Abstract

Biodiesel is a renewable alternative to diesel which is used in transportation and industrial sectors. However, it is more susceptible to oxidation compared to diesel hence the use of antioxidants is proposed to enhance its oxidation stability. This paper aims to provide a concise perspective on the influencing factors in the use of commonly reported antioxidants for biodiesel oxidation stability enhancement. The scope here covers the type of antioxidant, concentration of antioxidant, biodiesel blend, storage time and temperature, with focus on the implications on palm biodiesel oxidation stability over an extended period. Data analysis suggests the order of effectiveness of synthetic antioxidants to be TBHQ > PY > PG > BHT ≥ BHA while for natural antioxidants, the order is quercetin ≥ curcumin > α-tocopherol. A higher applied antioxidant concentration generally results in higher IP extension though the relationship is not directly proportional. Further work can investigate the threshold of antioxidation activity with increasing concentration. Increasing the blend ratio enable the possibility of reducing antioxidant cost, but this would not be a major influencing factor unless the practice of adding antioxidant first prior to blending changes. The storage time is a major influencing factor in the context of stored biodiesel used as a backup energy source. At least 6 months to 1 year is recommended for such tests. Temperature affects the thermodynamics and kinetics of antioxidants performance. More studies on this for palm biodiesel are recommended for comparison and elucidation of the underlying mechanisms.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Worldwide, the use of non-renewable fossil fuels like diesel has resulted in environmental pollution and serious health impacts. As such, alternative fuels such as biodiesel has been developed, researched, and adopted in transportation cum industrial sectors. Biodiesel made up of fatty acid methyl esters (FAME) originates from vegetable oils and animal fats. It has characteristics such as better degradability, higher flashpoint, negligible sulphur content and good lubricity compared to diesel [1]. Biodiesel combustion results in reduced carbon monoxide, particulate matter and unburnt hydrocarbons, but higher nitrogen oxides (NOx) [2]. Nevertheless, biodiesel is more prone to oxidative degradation due to their unsaturated and polyunsaturated FAME [3]. This in turn poses difficulties in the storage of biodiesel and its wide-scale application as a renewable fuel [4]. To increase the oxidation stability of biodiesel during storage, an antioxidant can be added to delay the oxidation process that occurs naturally through exposure to air, metal and light [5].

The effects of synthetic antioxidants such as tert-butylhydroquinone (TBHQ), butylated hydroxytoluene (BHT), butylated hydroxyanisol (BHA), pyrogallol (PY) and propyl gallate (PG) in biodiesel have been extensively studied [6,7,8,9,10,11,12,13,14,15,16,17,18]. Natural antioxidants such as α-tocopherol, curcumin and quercetin have also been proposed as safer antioxidant alternatives [6, 10, 12, 16, 19,20,21,22]. When assessing the oxidation stability of biodiesel, the induction period (IP) in hours is typically measured. A higher IP value would be interpreted as the biodiesel lasting longer before it oxidises to an unacceptable level. The minimum biodiesel oxidation stability measured in IP is 3 h and 8 h for the ASTM D6751 and the EN 14214 standards, respectively.

With the rise in research on antioxidants in biodiesel over the years, this review aims to provide a concise perspective on the influencing factors in the use of commonly reported antioxidants for biodiesel oxidation stability enhancement. The scope of work discussed here covers the type of antioxidant, concentration of antioxidant, biodiesel blend, storage time and temperature. The novelty of this review lies in providing a fresh interpretation of the reported data with palm biodiesel in mind, for which limited studies exist. More specifically, the implications of the reported data in view of the fuel oxidation stability over an extended period as backup energy source is of interest here. Finally, this review also aims to identify future research directions based on the status of development in this area.

2 Type of Antioxidant

Among the most widely studied synthetic antioxidants over the past two decades, tert-butylhydroquinone (TBHQ) has constantly showed high antioxidation activities on different biodiesel types. This is evident from Table 1 which compiles the IP increments measured when TBHQ is added to different biodiesel fuels. For instance, in [6], TBHQ at 100 pm was already found to be effective in increasing the IP value of distilled palm oil methyl ester (DPOME) to above 8 h, the limit specified in the EN14214 standard. At 500 ppm, the antioxidant raised the IP even further to 26.68 h. The data aligns with the results obtained for beef tallow [15], where 5000 ppm of TBHQ was able to achieve a 9-fold increase in the standard IP value. Interestingly, the findings reported in [8] for waste cooking oil methyl ester (WCOME) showed a similar trend to that for DPOME whereby the increments of IP at 100 ppm and 500 ppm for both biodiesels were noticeably close.

When comparing the results of [6] and [8] for butylated hydroxytoluene (BHT) as shown in Table 2, it appears that BHT is more effective in enhancing the IP value for DPOME compared to WCOME. Nevertheless, the trends of increment are still similar, and it might be possible to predict the IP outcomes by the difference between the increment rates for both antioxidants for higher concentrations, say 2000 ppm. Additionally, comparing Tables 1 and 2, TBHQ outperforms BHT in terms of antioxidation potential in the context of DPOME, as TBHQ requires as little as 100 ppm to achieve the minimum of 8 h IP value as required by the EN14214 standard. Here, it is hypothesised that BHT performs better in methyl esters with higher unsaturated fatty acid percentage based on the data for [6] and [8] since the reported C18:2 for [8] is 27.78% compared to 10.25% for [6]. The application of BHT in used cooking oil methyl ester (UCOME) in [12] resulted in the IP values increasing by 7 and 10 h at 300 and 600 ppm, respectively, corresponding to having 83.9% unsaturated C18 fatty acids combined. Their base IP value was also very stable, which was 8 h without any addition of antioxidants. For most of the biodiesels listed in Tables 1 and 2, the use of BHT is not as effective as TBHQ. Furthermore, a decline in the IP value was noted when BHT was dosed at 1000 to 1500 ppm in C. inophyllum biodiesel [17].

From Table 3, the performance of butylated hydroxyanisole (BHA) is similar to BHT. It is seen that BHA underperforms compared to BHT in both rapeseed methyl ester (RME) and soybean methyl ester (SME) [18]. The same observations for SME are shown in [16], even though the differences between the IP increase for both antioxidants at multiple concentrations are insignificant. Out of all the studies listed in Table 3, only 500 ppm in RME and 600 ppm SME [18], 500 ppm and above in WCOME [8], and 1000 ppm in Karanja oil methyl ester (KOME) [11] are above the limit of 8 h IP value.

There are fewer studies using propyl gallate (PG) and pyrogallol (PY) in biodiesels compared to TBHQ, BHT and BHA as the latter three antioxidants are cheaper and generally demonstrate high antioxidation capabilities. Even so, the compilation of data from multiple studies listed in Tables 4 and 5 show that both PG and PY have comparable, if not stronger effects, than that of TBHQ in Table 1. It is important to note that all the biodiesels listed in Tables 4 and 5 have high percentages of C18:1 and C18:2, with Camelina biodiesel (CBD) having the highest C18:3 (33.5%) [14]. PG in WCOME was less effective compared to TBHQ while PY surpassed TBHQ. Similar findings were reported for KOME where PG and PY were more effective than TBHQ [11]. Meanwhile, it was also reported that PY was the better antioxidant followed by TBHQ and PG for SME [10]. It is possible that PG and PY perform better in fuels with higher unsaturated fatty acid contents, but further studies are warranted to fully understand the relationship between the extension of IP and fatty acid composition. Another interesting thing to note is that while KOME in study [13] showed a similar trend in terms of the ranking of antioxidants, all antioxidants used performed poorly at the same concentrations as compared to study [11]. The former reported 13.57% of C18 present in their fuel. There might be a relationship between the saturation level of FAME with the performance of antioxidants.

For natural antioxidants, α-tocopherol or vitamin E is found predominantly in plant-based feedstock. It is not as widely studied as an alternative to current biodiesel additives due to its high cost. As seen in Table 6, 3000 ppm of α-tocopherol can increase the IP value to 11 h for DPOME [6]. Based on the IP increment value from 1000 ppm to 3000 ppm, it is estimated that at least 2000 ppm is required to ensure the stability of DPOME. Conversely, [10] and [16] discussed the ineffectiveness of α-tocopherol in SME, whereby 250 ppm was only able to increase the IP value by 0.10 h. Furthermore, there were also other studies that showed α-tocopherol was incapable of protecting the fuel from oxidation.

Meanwhile, curcumin is more widely studied as compared to α-tocopherol. Different from α-tocopherol, the antioxidation potential of curcurmin in UCOME [12] and SME [20] showed promising results even at low concentrations. At 500 ppm, curcumin was able to boost the IP of cottonseed methyl ester (CSME) to 7.9 h [21]. Although in this study the exact composition of CSME was not reported, it was stated that the fuel contained high unsaturated fatty acid chains. The results based on [12] and [20] showed that while the IP increases were lesser than those of synthetic antioxidants, curcumin is still considered as an effective natural-based antioxidant.

Comparing the performance of curcumin and quercetin in [21], it is noted that both antioxidants showed the same increment in IP value at 500 ppm. This alone proved that quercetin is another antioxidant that has stronger antioxidation capability compared to α-tocopherol. Additionally, quercetin also performed better than curcumin when dosed into biodiesel at a higher concentration. At 3000 ppm, the final IP value of CSME was exactly 16 h, which was doubled the standard requirement. Another study by [22] also showed that quercetin performed equally well as curcumin in SME.

3 Concentration of Antioxidant

The concentration of antioxidants is widely studied in the literature over the past decades. Multiple types of antioxidants, synthetic and natural included, have been investigated in varying concentrations to understand the relationship between the antioxidant concentration with the IP value.

From Table 2, taking BHT as an illustrative antioxidant, it is noticeable that the IP extension generally increases with the increase in concentration of BHT. However, the IP extension is not directly proportional to the concentration increase. For instance, [16]’s results for SME showed small increase when the dose was increased from 1500 to 2000 ppm. This was further proved in [11]. The IP extension dropped from 8.48 h (from 4.35 h at 300 ppm to 12.83 h at 500 ppm) to 2.54 h (from 12.83 h at 500 ppm to 15.37 h at 700 ppm), then it further increased by 5.30 h when increased to 1000 ppm (20.67 h).

Furthermore, it is also obvious that IP values of C. inophyllum [17] showed a decreasing trend after 1000 ppm of BHT application. Similarly, the same trend was recorded by [14] for BHA use in Camelina biodiesel. The IP extension decreased from 3.7 h to 3.2 h when the dosage was increased from 2000 to 3000 ppm. It is noteworthy that these observations occur when the concentrations are in the order of thousands. This implies there might be a maximum limit of activity whereby when the antioxidants dosage has reached a certain threshold, it is no longer effective to protect the fuel. Furthermore, there might also be some reactions yet to be understood at this current stage of research and development.

Most studies on antioxidants concentration conclude with the concentration needed for the biodiesel to meet the required standard while evaluating and comparing different antioxidants to see which has the best performance. This would be sufficient for biodiesel that is distributed quickly to the end-users such as petrol stations. However, for ensuring long-term fuel stability for use in backup generators, it would be preferable to screen the type of antioxidants first at a fixed concentration considering the large differences seen and discussed in Sect. 2.

4 Biodiesel Blend

In industrial practice, after B100 production, the antioxidant is added into the fuel prior to further processing to biodiesel blends such as B7 to B20. It is particularly important to add the antioxidant as soon as possible since biodiesel oxidises as soon as it is produced.

The results adapted from [23] as presented in Table 7 show a drastic change in biodiesel oxidative stability when raw B100 is blended to B5, B7 and B10. Significantly, even without the presence of antioxidants, the IP values are at least 15 h, which is way higher than the EN14214 standard limit of 8 h. In the Malaysian context, the minimum IP value for palm B100 without antioxidants is at least 10 h. If the same formula is applied to palm B100, its IP value might hit at least 30 h even without any antioxidants added. The main reason why it is important to raise the initial IP so high is because it will gradually drop as time passes. The high initial IP ensures high stability even after long storage period. Interestingly, the IP values do not increase at 200 ppm and 300 ppm of BHT in both B5 and B10 mixed methyl ester (MME). As previously discussed, there might be a limit in the antioxidant capability in the fuel as the fatty acid compositions for rapeseed methyl ester (RME) and MME used were quite similar, with less than 2% differences in C16, C18:1 and C18:2.

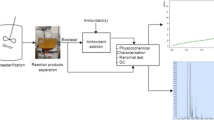

The stability of biodiesel blends dosed with antioxidants increases not only with increased concentration of antioxidants but also with higher percentage of blended diesel. However, TBHQ was reportedly less effective compared to BHT and BHA when B100 Jatropha methyl ester (JME) was blended to B50 [24]. While the authors discussed the possibility of hydrocarbons hindering the polar phenol groups of BHT and BHA, the reasoning behind TBHQ being less effective in these blends was not reported. From Fig. 1 [25], both B7 and B20 at t = 0 showed similar ranking of antioxidant capabilities as those of [24] though it remains to be elucidated why TBHQ is less effective when blended down in the latter while there are no changes to the former. This makes the study of antioxidants under different biodiesel blends worth to be explored. The possibility of reducing antioxidant cost is enabled by increasing the blend ratio. Nevertheless, unless the norm of adding antioxidants first prior to blending is changed, it would not be considered a major influencing factor.

IP value of B7 (left) and B20 (right) commercial biodiesel dosed with 1000 ppm antioxidants over 10 weeks [25].

5 Storage Time

This is arguably the best parameter if the concern behind the experimental programme is the fuel stability over a longer period such as reservoir tanks for backup generators. Investigating the protection offered by antioxidants over a period allows researchers to understand the rate of depletion of these antioxidants and enable the estimation of how long it takes before the biodiesel becomes fully oxidised. During oxidation, the antioxidants work as a layer of protection for the fuel by acting as a chain inhibitor, an oxygen quencher, or a reducing agent. As such, these antioxidants burn out themselves before the initiation of oxidation occurs on the biodiesel.

The tested storage times of biodiesel are usually more than 4 months [10, 11, 13, 20, 25, 26]. Even so, it is uncertain that the change in IP is significant enough to conclude that IP decreases over storage time. From Fig. 1 [25], BHA in B7 for the first two weeks barely has any change in the IP value though there is an overall decreasing trend over 10 weeks. Similarly, in Fig. 2 [11], 500 ppm of PG and PY show little to no change to the IP value after 1 month whereas 300 ppm of PG and 700 ppm of PY show increased IP values.

Figure 3 [26] also show a decreasing trend with a few notable outliers. The stability of B20 prepared from B100 D with 6 h initial IP increased over time for the hydrocracked diesel blended in the fuel. Meanwhile, fluctuating trends are seen between weeks 17 to 27 for the hydrotreated diesel version. Fluctuating trends are also observed for C-6 h and D-3 h for hydrocracked fuels, which might be due to uncontrollable conditions at those times though there were no plausible reasonings reported.

Overall, the study of antioxidants over an extended period allows researchers to understand the progression of antioxidants consumption to protect the biodiesel from oxidation. The ability to know how long a known concentration of a particular antioxidant can protect a fuel is a step needed to maximise the usage of antioxidants while reducing cost of adding antioxidant. A timeframe below 4 months would appear to be less than ideal as it might not fully project the processes occurring within the fuel. Whilst it is better if a fuel is stored longer for testing, there is also a risk of the fuel completely oxidising before that timeframe, leading to stagnant IP results. Thus, at least 6 months to 1 year of storage is recommended when doing such tests. Additionally, it will be useful to include periodic measurements of the antioxidant concentration to ascertain the temporal consumption. Similarly, testing the fatty acid methyl ester compositions at the initial and final points for more in-depth analysis is recommended. Nevertheless, a point of consideration here is that results might vary due to changing ambient storage conditions, e.g., temperature and weather. Hence, it is important to keep these constant, or near constant as much as possible. In summary, storage time is a key influencing factor when it comes to evaluating the effects of antioxidants in stored biodiesel used as a backup energy source.

6 Temperature

The influencing factor of temperature is typically studied in conjunction with thermodynamics and kinetics studies. Temperature dependent oxidation tests are carried out to obtain the necessary data for calculation of fundamental thermodynamics and kinetics parameters. For thermodynamics parameters, the enthalpy (ΔH‡) value indicates the heat change during the reaction while the entropy (ΔS‡) value determines the spontaneity of the reaction. A positive ΔH‡ value means that the reaction is endothermic while a positive ΔS‡ indicates that the reaction is spontaneous. Meanwhile, the Gibbs free energy (ΔG‡) corresponds to the total amount of work done in the system when temperature and pressure is kept constant. In terms of kinetics, parameters such as the reaction constant (k) and activation energy (Ea) are determined.

The IP of B100 samples was affected by temperature whereby an IP decrease corresponded to an increase in temperature of the Rancimat oxidation test [27]. This implies that the k value increases as the temperature increases, which can be viewed as the antioxidant consumption rate increasing as the temperature increases [28, 29].

The evaluation of thermodynamics and kinetics of antioxidants enables detailed fundamental understanding of how the antioxidants work in biodiesel. It also allows the mechanism of antioxidation in biodiesel to be elucidated though these would be unnecessary if the objective is merely to obtain an antioxidant sufficiently effective to produce biodiesel meeting the oxidation stability standards. Currently, there is a lack of overall studies on this topic and studies which focus on comparing and interpreting the varying results obtained for different antioxidants and biodiesel fuels. Hence, this could be a potential future research direction.

IP trends for KOME dosed with PG, PY, TBHQ and BHT over 4 months of storage time. Adapted from [11].

IP trends of B20 blended from B100 with 3 and 6 h initial IP over 40 weeks of storage. (A: hydrocracked diesel, B: hydrotreated diesel) [26].

7 Conclusion and Future Research Direction

To date, is a lack of studies on comprehensive palm biodiesel oxidation stability evaluation with various antioxidants. A notable study on antioxidants in palm biodiesel was carried out by [6]. Significantly, for palm biodiesel, the antioxidant research would be focussing on DPOME, which has been stripped of its natural carotenes and vitamin E (tocopherol variants) since its IP has been reported as below the minimum requirement of the EN14214 standard at 3.52 h, unlike crude palm oil methyl ester at 25.70 h [6]. Such high stability of palm biodiesel is attributed to the fatty acid composition of palm oil since palm oil methyl ester has high C16 and C18:1 content as compared to other oils such as camelina, Karanja and safflower [7, 11, 14]. Likewise, high stability is accorded to RME [18], where C18 and C18:1 are the dominant fatty acids. The presence of such high concentration of saturated fatty acids, namely C16 and C18, contributes significant fuel stability. The amount of different C18 unsaturated fatty acids also impacts the oxidation stability. Fuels with a higher content of C18:1 will have a higher stability compared to fuels with higher content of C18:2 and C18:3.

Considering the saturation of FAME in DPOME and the compiled data in Table 1 till Table 5, it is suggested that the order of effectiveness of the five commonly used synthetic antioxidants would be TBHQ > PY > PG > BHT ≥ BHA for DPOME. For natural antioxidants, it is hypothesised that the effectiveness would be in the order of quercetin ≥ curcumin > α-tocopherol. To the best knowledge of the authors, there are no studies to date on the use of curcumin and quercetin in palm biodiesel.

Generally, a higher applied antioxidant concentration results in higher IP extension though the relationship does not appear to be directly proportional. An area yet to be explored is the threshold of antioxidation activity with increasing concentration. For ensuring long-term palm biodiesel stability for use in backup generators, it would be preferable to screen the type of antioxidants first at a fixed concentration.

The stability of biodiesel blends dosed with antioxidants increases not only with increased concentration of antioxidants but also with higher percentage of blended diesel. Nonetheless, unless the norm of adding antioxidants prior to blending is changed, it would not be considered a major influencing factor.

The storage time is a major influencing factor for stored biodiesel used as a backup energy source. At least 6 months to 1 year of storage is recommended when doing such tests for palm biodiesel. Additionally, it will be useful to include periodic measurements of the antioxidant concentration to ascertain the temporal consumption and to test the FAME compositions at the initial and final points for more in-depth analysis. Bearing in mind ambient storage conditions vary, it is important to keep these constant, or near constant as much as possible.

Finally, temperature affects the thermodynamics and kinetics of antioxidants in biodiesel. Future work can focus on this aspect for palm biodiesel for comparison with other fuels considering the limited reported studies. From this, fundamental understanding of mechanism and how the antioxidants work in biodiesel can be gained.

References

Knothe, G., Razon, L.F.: Biodiesel fuels. Prog. Energy Combust. Sci. 58, 36–59 (2017)

Xue, J., Grift, T.E., Hansen, A.C.: Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 15, 1098–1116 (2011)

Lapuerta, M., Rodríguez-Fernández, J., Ramos, A., Álvarez, B.: Effect of the test temperature and anti-oxidant addition on the oxidation stability of commercial biodiesel fuels. Fuel 93, 391–396 (2012)

Mantovani, A.C.G., Chendynski, L.T., Santana, V.T., Borsato, D., Di Mauro, E.: Influence of antioxidants in biodiesel degradation: electronic paramagnetic resonance tracking of free radicals. Fuel 287, 119531 (2021)

Goh, B.H.H., Chong, C.T., Ong, H.C., Milano, J., Shamsuddin, A.H., Lee, X.J., et al.: Strategies for fuel property enhancement for second-generation multi-feedstock biodiesel. Fuel 315, 123178 (2022)

Yung, C.L., Choo, Y.M., Cheng, S.F., Ma, A.N., Chuah, C.H., Basiron, Y.: The effect of natural and synthetic antioxidants on the oxidative stability of palm diesel. Fuel 85, 867–870 (2006)

Nogales-Delgado, S., Encinar, J.M., González, J.F.: Safflower biodiesel: improvement of its oxidative stability by using BHA and TBHQ. Energies 12(10), 1940 (2019)

Zhou, J., Xiong, Y., Xu, S.: Evaluation of the oxidation stability of biodiesel stabilized with antioxidants using the PetroOXY method. Fuel 184, 808–814 (2016)

Tavares, M.L.A., Queiroz, N., Santos, I.M.G., Souza, A.L., Cavalcanti, E.H.S., Barros, A.K.D., et al.: Sunflower biodiesel: Use of P-DSC in the evaluation of antioxidant efficiency. J. Therm. Anal. Calorim. 106, 575–579 (2011)

Tang, H., De Guzman, R.C., Ng, K.Y.S., O Salley, S.: Effect of antioxidants on the storage stability of soybean-oil-based biodiesel. Energy Fuels. 24(3), 2028–2033 (2010)

Agarwal, A.K., Khurana, D.: Long-term storage oxidation stability of Karanja biodiesel with the use of antioxidants. Fuel Process. Technol. 106, 447–452 (2013)

Serqueira, D.S., Pereira, J.F.S., Squissato, A.L., Rodrigues, M.A., Lima, R.C., Faria, A.M., et al.: Oxidative stability and corrosivity of biodiesel produced from residual cooking oil exposed to copper and carbon steel under simulated storage conditions: dual effect of antioxidants. Renew. Energy 164, 1485–1495 (2021)

Obadiah, A., Kannan, R., Ramasubbu, A., Kumar, S.V.: Studies on the effect of antioxidants on the long-term storage and oxidation stability of Pongamia pinnata (L.) Pierre biodiesel. Fuel Process. Technol. 99, 56–63 (2012)

Yang, J., He, Q.S., Corscadden, K., Caldwell, C.: Improvement on oxidation and storage stability of biodiesel derived from an emerging feedstock camelina. Fuel Process. Technol. 157, 90–98 (2017)

Kleinberg, M.N., Rios, M.A.S., Buarque, H.L.B., Parente, M.M.V., Cavalcante, C.L., Luna, F.M.T.: Influence of synthetic and natural antioxidants on the oxidation stability of beef tallow before biodiesel production. Waste Biomass Valori. 10, 797–803 (2019)

Luo, M., Zhang, R.-Y., Zheng, Z., Wang, J.-l, Ji, J.-B.: Impact of some natural derivatives on the oxidative stability of soybean oil based biodiesel. J. Brazil. Chem. Soc. 23(2), 241–246 (2012). https://doi.org/10.1590/S0103-50532012000200008

MohamedShameer, P., Ramesh, K.: FTIR assessment and investigation of synthetic antioxidant on the fuel stability of Calophyllum inophyllum biodiesel. Fuel 209, 411–416 (2017)

Canha, N., Felizardo, P., Correia, M.J.N.: Controlling the oxidative stability of biodiesel using oils or biodiesel blending or antioxidants addition. Environ. Prog. Sustain. Energy 37, 1031–1040 (2018)

Santos, M.N., de Souza, E.F., Moreira Ramos, T.C.P., Cavalheiro, A.A., Fiorucci, A.R., da Silva, M.S.: Effect of curcumin natural antioxidant on oxidative stability of commercial biodiesels from different raw materials. Orbital. 11, 239–245 (2019)

de Sousa, L.S., de Moura, C.V.R., de Oliveira, J.E., de Moura, E.M.: Use of natural antioxidants in soybean biodiesel. Fuel 134, 420–428 (2014)

Freitas, J.P.A., França, F.R.M., Silva, M.S., Toms, R.J., Silva, G.: Cottonseed biodiesel oxidative stability in mixture with natural antioxidants. Korean J. Chem. Eng. 36(8), 1298–1304 (2019). https://doi.org/10.1007/s11814-019-0287-x

de Sousa, L.S., de Moura, C.V.R., de Moura, E.M.: Action of natural antioxidants on the oxidative stability of soy biodiesel during storage. Fuel 288, 119632 (2021)

Beck, A., Pölczmann, G., Eller, Z., Hancsók, J.: Investigation of the effect of detergent-dispersant additives on the oxidation stability of biodiesel, diesel fuel and their blends. Biomass Bioenergy 66, 328–336 (2014)

Jain, S., Sharma, M.P.: Oxidation stability of blends of Jatropha biodiesel with diesel. Fuel 90(10), 3014–3020 (2011)

Karavalakis, G., Hilari, D., Givalou, L., Karonis, K., Stournas, S.: Storage stability and ageing effect of biodiesel blends treated with different antioxidants. Energy 36, 369–374 (2011)

Christensen, E., McCormick, R.L.: Long-term storage stability of biodiesel and biodiesel blends. Fuel Process. Technol. 128, 339–348 (2014)

Spacino, K.R., Borsato, D., Buosi, G.M., Chendynski, L.T.: Determination of kinetic and thermodynamic parameters of the B100 biodiesel oxidation process in mixtures with natural antioxidants. Fuel Process. Technol. 137, 366–370 (2015)

Xin, J., Imahara, H., Saka, S.: Kinetics on the oxidation of biodiesel stabilized with antioxidant. Fuel 88, 282–286 (2009)

Zhou, J., Xiong, Y., Shi, Y.: Antioxidant consumption kinetics and shelf-life prediction for biodiesel stabilized with antioxidants using the Rancimat method. Energy Fuels 30, 10534–10542 (2016)

Acknowledgements

The Ministry of Higher Education (MOHE), Malaysia is gratefully acknowledged for the funding of this project under the Fundamental Research Grant Scheme FRGS/1/2020/TK02/UNIM/01/1. The Malaysian Palm Oil Board (MPOB) is also thanked for the provision of facilities and technical support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lau, C.H., Gan, S., Lau, H.L.N., Lee, L.Y., Thangalazhy-Gopakumar, S. (2023). A Perspective on the Influencing Factors in the Use of Antioxidants for Biodiesel Oxidation Stability Enhancement. In: Kim, J., Chen, Z. (eds) Trends in Environmental Sustainability and Green Energy. CGEEE 2022. Springer Proceedings in Earth and Environmental Sciences. Springer, Cham. https://doi.org/10.1007/978-3-031-27803-7_9

Download citation

DOI: https://doi.org/10.1007/978-3-031-27803-7_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-27802-0

Online ISBN: 978-3-031-27803-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)