Abstract

Researchers are exploring alternative fuels due to decreasing fossil fuel reserves, increased prices, and environmental concerns. Biodiesel is found one of the possible solutions to utilize. For instance, biodiesel contains no sulfur or aromatics that contribute to air pollution or acid rain but has poor oxidation stability. Antioxidant additives enhance the stability of a fuel blend against thermo-oxidative degradation during storage through inhibition of free radical chain reactions between unsaturated compounds found in biodiesel. In the present research work, waste cooking oil biodiesel is used, containing a highly unsaturated compound, to evaluate the performance of L-ascorbic acid antioxidant. The induction period of antioxidant-treated biodiesel has been evaluated at different ppm levels to maintain standard of biodiesel. 200 ppm of L-ascorbic acid antioxidant enhance oxidation stability and meeting EN standard.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Biodiesel is one of the promising non-toxic and ecofriendly renewable alternative fuel made from vegetable oil or animal fats by transesterification process. Properties of biodiesel are similar to petro-diesel which makes it available to use in transportation sectors by blending it in conventional diesel. India is importer of vegetable oil for consumption so production of biodiesel from edible vegetable oils cannot be considered as good choice Non-edible vegetable oil can be produced by harvesting of plants which helps in providing green cover to waste land and provide support to agriculture and rural economy [1]. Canada uses canola, The United States uses soybean, Japan uses animal fat, Europe uses rapeseed, and Malaysia uses palm oil for production of biodiesel. Non-edible oils such as neem, sal, kusum, mahua, pongamia, jatropha are easily available in many parts of India and could be utilized for production of biodiesel. Potential availability of oil source is Jatropha 3–4 MT/(ha year) Neem oil (100,000 tons/year), sal (180,000 tons/year), Mahua (180,000 tons/year), Pongamia (55,000 tons/year) per year [2]. Low oxidation stability is one of the drawbacks of biodiesel due to presence of unsaturated fatty present in the ester. Auto-oxidation of biodiesel leads to formation of oxidation product, gum formation, change in color, insoluble and sedimentation in the biodiesel. To overcome these stability problems various additives, synthetic as well as natural, used as an antioxidant [3]. Biodiesel consist of saturated fatty acid (SFA), monounsaturated fatty acid (MUSFA), and polyunsaturated fatty acid (PUFA). Unsaturated fatty acids with a higher percentage of unsaturated fatty acids are prone to oxidative degradation and highly saturated leads to low cold flow properties. Fuel properties are influenced by the fatty acid profile of the vegetable oil [4]. The methyl esters of highly unsaturated fatty acids have superior cold flow characteristics and low oxidation stability, whereas saturated fatty acids have significant high oxidation stability and poor cold flow properties. To get a high-quality fuel, the fatty acid profile of biodiesel must be optimized, which may be accomplished by mixing biodiesel from various feedstocks. Poor low temperature performance of biodiesel limits its use in cold climate [5].

Biodiesel produced by straight vegetable oil through chemical process know as transesterification or esterification. Vegetable oils and animal fats converted into Fatty Acid Methyl Esters (FAME) or mono alkyl esters of long chain. Vegetable oils (cottonseed oil, sunflower oil, peanut oil, coconut oil, soybean oil, canola/rapeseed oil, corn oil) and animal fats considered as edible feedstock’s of 1st generation for production of biodiesel. Second generation non-edible feedstock’s are plant waste biomass and agricultural waste (Jatropha oil, Pongamia oil, Mahua oil, Rubber seed, Caster oil, neem, sal, etc.). In this research article, 100 pound of biodiesel produced by 100 pound of vegetable oil reacted with 10 pound of alcohol (i.e., methanol and ethanol) in the presence of base catalyst [6]. Biodiesel can use in exiting engine without any modification. Utilization of biodiesel reduces Carbon monoxides, hydrocarbon, and sulfur emission. Only NOx emission slightly risen up in comparison to diesel fuel. Nitrogen oxides and particulate matter were changed by changing chain length of concentration [7]. Shahir et al. [8] performed analysis on CRDI engine with pure diesel and several blends of animal fat biodiesel, brake thermal efficiency, exhaust gas temperature, and BSFC increases with lower value of CO, NOx, and HC for 30% blend of biodiesel when compared to diesel.

Dutta et al. [9] investigated palm stearin biodiesel, Brake Thermal Efficiency slightly increases by adding Alcohols (Ethanol and Methanol) to biodiesel during synthesis of. Rising in alcohols maximum in-cylinder temperature decreases with decreasing the value of peak pressure rise, decrease in NOx emission and increases PM and Smoke. Imtenanet et al. [10] Investigates biodiesel-diesel blends performance and emission analysis with additives. Palm biodiesel-diesel blend with ethanol, n-butanol, and diethyl ether used as additives. Author used 80% of diesel, 15% of palm biodiesel with 5% of additives. The result shows improvement in brake power, brake thermal efficiency and decrease in brake specific fuel consumption. With diethyl ether additive brake power increase by 6.25%, brake specific fuel consumption by 3.28% and brake thermal efficiency by 4%. Ethanol and n-butanol enhance the performance like decrease NO and CO emission with slightly increase in HC emission. Sousaet et al. [11] used curcumin and β-carotene as antioxidant additives in methyl soybean biodiesel to control their oxidative process. Antioxidant activity checked against radical 2 of these two chemicals by DPPH (2-diphyenyl-1-picrylhydrozyl) technique. Result shows that curcumin act as good antioxidant for soybean biodiesel because it increases induction period of biodiesel up to 83%. While β-carotene did not show any antioxidant activity for and concentration. The Petro-oxy and Rancimat techniques used to determine antioxidant activity.

Utilization of biodiesel in existing diesel engine should have similar physico-chemical properties to diesel. Biodiesel physico-chemical properties are viscosity, specific gravity, flash point, fire point, pour point, cloud point, and calorific value, cetane number, etc. these properties should meet ASTM standard given in Table 1.

2 Fatty Acid Composition

Physical and chemical structure of oil is greatly influenced by type and amount of fatty acid present. Fatty acids are classified into in two classes, saturated and unsaturated. Unsaturated fatty acid combines polyunsaturated and monounsaturated fatty acid. High degree of unsaturated acid present in oil leads to more susceptible to oxidative deterioration. Higher degree of unsaturation of fatty acids in vegetable oils, the more susceptible they are to oxidative deterioration [13, 14]. Most common form of saturated fatty acids (SFA) are Palmitic [C16:0] & Stearic [C18:0] and unsaturated fatty acids (UFA) are Oleic acid [C18:1], Linoleic acid [C18:2], and Linolenic [C18:3]. Fatty acid profile of different oils with saturated and unsaturated compound is given in Table 2. Highly unsaturated oil shows oxidation degradation can be overcome by utilization of antioxidants [8, 15]. Fatty acid composition of waste cooking oil biodiesel is given in Table 3, shows availability of higher amount of unsaturated fats.

3 Additives

Antioxidants are chemicals that slow down, regulate, or prevent the autoxidation of substrates, lowering the yields of undesirable secondary products. Chain breaking antioxidants (primary antioxidants) and hydroperoxide decomposers (secondary antioxidants) are the two types of antioxidants. By giving a hydrogen atom to a free radical (particularly the peroxyl radical ROO*), primary antioxidants (AH) slow or stop the propagation process [10]. The hydrogen is liberated from main antioxidants' active OH or NH groups and subsequently given to free radicals. The most often used main antioxidants are substituted phenolic compounds, secondary aromatic amines, and thiophenols. Tocopherols and flavonoids, which are natural antioxidants, belong to this category as well [18, 19]. Light-induced photooxidation is not inhibited by primary antioxidants. Secondary antioxidants scavenge oxygen, metal ions, and pro-oxidative enzymes by decomposing hydroperoxides through chain-breaking. Because of their effectiveness in scavenging free radicals, hybrid or bifunctional antioxidants such as aminophenols, hydroxy hydroquinolines, and hydroxyl benzimidazoles have become popular in recent years. They have OH and NH groups in their molecular structure [19].

Additives can be divided into these categories are listed below.

-

1.

Metal-based additives

-

2.

Oxygenated additives

-

3.

Cetane Number Improver Additives

-

4.

Antioxidant additives.

4 Effect of Antioxidant Additives on Engine Performance and Emission

Nabi et al. [16] Experiment performed on biodiesel derived from waste cooking oil to check engine performance and emission under the 13-Mode European Stationary Cycle. Reduction in 13% blow by emission, 11–15% reduction in CO, 47–70% reduction in unburnt hydrocarbon emission, 84% reduction in PM, 88% reduction in PN and slightly increase in NOx emission with reference fuel were observed. Nair et al. [17] investigated on diesel and blends of Neem biodiesel. By using Neem biodiesel brake thermal efficiency found to higher than diesel and brake power is approximately same. CO, HC, NOX emission decreased and O2 emission increases as compared to reference fuel. At B10 blend of neem biodiesel with diesel gives higher performance and lower emission than other blends. Oxygen-based emission caused by biodiesel reduced by using additives.

5 Properties of Waste Cooking Oil Biodiesel

Waste cooking oil was collected from local market. For converting waste cooking oil in to waste cooking oil biodiesl (WCOB) transesterification process has been done with methanol and NOH as catalyst. Properties of WCOB was tested as per ASTM standard and found be to in the range as given in Table 4.

6 Oxidation Stability of Waste Cooking Oil Biodiesel

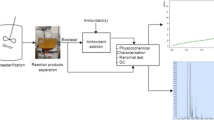

To achieve the oxidation stability standards, ASTM D6751 (3 h) or EN 14214 (6 h) [6, 7], the majority of biodiesel produced requires the application of antioxidants. Antioxidants added to biodiesel help to slow down the oxidation process. Rancimat is one of the method for determining the oxidation stability of biodiesel that is authorized by the EN 14214 standard. The induction duration is measured by tracking the steady increase in conductivity, which is mostly driven by volatile secondary oxidation products including formic and acetic acids [12,13,14]. The higher the oxidation stability, the longer the induction duration. In this investigation waste cooking biodiesel was used. Waste cooking oil biodiesel meets all properties of biodiesel as per standard but did not meet oxidation standard. Induction period was determined by Rancimat test methods and found to be 2.49 h. Figure 1, shows Rancimat setup and induction time of waste cooking oil biodiesel.

7 Effect of Antioxidant on Oxidation Stability of Waste Cooking Oil Biodiesel

Antioxidant additive helps to improve oxidation stability of biodiesel. L-ascorbic acid was used to evaluate oxidation stability. Antioxidant added in 100 and 200 ppm quantity in biodiesel. 100 ppm not able to meet EN14214. By adding 100 and 200 ppm of antioxidant, induction period increases to 3.24 and 6 h, respectively. Figures 2 and 3 shows representation of induction time evaluated by Rancimat method (Table 5).

8 Conclusion

In this paper, biodiesel was produced from waste cooking oil. Physico-chemical properties were evaluated and found in range as per ASTM. Fatty acid composition focusing on saturated and unsaturated compound of different oil have done. Unsaturated fatty acid composition is found more in in waste cooking oil biodiesel. Oxidation stability of pure waste cooking oil biodiesel was evaluated. Although, pure waste cooking oil biodiesel did not meet EN14214 standard. L-ascorbic antioxidant additive used in 100 ppm and 200 ppm quantity to evaluated Oxidation stability. 200 ppm of antioxidants were found effective to enhance oxidation stability to meet EN14214 standard.

References

Demirbas A (2009) Political, economic and environmental impacts of biofuels: a review. Appl Energy 86:S108–S117. https://doi.org/10.1016/j.apenergy.2009.04.036

Karmakar A, Karmakar S, Mukherjee S (2012) Biodiesel production from neem towards feedstock diversification: Indian perspective. Renew Sustain Energy Rev 16:1050–1060. https://doi.org/10.1016/j.rser.2011.10.001

Dwivedi G, Sharma MP (2014) Impact of antioxidant and metals on biodiesel stability—a review. J Mater Environ Sci 5:1412–1425

Serrano M, Oliveros R, Sánchez M et al (2014) Influence of blending vegetable oil methyl esters on biodiesel fuel properties: oxidative stability and cold flow properties. Energy 65:109–115. https://doi.org/10.1016/j.energy.2013.11.072

Misra RD, Murthy MS (2011) Blending of additives with biodiesels to improve the cold flow properties, combustion and emission performance in a compression ignition engine—a review. Renew Sustain Energy Rev 15:2413–2422. https://doi.org/10.1016/j.rser.2011.02.023

Vijay Kumar M, Veeresh Babu A, Ravi Kumar P (2018) The impacts on combustion, performance and emissions of biodiesel by using additives in direct injection diesel engine. Alexandria Eng J 57:509–516. https://doi.org/10.1016/j.aej.2016.12.016

Sierra-Cantor JF, Guerrero-Fajardo CA (2017) Methods for improving the cold flow properties of biodiesel with high saturated fatty acids content: a review. Renew Sustain Energy Rev 72:774–790. https://doi.org/10.1016/j.rser.2017.01.077

Supriyono SH, Almeida MF, Dias JM (2015) Influence of synthetic antioxidants on the oxidation stability of biodiesel produced from acid raw Jatropha curcas oil. Fuel Process Technol 132:133–138. https://doi.org/10.1016/j.fuproc.2014.12.003

Kostik V, Memeti S, Bauer B (2013) Fatty acid composition of edible oils and fats. J Hyg Eng Des 4:112–116

Kumar N (2017) Oxidative stability of biodiesel: causes, effects and prevention. Fuel 190:328–350. https://doi.org/10.1016/j.fuel.2016.11.001

De Sousa LS, De Moura CVR, De Oliveira JE, De Moura EM (2014) Use of natural antioxidants in soybean biodiesel. Fuel 134:420–428. https://doi.org/10.1016/j.fuel.2014.06.007

Yaakob Z, Narayanan BN, Padikkaparambil S et al (2014) A review on the oxidation stability of biodiesel. Renew Sustain Energy Rev 35:136–153. https://doi.org/10.1016/j.rser.2014.03.055

Freire LMS, Filho JRC, Moura CVR et al (2012) Evaluation of the oxidative stability and flow properties of quaternary mixtures of vegetable oils for biodiesel production. Fuel 95:126–130. https://doi.org/10.1016/j.fuel.2011.11.014

Sharma V, Duraisamy G (2019) Production and characterization of bio-mix fuel produced from a ternary and quaternary mixture of raw oil feedstock. J Clean Prod 221:271–285. https://doi.org/10.1016/j.jclepro.2019.02.214

Elsayed HH, Elrahman MKA, Emara AH, El-hafez A (2015) Compare effect of fatty acid composition (olive, coconut oil and butter) on adipose liver tissue, and serum lipid profile in albino rats. IOSR J Biotechnol Biochem 1:28–38

Orsavova J, Misurcova L, Vavra Ambrozova J et al (2015) Fatty acids composition of vegetable oils and its contribution to dietary energy intake and dependence of cardiovascular mortality on dietary intake of fatty acids. Int J Mol Sci 16:12871–12890. https://doi.org/10.3390/ijms160612871

Akbar E, Yaakob Z, Kamarudin SK et al (2009) Characteristic and composition of Jatropha curcas oil seed from Malaysia and its potential as biodiesel feedstock feedstock. Eur J Sci Res 29:396–403

Kumar S, Yadav K, Dwivedi G (2018) Impact analysis of oxidation stability for biodiesel and its blends. Mater Today Proc 5:19255–19261. https://doi.org/10.1016/j.matpr.2018.06.283

Saluja RK, Kumar V, Sham R (2016) Stability of biodiesel—a review. Renew Sustain Energy Rev 62:866–881. https://doi.org/10.1016/j.rser.2016.05.001

Ramalingam S, Ganesan P, Murugasan E (2020) Effect of antioxidant additives on performance and emission behavior of biodiesel fueled DI diesel engine. Energy Sources, Part A Recover Util Environ Eff 42:1085–1096. https://doi.org/10.1080/15567036.2019.1602219

Sathiyamoorthi R, Sankaranarayanan G (2016) Effect of antioxidant additives on the performance and emission characteristics of a DICI engine using neat lemongrass oil-diesel blend. Fuel 174:89–96. https://doi.org/10.1016/j.fuel.2016.01.076

Nagappan B, Devarajan Y, Kariappan E et al (2021) Influence of antioxidant additives on performance and emission characteristics of beef tallow biodiesel-fuelled C.I engine. Environ Sci Pollut Res 28:12041–12055. https://doi.org/10.1007/s11356-020-09065-9

Ali MH, Abdullah A, Yasin MHM (2019) Effect of BHA and BHT antioxidant additiveson engine performance and emission of a CI engine fueled with a palm oil methyl ester- diesel fuel blend. AIP Conf Proc 2059. https://doi.org/10.1063/1.5085994

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Yadav, K., Kumar, N., Chaudhary, R. (2023). Effect of L-Ascorbic Acid Antioxidant on Oxidation Stability of Biodiesel. In: Li, X., Rashidi, M.M., Lather, R.S., Raman, R. (eds) Emerging Trends in Mechanical and Industrial Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-6945-4_30

Download citation

DOI: https://doi.org/10.1007/978-981-19-6945-4_30

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6944-7

Online ISBN: 978-981-19-6945-4

eBook Packages: EngineeringEngineering (R0)