transformation process of a type of energy to another. In order to determine such efficiencies, the following equations were used [17]:

Gained Output Ratio (GOR) a commonly used performance parameter for evaluating a desalination system is expressed by;

The GOR of each stage of the HDH system can be estimated from the above equation is used to compare the performance of each dehumidifier. Effect of cooling is seen via this performance parameter.

3 Results and Discussion

Exergy destruction, exergy efficiency, stage-wise GOR comparison and total yield comparison among the stages of the system are estimated in this study. Highest irreversibility was observed during sensible heating process, while humidification and dehumidification process had lowest, and humidification being the least. Hence exergy destruction for APHs at various configurations was studied.

Figure 2 show the exergy destruction in APHs for two stages has similar trend except for 100 LPH and 48 ˚C. The exergy destruction increases linearly with raise in inlet water temperature for 100 and 150 LPH flowrate, while for 200 LPH it decreases. This would be due to increased heat loss to ambient.

The variation of exergy efficiency of 1st and 2nd stage humidifiers is shown in Fig. 3. It is observed that efficiency of humidifier 1st stage remains constant but tends to slightly increase at higher inlet temperature of hot water except for 150 LPH configuration. In humidifier 2nd stage exergy efficiency increases with inlet water temperature having lowest for 100 LPH. However, decreasing trend was observed for 125 LPH. It can be concluded that exergy efficiency of humidifier increases with increase in temperature and flow rate of water with 2nd stage acquiring higher exergetic efficiency than 1st stage humidifier. It is observed that highest efficiency of 80 and 90% was observed at 200 LPH flow rate and 51 ˚C inlet temperature of water.

Variation of exergy efficiency of 1st and 2nd stage dehumidifiers at different inlet hot water temperature is shown in Fig. 4. Exergetic efficiency decrease with increase in inlet hot water temperature and decrease as hot water flowrate increase. However, at dehumidifier second stage, efficiency increases with hot water inlet temperature and flowrate. Best configuration for first stage dehumidifier is observed for 100 LPH and 46 ˚C with exergy efficiency of 47% while for second stage, best condition is noted for 200 LPH and 51 ˚C with an efficiency of 55%.

Figure 5a shows the fresh water yield obtained for the two stages of dehumidifier, it can be concluded that in second stage of the HDH system is always higher than the first stage of the system. Hence, cooling effect does increase with the yield of the respective stages. At 48 ˚C, the total yield decreases irrespective of inlet hot water flow rate and an increase with increase in temperature. Highest yield is obtained for 125 LPH at 51 ˚C of 1.9 kg/h at 200 LPH and 51 ˚C with second stage being the better. Figure 5b shows the GOR of the two-stage HDH desalination system. Considering the system GOR for the two stages, second stage has lower value than first stage in all the configurations considered in this study. For achieving higher performance, low flowrate and higher inlet water temperature to humidifier are suggested for first and second stage, respectively, with two-stage humidifier yielding better performance.

4 Conclusions

Exergy studies were carried out on an integrated two-stage HDH desalination with the cooling system is analyzed in this study. It is observed that Exergy destruction during sensible heating reduces with decreasing inlet hot water temperature. By reducing hot water inlet temperature, exergetic efficiency of dehumidifier as well as GOR of the system can increase but humidifier’s exergetic efficiency will decrease. Therefore, increasing dehumidifier efficiency will increase GOR of the system. The configuration of 200 LPH and 51 ˚C can be said as the best configuration in terms of exergetic efficiency, 125 LPH and 51 ˚C for higher yield of condensate and 150 LPH and 46 ˚C configuration for lesser irreversibility during sensible heating.

Abbreviations

- LPH:

-

Liters per hour

- ν:

-

Humidity ratio

- H:

-

Heat supplied/absorbed

- χ:

-

Exergy

- Ω:

-

Exergy destroyed

- П:

-

Exergy efficiency

- hw:

-

Hot water

- wv:

-

Water vapour

- cw:

-

Circulating water

- chw:

-

Chilled water

- sp1, sp2:

-

Hot water absorbed in humidifier1, humidifier2

- ds1, ds2:

-

Desalinated water from dehumidifier1, dehumidifier2

References

Mistry KH, Zubair SM (2010) Effect of entropy generation on the performance of humidification-dehumidification desalination cycles. Int J Therm Sci 49(9):1837–1847

Alhazmy MM (2007) Minimum work requirement for water production in humidification—dehumidification desalination cycle. Desalination 214(1–3):102–111

Tiwari A, Sachdev T (2012) Conceptual analysis of desalination system working on humidify and dehumidify technique using solar air heater. In: International conference on mechanical and robotics engineering (ICMRE’ 2012) May 26–27, 2012 Phuket

Al-Enezi G, Ettouney H, Fawzy N (2006) Low temperature humidification dehumidification desalination process. Energy Convers Manage 47(4):470–484

Ashrafizadeh SA, Amidpour M (2012) Exergy analysis of humidification–dehumidification desalination systems using driving forces concept. Desalination 285:108–116

Chiranjeevi C, Srinivas T (2014) Combined two stage desalination and cooling plant. Desalination 345:56–63

Chiranjeevi C, Srinivas T (2015) Experimental and simulation studies on two stage humidification–dehumidification desalination and cooling plant. Desalination 376:9–16

Chiranjeevi C, Srinivas T (2016) Influence of vapor absorption cooling on humidification-dehumidification (HDH) desalination. Alexandria Eng J 55(3):1961–1967

Marale SC, Chiranjeevi TS, ThundilKaruppa Raj R (2017) Experimental and computational fluid dynamics studies on dehumidifier in a combined cooling and desalination plant. J Thermal Sci Eng Appl 9:1–10

Chiranjeevi C, Srinivas T (2017) Augmented desalination with cooling integration. Int J Refrig 80:106–119

Chiranjeevi C, Srinivas T, Shankar R (2019) Experimental investigation on a hybrid desalination and cooling unit using humidification-dehumidification technique. Desalin Water Treatment 156:148–160

Hou S, Zeng D, Ye S, Zhang H (2007) Exergy analysis of the solar multi-effect humidification–dehumidification desalination process. Desalination 203(1–3):403–409

Qureshi BA, Zubair SM (2003) Application of exergy analysis to various psychrometric processes. Int J Energy Res 27(12):1079–1094

Muthusamy C, Srithar K (2015) Energy and exergy analysis for a humidification–dehumidification desalination system integrated with multiple inserts. Desalination 367:49–59

Yamalı C, Solmus İ (2008) A solar desalination system using humidification–dehumidification process: experimental study and comparison with the theoretical results. Desalination 220(1–3):538–551

Deniz E, Çınar S (2016) Energy, exergy, economic and environmental (4E) analysis of a solar desalination system with humidification-dehumidification. Energy Convers Manage 126:12–19

Dincer I, Rosen MA (2012) Exergy: energy, environment and sustainable development. Newnes

Narayan GP, Sharqawy MH, John H, Lienhard V, Zubair SM (2010) Thermodynamic analysis of humidification dehumidification desalination cycles. Desalin Water Treatment 16(1–3):339–353

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chiranjeevi, C., Raja Sekhar, Y., Natarajan, M., Srinivas, T., Hashemian, M., Aditya, V. (2021). Exergy Studies on a Hybrid Desalination and Cooling Plant. In: Palanisamy, M., Ramalingam, V., Sivalingam, M. (eds) Theoretical, Computational, and Experimental Solutions to Thermo-Fluid Systems. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-4165-4_26

Download citation

DOI: https://doi.org/10.1007/978-981-33-4165-4_26

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4164-7

Online ISBN: 978-981-33-4165-4

eBook Packages: EngineeringEngineering (R0)