Abstract

Clothing comfort based on fabric mechanical properties was studied by making a comparison between subjective and objective evaluation. The subjective evaluation was done by conducting surveys to 100 working female respondents. The objective evaluation was done by testing the fabric mechanical properties which included drapability, sweat absorbency, stiffness and air permeability. The study aimed to find a correlation on the relationship between human’s comfort interpretation based on hand touch and laboratory testing using mechanical action related to the fabric properties. It was found that good correlations of R 2 values were obtained between human and machine interpretation for stiffness, sweat absorbency and air permeability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Clothing

- Comfort

- Subjective evaluation

- Objective evaluation

- Drapability

- Sweat absorbency

- Stiffness

- Air permeability

Introduction

Comfort is one of the important characteristics needed by consumers when buying cloths. The feeling of comfort in clothing is related between physical, psychological and sensorial perception [1]. Fabric comfort can be classified into three groups which include psychological, tactile and thermal [2]. Psychological comfort is not related with the fabric properties but more on the garment style, proper fit, fashion and suitability for the occasion. A tactile factor is related to the skin in contact with the fabrics or how the wearer feels when the skin touches the fabric [3]. Factors attributing to tactile property include types of fibre, yarn structure, fabric type, dimension characteristics, tensile properties, stiffness, elasticity and surface morphology or surface roughness. Fabric finishing also contributes to the comfort aspect especially in the usage of chemicals and types of finishing treatment [4].

Thermal property is determined by the movement of air, heat and moisture in and out of the fabrics [4]. Thermal property is influenced by the type of fibre, yarn, fabric and finishes [5]. Fabrics play an important role in maintaining the heat balance as it modifies the heat loss from the skin and at the same time altering the moisture loss from the skin [6].

The comfort property of fabrics has been the subject of interest for many researchers [7–9]. Unfortunately, limited studies were done on human’s perspective towards fabric comfort. The human perspective is very important in decision-making during purchasing of their outfit [10].

Because of that, the main aim of the study is to investigate whether the human perspective is related and comparative or significantly different with the result of laboratory testing. The fabric comfort properties that were investigated include drapability, sweat absorbency, stiffness and air permeability.

Materials and Methods

Fabrics

Five woven fabrics with plain weave structures of rayon, cotton, polyester (plain and satin weave) and polyester/cotton fabrics were used. The fabrics were of light weight to medium weight in the range of 80–180 gm−2. The fabrics were divided into two parts: one part for subjective evaluation or survey and the other part for objective evaluation or laboratory testing. All the samples used were white in colour since the purpose of this study was to know the human’s perception on the fabrics based on texture and fabric feel which should not be influenced by colour psychology.

Objective Evaluation

Drapability

The Cusick drape tester was used in order to determine the drape coefficient of the fabric. The fabric was cut into circular samples using a 30 cm diameter template cutter. Each sample was placed in the centre pin of the drapability tester disk. Once the light on the tester was switched on, the shadow of the fabric drape appeared on the drape paper. The resultant shadow was traced and the shape of the shadow on the drape paper was cut. The cut-out of the draping paper was weighted and the value was divided with the uncut draping paper to get the drape coefficient. All the steps were repeated three times for the front and back surfaces for each sample and the average reading was calculated.

Sweat Absorbency

The sweat absorbency test was done by determining the time a drop of sweat flattened onto the surface of the fabric. Alkaline sweat was prepared by mixing 0.1 g of l-histidine monohydrochloride mono-hydrate, 1 g sodium chloride, 1 g crystallized disodium hydrogen orthophosphate, 200 ml distilled water and 0.1 N of sodium hydroxide together. A sample of fabric was placed on top of the beaker without any support at the centre of the sample. Then a drop of sweat was dropped in a distance of 1 cm from the top of the fabric. The time for the sweat to be fully flattened was taken using a stop watch.

Stiffness

All the samples were prepared for warps and weft direction with three replicates. The samples were cut according to the test template. A sample was then placed on the sliding board with the edge of the sample at the edge of the dotted point. The template was placed on the top of the sample and slides until the edge of the sample touched the black line. The readings of the edge touching the black line were taken four times and the average was calculated. Both edges of each sample were tested.

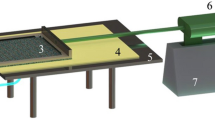

Air Permeability

A sample was firmly clamped in the rig of the selected test head or area. The machine was operated through a control panel that allows the operators to set the parameters needed. 20 cm2 of testing area was chosen because it is the recommended testing area for woven fabric. The machine determined the resistance of the sample to the passage of airflow under constant preset air pressure.

Subjective Evaluation

A survey was conducted to 100 office working female respondents with the range age between 20 and 45 years old. The questionnaires and a sample book were given to the respondents during the survey. The questions were related with the fabric properties which were tested using appropriate testing equipments.

-

Samples of Questions

-

Arrange the fabric (in the sample book) based on the following fabric performance:

-

1. Excellent, 2. Good, 3. Moderate, 4. Fair and 5. Bad

Questions

-

1.

That drapes well on your body

-

2.

That absorbs your sweat quickly

-

3.

That ease your body movement

-

4.

That you feel suitable to wear in hot weather

-

1.

-

Objective Versus Subjective Evaluation

Question 1 in the survey was to reflect the drape coefficient of the fabric using the Cusick drape tester. Question 2 was to determine the rate of sweat absorbency. Question 3 was regarding stiffness property of the fabric and Question 4 was to evaluate the air permeability.

The ranking for both objective and subjective evaluation was done in order to get R 2 values on the correlation between these selected properties.

Results and Discussion

All fabrics were tested for their basic properties such as weight, thickness and density as shown in Table 1. The weight of the fabric was in the range of between 80 and 140 gm−2 with the thickness in the range of 0.2–0.6 mm.

All the fabric mechanical properties which include drape coefficient sweat absorbency, for both alkaline and acidic, bending length for warp and weft and air permeability are shown in Table 2.

All the fabric comfort properties were considered objective evaluation and were compared to subjective evaluation in terms of their ranking. The ranking was based on the best properties, labelled as 5 and the lowest, labelled as 1. For drape coefficient, the lowest value was the best, the ranking also applied to sweat absorbency and stiffness. For air permeability, the highest value gave an indicator that air can pass through more efficiently. The highest reading was ranked as 5. All the ranking value for both subjective and objective evaluation was compared and shown in Figs. 1, 2 and 3.

R 2 for sweat absorbency, stiffness and air permeability was very good at the value of 0.81. The R 2 value of 0.81 showed that humans can do a good prediction on the comfort properties on sweat absorbency, bending property and air permeability just by looking and feeling the fabric by hand. The accuracy of human ranking on the five selected fabrics was close to the ranking that was done by using human interpretation. The drapability R 2 was 0.64, which is statistically significant but not as strong as the other three properties.

Conclusion

From the study, it can be concluded that humans can predict fabric properties such as drapability, sweat absorbency, stiffness and air permeability based on the hand touch and eye coordination. The survey was done on working females and contributed to a very good correlation with the results from the machine. The respondents were people experienced in buying and selecting fabrics especially for fabric sold in rolls. The study can be continued by conducting surveys to different sets of target groups and other fabric comfort properties such as water vapour and thermal properties.

References

G.K. Tyagi, G. Krishna, S. Bhattacharya, P. Kumar, Comfort aspect of finished polyester-cotton and polyester-viscose ring and MJS yarn fabrics. Ind. J. Fibre Text. Res. 34, 137–143 (2009)

A. Das, S.M. Ishtaque, Comfort characteristics of fabrics containing twistless and hollow fibrous assemblies in weft. JTATM 3(4), 1–7 (2004)

R.K. Nayak, S.K. Punj, K.N. Chatterjee, Comfort properties of suiting fabrics. Ind. J. Fibre Text. Res. 34, 122–128 (2008)

A.H. Taieb, S. Msahli, F. Sakli, A new approach for optimizing mechanical clothing tactile comfort. J. Adv. Res. Mech. Eng. 1-2010(1), 43–51 (2010)

A. Mitra, A. Majumdar, P.K. Majumdar, D. Banerjee, Comparative analysis of regression and ANN models for predictind drape coefficient of handloom fabrics. Ind. J. Fibre Text. Res. 37, 313–320 (2011)

M. Dhinakaran, S. Sundaresan, B.S. Dasaradan, Comfort properties of apparel. Ind. J. (Department of Textile Technology, Kumaraguru College of Technology, Coimbatore)

K.V.P. Singh, A. Chartterjee, Study on physiological comfort of fabric made of structural modified friction spun yarns: part II- liquid transmission. Ind. J. Fibre Text. Res. 35, 134–138 (2009)

S.A.R. Zeinab, M. Saad, M. El Shinkery, I. Hanafy, Textile fabrics as thermal insulators. Autex Res. J. 6(3), 148 (2006)

I. Frydrych, G. Dziworska, J. Bilska, Comparative analysis of the thermal insulation properties of fabrics made of natural and man-made cellulose fibres. Fibres and Textile in Eastern Europe, 2002

M. Mushtaq, Clothing Comfort a Combination of Objective and Subjective Evaluation (Technical University Liberce, Liberce, 2010)

Acknowledgement

The authors gratefully acknowledge the Ministry of Higher Education (MOHE) for the Fundamental Research Grant Scheme (FRGS) and the Research Management Institute (RMI), Universiti Teknologi MARA (UiTM), for the management of the fund.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Singapore

About this paper

Cite this paper

Ghani, S.A., Yahya, M.F., Dahalan, S.N. (2014). Fabric Mechanical Properties: Human Versus Machine Interpretation. In: Ahmad, M., Yahya, M. (eds) Proceedings of the International Colloquium in Textile Engineering, Fashion, Apparel and Design 2014 (ICTEFAD 2014). Springer, Singapore. https://doi.org/10.1007/978-981-287-011-7_10

Download citation

DOI: https://doi.org/10.1007/978-981-287-011-7_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-287-010-0

Online ISBN: 978-981-287-011-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)