Abstract

A study on stone column embedded soil system with different parametric variations is presented in this article. The investigation parameters included variation in footing diameter (D), column geometry, surrounding soil stiffness (cu) and size of in-filling stone chips. The unit cell concept was referred to design the column and foundation bed dimensions in such a way that both the end-bearing and floating conditions can be simulated. The effect of footing area was considered by varying the footing diameter and keeping the column dimensions constant for each case. A clayey soil, with cu = 5, 10 and 25 kPa, was selected for simulating the very soft, soft and medium stiff ground conditions. Different stone sizes were considered to find the influence of infilling material. Column behavior was monitored and recorded in terms of load-settlement responses. Responses thus received indicated considerable effects of each of parameter varied. Though a physical study was aimed initially, however, only few tests could be performed due to pandemic and rests have been simulated through Plaxis3D.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

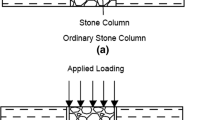

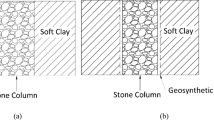

Ggranular column in soft soil has been very effective in improving bearing capacity and limiting the settlements of concern geo-structure. It is constructed by filling and compacting the granules in a pre-bored vertical-hollow. The aggregates bear majority of the imposed load and transfer it deeper through interconnections. The column is with high permeability which allows the pore water to dissipate faster and accelerates the consolidation. Studies have revealed various parametric influences, including geometry (diameter, length and column-arrangement), in-fill material (granules) quality, stiffness of surrounding soil (shear strength) and/or encasement type etc., on the performance of granular column. In this regard, articles by Najjar [1] and Ghose et al. [2] would be good reads to have a glimpse of performance of stone column in soft clay.

The natural lateral confinement to granular column is provided by the undrained shear strength (cu) of surrounding soil; however, its effect is minimal with respect to limiting axial stress [3]. Ambily and Gandhi [3] found that column-aggregates and soft clay squeeze into each other causing disturbance in expected mechanisms. It has been mentioned that the overall ground stiffness depends on spacing between the columns and improves with surcharge loading. Reportedly, the angularity, packing and frictional angle of aggregates influence the behavior of granular columns [4,5,6]. It is further mentioned that the more the friction angle is, the more will be the column-stiffness, bearing capacity and stability; however, the same has resulted in reduced settlement and lateral bulging. The dependence of column performance on its geometry (i.e., diameter and length) has also been investigated [7,8,9,10,11] and reported that increase in diameter (while installation) may affect the pre-estimated bearing capacity and drainage function of the granular column. Researchers [12,13,14] have mentioned a bulge formation for longer columns which limits the overall settlement; however, a punching failure is found for shorter columns which influence bearing capacity [15, 16]. In this regard, there is a mentioned critical length (lcrit) of 5–8 times the diameter, beyond which it does not contribute further on bearing capacity.

In this article the performance of model stone column on clay of varying strengths is reported. The investigation program included variation in the strength of surrounded clay (cu) as 5, 10 and 25 kPa. Two different stone sizes were selected (ranged between 10–4.75 mm and 4.75–1.18 mm) for in-filling the column. The foundation bed-cum-test mold was prepared as per unit cell concept described in Indian Standard [17]. Three column diameters, lengths and footing sizes were selected to simulate the floating and end-bearing column conditions. The initial study was based on physical tests; however, the authors are forced to focus on the numerical simulation (Plaxis3D) due to pandemic condition. As per the observation made till date, it is found that the behavior of stone columns is immensely influenced by the parameters considered.

2 Material and Methodology

In the study locally available clay-soil used for preparing the foundation bed by varying its water content (to vary the shear strength). The Pakur variety stone chips were selected for constructing the granular columns. Basic characterization of soils were performed as per designated Indian Standards and the determined properties are presented in Table 1. The table also includes the parameters required to define materials in the numerical simulation.

2.1 Preparation of Clay

For preparing the clay beds, a relationship is established between the undrained shear strength of clay with water content (Fig. 1), following the procedure described by Biswas [18]. The curve acted as the backbone for selecting clay strengths and calculating the corresponding water contents (with bulk densities) keeping the clay saturated.

2.2 Preparation of Clay Bed

The foundation bed was prepared in a split-mold made of metal sheet of 2 mm thick. The mold was braced with steel clamps (4 mm thick and 20 mm wide flat steel bars) to avoid bending of walls during the bed preparation and while the test progresses. The mold and other accessories are shown schematically in Fig. 2. Thick PVC pipes of different diameters were used to create the column-core. Three nos. of 18 mm thick wooden-plates, having hole at the center (avg. hole diameter = external diameter of corresponding pipe + 2 mm) were fabricated for compacting clay layers (with the pipe inserted) within the mold. Before placing the clay in mold, pipes were made vertical with holders (fabricated and can be fixed strongly with the mold) (Fig. 2). The clay was placed in the mold in layers (about 50 mm thick). After placing clay for a layer, a wooden-plate (with a plastic sheet at the bottom) was placed on the clay surface for compaction. The wooden-plate was supposed to distribute the compactive effort all over the clay surface. A plastic sheet was used to avoid the sticking of clay on the wooden-plate. The layers were compacted with equal number (pre-determined) of blows, with the hammer designated for standard proctor test. After preparing each layer, the clay surface was scratched to get adequate grip with the successive layer. Completion of clay bed preparation allows stone chips to be placed in the PVC pipes in desired density with tamping.

2.3 Preparation of Stone Column

Stone columns were prepared in layers with tamping. The entire length was formed by 50 mm equal lifting. For each layer, the required mass of stone chips was calculated, weighted, poured and compacted until the desired thickness was achieved. The desired effort for tamping was confirmed through several trial tests. After each layer, the PVC pipe was lifted up to the thickness prepared to start preparation of the next layer. Due to softness of surrounding soil, the compaction increased the column volume (length and diameter). Thus, care and trials were made in such a way that the enhancement in column volume should be limited to 5% of the stone weight calculated for each layer. After preparation of stone column footing was placed centrally and load was applied.

2.4 Test Procedure

The schematic test setup is shown in Fig. 3. The load-test was conducted in a universal load frame having 36 nos. strain rates. The prepared test mold, with footing, was placed under the load frame. The load was applied through a load cell of 10 kN capacity. A LVDT (50 mm run) was used to record footing settlement. The load-settlement was measured and recorded in a data logger. After successful placement of all instruments, test was started with the pre-determined strain rate.

3 Results and Discussion

The tests parameters selected, and aimed for, were footing size (D), diameter of stone column (Dc), length of stone column (L), stone sizes, undrained shear strength of clay (cu) and the strain rate of load applied. Obstructed by the pandemic situation, the variables were curtailed and only a few tests were possible to perform physically. Behavior of circular footing of different diameters (D = 30, 45 and 60 mm) rested on homogeneous clay with cu = 5 kPa were obtained under single strain rate of loading (1.2 mm/min). The load-settlement behavior is presented in Fig. 4. The responses depicted increase in pressure-settlement behavior with the footing diameter. A test with stone column (Dc = 30 mm; L = 175 mm) made of “4.75 mm passing and 1.18 mm retained” fraction of stone chips was performed in clay with cu = 5 kPa. Comparing with the corresponding homogeneous response, it can be said that pressure-settlement behavior improved with the installed stone column.

In the numerical simulation, the material properties used were same as determined through laboratory tests. The axisymmetric numerical simulation is performed in Plaxis3D with 60, 90, 120 and 180 mm diameter footing in clay having cu = 5, 10 and 25 kPa (selected from Fig. 1). The laboratory determined properties of two stone chips, designated as 4.75 mm (10 mm passing and 4.75 mm retained) and 1.18 mm (4.75 mm passing and 1.18 mm retained), were used to model the stone column having lengths as 1, 1.5 and 2 m within a 2 × 2 × 2 m3 soil block. A typical model schematic and corresponding analysis response are shown in Fig. 5.

The simulation results have depicted a considerable increase in load-bearing capacity with increase in undrained shear strength of surrounding clay (Fig. 6). However, it was also found that the short floating column of 1 m length has behaved better than the other two configurations in a clay of same undrained shear strength. This can be attributed to bulging of short column to improve the bearing capacity and failure of slender column before achieving the desired benefits (Fig. 6). A typical comparison of behavior of short (1 m) and slender (2 m) column, in a clay with cu = 10 kPa, is presented in Fig. 7a–d.

A comparison of influence of footing diameter (120 mm and 180 mm) and column length (1, 1.5 and 2 m), keeping the column diameter same (60 mm) with a constant clay consistency of 25 kPa (cu), is presented in Fig. 8. It is seen that the bearing capacity of the foundation systems improves considerably with increase in footing diameter and column lengths. It may be attributed to influence of increased footing area supported by the surrounded clay. This in turn enhances the confining surcharge toward the possible bulging of concern stone column. It eventually restrict the column deformation to keep its integrity for load transfer to enhance the bearing capacity of foundation system. However, the influence of column diameter beyond L = 1.5 m is found to be negligible.

4 Conclusions

The study investigated responses of footing rested on stone column in clay with varying strengths. Responses indicated considerable effect of parametric variations. The column diameter and length was varied along with the in-fill materials. Improvement in bearing capacity is observed with increase in clay consistency, column length and footing diameter. However, the influence of column diameter beyond 1.5 m was found to be negligible which is attributed to excessive bulging. The increase in loading area through enhanced footing diameter effected in confinement (lateral pressure) of surrounding clay (in addition to direct support provided to the footing). The authors admit that the numerical simulation should have been verified with physical test results; however, the research progress has been badly affected due to the pandemic and the restrictions thereby till date.

References

Najjar, S.S.: A state-of-the-art review of stone/stand-column reinforced clay systems. Geotech. Geol. Eng. 31, 355–386 (2013)

Ghose, S., Biswas, A., Mandal, U.: Parametric effect on granular columns: a brief review. In: Proceedings of 7th Indian Young Geotechnical Engineers Conference, NIT Silchar, Assam, India, pp. 58–63 (2019)

Ambily, A.P., Gandhi, S.R.: Behaviour of stone columns based on experimental and FEM analysis. J. Geotech. Geoenviron. Eng. (ASCE) 133(4), 405–415 (2007)

Bergado, D.T., Lam, F.L.: Full scale load test of granular piles with different densities and different proportions of gravel and sand in the soft Bangkok clay. Soils Found. 27(1), 86–93 (1987)

Malarvizhi, S.N., Ilamparuthi, K.: Comparative study on behaviour of encased stone column and conventional stone column. Soil Found. 47(5), 873–885 (2007)

Keykhosropur, L., Soroush, A., Imam, R.: 3D numerical analyses of geosynthetic encased stone columns. Geotext. Geomembr. 35, 61–68 (2012)

Hughes, J.M.O., Withers, N.J.: Reinforcing of soft cohesive soils with stone columns. Ground Eng. 7(3), 42–49 (1974)

Hughes, J.M.O., Withers, N.J., Greenwood, D.A.: A field trial of the reinforcing effect of a stone column in soil. Geotechnique 25(1), 31–44 (1975)

Murugesan, S., Rajagopal, K.: Model tests on geosynthetic encased stone columns. Geosynthetics International 24(6), 349–358 (2007)

Rao, N.S, Prasad, Y.V.S., Rao, H.V.: Use of stone columns in soft marine clays. In: Proceedings of 45th Canadian Geotechnical Conference, Toronto, Ont, pp. 9/1–9/7 (1992)

Wood, M.D., Hu, W., Nash, D.F.T.: Group effects in stone column foundations: model tests. Geotechnique 50(6), 689–698 (2000)

Mckelvey, D., Sivakumar, V., Bell, A., Graham, J.: Modeling of vibrated stone columns in soft clay. Geotech. Eng. 157(3), 137–149 (2004)

Sivakumar, V., McKelvey, D., Graham, J., Hughes, D.: Triaxial tests on model sand columns in clay. Can. Geotech. J. 41, 299–312 (2004)

Black, J.V., Sivakumar, V., Bell, A.: The settlement performance of stone column foundations. Geotechnique 61(11), 909–922 (2011)

Black, J.V., Sivakumar, V., Mckinley, J.D.: Performance of clay samples reinforced with vertical granular columns. Can. Geotech. J. 44, 89–95 (2007)

Ali, K., Shahu, J.T., Sharma, K.G.: Model test on geosynthetics-reinforced stone columns: a comparative study. Geosynthetics Int. 19(4), 292–305 (2012)

IS 15284 (Part 1): Design and construction for ground improvement guidelines: stone columns. Bureau of Indian Standards (2003)

Biswas, A.: Comparative performance of different geosynthetics on sandy soil overlying clay subgrades of varying strengths. In: Innovative Infrastructure Solutions. Springer (2019). https://doi.org/10.1007/s41062-019-0204-5

Acknowledgments

The authors sincerely acknowledge the support received from DHESTBT, Govt. of West Bengal, India [Ref. No. 183(Sanc.)/ST/P/S&T/6G-33/2017 dated 16/03/2018].

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Biswas, A., Mandal, U., Chakraborty, A. (2022). Experimental Study on Parametric Influences of Stone Column Reinforced Foundation Systems. In: Satyanarayana Reddy, C.N.V., Saride, S., Krishna, A.M. (eds) Ground Improvement and Reinforced Soil Structures. Lecture Notes in Civil Engineering, vol 152. Springer, Singapore. https://doi.org/10.1007/978-981-16-1831-4_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-1831-4_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1830-7

Online ISBN: 978-981-16-1831-4

eBook Packages: EngineeringEngineering (R0)