Abstract

Extraction methods (sample preparation methods) determine the outcome and result for the study of any medicinal plants. The concerned bioactive phytochemicals are bound with other compounds in the plants most of the time. Hence, various crucial factors of extraction methods like the proper selection of plant parts, solvent, pressure, temperature, and time of process can affect the method’s success. The classical techniques of plant extraction like maceration, percolation, Soxhlet extraction are used in ‘small-scale’ manufacture or research settings. Novel methods like microwave extraction, supercritical fluid extraction, accelerated solvent extraction, sonication, and enzyme-assisted extraction have made the extraction process of bioactive compounds relatively easier. This chapter will describe in detail the various methods, procedural steps, requirements, uses, and limitations available to extract bioactive phytochemicals from the plants.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Extraction methods

- Sample preparation methods

- Percolation

- Maceration

- Soxhlet

- Microwave extraction

- Supercritical fluid extraction

1 Introduction

-

For the study of medicinal plants, extraction methods (also called ‘sample preparation methods’) determine the outcome and result. Most of the time, the concerned bioactive phytochemicals are bound with other compounds in the plants. Therefore, various crucial factors of extraction methods like the proper selection of plant parts, solvent, pressure, temperature, and time of process can affect the success of the method.

-

With the invention of modern chromatographic/spectrometric techniques, the process of extraction of bioactive compounds has become relatively more comfortable. However, the classical techniques of plant extraction like maceration, percolation, Soxhlet extraction are being used in ‘small-scale’ manufacture or research settings.

-

An outline about the basic principles, choice of solvent selection, and pre-extraction procedures has already been covered in this book series (Refer section: ‘Discovery of drugs from plants’ in Chap. 18 of Volume 1).

-

This chapter will describe the various methods, procedural steps, requirements, uses, and limitations available to extract bioactive phytochemicals from the plants.

2 Classification

-

The plant extraction methods can be broadly classified into two types

-

Traditional methods (Conventional or classical methods):

-

Maceration, re-maceration, and sequential maceration

-

Soxhlet extraction

-

Reflux extraction

-

Decoction

-

Infusion

-

Percolation and Re-percolation

-

-

Novel (Non-conventional) methods:

-

Microwave extraction

-

Ultrasound-assisted extraction (Sonication extraction)

-

Supercritical fluid extraction

-

Pressurized liquid extraction (Accelerated solvent extraction)

-

Pulsed electric field extraction

-

Vibrocavitation homogenizer extraction

-

Enzyme assisted extraction

-

Hydro/Steam distillation

-

Two-phase extraction

-

-

3 Traditional Extraction Methods

3.1 Maceration

-

Maceration is one of the oldest used methods worldwide. Since no heat is usually applied in this method, the term ‘cold-maceration’ can also be used. Traditionally, for many centuries, it is used for wine preparation.

-

The finely powdered or coarsely powdered plant parts are soaked in the appropriate solvent (also called menstruum) for 3–7 days inside the tightly sealed container. The finely powdered material yields better in maceration than coarsely powdered by increasing the contact area between the solvent and plant parts.

-

The mixture is repeatedly agitated to ensure uniform soaking and increase solvent penetration

-

The solvent slowly digests the plant cell wall and releases the phytochemicals during the storage time. After 3 to 7 days, the initial liquid part is strained off from the container. The residual solid part (also called marc) is then pressed to release the remaining occluded solutions.

-

The solutions contain phytochemicals mixed with a solvent. It is then subjected to further purification by filtration methods.

-

Re-maceration: It is also called fractional maceration. The solvent used is first divided into three or four parts and added one by one after extracting the first part. Since new solvents are added periodically over the whole process, it results in extractant liquid production with different concentrations due to a diffusion rate difference. The extractant liquid can be later combined or used for analysis separately.

-

Sequential maceration: This method is also slightly different from the traditional maceration method. Here, instead of one solvent, different solvents are used after completing the entire procedure with the first solvent. The ‘marc’ obtained after the first solvent is dried and reused with different solvents using the same maceration principle. The extractant of each step should be mixed with others, unlike in remaceration.

-

Advantages:

-

Simple technique and suits best for small scale extraction

-

Thermolabile components can be extracted using this technique

-

A suitable method of choice for extraction of phenolic and polyphenolic compounds.

-

-

Disadvantages:

-

Time for extraction is significantly longer

-

Extraction efficiency for other phytochemicals besides phenols like flavonoids is very low

-

3.2 Soxhlet Extraction

-

It is also called as ‘hot-continuous extraction’ method.

-

A specific apparatus called the ‘soxhlet’ apparatus is required for this method. The setup consists of a thimble, siphon arm, extraction chamber, condenser, and an outlet for a round-bottomed flask to collect the extraction solvent.

-

A thimble is simply a porous bag made of either cellulose or filter paper that fits into the ‘well’ present in the apparatus’s siphon arm. A heating mantle is required to heat the round-bottomed flask.

-

First, the round bottom flask is filled with an adequate amount of appropriate solvent and kept inside the heating mantle. The round bottom flask is then fixed with the supporting stand.

-

The siphon arm is now then fixed with the supporting stand such that the outlet is fitted to the mouth of the round-bottomed flask and sealed tightly. Next, the finely powdered plant parts are then placed inside the thimble and placed into the thimble chamber (well) present inside the siphon arm

-

The condenser is then connected to the top of the siphon arm and fixed with the supporting stand. The condenser contains one ‘water inlet port’ at the bottom and one ‘water out-let port’ at the top. Both these ports are connected to the water source such that the continuous flow of cold water is ensured.

-

When the solvent is heated continuously by heating the mantle inside the round-bottomed flask, the solvent’s vapors reach the condenser via arms present in the siphon.

-

Once the vapors are condensed, it drips back into the ‘thimble’ present inside the siphon, gets mixed with the plant parts, and produces ‘extractant.’

-

Once the maximum volume of extractant is attained inside the siphon via another small arm present in the siphon, the extractant gets emptied down into the round-bottomed flask (called one extraction cycle).

-

The process keeps repeating until the extractant is concentrated inside the round-bottom flask.

-

Advantages:

-

Required only a small quantity of solvent as the solvent is recycled using a condenser.

-

An excellent method to extract non-polar compounds

-

-

Disadvantages:

-

Increased risk of fire accidents

-

Continuous exposure to flammable and hazardous solvents

-

The requirement of solvent purity is very high, leading to the high cost

-

Phytochemicals that are thermolabile could not be extracted by this method. For e.g., anthocyanin undergoes oxidation and degradation when extracted using Soxhlet apparatus.

-

3.3 Reflux Extraction

-

The principle of reflux extraction similar to the Soxhlet extraction method.

-

However, it differs from the Soxhlet method in terms of set-up

-

It does not require a siphon and thimble.

-

The round-bottomed flask is directly connected to the condenser.

-

Plant parts are added directly into the round-bottomed flask instead of the thimble in the Soxhlet apparatus.

-

Upon heating, the solvent evaporates and is recycled back to the round-bottomed flask after condensation and provides extractants.

-

-

Similar to Soxhlet extraction, this is method cannot be used for thermolabile phytochemicals

3.4 Decoction

-

This method is very suitable for extracting hard plant parts like roots and barks.

-

The plant parts are boiled with water for a few hours until the plant cell wall is destroyed by the heat leading to the release of phytochemicals.

-

Decoction, compared with maceration, increases the dissolution of compounds like baicalin, wogonoside, etc. This is because decoction utilizes a high temperature that prevents the beta-glucuronidase enzyme-based transformation of baicalin and wogonin to baicalein and wogonin, respectively.

-

This method is often used in various traditional medicines like Ayurveda, Sidha, and Chinese traditional medicine to prepare herbal mixtures and paste.

-

This method also utilizes heat and cannot be used for thermolabile compound extractions.

3.5 Infusion

-

This is the simplest method of extraction in which the plant parts as a whole or cut minimally are suspended in the solvent (usually water or alcohol).

-

It differs from the maceration method as follows

-

Infusion involves a shorter time

-

Plant parts are not powdered or crushed

-

-

Both cold and hot methods can be used in the infusion.

3.6 Percolation and Re-percolation

-

This method involves a constant passage of solvent into the plant parts at a predetermined flow rate. This method mainly works by gravitational force. The coffee maker is a simple example of a percolator in day-to-day life.

-

It requires specialized equipment called ‘percolator.’ Percolator is a simple conical instrument with an outlet at the bottom. The conical space is filled with layers of different materials like plant parts, solvent, sand, filter paper, etc., depending upon the type of compound extracted.

-

Percolation is done in three steps as follows

-

Wetting (Imbibition): Half amount of solvent is used in this step. The plant part swells and becomes easier for penetration of solvent in later steps. This step is conducted outside the percolator. It usually requires 4–5 h.

-

Soaking: The swollen raw material is now placed inside the percolator, filled up with the remaining volume of solvent, and left undisturbed. This step lasts for 1–2 days, and extraction efficiency is similar to maceration.

-

Percolation: Solvent is passed over the raw material at a constant rate, and the extract is collected until the raw material ran-out. The drop rate is usually fixed at a moderate value (6–7 drops/min).

-

-

Re-percolation: Here, percolation is done in repeated steps by dividing plant parts into quotas. This is followed by the extraction of consecutive parts with the extractant from the former one. This increases the yield of bioactive phytochemicals.

-

Advantages:

-

Simple technique and easy to operate

-

Alteration in the procedure can be done quickly to increase the extractant yield.

-

It can be used for both thermolabile and thermostable compounds.

-

-

Disadvantages:

-

Requires large volume of solvent

-

Exposure to toxic and hazardous solvent for a long duration of time

-

Organic waste generation is high and requires a proper disposal method.

-

4 Novel/Modern (Non-conventional) Plant Extraction Methods

4.1 Microwave Extraction

-

Principle: Analyte from the sample can be partitioned into the solvent by using microwave energy. The microwave produces heat by interacting with the dipoles of polarizable materials. This heat is then transferred by conduction. Rotation of dipole molecule under electromagnetic field by microwave results in the breaking of hydrogen bonds in the sample, enhancing solvent penetration.

-

Advantages:

-

It can also be used for sample preparation techniques like drying besides extraction methods

-

The best method to rapidly evaporate the solvent in the extracted solution.

-

Shorter time for extraction (15–30 min) with less solvent consumption

-

Temperature and time can be fine-tuned when compared to conventional methods for a better quality of yield.

-

More number of the analyte can be isolated from the sample using this method

-

-

Disadvantages:

-

Standard guidelines for temperature range and time are not available for various type of raw materials for extracting

-

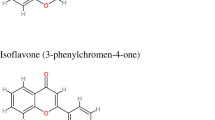

Thermolabile compounds cannot be extracted by this method. Few thermostable compounds like isoflavones, gallic acid, and trans-resveratrol can undergo oxidative damage when the temperature crosses 100°C or subjected to microwave for more than 20 min.

-

It cannot be used to extract the non-polar compounds

-

4.2 Ultrasound-Assisted Extraction (Sonication Extraction)

-

Principle: Ultrasound (20 kHz to 100 MHz) creates a mechanical force called ‘cavitation’ via sound energy. Cavitation is nothing but the formation, growth, and collapse of a bubble inside the medium formed when microwave travels and produces rapid compression and expansion in the medium. The cavitation results in the disruption of the plant cell wall and releases the phytochemicals by rinsing the cellular contents. Due to this mechanical effect by ultrasonic waves, the surface contact between the sample and solvent is also increased, resulting in enhanced solvent permeability.

-

When used in a liquid-liquid-containing solid medium, ultrasound can produce a temperature up to 5000 k with 1000 atm pressure by forming a cavitation effect. This leads to leaching out of various organic and inorganic compounds from the plant parts rapidly.

-

Advantages:

-

Drastic reduction in the extraction time and quantity of solvent used.

-

Simple equipment, simple procedure, and relatively low-cost technology

-

It can be adopted in both large and small-scale manufacturing.

-

-

Disadvantages:

-

Free radical generation may occur when more than 20 KHz is used results in an alteration in the phytochemical properties

-

Efficacy is decreased when used for extraction in thick woody compact materials.

4.3 Supercritical Fluid Extraction

-

This method is extensively used in the cosmetic, pharmaceutical, and food sectors to purify and isolate the active ingredients from raw materials.

-

Principle: Supercritical fluid (called dense-gas) is a substance with the physical property of gas and liquid at a given critical temperature and pressure, leading to a dramatic change in its solving property.

-

The CO2 can act as a supercritical fluid above 7380 kPa and 31.1°C. At this condition, the solving property of CO2 changes dramatically and can be used as a supercritical extractant (S-CO2). The S-CO2 is a commonly used solvent due to its lower critical temperature, inertness, non-toxicity, and low cost.

-

Advantages:

-

By varying the pressure of the supercritical fluid, fine-tuning of extraction can be done by this method, i.e., the selectivity of extraction by this method is very high. E.g., Volatile terpenes in the plants are extracted while carotenoid pigments and waxes can be stopped from being dissolved by changing the pressure of the critical fluid. Hence impurities like waxes and carotenoid pigment will not appear in the final extract.

-

An excellent method for extracting non-polar compounds

-

Usually operated at room temperature and hence thermolabile compounds can be extracted by this method

-

Easy modification of procedure so that even the spectrum of extraction can be increased. E.g., Though S-CO2 has low extraction efficacy for polar compounds, it can be increased significantly by adding ethanol and methanol in a small amount. As another example, dicarboxylic acids are insoluble in S-CO2 and cannot be extracted. However, adding tertiary amines along with S-CO2 will shield carboxylic acid and increases its solubility in S-CO2

-

Utilizes a small amount of solvent (green-type- extractor), environment-friendly, and less pollutant

-

Supercritical fluid can be reused, and hence minimal waster generation

-

The solvent can be easily separated from the solute just in a matter of seconds by decompressing (liquid form of S-CO2 will turn into gas-CO2 instantly)

-

-

Disadvantage:

-

Very high cost and can be used only in large-scale manufacturing units.

-

4.4 Pressurized Liquid/Solvent Extraction

-

It is also called as enhanced fluid/solvent extraction, accelerated fluid/solvent extraction, high-pressure liquid/solvent extraction.

-

Principle: Application of high pressure maintains the solvent in the liquid phase resulting in an increase of solubility and diffusion rate of solutes into the solvent. This results in high penetration of solvent in the plant parts and yields better extractants.

-

Advantages:

-

A suitable method for extraction of saponins, essential oils, and flavonoids.

-

Decreases the extraction time significantly

-

Less use of solvent and eco-friendly

-

Better repeatability

-

-

Disadvantage:

-

Inconsistent results for thermolabile compounds though few researchers successfully extracted using this technique

-

4.5 Pulsed Electric Field Extraction

-

Principle: An electric potential is passed in the suspension containing the living cells of plant parts. The generated electric field will disrupt the dipole nature of the cellular membrane molecules as per their charge. When the electric potential exceeds a critical value (usually >1 V), pores are formed in the cell membrane due to repulsion between the charged molecules. This results in increased permeability and leaching out of phytochemicals from the cell into the solvent

-

Usually, plant cell membranes are damaged when the electric field is generated as 500–1000 V/cm and applied in a pulsed manner (0.01–0.0001 s duration range).

-

Advantages:

-

This method will not increase the temperature drastically and can be used to extract thermolabile compounds

-

It can also be used as a pretreatment method before extraction by traditional methods.

-

-

Disadvantages:

-

Various factors like field strength, pulse number, energy input, and temperature play a role, and hence consistency of outcome is not uniform.

-

4.6 Vibrocavitation Homogenizer Extraction

-

Principle: Mechanical vigorous mixing can increase the interfacial area of components in the mixer and concentrate energy in small volumes, leading to mixing compounds with different viscosity. This enables the excellent dissolution of solutes in the solvent.

-

This method runs as a multi-step process.

-

Preliminary mixing is the first step, followed by dispersion/homogenization to the particles of <5 μm.

-

Later, the mixer is fed to the multi-stage homogenizers, which further disperse and homogenize the mixer by vigorous mixing. Later the generated emulsion is fed to the separation device, which extracts the phytochemicals from the raw material.

-

Advantage:

-

It can be used as a pretreatment method for conventional extraction methods

-

Liquids with a broad range of viscosities can be extracted.

-

4.7 Enzyme Assisted Extraction

-

Principle: Instead of heat-induced destruction, which causes the formation of micelles, denaturation, and coagulation of proteins, the cell wall and other macromolecules can be destroyed with enzymes. Cellulase, pectinase, and alpha-amylase are added to the extract, which destroys the cell wall and macromolecules and releases phytochemicals.

-

The polysaccharide-lignin matrix formed by hydrogen bonds is inaccessible by the solvent in other methods. However, enzymatic pre-treatment breaks these bond and release the phytochemicals better.

-

Two variants exist in this method:

-

Enzyme-assisted aqueous extraction—enzymes are used for the extraction of various seed oils.

-

Enzyme-assisted cold pressing—the enzyme is used to dissolve the cell wall of the seed by hydrolysis.

-

-

Factors like particle size, enzyme concentration, water-solid ratio, and time to hydrolysis determine the outcome of extraction

-

Advantages:

-

Water is used as a solvent and hence eco-friendly method

-

Non-toxic and non-inflammable method

-

One of the best method for extraction of thermolabile compounds

-

-

Disadvantage:

-

Raw material with high moisture content cannot be processed effectively by this method as moisture interferes with enzymatic activity.

-

4.8 Hydro/Steam Distillation

-

Principle: Water, either directly or in the form of steam, is used as a solvent for extraction. This method is commonly used for extracting the volatile oils

-

Few natural compounds may undergo decomposition by this technique

-

It takes a long time for extraction, and water-insoluble compounds cannot be extracted by this method

4.9 Two Phase Extraction

-

This method is under development and standardization and not used widely.

-

Most of the time, while extraction, the remaining pulp still contains useful biologically active compounds. This is because the solvent used is not appropriate for those compounds.

-

Hence instead of using a single solvent, a two-phase solvent can completely extract the biologically active phytochemicals from the plant parts. E.g., using two-phase vegetable oil- aqueous EtOH as a solvent, both lipophilic and hydrophilic compounds can be extracted.

-

Alternatively, surfactants (has both lipophilic and hydrophilic property) are mixed in the plant part, and by controlling the ratio of surfactants in the different phases, a controlled extraction can be done.

-

Two-phase extraction is still in the standardizing phase, and the outcome is based on various factors like ratio of oil to plant part, type of oil used, and polar-phase composition, etc.,

5 Conclusion

The choice of extraction techniques depends upon various factors like the type of scale of production, area of research, and nature of phytochemicals being studied. Hence no extraction method is ideal for all types of plant parts, and the researcher should put maximum effort into choosing a particular method such that the final yield should be repeatable and of good quality in nature.

Bibliography

Bouras M, Grimi N, Bals O, Vorobiev E. Impact of pulsed electric fields on polyphenols extraction from Norway spruce bark. Ind Crop Prod. 2016;80:50–8.

Chemat F, Cravotto G. Microwave-assisted extraction for bioactive compounds. Boston: Springer; 2013.

Chen H, Zhou X, Zhang J. Optimization of enzyme assisted extraction of polysaccharides from Astragalus membranaceus. Carbohydr Polym. 2014;111:567–75.

Delazar A, Nahar L, Hamedeyazdan S, Sarker SD. Microwave-assisted extraction in natural products isolation. Methods Mol Biol. 2012;864:89–115.

Jones WP, Kinghorn AD. Extraction of plant secondary metabolites. Methods Mol Biol. 2012;864:341–66.

Santos-Buelga C, Gonzalez-Manzano S, Dueñas M, Gonzalez-Paramas AM. Extraction and isolation of phenolic compounds. Methods Mol Biol. 2012;864:427–64.

Seidel V. Initial and bulk extraction of natural products isolation. Methods Mol Biol. 2012;864:27–41.

Strati IF, Gogou E, Oreopoulou V. Enzyme and high pressure assisted extraction of carotenoids from tomato waste. Food Bioprod Process. 2015;94:668–74.

Vinatoru M, Mason TJ, Calinescu I. Ultrasonically assisted extraction (UAE) and microwave assisted extraction (MAE) of functional compounds from plant materials. TrAC Trends Anal Chem. 2017;97:159–78.

Wei Q, Yang GW, Wang XJ, Hu XX, Chen L. The study on optimization of Soxhlet extraction process for ursolic acid from Cynomorium. Shipin Yanjiu Yu Kaifa. 2013;34(7):85–8.

Wrona O, Rafińska K, Możeński C, Buszewski B. Supercritical fluid extraction of bioactive compounds from plant materials. J AOAC Int. 2017;100(6):1624–35.

Yahya A, Yunus RM. Infuence of sample preparation and extraction time on chemical composition of steam distillation derived patchouli oil. Process Eng. 2013;53:1–6.

Zhang H, Wang W, Fu ZM, Han CC, Song Y. Study on comparison of extracting fucoxanthin from Undaria pinnatifid with percolation extraction and refuxing methods. Zhongguo Shipin Tianjiaji. 2014;9:91–5.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Lakshmanan, M. (2022). Plant Extraction Methods. In: Lakshmanan, M., Shewade, D.G., Raj, G.M. (eds) Introduction to Basics of Pharmacology and Toxicology. Springer, Singapore. https://doi.org/10.1007/978-981-19-5343-9_54

Download citation

DOI: https://doi.org/10.1007/978-981-19-5343-9_54

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5342-2

Online ISBN: 978-981-19-5343-9

eBook Packages: MedicineMedicine (R0)