Abstract

Open-pit mine design and long-term planning are crucial parts of the mining industry. It contains the technical plan that must be followed from the beginning of mine development to mine closure. Every deposit can be mined entirely, however, many things need to be carefully considered before mining the whole deposit. An optimal pit outline is one of the most important parameters that affect both the economy and the safety of mining. Therefore, the purpose of this study is to determine the effectiveness of an optimal pit outline by using both software and hand methods based on cost and revenue. This study investigates Dadiin-Khar Tolgoi2’s optimal pit outline and design to maximize the profit of using Surpac and Whittle software. The study compares the economic gain of both entirely extracted proved (B) and probable (C) reserve mines that were designed on the Surpac software and the hand technique of determining optimal pit outline. Whittle software computed that Pit Shell – 27 of Dadiin-Khar Tolgoi – 2 is the best pit outline regarding profit and safety. Besides, entirely mined Pit outline –B and Pit outline – C gives the loss in economics both −$6 344 080 and $171 304 160, respectively. On the other hand, the optimized pit (Pit Shell – 27) has offered the highest gain in finance, which is $40,945,661. This economic profit shows that every mining should determine its optimal pit limit to maximize its economics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

An open-pit mine design and long-term planning is a complex structure part of the mining industry, however, it is one of the most critical aspects of the mining project. It involves the plan that needs to carry through from early-stage mining to mine closure to maximize the economy's value. The primary purpose of running an open-pit mine is to obtain maximum ore recovery with the lowest possible cost to earn maximum profit. In other words, the availability of extracting low-grade ore needs to be carefully considered to mine. Thus, it can lead to well-organized planning and design of the pit to achieve maximum profit. Open-pit mine design and long-term planning are complex components, however, it is an essential part of mining projects. Furthermore, it gives the technical plan that must be followed from the opening of mine to mine closure. Dimitrakopolous (2007) makes the very valid point that an optimized mine design has a great deal of effect on the economic value of the mine time [4,5,6]. Indeed, mining engineers do carefully design an open pit to get the highest financial revenue. On the other hand, inverse, insufficient planned mine design might lead to a loss of profit, even bankruptcy.

This study's primary goal is to determine Dadiin Khar Tolgoi-2 optimal pit design, optimization, the starting point of the mining operation, and mineable ore reserve regarding optimal pit outline. There are a number of critical factors used to investigate the primary goal, such as the geological features of the deposit, cut-off grade, topography and mineral resource, reserve, etc. [1, 5,6,7]. This highlights that numerous research studies agreed with mentioned essential factors to determine the optimal open-pit design.

There are a number of studies that have focused on computer software to determine optimal pit design, such as Whittle, Minemax, Surpac, Vulcan, MineSight3D, and Datamine software because limiting pit outline is time-consuming and laborious [3, 6, 7]. Their study, however, was limited in its application as it relied on computer software solely. This study would have been more illustrative if it had broadened the methods evaluated and compared with hand methods or computer-assisted hand methods to determine optimal pit design and outline. While there has been much research on computer software, few researchers have taken hand methods or computer-assisted hand methods [2, 5]. This study compares and evaluates the results of Dadiin Khar Togloi – 2 mining’s both computer software and hand methods or computer-assisted hand methods. For computer simulation, Surpac and Whittle software are used, whereas for hand methods or computer-assisted hand methods, a basic concept of Hustrulid’s technique published in 2013 is used.

2 Case Study

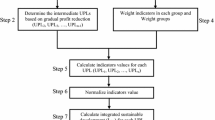

This study approaches its aim in two different ways, i.e. software and hand methods. Moreover, these two different way starts from the same step, which is creating a block model [4, 7]. Figure 1 shows a summary flow chart of optimizing the pit and designing both methods.

2.1 Resource

The exploration data of the Dadiin-Khar Tolgoi-2 deposit was obtained and processed by the QMC group in Mongolia. Furthermore, this study has processed the borehole database using Surpac software. From the exploration data, the QMC group has estimated about 9 390 800 tonnes of coal with an average grade of 1.35 t/m3 that can be mined using the open-pit method (Fig. 2).

2.2 Generating a block model on Surpac

Block model helps to determine ore shape, dimensions, and grade by generating a 3D model [4] as well as it contains all information about coal such as ash, calorie, sulphur even angle of dip of deposit. In addition, it is the base of any mining project as it includes every crucial information about the ore. The creation of the block model on Surpac consists of several essential steps that must be carefully done in Surpac to design a decent actual life project. Even the slightest mistake leads to error and miscalculation. The following steps show generating a block model on Surpac.

2.2.1 Loading and Creation of Borehole Database

Loading and creation of borehole database started from arranging drill hole data. Furthermore, organized drill hole data must be categorized into three different text files such as survey, collar, and assay. Tables 1, 2 and 3 show each text file. The survey, collar, and assay categories represent the depth of borehole data, coordination, and information of the borehole core, such as coal ash, calorie, and percentage of sulphur.

Table 1 illustrates the survey text file of borehole data. It consists of hole ID, depth, dip, and the azimuth of a borehole.

Table 2 shows the collar text file of borehole data. It is made of hole ID, coordination of hole, and depth.

Table 3 represents the assay of borehole data. It consists of borehole id, depth regarding average components such as ash, sulphur, and calorie of coal.

2.2.2 Creation of Solid 3-D Model

After slicing a borehole into a plane regarding digitized geological ore zones, the same was drawn on Surpac software by a string. In addition, digitized geological ore one is computed and processed by a geologist. There are ten sections of slices drawn at 200–250 m intervals. Figures 3, 4 and 5 show some of the cross-sectional slices of borehole data done by a geologist. In addition, cross-sectional slices of coal deposit are used to make 2-D solid on software which is Surpac and Minex. Lastly, Surpac software connected those sliced digitized ore zones using a simple command to make a solid 3-D model. The 3-D model shows that there are five coal seams underneath of crest.

2.2.3 Creation of Empty Block Model

Using MINEX software, the coal seam’s ceiling and ground have been converted into Surpac software. The following steps are a very crucial part of determining an optimized open-pit depth.

-

Determination of coal seam (1, 2, 3, 4, and 5)

-

Determination of coal category (Probable (C) and Proved (B))

-

Determination of categorized weight on coal.

-

Using the techniques of Geostatistics, interpolated the value of a coalfield.

2.2.4 Filling the Empty Block Model with Attribute Values

Dadiin Khar Tolgoi −2 coal deposit consists of 5 seams, and it’s located between the West to the East angle of dip ranges 30–45°. Furthermore, it belongs to the class of steep ore reserves. The following attribute values are loaded into Surpac software to fill the empty block model with attributes such as interpolation of coal calorie, average sulphur, ash, ore reserve classification, seam numbers, etc. (Figs. 5 and 6).

2.3 Exportation of the Block Model to Whittle Software

The Dadiin-Khar Tolgoi-2 block model was exported into Whittle software for optimization of the pit. Tables 4 and 5 show the economic and technical parameters that determined the optimized pit (Table 4).

Whittle software is commonly used for the determination of open-pit depth and shells. It is using the market selling price of coal, the cost of mining, and processing. Moreover, it finds out revenue factor = 1,0, which gives the highest profit of pit shell. Coal price has been calculated as $25/t, and the overall angle of slope is 38–42, which is based on rock mechanics of geological condition of Dadiin Khar Tolgoi – 2 mines (Table 5).

Pit outlines can differ from each other depending on their open-pit limit and economic factors.

Table 5 shows that pit shell – 27 has a lower amount of the whole production of coal. However, it gives the highest NPV of all pit limits. In conclusion, pit shell – 27 has been chosen as the best-optimized open-pit.

2.4 Exportation of the Optimal Pit to Surpac

Exportation from Whittle pit shell to Surpac software will be done by a straightforward command. However, it will be designed as a block model. A block model of whittle was redesigned to pit design using Surpac software.

2.5 Pit Design Using Surpac Software

This study has been completed to design three kinds of pit outlines using the same block model of mine to compare how efficient the determined pit outline is – 27. Pit outline – 1 pit design is mainly focused on extracting proved (B) reserve, whereas pit outline – 2 is focused on removing whole (B+C) ore reserve. The designing of the open-pit requires crucial parameters. Table 6 shows parameters applied to the pit design.

2.5.1 Pit Outline – 1

For this particular mine design, proved (B) ore reserve was the main aim of it. This mine design will extract all proved (B) reserves. In addition, it also contains some probable (C) ore (Fig. 7).

For this particular mine design, probable (C) ore reserve was the main of it. This design will extract all the up to down (B + C) ore reserves (Fig. 8).

Optimal pit outline – 27

This pit outline was achieved by the Lerch-Grossman algorithm employed by the Whittle software. It is challenging and time-consuming to design an optimized pit design using a shell that Whittle software gave (Fig. 9).

2.6 Locating a Pit Limit by Using the Basic Concept of the Hand Method

The hand method technique can’t be done in a short period in the whole mine. Thus, this study has chosen four primary cross-sectional slices that can represent the entire mine. Figure 10 demonstrates the location of the cross-sectional slices and borehole ID. In 2013, Hustrulid stated that there are a number of hand methods for determining pit limits by using simple calculations, however, hand methods are very laborious and time-consuming. It is impossible to determine the pit limit on any whole deposit because it requires enormous time to complete. Thus, Dadiin-Khar Tolgoi – 2 will analyze pit limits on cross-sectional slices of A–A’, B–B’, C–C’, and D–D’, where cross-sectional slice interval ranges from 200–250 m.

2.7 Calculation Part on the Cross-Sectional Slices to Determine Optimal Pit Limit

The coal seams extend ranges surface from 755 to 610 m in depth. The following equation is used to determine the location of the final pit wall.

-

where:

-

\({V}_{o}\) − Volume of waste

-

\({V}_{w}\) − Volume of ore

-

\({C}_{w}\) − Net value from selling one unit volume of ore (the money remaining after all expenses have been paid)

-

\({V}_{w}\) − Cost for mining and disposing of the waste [4].

This basic concept of the hand method chooses the pit limit that gives the highest net value. Moreover, there are four kinds of comparison on pit limit depth that ranges from 80–140 m.

There are some crucial parameters to determine the net value of the ultimate pit limit, such as the cost of mining, stripping cost and coal price. Table 7 shows parameters applied to the pit design. Autocad software measures how much coal and waste locates between the pit limit using the simple code of “AREA.” Furthermore, this study assumes a thickness of 1 m hypothetically.

Pit limit on A–A’ cross-sectional slice (Fig. 11 and Table 8).

Pit limit on B–B’s cross-sectional slice (Fig. 12 and Table 9).

Pit limit on C–C’ cross-sectional slice (Fig. 13 and Table 10).

Pit limit on D–D’ cross-sectional slice (Fig. 14 and Table 11).

3 Results and Discussion

3.1 Summary Results of Whittle Software

Exploration data of Dadiin-Khar Tolgoi – 2 deposit of mine has announced about 9 390 800 tonnes of coal with an average calorific value and a grade of 7000 J/m3 and 1.35 t/m3, respectively, that can be mined using the open-pit method. Table 12 shows the simplistic technical–economic result of both three mine designs. It indicates that Pit-Outline 2 has the highest revenue in selling coal, on the other hand, its overall cost has already outnumbered its income. Also, pit outline – 1 is not able to recover its cost (Table 12).

This simple table shows that optimized pit outline −27 has enormous profit compared with the other two pit outlines due to a high total of coal and low waste. However, this particular economic analysis is limited by operating costs excluding capital costs and general and administrative costs. Figures 15, 16, 17 and 18 compare open-pit designs and cross-sectional slices of A–A’, B–B’, C–C’, and D–D’ of pit outlines made by software.

3.2 Summary Results of Manual Method

The highest net value of the pit limit has been calculated in four different cross-sectional slices on Dadiin Khar Tolgoi −2 open-pit mine. For this particular sub-chapter, this study will compare optimized pit outline – 27 and the highest net value of pit outline that used the hand method. Moreover, economic analysis will be done on operating costs excluding capital, and general and administrative costs.

The cross-sectional slice A–A’ shows that the highest net value of the pit limit is at 100 m by using the hand method on the 2-D block model (Fig. 15).

The cross-sectional slice B-B’ shows that the highest net value of pit limit is at 130 m by using the hand method on the 2-D block model (Fig. 16).

The cross-sectional slice C–C’ shows that the highest net value of pit limit is at 110 m by using the hand method on the 2-D block model (Fig. 17).

The cross-sectional slice D-D’ shows that the highest net value of pit limit is at 130 m by using the hand method on the 2-D block model (Fig. 18 and Table 13).

Table 13 shows economic analysis on both different processes and evaluates it.

4 Discussion

This study aims to determine the optimal pit outline of Dadiin Khar Tolgoi – 2 using the computation technique such as Whittle and Surpac software.

4.1 Analysis of Both Results

The determination of pit limit is an essential aspect of the mining industry, as well as it is time-consuming and laborious. Dadiin Khar Tolgoi – 2 coal mine computed the pit limit with the help of Whittle and Surpac software, which gives the highest net value compared with other versions. Economic analysis of blindly extracted pit limits 1 and 2 show that operating cost outnumbered the revenue. The pit limit analysis using the hand method technique has been done in the primary four cross-sectional slices, which represent the whole mine. Every cross-sectional 2-D block model is analyzed in different depths of the mine. The economic analysis gives the best net value depending on their depth and pit limit. Moreover, the highest net value of the pit has been chosen.

4.2 Analysis of Economics

The analysis of economics on both methods shows that the computation method is a higher net value than the hand method. However, A–A’ cross-sectional slice shows that the net value of this particular pit net value is slightly higher than the computation technique. Figure 19 shows the economic analysis of both methods.

Figure 19 also shows that the net value of the computation method is remarkably high compared with the hand method.

5 Conclusions

The determination of optimal open-pit design required the consideration of many parameters such as the deposit geology, borehole data, cut-off grade, the market price of a deposit, the cost of mining, the cost of processing, and the market price of ore. This study provided a simple method to determine the ultimate open pit outline by using Whittle. On the other hand, design and planning were completed on blindly extracted ore reserve (B) and probable reserve (C) with the same pit design parameters. The profit of the ultimate pit outline is remarkably the highest, $40,945,661, compared with any pit outline. However, it can be changed, if the market price of coal increases, our optimal pit outline will expand too. On the other hand, if the market price of coal goes down, the pit outline will shrink.

The hand technique of determining pit limit is time-consuming and very hard to apply to the whole mine. Thus, it has been designed on four primary cross-sectional slices of Dadiin Khar Tolgoi – 2 mine. It is not as effective as the software method, whereas it mainly focuses on the pit's depth. However, the analysis of the financial results shows that the design and plan are relatively close to optimized pit mine – 27.

Overall, it shows that the computation method Whittle, which applies the Lerch’s-Grossman method, can be the best technique for the determination of the open-pit limit for Dadiin Khar Tolgoi −2 mine. It gives the opportunity of calculating the average grade of calorific value, ash, and sulphur with single command of Surpac software.

References

Akisa DM, Mireku-Gyimah D (2015) Application of surpac and whittle software in open pit optimisation and design. Ghana Mining J 15(1):35–43

Bakhtavar E, Shahriar K, Oraee K (2008) A model for determining optimal transition depth over from open-pit to underground mining. In: Paper presented at the proceedings of 5th international conference on mass mining, Luleå, Sweden.

Githiria J (2016) Cut-off grade optimisation to maximise the net present value using whittle 4X. International Journal of Mining and Mineral Engineering 7(4):313–327

Hustrulid WA, Kuchta M, Martin RK (2013) Open pit mine planning and design, two volume set & CD-ROM pack: CRC Press, Boca Raton

Kennedy BA (1990) Surface mining: SME

Kentwell D (2002) MineMAX Planner vs Whittle Four-X an open pit optimisation software evaluation and comparison. MineMax. https://www.minemax.com/downloads/Minemax-Planner-vs-FourX.pdf

Mariko I, Mireku-Gyimah D (2018) Open pit optimisation and design of tabakoto pit at anglogold ashanti sadiola mine using surpac and whittle software. Ghana Mining J 18(2):37–47

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Purevdavaa, T., Khandelwal, M. (2022). Ultimate Pit Limit Optimization by Computerized and Manual Methods for Dadiin Khar Tolgoi – 2 Coal Mine – A Case Study. In: Verma, A.K., et al. Proceedings of Geotechnical Challenges in Mining, Tunneling and Underground Infrastructures. ICGMTU 2021. Lecture Notes in Civil Engineering, vol 228. Springer, Singapore. https://doi.org/10.1007/978-981-16-9770-8_5

Download citation

DOI: https://doi.org/10.1007/978-981-16-9770-8_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9769-2

Online ISBN: 978-981-16-9770-8

eBook Packages: EngineeringEngineering (R0)