Abstract

Shortage of energy and pollution of water are two concern global issues. The treatment of polluted water usually requires a lot of energy. The demand for wastewater treatment and energy shortage has attracted the interest of research on converting pollutants to energy. Constructed wetland (CW) is environmentally friendly technology developed for the purification of polluted water and microbial fuel cell (MFC) is biotechnology that could turn organic pollutants into electricity. Hence, this paper aimed to identify the advantage of integrating MFC into CW through the study of the closed and open circuit on the wastewater treatment performance as well as the effect of spacing between cathode and anode on the generation of electricity in up-flow constructed wetland coupled microbial fuel cell (UFCW-MFC) system. The wastewater treatment performance was evaluated through the analysis of COD. The total COD removal efficiency was 99%. The closed circuit improved 10.9% compared to the open circuit at the anaerobic compartment (S1) in terms of COD removal. The effect of electrode spacing was investigated by comparing the maximum power density produced by three different electrode spacing between cathode and anode (15, 30, 45 cm). The highest maximum power density was achieved at the smallest spacing of electrode (15 cm), which recorded 73.48 ± 0.31 mW/m3. In conclusion, the MFC feature (closed circuit) improved the organic matter degradation and smaller electrode spacing benefits the energy production in UFCW-MFC.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Constructed wetland (CW) is a method that utilizes the natural process to purify wastewater. Treatment mechanisms of CW included microbial activities, chemical, and physical [1]. CW has been developed to treat a wide range of wastewater, which is not limited to municipal wastewaters but also included industrial wastewaters, stormwater runoff and landfill leachate because of its advantages such as low construction and maintenance cost [2].

Microbial fuel cell (MFC) is promising biotechnology that has shown capability in organic wastewater treatment and produces electricity simultaneously. MFC utilizes microorganisms to degrade organic pollutants and convert them to electricity. MFC consists of a cathode chamber and an anode chamber. The organic pollutants in the wastewater are used by the microbes for the metabolism activities and produce electrons at the anode. These electrons are then flowing from anode chamber to cathode chamber through an external circuit to complete the loop [3]. The electrons then react with the protons and electron acceptor at the cathode chamber to complete the circuit [4].

The integrating system of constructed wetland and microbial fuel cell (CW-MFC) is a technology that embeds the electrodes of MFC in CW. The utilization of microbial activities for the breakdown of organic pollutants has driven the combination of these two systems. Moreover, CWs could provide the redox gradient required for electricity generation in MFCs based on the depth of the bioreactor and flow direction of the wastewater [5]. The advantages of integrating MFC into CW have not been clarified. Therefore, this paper aims to identify the advantage through the study of the closed and open circuit on the treatment performance of wastewater as well as the effect of spacing between cathode and anode on the production of electricity in up-flow constructed wetland coupled microbial fuel cell (UFCW-MFC) system.

2 Material and Method

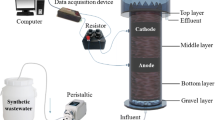

The UFCW–MFC reactor was developed using an acrylic column (height of 75 cm and diameter of 18 cm). The reactor was established outdoor (temperature of 28 ± 4 °C). The bioreactor was packed with glass beads (size of 10 mm) up to 3 cm to establish an even flow of wastewater. The supporting medium of the wetland bed used in this study was gravel. The bioreactor was developed with five sampling points at the height of 7, 21, 36, 51, 66 cm from the bottom [6]. The macrophyte employed in this study was water hyacinth (Eichhornia crassipes). Figure 1 depicts the structure of the bioreactor.

The cathode and anode used were activated carbon. The total volume of activated carbon for each cathode and anode was 2405.59 cm3. The bioreactor was embedded with three layers of the anode at the lower region (8 cm, 23 cm, and 38 cm from the bottom of the wetland bed), while the cathode was developed at the upper region of the bioreactor (53 cm from the bottom of the bioreactor). Electrode spacing between the cathode and three anodes were 15 cm, 30 cm and 45 cm, respectively. The cathode and anode were connected by stainless steel, carbon rod, and insulated copper wires with an external resistance of 1000 Ω. The mixed culture sludge obtained from a glove manufacturing factory wastewater plant was used for the inoculation of gravels and activated carbon.

The synthetic wastewater consists of 1024.5 mg/L CH3COONa, 535.5 mg/L C6H5COONa, 4.0 mg/L CaCl2·2H2O, 3.4 mg/L MgCl2·6H2O, 36.7 mg/L K2HPO4 and 7.0 mg/L NaCl. A peristaltic pump was used to feed the wastewater to the bioreactor with a hydraulic retention time (HRT) of 1 day. The wastewater from influent and all sampling points were collected for the analysis of COD. The voltage output in the system was recorded using a data logger. Calculations were done on current (I = V/R) to obtain power (P = IV). The power density was determined by dividing the power with the volume (v) of the anode chamber (Pd = P/v).

3 Results

3.1 Removal of Chemical Oxygen Demand (COD)

The influent COD concentration of the synthetic wastewater was 1395 ± 22 mg/L. Figure 2 demonstrates the COD profile of UFCW-MFC for both closed circuit and open circuit. As shown in Fig. 2, there was a drastic drop from influent to S1 followed by S2 to S3, which contribute 98.2% and 97.6% for closed and open circuits, respectively. The results showed that COD removal was mainly occurred in the anaerobic region (S1–S3). The existing microorganisms at the anaerobic region utilized the organic matter as energy sources for the microbial activity, which resulted in the decrement of COD [7]. Further removal of unutilized organic substrates was observed at sampling points S4 and S5, which achieved a COD removal efficiency of 99%. Supplementary aeration and macrophyte could enhance the biodegradation of organic matter by promoting the growth of the aerobes. Therefore, oxygen released from the supplementary aeration and E. crassipes in the aerobic region (S4–S5) may contribute to further COD reduction in the upper bed of reactors.

The effect of circuit connection on the COD removal efficiency was shown in Fig. 2. The effect of circuit connection on total COD removal was insignificant in this study since most of the organic pollutants were treated at S3. The significant effect of circuit connection on COD removal was observed at S1, which achieved removal efficiency of 81.9% and 71% in closed circuit and open circuit system, respectively. The closed circuit system showed 10.9% higher compared to the open circuit system in the anaerobic compartment. This indicated that in a closed circuit system, the transfer of electrons could enhance the degradation rate of the organic pollutants as well as promoting the growth of electrogenic bacteria. Oon et al. [8] reported a similar finding, where closed circuit improved the COD reduction in the anaerobic compartment by 8% compared to open circuit. Srivastava et al. [9] also reported that closed circuit enhanced 12–20% compared to open circuit. This study revealed that circuit connection could play an essential role in improving the COD removal in UFCW-MFC.

3.2 Electricity Generation Performance

The effect of spacing between cathode and anode on power production was investigated by developing three anodes in the reactor. The electrode spacing between the cathode and three anodes were 15 (C-A1), 30 (C-A2), and 45 cm (C-A3), respectively. Figure 3 demonstrates the power density generated by the three different electrode spacings. The highest maximum power density was achieved at C-A1 (73.48 ± 0.31 mW/m3), followed by C-A2 (58.3 ± 6.26 mW/m3) and C-A3 (51.71 ± 8.91 mW/m3). The internal resistance showed a similar trend of power densities. The internal resistance of the hybrid system at A1, A2, and A3 were 620, 620, and 720 Ω, respectively. The results suggested that electrode spacing could affect the power density generated as lower internal resistance was observed with smaller electrode spacing. Oon et al. [10] reported a similar finding, where the smallest electrode spacing produced the highest maximum power density.

4 Conclusion

This paper demonstrated the benefit of integrating MFC in CW through the study of the closed and open circuit on the treatment performance of wastewater as well as the effect of spacing between cathode and anode on the production of electricity. MFC feature (closed circuit) improved the degradation of organic pollutants as the transfer of electrons stimulated the breakdown of organic pollutants as well as promoting the growth of electrogenic bacteria. In terms of electricity generation, smaller spacing between cathode and anode could lower the internal resistance, which increases the electricity output of UFCW-MFC.

References

Vymazal J (2007) Removal of nutrients in various types of constructed wetlands. Sci Total Environ 380:48–65. https://doi.org/10.1016/j.scitotenv.2006.09.014

Vymazal J (2011) Constructed wetlands for wastewater treatment: five decades of experience. Environ Sci Technol 45:61–69. https://doi.org/10.1021/es101403q

Fang Z, Song HL, Cang N, Li XN (2013) Performance of microbial fuel cell coupled constructed wetland system for decolorization of azo dye and bioelectricity generation. Bioresour Technol 144:165–171. https://doi.org/10.1016/j.biortech.2013.06.073

Liu R, Zhao Y, Doherty L, Hu Y, Hao X (2015) A review of incorporation of constructed wetland with other treatment processes. 279:220–230

Yadav AK, Dash P, Mohanty A, Abbassi R, Mishra BK (2012) Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal. Ecol Eng 47:126–131. https://doi.org/10.1016/j.ecoleng.2012.06.029

Teoh TP, Ong SA, Ho LN, Wong YS, Oon YL, Oon YS, Tan SM, Thung WE (2020) Up-flow constructed wetland-microbial fuel cell: influence of floating plant, aeration and circuit connection on wastewater treatment performance and bioelectricity generation. J Water Process Eng 36:101371. https://doi.org/10.1016/j.jwpe.2020.101371

Oon YL, Ong SA, Ho LN, Wong YS, Oon YS, Lehl HK, Thung WE (2015) Hybrid system up-flow constructed wetland integrated with microbial fuel cell for simultaneous wastewater treatment and electricity generation. Bioresour Technol 186:270–275. https://doi.org/10.1016/j.biortech.2015.03.014

Oon YL, Ong SA, Ho LN, Wong YS, Dahalan FA, Oon YS, Lehl HK, Thung WE (2016) Synergistic effect of up-flow constructed wetland and microbial fuel cell for simultaneous wastewater treatment and energy recovery. Bioresour Technol 203:190–197. https://doi.org/10.1016/j.biortech.2015.12.011

Srivastava P, Yadav AK, Mishra BK (2015) The effects of microbial fuel cell integration into constructed wetland on the performance of constructed wetland. Bioresour Technol 195:223–230. https://doi.org/10.1016/j.biortech.2015.05.072

Oon YL, Ong SA, Ho LN, Wong YS, Dahalan FA, Oon YS, Lehl HK, Thung WE, Nordin N (2017) Role of macrophyte and effect of supplementary aeration in up-flow constructed wetland-microbial fuel cell for simultaneous wastewater treatment and energy recovery. Bioresour Technol 224:265–275. https://doi.org/10.1016/j.biortech.2016.10.079

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Teoh, T.P., Ong, S.A., Wong, Y.S., Ho, L.N., Noor, N.M., Matei, M. (2022). Constructed Wetland-Microbial Fuel: Biotechnology for Simultaneous Wastewater Treatment and Electricity Generation. In: Mohamed Noor, N., Sam, S.T., Abdul Kadir, A. (eds) Proceedings of the 3rd International Conference on Green Environmental Engineering and Technology. Lecture Notes in Civil Engineering, vol 214. Springer, Singapore. https://doi.org/10.1007/978-981-16-7920-9_45

Download citation

DOI: https://doi.org/10.1007/978-981-16-7920-9_45

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7919-3

Online ISBN: 978-981-16-7920-9

eBook Packages: EngineeringEngineering (R0)