Abstract

Ordinary stone column (OSC) reinforced soft soils undergo excessive settlements under vertical stresses due to the lack of adequate lateral support from the surrounding native soil. To overcome this issue, stone columns are suitably encased by a geosynthetic material having high axial stiffness, which provides the required additional confinement. A numerical analysis aimed at analyzing the effect of geosynthetic encasement on the load settlement behavior of geosynthetic encased stone columns (GESC) under vertical stresses is presented. Three dimensional (3D) models were developed in PLAXIS3D to simulate the behavior of stone column reinforced soft soils using the unit cell idealization concept. The numerical models were first validated with the help of experimental data of model tests on GESCs from literature. Various parameters were varied to quantify their impact on the load settlement behavior under column only loaded condition. The parameters varied include the diameter of GESCs, spacing to diameter (S/D) ratio, pattern of stone column installation, geosynthetic encasement stiffness, length of encasement, length of floating column, cohesion of soil and friction angle of stone column infill. Increase in the diameter of GESCs led to increased settlement for a particular vertical load intensity. The bearing capacity improved with increase in the geosynthetic stiffness, encasement length, length of floating GESCs, the cohesion of soil and the friction angle of the stone column infill. Increase in S/D ratio decreased the bearing capacity and triangular pattern of stone column installation was found to be more efficient. Moreover, the lateral bulging indicated a reducing trend upon increasing the axial stiffness of encasement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

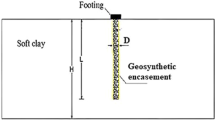

Soft soil conditions present huge challenges for geotechnical engineers. Due to increase in population and unavailability of land, infrastructure development over soft soils has become unavoidable. These soft soils undergo large deformations under external loading conditions. Hence, the need for improvement of these problematic soils arises so as to make them feasible. Over the years various ground improvement techniques have been developed to address this issue which include dewatering, pre-loading, sand drains, prefabricated vertical drains (PVD’s), granular columns, vacuum consolidation etc. (Rajasekaran and Rao 2002; Rampello and Callisto 2003; Indraratna et al. 2004; Shen et al. 2005). Providing granular piles (or stone columns) in soft soil conditions is one of the most widely used ground improvement techniques. In this technique, the soft soil is partially replaced by a dense and highly permeable material. The inclusion of stone columns reduce the lengths of flow paths and hence provide the added advantage of accelerated consolidation (Greenwood 1970; Han and Ye 2001; Castro et al. 2013). Stone columns placed in soft soils sustain under vertical stresses due to the lateral support provided by the surrounding soil (Greenwood 1970). When the stone columns are loaded, they tend to bulge and hence induce passive pressures on the surrounding native soil. Therefore, providing ordinary stone columns in soft soils conditions may not yield the desired results. In presence of very soft clays having un-drained shear strength (Su)< 15 kPa, the soil is not able to provide the required passive resistance to stone columns and they undergo failure due to bulging and general shear (Aboshi et al. 1979). In soft soil conditions the loss of infill material in the surrounding soil renders the granular columns ineffective. Moreover the soil may enter in the voids of the granular material, thereby clogging the granular columns which leads to reduction in permeability of these columns. Encasing the stone columns with suitable geosynthetic material can solve these issues as this encasement provides the additional lateral confinement and also acts as a barrier between the soft soil and the granular material. The geosynthetic encasement also stiffens the stone columns leading to reduction in bulging by mobilization of hoop stress in the reinforcing material (Van Impe and Silence 1986; Murugesan and Rajagopal 2006; Malarvizhi and Ilamparuthi 2007; Ghazavi and Afshar 2013; Dar and Shah 2020). Due to these advantages, GESCs are being widely used in soft soil conditions with low un-drained shear strengths. The behavior of a typical ordinary and GESC surrounded by soft soil is shown in Fig. 1. Ordinary stone columns placed in soft soils undergo bulging and excessive settlements due to unavailability of adequate passive resistance from the surrounding soil. The geosynthetic encasement in stone columns provides additional confinement and hence the additional passive resistance against bulging, thereby increasing the bearing capacity. The encasement in stone columns can be of various types viz. geotextiles, geogrids etc. The axial stiffness of these materials is very large and huge hoop stresses need to be mobilized to undergo any considerable lateral strain. The stone columns may be constructed by two methods viz. displacement and non-displacement method. In displacement method, a tube or casing is driven into the soil and the soil gets laterally displaced while in case of non-displacement method, the surrounding soil is not displaced as the soil is taken out while boring (IS: 15284 Part 1 2003). Moreover, the stone columns can be installed in various patterns as shown in Fig. 2. The triangular pattern gives the closest packing. Unit cell idealization concept was used to analyze the behavior of GESCs in this study. This concept is used for studying the behavior of a large group of columns beneath large loaded areas e.g., embankments etc. The concept of unit cell idealization is based on the idea of simplifying the analysis of behavior of a large number of stone columns by only analyzing an individual representative column. Figure 3 explains the concept of unit cell idealization under embankment wherein an individual stone column is analyzed under an equivalent vertical stress as it would experience in presence of the actual embankment. Most of the methods used for design of granular columns are based on this concept. A unit cell comprises of a granular column at the center and the extent of surrounding soil depends upon the spacing between the stone columns and the pattern of installation. The column and its zone of influence collectively is called ‘unit cell’. The diameter of the unit cell is equal to the equivalent diameter as shown in Fig. 2. A unit cell is a cylindrical element, the behavior of which is studied by loading the unit cell area with an equivalent loading intensity as experienced by it. The equivalent diameter (De) of the columns placed in triangular and square patterns is 1.05 and 1.13 times the spacing between the columns respectively. The spacing ‘S’ between the stone columns vary between 2 - 3 times the diameter of a column. In unit cell idealization, only vertical settlement is allowed along the perimeter of the unit cell and rigid boundary conditions are applied at the bottom to simulate the stone columns resting on a hart strata. This method has been used by various researchers over the years and the results show that the unit cell analysis closely represents the behavior of large number of columns underneath a structure (Hughes et al. 1975; Priebe 1995; Goughnour 1983; Murtaza and Samadhiya 2016, Khadhim et al. 2018). Hence, the unit cell concept provides an easy and simple solution to a complex problem. Attempts have been made by various researchers to study and analyze the influence of providing geosynthetic encasement on the load settlement behavior of granular piles. Model tests were conducted by various researchers to analyze the impact of encasement on the behavior of granular piles (Murtaza and Samadhiya 2016; Sharma et al. 2004; Ayadat and Hanna 2005; Murugesan and Rajagopal 2007; Wu and Hong 2009; Gniel and Bouazza 2009; Ali et al. 2012; Yoo and Lee 2012). Various numerical analyses were also carried out that successfully simulated the effect of geosynthetic encasement on bearing capacity of granular piles (Murugesan and Rajagopal 2006; Malarvizhi and Ilamparuthi 2007; Khabbazian et al. 2010; Yoo 2010; Keykhosropur et al. 2012; Almeida et al. 2013). However, the majority of numerical analysis on stone columns has been carried out using two dimensional (2D) axisymmetrical models. The analysis of behavior of the encased stone columns using Three Dimensional (3D) numerical models is yet to be explored fully.

In this study, the behavior of vertically loaded stone columns surrounded by soft soil has been simulated and quantified using a 3D Finite Element (FE) programme (PLAXIS3D). Experimental data from the literature was used to validate the FE model. Subsequently a parametric study was conducted to study the impact of various parameters on the load settlement behavior of the stone columns. The parameters varied include the diameter of GESCs, geosynthetic encasement stiffness, length of encasement, length of floating column, cohesion of soil and the friction angle of stone column infill.

2 Numerical Modelling

Numerical investigations were carried out in this study using an FE programme (PLAXIS3D). This FE package comprises of robust computational procedures that have been well tested over the years and enables the users to solve complex geotechnical engineering problems wherein the analysis and simulation of soil behavior is carried by development of 3D soil models. Settlement analysis was carried out on an individual column using the unit cell concept. Triangular arrangement of stone columns was chosen to carry out the current study for the said pattern provides the densest possible packing. The equivalent diameter (De) of equivalent cylindrical unit cell in case of triangular pattern is, De = 1.05 × S, where ‘S’ is the spacing between columns which is normally 2-3 times the diameter (D). For the current study, the spacing between the stone columns was kept twice the diameter i.e. S = 2D. Columns of diameter 0.5 m, 0.75 m and 1.0 m were investigated. The length (L) of columns for each diameter was so taken that the L/D ratio for all the cases remains constant at 6. The settlement behavior of unreinforced soil, ordinary stone column (OSC) reinforced soil and geosynthetic encased stone column (GESC) reinforced soft soils were studied. For analyzing the behavior of soft soils and stone columns, Mohr-Columb model was used as done by various researchers in the past (Ghazavi and Afshar 2013; Murtaza and Samadhiya 2016; Pulko et al. 2011; Chen et al. 2015; Mohanty and Samanta 2015). The geosynthetic encasement was modelled as a linear elastic material. There are geometrical limitations with the PLAXIS3D due to which a cylindrical unit cell cannot be created. Since the shape of a unit cell has no influence on the load settlement relationship, an equivalent square unit cell was analyzed in this study. The square unit cell has been used by various researchers for analyzing the load intensity settlement behavior in the past (Ghazavi and Afshar 2013; Murtaza and Samadhiya 2016; Mohanty and Samanta 2015; Ambily and Gandhi 2007). Various researches regarding the impact of geosynthetic encasement on the settlement behavior of stone column reinforced soft soils of different un-drained shear strengths suggest that interface element is not required since the settlement of the column occurs due to lateral bulging of the stone columns and shear is not possible (Ambily and Gandhi 2007; Khadhim et al. 2018). Hence, interface elements were not used in this study. The typical FE models generated in the PLAXIS3D are shown in Fig. 4.

2.1 Validation of the Numerical Model

The validation of numerical models was carried by simulating the load settlement behavior of model tests carried out by Murtaza and Samadhiya (2016). They carried out laboratory model tests on individual stone columns surrounded by soft clays using the unit cell method. These tests were carried out on stone columns of two diameters viz. 75 mm and 90 mm in end bearing and floating conditions under two loading conditions (a) by loading the column only and (b) by loading whole area of unit cell. The case of ‘column only loaded’ under floating and end bearing conditions was taken for validation.

The numerical models developed in this study were validated by comparison with the experimental results of Murtaza and Samadhiya (2016). The various material properties used by Murtaza and Samadhiya (2016) are given in Table 1. Figure 5 shows that the results obtained from PLAXIS3D are in good agreement with the experimental model tests carried by Murtaza and Samadhiya (2016) under both the end bearing and as well as floating conditions. These validated models were then used for conducting further parametric studies.

2.2 Material Properties

The material properties for the benchmark case used for development of numerical models in this study are shown in Table 2. Various parameters were varied to quantify the influence of their variation on the load–intensity settlement behavior of the soil. Axial stiffness (J) of the geosynthetic was also one of the parameters varied in this study. The axial stiffness of the geosynthetic encasing was varied as 250kN/m, 500 kN/m, 1000kN/m and 2000kN/m. The influence of this variation in stiffness of encasement on the load-settlement behavior and bulging of the stone columns was studied. For the benchmark case, the axial stiffness of the geosynthetic was taken as J = 500 kN/m.

3 Parametric Studies and Discussion

The influence of various parameters on the load-intensity versus settlement behavior of GESCs was investigated by developing 3D FE models. For the baseline model, a stone column of diameter 0.5 m was taken up for analysis, Najjar et al. (2010), from their experimental investigations found the critical column length of granular column to be around 6D, which means the load carrying capacity of granular column increases up to the column length of six diameters, beyond which there is no considerable improvement in the bearing capacity. Hence the length to diameter (L/D) ratio of 6 was used in the present study. To simulate the column only loaded condition, the load was applied on top of the stone column in terms of prescribed displacement of up to 150 mm. The parameters varied included the diameter of GESCs, S/D ratio, pattern of stone column installation, geosynthetic encasement stiffness, length of encasement, length of floating column, cohesion of soil and frictional angle of the stone column infill. The parametric studies were conducted by changing one parameter at a time while keeping others constant. The parametric studies are discussed in detail as follows.

3.1 Effect of the Diameter of Encased Stone Column

The influence of diameter of GESC on the load settlement behavior and lateral bulging was analyzed by using GESCs of three different diameters viz. 0.5 m, 0.75 m and 1.0 m. The ‘L/D’ ratio in all the cases was kept at 6 which correspond to column lengths of 3.0 m, 4.5 m, and 6.0 m respectively. Axial stiffness of the encasement was kept constant in all the cases with J = 500kN/m. Unit cell parameters corresponding to the largest diameter column were used. The area replacement ratios for 0.5 m, 0.75 m and 1.0 m diameter columns correspond to 5.7%, 12.93% and 22.93% respectively. Figure 6 shows the load-intensity settlement behavior of GESCs with varying diameters. A perusal of Fig. 6 shows that for a particular load intensity the larger diameter GESCs undergo larger settlements. These findings are consistent and in agreement with that of Murugesan and Rajagopal (2006); Ali et al. (2012). The variation in the load intensity settlement behavior for various prescribed settlements by varying diameter of GESCs is shown in Fig. 7. The vertical load intensity for 0.75 m diameter GESC compared to 0.5 m diameter column decreased by 17.50%, 18.67% and 19.71% for prescribed settlements of 50 mm, 100 mm and 150 mm respectively while in case of 1 m diameter column the reduction in vertical load intensity was 21.98%, 26.33% and 27.89%. Hence, it can be deduced that the vertical load intensity vs settlement behavior of the stone columns is dependent on the diameter of the GESCs. The increased settlement in case of larger diameter columns can be attributed to (a) the re-adjustment of the granular particles within the GESC and (b) the elongation of the geosynthetic encasement (Rajagopal and Mohanty 2016). Moreover, as the diameter of the column increases there is large scope for readjustment of the particles. As a result, larger diameter mobilizes lower tensile hoop stresses in the geosynthetic material leading to larger settlements. In case of ordinary stone columns, there is no considerable impact on the load-settlement behavior on increasing the diameter. The load-intensity vs settlement behavior of unreinforced stone columns (OSCs) is shown in Fig. 8.

3.2 Effect of S/D ratio

The stone columns are generally installed with S/D ratios ranging from 2-3. To study the impact of the variation in S/D ratio on the load carrying capacity, GESCs with three different S/D ratios viz. 2, 2.5 and 3 were taken up for analysis. The equivalent diameters of the unit cell corresponding to S/D ratios of 2, 2.5 and 3.0 vary as 1.05 m, 1.3125 m and 1.575 m respectively. The variation in the vertical load intensity versuss settlement behavior for different S/D ratios is shown in Fig. 9.

As the S/D ratio increases, there is reduction in the bearing capacity of GESCs. It can be attributed to the fact that as the S/D ratio increases, the extent of partial replacement of soft soil with better quality material also reduces which results in reduced bearing capacity. The variation in the vertical load intensities for various prescribed displacements is presented in Fig. 10. On varying the S/D ratio from 2 - 3, the vertical load intensity for prescribed settlements of 50 mm, 100 mm and 150 mm reduced by 5.75%, 3.03% and 2.47% respectively.

3.3 Effect of Pattern of Stone Column Installation

The stone column are generally placed in triangular or square arrangement. The influence of pattern of installation of GESCs on the load carrying capacity was analyzed in this study. GESCs placed in triangular and square arrangement were analyzed. The equivalent diameters of unit cell for triangular and square arrangement was taken as 1.05 m and 1.13 corresponding to equivalent diameters of 1.05 × S and 1.13 × S respectively.

Figure 11 shows the influence of pattern of stone column installation on the vertical load intensity settlement behavior of GESCs. The bearing capacity of GESCs in case of triangular arrangements were higher compared to the square pattern. This is due to the fact that in case of triangular arrangement of installation of stone columns, the columns are closer compared to the square arrangement. The variation in the vertical load intensity for different prescribed settlements are for different patterns of stone column installation is presented in Fig. 12. On changing the pattern of installation of stone column from triangular to square, the vertical load intensity for prescribed settlements of 50 mm, 100 mm and 100 mm reduced by 6.60%, 3.54% and 3.59% respectively.

3.4 Effect of Geosynthetic Encasement Stiffness

Stiffness of the geosynthetic encasement determines the hoop stress required to be mobilized to undergo any considerable strain. To study the influence of this stiffness on the load carrying capacity of GESCs, the stiffness ‘J’ of the encasement was varied as 250 kN/m, 500 kN/m, 1000 kN/m and 2000 kN/m. The behavior of fully encased column (end bearing as well as floating) was captured whilst keeping all other parameters constant. Figure 13 shows the variation of the vertical load-intensity versus settlement behavior of a 0.5 m diameter end bearing column for different values of encasement stiffness. A perusal of Fig. 13 shows that there is a significant enhancement in bearing capacity as the encasement stiffness increases from 250 to 2000 kN/m. This enhancement in the bearing capacity is due to larger lateral confinement provided by the encasement of higher stiffness, thereby increasing the overall stiffness of the GESCs. As the stiffness of the encasement is increased, it simulates the stiffer surrounding soil conditions. These findings are in agreement with those of Murugesan and Rajagopal (2006). Figure 14 shows the enhancement in the vertical load intensities in the end bearing column for various prescribed settlements. For geosynthetic encasement stiffness of 2000 kN/m, the vertical load intensity of the columns increased by 1284.33%, 2091.65% and 2767.84% for the prescribed settlements of 50 mm, 100 mm and 150 mm respectively relative to clay bed. This enhancement was found to be 347.47%, 624.60% and 859.82% respectively relative to the ordinary stone columns. The change in the encasement stiffness influences the extent of lateral bulging in GESCs as shown in Fig. 15. As the stiffness of geosynthetic encasement increases, there is reduction in the extent of lateral bulging, hence reducing the settlement. This can be ascribed to the additional lateral confining effect of the geosynthetic encasement, thereby increasing the bearing capacity of GESCs. The effect of stiffness of encasement on the bearing capacity of floating columns was also studied. For this purpose, a floating column of 0.5 m diameter and 1.5 m length was placed in a unit cell of 3 m depth. The values of encasement stiffness ‘J’ were varied as 125 kN/m, 250 kN/m, 500 kN/m and 1000 kN/m. Figure 16 shows the influence of geosynthetic stiffness on the behavior of floating GESC. The floating GESCs showed improvement in the load carrying capacity with increase in the encasement stiffness. However there is no significant improvement on increasing the encasement stiffness beyond 500kN/m. This is attributed to the punching effect of floating stone columns encased with geosynthetic material of higher stiffness. Such columns tend to punch into the soft soil rather than undergoing settlement due to radial bulging.

3.5 Effect of Geosynthetic Encasement Length

The settlement in stone columns occurs primarily due to radial bulging. It has been found out that the bulging occurs near the top of the stone column which is usually up to the depth of 1.5–2 times the diameter of stone column (Murugesan and Rajagopal 2006). Hence it may be redundant to encase the column fully so as to improve its performance. Only encasing the top portion of the column can provide the required additional lateral confinement in the zone susceptible to bulging, thereby improving the bearing capacity. Stone columns of different geosynthetic encasement lengths were investigated in this study to analyze their influence on load-intensity versus settlement behavior. The encasement lengths were varied as 1D, 2D, 3D, 4D, 5Dand 6D (fully encased). The purpose of this analysis was to find the optimum length of encasement for improving the performance of GESCs i.e. improvement in the load carrying capacity. Keeping the encasement stiffness constant as 500 kN/m, a stone column of diameter 0.5 m, having L/D ratio of 6, was considered for the study. The load intensity-settlement behavior of stone columns with varying encasement lengths is presented in Fig. 17. Increasing the encasement length increases the bearing capacity of the stone columns. However, the increase in the vertical load carrying capacity was more prominent at smaller encasement lengths. The variation in the vertical load intensities for various prescribed settlements is presented in Fig. 18. For the prescribed settlement of 50 mm, the increase of 160.8% in the vertical load intensity with respect to the OSC was prominent up to the geosynthetic encasement length of 2D (or 1 m) beyond which the increased encasement length had no considerable impact on the performance of the stone column. These findings are in agreement with that of Murugesan and Rajagopal (2006). The comparison of improvement trends on increasing the encasement lengths up to 1 m between the results of Murugesan and Rajagopal (2006) and current study is presented in Fig. 19.

Comparison of results of Current study with Murugesan and Rajagopal (2006)

For the prescribed settlement of 100 mm, the vertical load intensity on the stone column increased by 298.29% up to the encasement length of 3D (or 1.5 m) beyond which no considerable improvement in load-carrying capacity could be observed. For the settlement of 150 mm the maximum improvement in the vertical load intensity was up to the encasement length of 4D (or 2 m) i.e. 394.35%. Hence, it can be concluded that the optimum length of the encasement is directly related to the prescribed settlements or vertical stresses on the stone column. For greater vertical stresses, larger lengths of encasements are required. These findings are consistent with the findings of studies conducted by Khabbazian et al. (2010). According to them the optimum length of the geosynthetic encasement is proportional to the load on the granular column.

3.6 Effect of the Length of Floating Column

The feasibility of using end bearing granular piles may be restricted due to certain limitations at site like a deep soft soil layer or a lightly loaded structure. In such cases, floating granular piles are more effective and economical. Very little literature is available on the behavior of floating GESCs. Hence it becomes important to quantify the influence of the length of floating GESCs on the bearing capacity. To analyze this, floating stone columns of various L/T ratios, where ‘L’ is the length of the stone column and ‘T’ is the total thickness of soft soil taken for analysis. A GESC of 0.5 m diameter was considered with the geosynthetic encasement stiffness J = 500 kN/m. The influence of length of floating column on load intensity-settlement behavior was analyzed by varying the length of the column as 0.5 m, 1.0 m, 1.5 m, 2.0 m, 2.5 m and 3 m while keeping the thickness ‘T’ of soil constant as 3 m which correspond to L/T ratios of 0.16, 0.33, 0.5, 0.67, 0.83 and 1.0 respectively. The vertical load-intensity settlement behavior of partially penetrating GESC with different L/T ratios is depicted in Fig. 20. A perusal of Fig. 20 shows that increase in the length of floating GESCs leads to the improvement in the bearing capacity. This can be attributed to the fact that the larger length GESCs transfer the applied loads to larger depths, thereby increasing the bearing capacity (Murugesan and Rajagopal 2006). Figure 21 shows the variation of vertical load intensities for various prescribed displacements. The load intensity enhanced by 189.90%, 196.21% and 195.05% for the prescribed settlements of 50 mm, 100 mm and 150 mm respectively, when the L/T ratio of the floating column changes from 0.167 to 0.83. The bearing capacity of the floating GESCs increases with increasing length and is maximum for L/T = 1 i.e. end bearing case. The improvement in the bearing capacity with increasing length of floating GESCs is more evident for larger prescribed settlements.

3.7 Effect of Cohesion of Soil

The cohesion of soil is one of the most important parameters to determine the suitability of soil for any specific purpose and it is an indicator of the passive resistance the soil can offer. Soft clays often have very low value of cohesion and hence are very susceptible to large deformations under external stresses. In this study, the influence of cohesion of surrounding soil on the load settlement behavior was carried out. A 0.5 m GESC with geosynthetic encasement stiffness, J = 500 kN/m was considered for the analysis. The impact of cohesion of the surrounding soil on the load settlement behavior of GESCs was analyzed by varying the cohesion of the surrounding soil from 5 to 100 kPa and the behavior is depicted in Fig. 22. On increasing the cohesion of the surrounding soil, the bearing capacity of the GESCs improves considerably. The improvement in vertical load intensity was more prominent up to the cohesion of 30 kPa, beyond which only marginal improvement can be seen. This can be attributed to the fact that at the smaller values of cohesion, the soil is soft and the geotextile encasement provides additional confinement, thereby improving the load carrying capacity of GESCs. However at higher values of cohesion (i.e. C > 30 kPa), the soil is strong enough to provide adequate passive resistance to bulging, hence only marginal improvement can be seen on increasing the stiffness of geotextile encasement. The marginal improvement gets further reduced with further increase in the cohesion.

Figure 23 shows the variation of vertical load intensities for various prescribed settlements of the GESC placed in soils of varying cohesion. A perusal of this figure shows that on increasing the cohesion of soil from 5-30 kPa, the vertical load intensity of the GESC increased by 119.54%, 138.21% and 138.77% for prescribed settlements of 50 mm, 100 mm and 150 mm respectively. However, on increasing the values of cohesion further from 30- 100 kPa, the vertical load intensity on the GESC increased only by 43.66%, 22.79% and 17.52% for prescribed settlements of 50 mm, 100 mm and 150 mm respectively. Hence the GESCs are more useful in soft soil environments.

3.8 Effect of Friction Angle of Stone Column

The stone column comprises of granular stone aggregates, the properties of which determine the angle of internal friction of the infill material. To study the impact of friction angle of stone column infill on the load settlement behavior of GESCs, the angle of friction of the stone column was changed between 30o- 50o keeping all other parameters as constant. The influence of different angles of friction on the load settlement behavior of 0.5 m diameter GESC is shown in Fig. 24. Mild enhancement in the bearing capacity of GESCs could be observed by increasing the friction angle of the stone column infill. The bearing capacity for the settlement of 50 mm, 100 mm and 150 mm increased with increasing frictional angle is shown in Fig. 25. The improvement in the vertical load intensity by varying friction angle from 30o to 50o for a prescribed displacement of 50 mm, 100 mm, and 150 mm increased by 76.32%, 83.43%, 87.72% respectively. The improvement in the bearing capacity is more prominent at larger prescribed displacements.

Various researches have been conducted in the past to analyze the behavior of GESCs under vertical loading conditions. Khabbazian et al. (2010) studied the effect of geotextile encasement on the behavior of granular columns using a finite element software ABAQUS. They varied various parameters to quantify their influence on the load carrying capacity of GESCs. Comparative graphs between the results of current study and the research conducted by Khabbazian et al. (2010) are shown in Fig. 26a–c. A perusal of these graphs show that the results of these studies are in close agreement. Although different soil parameters, stone column parameters, stone column diameter etc. were used for both studies, a similar trend of variation in vertical load intensity on varying the encasement length, geotextile encasement stiffness and friction angle of stone column is observed.

Comparative graphs between the results of current study and Khabbazian et al. (2010) for varying (a) encasement length (b) encasement stiffness and (c) friction angle of stone column

4 Conclusions

Numerical analysis of GESCs was carried out using PLAXIS3D. The models developed were first validated with the help of experimental data from the literature and then parametric studies were conducted to study their influence on the load settlement behavior of the GESCs. As a result of numerical analysis conducted, following conclusions were reached.

-

1.

With increase in diameter of GESCs, the vertical load intensity of the stone columns decreased under vertical loads. This is attributed to the fact that in larger diameter GESCs, there is larger scope for rearrangement of infill material. Moreover, larger diameter columns mobilize larger hoop stresses. However, in case of OSCs, there was no significant improvement in the bearing capacity upon increasing the diameter of the stone columns

-

2.

The bearing capacity of GESCs decreased with increasing S/D ratio. Similar trend was observed on changing the pattern of stone column installation from triangular to rectangular. Hence it can be concluded that as the spacing between the GESCs increases, there is reduction in the load carrying capacity

-

3.

Providing geosynthetic encasement significantly improved the bearing capacity of end bearing GESCs. The hoop strain reduced significantly as the geosynthetic encasement stiffness was increased. However, in case of floating GESCs, there was no considerable improvement when the stiffness of encasement was increased beyond 500kN/m. This is due to the fact that the settlement in floating GESCs at higher geosynthetic encasement stiffness is due to punching rather than bulging

-

4.

The bearing capacity increased with increase in the length of encasement. For the prescribed settlement of 50 mm there was no considerable improvement upon increasing the encasement length beyond 2D. For larger settlements of 100 mm and 150 mm, the optimum length of the encasement increased up to 3D and 4D respectively. Hence it can be concluded that the optimum length of encasement is directly proportional to the external loading

-

5.

Increasing the length of floating GESCs resulted in considerable improvement in the bearing capacity. This can be attributed to the fact that the longer floating GESCs transfer the applied loads to greater depths and thereby increase the bearing capacity

-

6.

Substantial improvement in the bearing capacity of GESCs was found on increasing the cohesion of surrounding soil from 5-100 kPa. However, the improvement is greater for smaller values of cohesion but at higher values, the improvement in the bearing capacities is not as significant

-

7.

Increase in the frictional angle of stone column infill led to enhancement in the bearing capacity of GESCs. This enhancement is more prominent in case of larger prescribed settlements

References

Aboshi H, Ichimoto E, Harada K, Emoki M (1979) The composer—a method to improve the characteristics of soft clays by inclusion of large diameter sand columns. In: Proceedings of international conference on soil reinforcement, Paris, p. 211–216

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic- reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305

Almeida MSS, Hosseinpour I, Riccio M (2013) Performance of a geosynthetic encased column (GEC) in soft ground: numerical and analytical studies. Geosynth Int 20(4):252–262

Ambily AP, Gandhi SR (2007) Behaviour of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng ASCE 133(4):405–415

Ayadat T, Hanna AM (2005) Encapsulated stone columns as a soil improvement technique for collapsible soil. Ground Improvem 9(4):137–147

Castro J, Cimentada A, Costa A, Canizal J, Sagaseta C (2013) Consolidation and deformation around stone columns: compar- ison of theoretical and laboratory results. Comput Geotech 49:326–337

Chen JF, Li LY, Xue JF, Feng SZ (2015) Failure mechanism of geosynthetic encased stone columns in soft soils under embankment. Geotext Geomembr 43(5):424–431

Dar LA, Shah MY (2020) Deep-seated slope stability analysis and development of simplistic FOS evaluation models for stone column-supported embankments. Transp Infrastruct, Geotech

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175

Goughnour RR (1983) Settlement of vertical loaded stone columns in soft ground. Proceedings of the 8th European conference on soil mechanics and foundation engineering, Helsinki 1:23–25

Greenwood DA (1970) Mechanical improvement of soils below ground surfaces. In: Proceedings, ground engineering conference, institution of civil engineers, London, pp 11–22

Han J, Ye SL (2001) Simplified method for consolidation rate of stone column reinforced foundation. J Geotech Geoenviron Eng ASCE 127(7):597–603

Hughes JMO, Withers NJ, Greenwood DA (1975) A field trial of the reinforcing effect of a stone column in soil. Geotechnique 25(1):31–44

Indraratna B, Bamunawita C, Khabbaz H (2004) Numerical modelling of vacuum preloading and field applications. Can Geotech J 41(6):1098–1110

IS: 15284 (part 1) (2003) Indian standard code of practice for design and construction for ground improvement—guidelines. Indian Standards Institution, New Delhi

Keykhosropur L, Soroush A, Imam R (2012) 3D numerical analyses of geosynthetic encased stone column. Geotext Geomembr 35(2012):61–68

Khabbazian M, Kaliakin VN, Meehan CL (2010) Numerical study of the effect of geosynthetic encasement on the behaviour of granular columns. Geosynth Int 17(3):132–143

Khadhim ST, Parsonsn RL, Han J (2018) Three dimensional numerical analysis of individual geotextile encased sand column with surrounding loose sand. Geotext Geomembr 46:836–847

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behaviour of encased stone column and conventional stone column. Soils Found 47(5):873–885

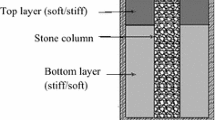

Mohanty P, Samanta M (2015) Experimental and numerical studies on response of the stone column in layered soil. Int J Geosynth Ground Eng 1:1–14

Murtaza H, Samadhiya NK (2016) Experimetal and numerical analysis of geosynthetic-reinforced floating granular pies in soft clays. Int J Geosynth Ground Eng 2:22

Murugesan S, Rajagopal K (2006) Geosynthetic-encased stone columns: numerical evaluation. Geotext Geomembr 24:349–358

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic encased stone columns. Geosynth Int J 24(6):346–354

Najjar SS, Sadek S, Maakaroun T (2010) Effect of sand columns on the undrained load response of soft clays. J Geotech Geoenviron Eng ASCE 136(9):1263–1277

Priebe HJ (1995) The design of vibro-replacement. Ground Eng 28(10):31–37

Pulko B, Majes B, Logar J (2011) Geosynthetic-encased stone columns: analytical calculation model. Geotext Geomembr 29(1):29–39

Rajagopal K and Mohanty SR (2016) Behaviour of geosynthetic encased granular columns under vertical and lateral loading. In: 6th Asian regional conference on geosynthetics

Rajasekaran G, Rao SN (2002) Compressibility behaviour of lime treated marine clay. Ocean Eng 29(5):545–559

Rampello S, Callisto L (2003) Predicted and observed performance of an oil tank founded on soil-cement columns in clayey soils. Soils Found 43(4):229–241

Sharma SR, Phanikumar BR, Nagendra G (2004) Compressive load response of granular piles reinforced with geogrids. Can Geotech J 41(1):187–192

Shen SL, Chai JC, Hong ZS, Cai FX (2005) Analysis of field performance of embankments on soft clay deposit with and without PVD-improvement. Geotext Geomembr 23(6):463–485

Van Impe W, Silence P (1986) Improving of the bearing capacity of weak hydraulic fills by means of geotextiles. In: Proceedings of the 3rd international conference on geotextiles, Vienna, pp 1411–1416

Wu CS, Hong YS (2009) Laboratory tests on geosynthetic encapsulated sand columns. Geotext Geomembr 27:107–120

Yoo C (2010) Performance of geosynthetic-encased stone columns in embankment construction: numerical investigation. J Geotech Geoenvir Eng ASCE 136(8):1

Yoo C, Lee D (2012) Performance of geogrid-encased stone columns in soft ground: full-scale load tests. Geosynth Int 19(6):480–490

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in publishing this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dar, L.A., Shah, M.Y. Three Dimensional Numerical Study on Behavior of Geosynthetic Encased Stone Column Placed in Soft Soil. Geotech Geol Eng 39, 1901–1922 (2021). https://doi.org/10.1007/s10706-020-01594-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01594-x