Abstract

In this study, natural fiber-reinforced polymer composite materials were fabricated by hand lay-up method. The pineapple leaf fiber as reinforced composite has been investigated for tensile strength using Universal Testing Machine (UTM). The chemical treatment with soaking in 5 wt% NaOH solution and varying the type of fiber arrangement, the composite specimens have been made. The comparing of fibers fraction volume is restricted from 20, 30, and 40 vol.% with Unsaturated Polyester Resin (UPR), Yukalac 157 BQTN-EX Series as a total volume of the composite. The results showed that the fiber volume fraction ratio of 40% and unidirectional fiber orientation succeeded in increasing the tensile strength to 103.5 MPa.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Increased application of technology in composite materials have been fully leading on the composite-based naturally well as material reinforcement [1, 2]. Natural fiber has become an important commodity for economic matters and becomes a significant source of employment for developing countries. The natural fibers can be easily obtainable in many areas of tropical and available in the whole world. The characteristic of this composite are the properties of the fibers and the matrix was enabled to modified without reducing the functions and chemical properties of the materials itself. The development of natural reinforced composite has replaced the function of metal and carbon [1,2,3].

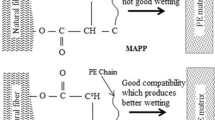

Study on the reinforced natural fibers as substitute glass fiber as composites had increased and got an opportunity to be mass-produced. However, the major weakness of the natural fibers is the compatibility between the fibers and the matrix. Consequently, chemical treatment has been considered in modifying the properties of the surface of the fiber [2, 3]. One of the reinforced natural fibers is made from the leaves of a pineapple. It has been a lot of research with improvement through the properties of physical and mechanical fiber pineapple that are combined with polyester resin as a matrix [3].

In this research, the pineapple leaf will be used as a natural reinforced fiber. The term of composites also includes the materials that have a form of particles or layers. Volume fraction (in wt%) is the rule for mixing the volume of fiber and the volume of the matrix towards the total volume of the composite [4]. Usually, the term volume fraction refers to a large proportion (%) of the volume of reinforcing materials used in the manufacture of composites.

If the purpose of making a composite is strength, the reinforced fibers must have a larger aspect ratio when compared to the matrix [4, 5]. Obviously, the reinforced composite should be a component that is powerful to carry the load, and the reinforced fibers must have higher modulus elasticity. When the value of stiffness between matrix and reinforcement is critical, the load must able transferred from the matrix to the fibers if the composite was desirable with function with either [6]. Pineapple leaf fiber (PALF) which is relatively inexpensive and widely available, has been to potential composites with natural fiber strengthened [7].

Based on previous research, it’s necessary to study the effect of volume fraction of pineapple leaf fiber with polyester matrix by comparing types of unidirectional and random fiber arrangement.

2 Experimental

2.1 Material

In this study, the materials of the natural composite of Pineapple Leaf Fiber (PALF) were obtained at the village in the district of Bener Meriah, Aceh. Unsaturated Polyester Resin (UPR), Yukalac 157 BQTN-EX Series with a density of 1.12 g/cm3 at 25 °C from Justus Sakti Raya Company used as matrix and 1% catalyst methyl ethyl ketone peroxide (MEKP) used as a hardener of polyester. From the other research in the same field, the physical and chemical properties of natural fiber summarized as shown in Table 1.

2.2 Preparation of Specimens

The chemical used for the treatments of pineapple leaf fiber (PALF) was Sodium Hydroxide (NaOH) at a concentration of 5% of water volume. The process of making the fiber is done by way of soaking pineapple leaves in water that contains NaOH 5 wt% for 2 h. Then, the pineapple leaves are scratched in order to produce fiber. The fibers are dried at room temperature for 48 h [3]. Some of the fibers are cut into short fibers and others are cut out to the size of the test mold.

2.3 Methods

Comparison of volume between fiber and matrix in at 20, 30, and 40 vol.% of the composite. The composite materials have been made by a hand lay-up method. Composite fiber with unidirectional and random short fiber was created in the mold with dimensions of 24 × 14 × 3.2 mm. Specimens have been removed from the mold were cutting according to standard ASTM D638 [10] for tensile tests. The specimen test sample is repeated several times and the average results are taken to be discussed as the characteristic properties of the composite. Figure 1a, shows the device that has been used for tensile test, and Fig. 1b and c, show the shape of the composite specimen that has been made accordingly to ASTM D638.

3 Results and Discussions

Has been achieved the results of tensile testing on reinforcement composites pineapple leaf fiber (PALF) with chemical treatment (5% NaOH) and optimization of fiber volume fraction of 20, 30, and 40 vol.%.

Figure 2 shows the relationship between the tensile strength of the differences in random fiber volume fraction. The results of the volume fraction of 20% random fiber arrangement have an average tensile strength value of 25.9 MPa. On the volume fraction of 30%, the average tensile strength only increased by 28.22 MPa. For fibers with 40% volume fraction, there was a significant increase in tensile strength above 40 MPa. This occurs since the greater the number of random fibers results in more bonds between the fibers and the matrix [11].

Figure 3 shows a tensile test specimen with a unidirectional fiber arrangement with a fiber volume fraction of 20, 30, and 40 vol.%. The average value of tensile strength increases more than 100% where the lowest value occurs at the fiber content of 20 vol.%, specifically 51.2 MPa. The highest tensile strength value was found in the fibers with a volume fraction of 40% is 103.5 MPa with an average tensile strength of 94.35 MPa.

The tensile strength increased of the reinforced composite was strongly influenced by the fiber arrangement and fiber volume from its comparison to the matrix [12]. The random arrangement did not significantly increase the tensile strength even with a large fiber volume (40%), While the unidirectional arrangement of the tensile plane showed significant strength results that exceeded twice than the random fibers with a minimum fiber volume fraction (20%).

Different types of pineapple leaves based on the sampling location and variations in chemical treatment also affected increased the tensile strength value. The bond between the fiber and matrix is more uniform across the surface of the fiber with chemical treatment [13]. The lower value of the tensile strength on this research, when compared with the previous studies, is due to the difficulty of obtaining a uniform dimension of natural fiber [14, 15]. To ensure the results of the tensile strength test, the specimen was taken in a microscopic image to see the shape of the fracture. Figure 4 shows the results of the microscopic picture on random fiber fracture and unidirectional arrangement at volume fraction 40%.

The fracture morphology of the two images in Fig. 4 shows different results. In random fibers, the fracture that occurs does not show a significant fiber effect. The fracture is shown in Fig. 4a shows the fracture of the brittle materials where the strength of the matrix was dominant. Figure 4b shows the shape of the fracture that extends in the direction of the pull, where the fracture results show the pull out of the fiber without visible voids in the bonds between the fibers and the matrix.

4 Conclusion

Pineapple fiber has been extensively studied with various techniques and compositions to achieved results as a reference for natural reinforced fiber. Research on the effect of chemical treatment with NaOH 5 wt% Pineapple leaf fiber showed that the ratio of fiber volume fraction and fiber direction orientation succeeded in increasing the tensile strength significantly up to 103.5 MPa. The selection of unidirectional fibers with a fiber volume fraction composition of 40% is highly recommended because it has an average tensile strength up to 94.35 MPa.

References

Asim M, Jawaid M, Abdan K, Ishak M (2017) Fiber Polym 18:940–947

Devi LU, Bhagawan S, Thomas (1997) J Appl Polym Sci 64(9):1739–1748

Suryani et al (2020) IOP Conf Ser: Mater Sci Eng 788:012038

Marliana M, Hassan A, Yuziah NM, Khalil AH, Inuwa I, Syakir M, Haafiz M (2016) Fiber Polym 17:940–947

Wan N, Jawaid M, Masri A, Khalil AS, Suhaily S, Mohamed RA (2012) J Polym Environ 20:404–411

Vlack Lawrence HV (2004) Elements of materials science & engineering. Addison-Wesley

Yusof Y, Nawi MN, Alias MSHB (2016) J Eng App Sci 11:4197–4202

Sanjay M, Yogesha B (2017) Mater Today: Proc 4:2739–2747

Yusoff RB, Takagi H, Nakagaito A (2016) Ind Crops Prod 94:562–573

ASTM D638-14, 2014 Standard Test Method for Tensile Properties of Plastics, West Conshohocken, PA

Akil H, Omar M, Mazuki A, Safiee S, Ishak ZM, Bakar A (2011) Rev Mater Des 32:4107–4121

Nirmal U, Hashim J, Ahmad MM (2015) Tribol Int 83:77–104

Jaafar J, Siregar JP, Piah MBM, Cionita T, Adnan S, Rihayat T (2019) J Polym Environ 26:4271–4281

Asim M, Jawaid M, Abdan K, Isaac (2016) J Bionic Eng 13:426–435

Panyasart K, Chaiyut N, Amornsakchai T, Santawitee O (2014) Energy Procedia 56:406–413

Acknowledgements

The authors are thankful to the LPPM and Faculty Engineering of Malikussaleh University for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Muhammad, Putra, R., Hafli, T., Asnawi (2021). Effect of Pineapple Leaf Fiber Volume Fraction with 157 BQTN-EX as a Matrix on the Tensile Strength of the Composite. In: Akhyar (eds) Proceedings of the 2nd International Conference on Experimental and Computational Mechanics in Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0736-3_24

Download citation

DOI: https://doi.org/10.1007/978-981-16-0736-3_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0735-6

Online ISBN: 978-981-16-0736-3

eBook Packages: EngineeringEngineering (R0)