Abstract

The mechanical smoke exhaust is as acknowledged as an effective smoke control manner by making use of some necessary exhaust facilities, also with more stability than natural exhaust. In this paper, the field model Fire Dynamic Simulator (FDS) with a combination of zone model Consolidate Fire and Smoke Transport (CFAST) were used to simulate the mechanical smoke exhaust in a loop corridor of the fire floor in a high-rise hotel, for the propose of evaluate fire safety of mechanical smoke exhaust. There were several factors under discussion, such as the arrangement of smoke vents, quantity of smoke vents, the volume of smoke exhaust, the position of the smoke vents and height of ceiling indoor. The conclusions were obtained as followed. When two exhaust vents were set symmetrically in the loop corridor, one of which was located nearby the fire room, the smoke exhausted better. The volume of smoke exhaust per unit area with 60 m3/h according to regulations could always ensure safety of smoke exhaust. The smoke exhausted worse within the corridor when ceiling height reduced. It was recommended that the lowest ceiling height limit should be provided in correlative regulation.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In high-rise building fires, mechanical exhaust was an effective and significant way for persons to evacuate, and was widely used in design. Specification states that “if there is no direct natural ventilation, or internal corridor with length of more than 20 m, or direct natural ventilation but internal corridor with the length of more than 60 m” [1], then the place should be set with mechanical exhaust facilities. When the building was on fire, the fire area produced large amounts of high-temperature flue gas and the pressure would be higher than in other areas, which averages about 10–l5 Pa, which in short term may reach about 35–40 Pa. The pressure differences and reading prompted the flue gas leakage through the gap of doors, windows, opening and pipe also through gap of the wall. Mechanical exhaust was an effective manner to exclude smoke in time. At the same time, causing the negative pressure, it could prevent the spread of the smoke to the security zone, creating the conditions of time and space for the evacuation.

Smoke control design in high-rise buildings usually used a combination of positive pressure air supply in the atria and stairwells, and mechanical exhaust in the corridor. In this paper, the field model Fire Dynamic Simulator (FDS) with a combination of zone model Consolidate Fire and Smoke Transport (CFAST) were used to simulate the mechanical smoke exhaust [2] in a loop corridor of the fire floor in a high-rise hotel, for the propose of evaluate fire safety of mechanical smoke exhaust.

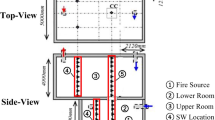

The general view of simulation model in 2D was represented in Fig. 10.1. The loop corridor was 60 m in length, and 1.8 m in width, with ceiling height of 2.5 m. There were two doors in the corridor, connected with atria, with the width 1.2 m and the height 2.1 m. The high-rise hotel was in urban district of Beijing, which had 30 floors and each floor height was 3 m. The fire room was on the 20th floor. Room 1 was on fire, with the fire source in corner.

The study showed that with the increase in the fire room door’s open size, the peak of HRR increased [1]. The corresponding smoke speed, temperature and concentration of the flue gas would also increase. After the fire, if a non-fire room door opened, it would save a certain amount of smoke. In this article, the condition of fire room with door fully open and non-fire room with door fully closed was simulated.

The door from corridor to atria was always closed, only opened for a short time for evacuation through the doors. According to provisions in GB50045-95, the door to atria should be kept at a wind speed of 0.7 m/s to block the intrusion of smoke when opening. When the door opened, the influx of air from atria to corridor would improve the pressure of lower layer air, which could accelerate the exhaust of the smoke. There were several factors that were considered in the simulation, as infiltration of doors and exhaust windows in bathroom, in order to maximize and reflect the real situation of the hotel building. The model was reasonable and simplified as shown in Fig. 10.2, also considering the limit of CFAST settings [2]. Relative size of opening and leakage were shown in Table 10.1.

There were several factors under analyzing, such as the arrangement of smoke vents, quantity of smoke vents, the volume of smoke exhaust, the position of the smoke vents and height of ceiling indoor. With intent of providing more accurate results, the loop corridor was divided into several regions [3], and contour vents were set between regions. These vents were set with the same dimensions of the length and height of corridor. There were 16 regions that were divided and named by c1, c2… c16. And c1, c3, c5… c15 were called access1 and c2, c4, c6… c16 were called access2. Height of smoke layer interface is used to evaluate the effect of smoke exhaust, which was less than 1.5 m, considered to be safe.

Fire development in fire room was simulated by FDS. Heat release rate (HRR) was set as Fig. 10.3 by calculations of FDS, which was transmitted to CFAST. Smoke spread was simulated by CFAST. The simulation time was 1,200 s. Height of smoke layer interface was used to evaluate the effect of smoke exhaust, with the limit of 1.5 m. Different schemes were set (in Fig. 10.4), the exhaust vent was located in the ceiling at the height of 2.5 m and exhaust system parameter settings are shown in Table 10.2.

2 Analyzing Simulation Results

2.1 Impact of Exhaust Vents Arrangement

The simulations were made by two schemes, as shown in Fig. 10.4. In the first scheme, the exhaust vents were set further away from the entrance to atria, than the second scheme. Exhaust volume per unit area was set with 60 m3/h. The results of two schemes simulated were represented in Fig. 10.5.

As seen in the results, in the two exhaust schemes, the smoke layer interface could maintain a safe altitude above, which could ensure the safe evacuation. Combined with the architectural pattern demonstrable, the first scheme was better than the second. In the first scheme, exhaust vents were located away from the exits to the atria, which benefited cooperation of the pressurization system in atria. Especially when the atria door was opened in a short time for the evacuation of staff, it was easy to form a reasonable airflow organization. The pressure distribution of the corridor along the persons’ evacuation increased. Control of the smoke concentration near the exits was conducive to the evacuation.

In addition, it was found in the domestic experiments that, when the mechanical exhaust system was running, there would be smoke gathered in the exhaust vents, seriously affecting people to identify safe evacuation export position, and also affecting people who went through the security exit. Therefore, the exhaust vents are supposed to be designed as far as possible from the evacuation exit.

2.2 Impact of Smoke Exhaust Volume

The simulations were made under scheme1, using exhaust volume per unit area set with 40 m3/h and 80 m3/h separately. The resulting curves are shown in Fig. 10.6. Compared with the two situations, when the smoke exhaust volume was small, a large number of flue gas gathered in the corridor, and smoke layer interface within the entire corridor was relatively low. Under the exhaust volume per unit area set with 40 m3/h, smoke layer could be reduced to close to floor. Compared with the curves in Fig. 10.5 which set exhaust volume per unit area as 60 m3/h, when it increased to 80 m3/h, the smoke layer interface height of access1 increased little, of which smoke layer interface was located between 1.5 and 2.0 m height. In access2, as the smoke exhaust volume added, smoke effect is improved obviously. Smoke layer interface of access2 could be increased to more than 1.9 m.

2.3 Impact of Location of Exhaust Vents

The simulations were made under scheme1 with exhaust volume per unit area as 60 m3/h, with the exhaust vents set in the ceiling or in side wall. When vents were in the side wall, middle point of the vents was 2.0 m in height, and the results were shown in Fig. 10.7. As seen in curves, whether the vents set in ceiling or in side wall, smoke exhaust effect of the two cases could satisfy people’s evacuation safety conditions. It was because, in scheme1, the vents were set symmetrically. One of them was nearby the fire room, and another vent was located in the area that was far away from the fire room. Though the area was far away from the fire room, the smoke layer interface would reduce because the smoke temperature was brought down by cooling. Due to the pumping action of the exhaust vents, the smoke layer interface was able to maintain a certain height. Mechanical exhaust affects the entire corridor.

2.4 Impact of Ceiling Height

There were always a large number of lines, water pipes, duct laying in the ceiling of corridor, which lead to the construction of ceiling at low altitudes, maybe less than 2.5 m. This would greatly affect much of the mechanical smoke exhaust. The simulations were made by changing the height of the ceiling, with a lower height of 2.2 m. The exhaust vents were set in ceiling and side wall, with the exhaust volume per unit area as 60 m3/h. When the vents were in the side wall, middle point of the vents was 1.8 m in height. The simulation results are shown in Figs. 10.8, 10.9.

In contrast, when the ceiling height was 2.2 m and the vents were in ceiling, smoke layer interface height of the regional decline overall in the corridor. Smoke layer interface of most areas of access1 had been reduced to between 1.3 and 1.5 m. Compared with the results of 2.5 m of ceiling height, it was found that after reducing the ceiling height, the evacuation of people in the building would be threatened. In Fig. 10.9, the vents were in the side wall and the smoke layer height of most of the area within the corridor fell below 1.5 m, mainly distributed in the 1.2–1.5 m, which was difficult to guarantee the safe evacuation. Smoke exhaust vents in sidewall should not be used at this time. Therefore, to recommend to the GB50045-95, the exhaust vents location should require the height of vents and ceiling top be minimum, to ensure the effective operation of the mechanical exhaust system.

3 Conclusions

The conclusions were obtained as followed. When two exhaust vents were set symmetrically in the loop corridor, one of which was located nearby the fire room, the smoke exhausted better. The volume of smoke exhaust per unit area with 60 m3/h according to regulations always could ensure safety of smoke exhaust. There would be no further effect with more volume. With the smoke exhaust vents in ceiling, effect of mechanical exhaust would be better than with vents in slide wall. The smoke exhausted worse within the corridor when ceiling height reduced. It was recommended that the ceiling lowest height limit should be provided in correlative regulation.

References

Qiu X (2003) Fire numerical simulation in high-rise building. Dissertation for the master degree. Harbin Institute of Technology, Harbin

Jones WW, Forney GP, Peacock RD et al (2009) CFAST: consolidated model of fire growth and smoke transport (Version 6). Technical reference guide, vol 1026, NIST SP, pp 13–17

Long-hua HU, Ran HUO, Bin YAO et al (2003) Preliminary study on engineering method to predict smoke movement in very long-narrow spaces with two closing ends. Fire Saf Sci 12(1):36–39

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Shi, W., Gao, F. (2014). Numerical Simulation and Evaluation of Mechanical Smoke Exhaust in a Loop Corridor of a High-Rise Hotel. In: Li, A., Zhu, Y., Li, Y. (eds) Proceedings of the 8th International Symposium on Heating, Ventilation and Air Conditioning. Lecture Notes in Electrical Engineering, vol 263. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-39578-9_10

Download citation

DOI: https://doi.org/10.1007/978-3-642-39578-9_10

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-39577-2

Online ISBN: 978-3-642-39578-9

eBook Packages: EngineeringEngineering (R0)