Abstract

Smoke is the real threat in a fire in an enclosed, underground parking garage. A model of the smoke movement in a basement was simulated using Fire Dynamics Simulator (FDS) 6.0 software. In this paper, the study used a basement model of 60 m (length) × 30 m (width) × 13 m (height) and has three typical floors. Smoke ventilation shafts were provided for the basement. The required ventilation was based on the air changing ten times per hour. Smoke modeling was investigated under different fire scenarios. Well-controlled liquid pool fire with a heat release rate (HRR) of 5, 10, 15, and 20 MW was used as an input parameter. The following parameters were varied: the location of the fire, the presence or absence of sprinklers, the presence or absence of a smoke extraction system, the variation of the quantity of makeup air to be introduced to basement, and the presence or absence of a jet fan and ducting. Simulation shows that the provision of sprinklers is very important to reduce the heat release rate. The ventilation strategy through a mechanical exhaust fans and makeup air fans can be applied to make the time for smoke removal faster. When makeup air is less, the heat release rates from the design fire more than 5 MW cause high temperature in the fire compartment which may cause fatal injury when exposed to human skin. Combination of ventilation fan and jet fan shows good performance to make smoke removal time shorter.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Even fire in the basement is rare event and this fire may initiate in numerous ways. Recently an incident of huge fire has destroyed up to 1400 vehicles in multistory car park in Liverpool during the celebration of new year 2018. Automobile parking garages can be either enclosed or partially opened. Unlike car park which is constructed above ground, underground parking garages generally provide enclosed conditions. A large amount of smoke is generated, which leads to unpredictable smoke movement and poor conditions for evacuation.

In the previous study, Chow [1] divides underground fire protection systems into mechanical ventilation systems and fire protection systems. The study concluded that smoke movement is critical and is subject to failure because most design engineers do not have a proper understanding of what happens when a fire breaks out.

It is commonly accepted that full-scale experiments are the best way to obtain valuable information, for example, a set of various past experimental studies of single-vehicle fires which were done by [2,3,4]. The main objective of the study was to determine heat release rate (HRR) of vehicle fires in enclosed basement fires, which focus on smoke movement [5, 6] and fire development [7]. A reference curve of heat release rate (HRR) for one burning car and wave of burning cars is discussed in the Profil ARBED Recherches [8].

Furthermore, Horvarth et al. [9] also performed a full-scale test and a reduced-scale test of parking garages on fire using different heat release values (500–4000 kW) with different inlet air velocities (0.3–2 m/s) and derived the empirical critical velocity based on the heat rate. It can be summarized from the study that the full-scale experiments on modern cars revealed high-fire HRR values for fires, which exceed 16 MW when three cars are on fire.

Automobile parking garages can be either enclosed or partially opened. Partially open parking garages are generally above ground with open sides. Unlike natural ventilation, the air circulation to the outside is not freely available in underground. In this case, the solution comprises of vertical stacks which are designed to transport fumes and smoke being extracted to external atmosphere. ANSI/AHSRAE 62.1 [10, 11] recommended the flat rate of ventilation rate 0.0075 m3/(s m2) or equal to 6 ACH for enclosed parking garages. In addition, National Fire Protection Association (NFPA 88A) [12] recommended the minimum 0.005 m3/(s m2) and SNI 03-6572-2001 [13] proposed 6 ACH. While most of the mentioned investigations were done experimentally, Tilley et al. [14] conducted a large set (more than 350) of computational fluid dynamics (CFD) simulations have been used as “numerical experiments.” A full-scale experiment on car park fires with jet fan ventilation was done by Deckers et al. [15] reveals that the impact of the exact position of the extraction fans on the smoke pattern is small when the extraction fans are not close to the fire source. Many of the studies discussed previously are using a model for a single-story underground parking garage, however, multistory basements are also important to be considered under different fire scenarios. The study here takes the different scenarios from the study which is done recently in [16].

2 Setup of the Simulation

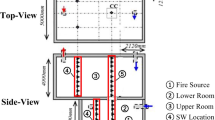

In the configuration of simulation, as shown in Fig. 1, the underground parking garage has three floors below ground containing the fire source and an array of sprinklers. The model’s size is 64 m (length) × 30 m (width) × 13 m (height). Intake and exhaust ventilation shafts that are 2 m wide are provided at the left and right sides of the basement. For expedience of calculation, the model’s domain is deliberately set to discrete meshes of size 50 cm × 50 cm × 25 cm in all simulations, which results in 199,680 cells in this case. The simulation is performed using Fire Dynamics Simulator (FDS) V.6. FDS is a computer program that solves the Large Eddy Simulation (LES) problems in Navier–Stokes equation for low-speed fluid flow, thermally driven flow in heat transfer for the growth and development of fire. Navier–Stokes equation can be expressed [17]:

The dimensions of the pool fire were 2 m × 2 m. Sprinklers were added above the fire source and separated to such a distance that each sprinkler covered a protection area of 12 m2. Each sprinkler is also operated at 0.5 bar pressure, working temperature of 56 °C, and had a K-value of 80, which met the conditions for the category of ordinary hazard by NFPA 13 [18]. Three sprinklers are then separated from each other by 4 m in groups as indicated by the blue color dots in Fig. 1. Table 1 list down the different Fire Scenario (FS) to be observed. Sprinklers are located 2.5 m above the fire source. When the fires were ignited, the heat spreads into the adjacent areas, sprinkler heads are activated. In this simulation, the sprinklers are operated quickly for all intentional fire scenarios. The sizing of a fan is based on the air changing ten times per hour for the basement during the fire. A combination of smoke extract and makeup air fan is applied.

Half of the basement area is treated as an extraction zone and the other half is the makeup air zone. The position of the mechanical fans can be seen in Fig. 1. Figure 2 indicates the position of thermocouples and beam detectors as measurement devices. The provision of jet fans may result in migration of smoke faster than conventional ventilation without jet fans. Jet fans are necessary because of the advantages they provide through eliminating the air distribution ductwork within the parking garages. Therefore, in order to push air from air the intake side to the negative pressure smoke extract side, the parking garage models contain three rows of jet fans. Each row consists of five jet fan units, each with a capacity of 2.0 m3/s. Ducting as the media of smoke exhaust in the extraction zone area is observed in FS 9 as shown in Fig. 3. The ducts are divided into higher and lower level extract. It is generally accepted that the system should be designed to run in two parts; commonly, each part is arranged so that 50% of the outlets are at high levels and 50% are at low levels.

The fire load is simulated as pool fire and chosen for HRR maximum of 5, 10, 15, and 20 MW in 4 m2 fire pool. In addition, another size of fire pool is set 1 m2 for 2 MW. Fire growth is ramped in time. The purpose of the fire ramp is to meet the actual fire growth during the experiment of car burning done by [8] at which fire reaches the peak at T = 15–20 min. Neither fire spread nor car fires are involved in the simulation.

3 Result and Discussion

There are neither sprinklers nor mechanical ventilation systems are provided in the Fire Scenario 1 (FS 1). The fire started at the center in basement 3. Once significant fire growth begins, these fires have the potential to spread throughout the other floors and develop into extremely large fire events beyond the capability of arriving fire departments. Opening in ramps also allows smoke to fill basement 1 and basement 2. In the period of less than 1400 s, basement 1 is fully contained with smoke and most of the basement 2 is covered as well. Furthermore, the case would be worse when the fire load is increased. When the fire load is 5, 10, 15, and 20 MW, simulation shows that basement 3 is faster totally filled with smoke in less than 500, 300, 120, and 60 s, respectively. The whole basement will be covered with smoke in 1800, 1400, 1200, and 900 s for 5, 10, 15, and 20 MW design fire, respectively.

In the Fire Scenario 2 (FS 2), fire is started in the center of basement 2. Similar to the FS 1, there is no active fire protection system is provided such as sprinkler and mechanical fan. This can be seen in Fig. 4 that smoke is naturally moved upward to leave the basement with a low possibility of smoke to travel downward.

3.1 Effect of the Variation in the Design Fire Load to the Obscuration of Beam Detector

When a fire ignites in this location and fire growth begins, the sprinkler systems are able to operate quickly as the sprinkler head is exposed to temperature at 57 °C. The fire may ignite for a moment and quickly extinguished. The fire growth is suppressed and the maximum heat release will not be achieved. Activation of sprinklers causes reduction in HRR when fire starts to decay. Figure 5 shows the extinguishing period of design fire load of 5, 10, 15, and 20 MW in FS 3. Fire is considered to be successfully extinguished when the fire heat release rate is zero. In addition, after the flaming fire growth, the smoke would spread to the surrounding area and then exit the basement through a ramp. The time needs to clear the basement from smoke is shown in Fig. 6 denoted by 0% obscuration. This means that when smoke filled the basement, the obscuration of beam detector is raised to 100% and reduces to 0% when smoke is cleared. Obscuration is the unit of measurement where smoke has an effect on visibility which is expressed in %/foot.

3.2 Effect of the Variation of the Quantity of Makeup Airflow Rate

In the following scenario, smoke exhaust and makeup air fans are added. Total smoke exhaust air is 15 m3/s served by two smoke extract fan at each 7.5 m3/s. The effect of variation of supply air introduced to basement is observed through FS 3 (equal capacity of smoke makeup air and smoke extract fan), FS 5 (makeup air fan is 50% of the total capacity of the exhaust fan or underventilated fire), FS 6 (capacity of the intake fan is 130% of the total capacity of extract fan/overventilated fire), and FS 7 (makeup air is turned off).

Figure 7 shows the effect of maximum temperature reaches in the basement over the variation of design fire load of 5 and 15 MW. The graphs show that the maximum room temperature is achieved in the case of overventilated fire compared to underventilated fire. Simulation shows that the maximum temperature is read by THCP 5. Having design fire load of 5 MW, the maximum room temperature of 73 °C is reached when the makeup air is totally turned off (FS 7) and 65 °C in case of overventilated case (FS 6). It is already the maximum temperature that human skin could be exposed without causing any harmful effect. Underventilated cases and higher fire load will result in higher room temperature. It is even worse when the fire design load is increased to 15 MW, the maximum room temperature is 160, and 130 °C in FS 7 and FS 6, respectively.

3.3 Effect of the Presence and Absence of Jet Fan Over the Smoke Clearance Time

Fire scenario 4 (FS 4) includes mechanical intake fan, exhaust fan, and series of jet fan in the simulation. Three rows of jet fans are installed in which every row consists of five unit jet fans. The airflow rate of each jet fan is 2 m3/s. However, intake air fan is turned off during fire in FS 8. Therefore, the smoke extract system involved only jet fan and smoke exhaust fan. Sprinklers and mechanical ventilation are activated during the fire mode as in the previous scenario. Simulation shows the assistance of jet fan (FS 4) cause the smoke to be extracted faster than without jet fans (FS 3). It is also shown in Fig. 8 that smoke is extracted longer compared to the scenario when intake fans are presented (FS 3 and FS 4) than without intake air fan run (FS 8).

3.4 Smoke Extract Using Ducting and Jet Fan

The simulation setup for Fire Scenario 9 is different from previous works. This scenario is also set for fire in the center of basement 3. Unlike the previous scenario, ducting is installed in the basement. Table 2 shows the setup specification of mechanical fans system. Figure 9 shows the temperature and obscuration overtime in Fire Scenario 9 with design fire load 5 MW and 10 MW. Ducting system is apparently effective during normal ventilation mode. However, during fire mode, smoke is likely to be dispersed in uni-direction which because the smoke is extracted longer than in the FS 3 where there is no ducting introduced to the basement.

4 Comparison to Full-Scale Experiment

This paper compares the full-scale experiment done by Deckers et al. [15] as seen in Fig. 10a using an experimental car park 28.6 m (length) × 30 m (width) × 3 m (height) using fire design load 4 MW. Fire originated in the middle of the room. Ventilation rate is set 200,000 m3/h. By plotting the car park into the plan of (x, y) coordinate system, few thermocouples are put in five rows from x-axis (as indicated by green dots in Fig. 12a in position X = 4.3 m; X = 9.3 m; X = 14.3 m; X = 19.3 m, X = 24.3 m. Ventilation controlled parameter is set 00000 when inlet opening is fully opened and MM0 if inlet opening is 80% obstructed and opening in the right side opened. In this paper, simulation using 00000 scenarios will be compared using design fire load 4 MW and extraction rate of 200.000 m3/h. The position of the thermocouples of the simulation model is shown in Fig. 10b.

Temperature measurement in full-scale model is done along y-axis at X = 4.3 and X = 24.3 (10 m distance from the fire source in x-axis). This is identic to the position of thermocouple in simulation model along y-axis at X = 19.5 m and X = 39.5 m. Another temperature measurement along y-axis at X = 9.3 m and X = 19.3 m is done as well in full-scale model. This is also identic to the temperature reading from simulation model in y-axis at X = 24.5 and X = 34.5. The comparison for the reading of temperature for full-scale experiment can be seen in Fig. 11 and simulation model in Fig. 12.

Full-scale experiment temperature profile at X = 4.3; X = 24.3 (a) and X = 9.3; X = 19.3 (b) [15]

5 Conclusion

When underground parking garage is not provided with active fire protection system, fire load more than 5 MW causes basement totally filled with smoke in less than 5 min. Water-based active fire protection sprinklers system is very critical to be provided for basement. It is also important to activate the mechanical fan system in another nonfire floor to avoid interfloor smoke migration. Provision of jet fans will cause smoke in the basement cleared faster. Underventilated fire because of lower quantity of makeup air introduced to the basement resulted in high temperature inside the fire compartment. The high temperature when exposed to human skin can cause severe injury for occupants in the basement.

References

Chow, W. K. (1998). On safety systems for underground car-parks. Tunneling and Underground Space Technology, 13(3), 281–287.

Mangs, J., & Keski-Rahkonen, O. (1994). Characterization of the fire behavior of a burning passenger car. Part II: Parameterization of measured rate of heat release rate. Fire Safety Journal, 23, 37–49.

Ship, M., & Spearpoint, M. (1995). Measurements of the severity of fire involving private vehicles. Fire and Materials, 19, 143–151.

Cheng, Y. P., & John, R. (2002). Experimental research of motorcar fire. Journal of China University of Mining and Technology, 31(6), 557–560.

Hwang, C. C., & Edwards, J. C. (2005). The critical ventilation velocity in tunnel fires—A computer simulation. Fire Safety Journal, 40, 213–244.

Vauquelin, O., & Telle, D. (2005). Definition and experimental evaluation of the smoke “confinement velocity” in tunnel fires. Fire Safety Journal, 40, 320–330.

Ingason, H., & Lonnemark, A. (2005). Heat release rates from heavy good vehicle trailer fires in tunnels. Fire Safety Journal, 40, 646–668.

Profil ARBED Researches. (1997). Development of Design Rules for Steel Structures Subjected to Natural Fires in Closed Car Parks.

Horvarth, I., Beeck, J. V., & Merci, B. (2013). Full-scale and reduced-scale tests on smoke movement in case of car park fire. Fire Safety Journal, 57, 35–43.

ASHRAE Handbook—Application 2015. American Standard of Heating, Ventilating and Air Conditioning Engineers, 1791—Tullie Circle NE, Atlanta, GA, 3029.

ANSI/ASHRAE Standard 62.1-2013 Ventilation for Acceptable Indoor Air Quality, 2013. American Standard of Heating, Ventilating and Air Conditioning Engineers, 1791—Tullie Circle NE, Atlanta, GA, 3029.

NFPA 88A Standard for Parking Structures. 2015, 1 Batterymarch Park, Quincy, MA, National Fire Protection Association.

SNI 03-6572-2001: Guidance for Ventilation and Air Conditioning Design, 2001. Standar Nasional Indonesia.

Tilley, N., Deckers, X., & Merci, B. (2012). CFD study of relation between ventilation velocity and smoke back-layering distance in large closed car parks. Fire Safety Journal, 48, 11–20.

Deckers, X., Haga, S., Settle, B., & Merci, B. (2013). Smoke control in case of fire in a large car park: Full-scale experiments. Fire Safety Journal, 57, 11–21.

Alianto, B., Astari, N., Nareshwara, D., & Nugroho, Y. S. (2017). Modeling of smoke control in underground parking garage. International Journal of Technology, 8(7), 1296–1305.

McGrattab, K., Hostika, S., McDermott, R., Flyod, J., Vanella, M., Weinschenk, C., & Overholt K. (2017). Fire dynamic simulator technical reference guide volume 1: Mathematical model. NIST Special Publication 1018-1, US Department of Commerce.

NFPA 13: Standard for the Installation of Sprinkler Systems. 2013, 1 Batterymarch Park, Quincy, MA, National Fire Protection Association.

Acknowledgements

The authors would like to thank Universitas Indonesia for the financial support through PITTA 2018 funding scheme with a contract number 2566/UN2.R3.1/HKP.05.00/2018.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Alianto, B., Nugroho, Y.S. (2020). Modeling of the Effect of Heat Release Rates on Fire Smoke Control in Multilevel Underground Parking Garage. In: Wu, GY., Tsai, KC., Chow, W.K. (eds) The Proceedings of 11th Asia-Oceania Symposium on Fire Science and Technology. AOSFST 2018. Springer, Singapore. https://doi.org/10.1007/978-981-32-9139-3_16

Download citation

DOI: https://doi.org/10.1007/978-981-32-9139-3_16

Publisher Name: Springer, Singapore

Print ISBN: 978-981-32-9138-6

Online ISBN: 978-981-32-9139-3

eBook Packages: EngineeringEngineering (R0)