Abstract

This study investigates various ways to present material and information at workstations, using various assembly scenarios. The experiment is conducted with fifteen participants and six types of pen. The material presentation factors considered are the use of intermixed parts, grouped parts, separated parts in different boxes, and part numbered box. The information presentation factors include text instructions and photographs. From the results, it can be concluded that by using part numbered box as material presentation and instructions as information presentation provides the highest number of parts assembled with least errors. Similarly, using intermixed parts with instructions resulted in a decreased number of assembled pens. The design and preparation of workstations can be performed based on the cognitive abilities of the subjects. The different material and knowledge presentation factors can be designed according to their abilities.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ergonomics at work is the study of developing the work environment, considering the laborer’s abilities and shortcomings. Awful workplace configuration prompts to worker fatigued, irritated, and suffering, which reduces worker productivity. Participatory ergonomics initiatives have been suggested as the most successful way of removing, or redesigning, manual activities in order to reduce the occurrence of musculoskeletal disorders in the workplace. This analysis reviews the evidence base for this claim; describes the range of approaches taken under the umbrella of participatory ergonomics in a variety of industries; and brings together the lessons learned in implementing these programs [1]. The journey toward Industry 4.0 and the growing introduction of Cyber Physical Systems provoke improvements in the organization of human life and employment, generating new challenges, and opportunities. To take advantage of these opportunities and address the obstacles, new human-centered solutions and digital technology have to be incorporated [2].

Ergonomic practitioners in general did not expand the usage of conventional direct assessment tools for risk factors. Certified ergonomics professionals tend to have expanded use of some of the formal observational-based evaluation approaches [3]. A reliable tool for assessment of visual work environments, especially for complex tasks. However, efficiency could be further improved by increasing the standard of assessor training. Such results also support further evaluation of new longitudinal studies evaluating its responsiveness to visual environment changes [4]. Modern manufacturing systems vary significantly depending on size of the business and plant, and the quality of the product. Complex manual assembly environment is not just one factor at a time which affects the assembler but several combined factors. The expected workload analysis is also conducted using the NASA Task Load Index (NASA-TLX) workload measurement tool [5]. The assembly work environment places tremendous pressure on the assembler from a cognitive viewpoint that varies from one factor level to other. The purpose of this experimental study is therefore to examine the variables previously identified in a small pen assembly station influencing the cognitive aspects of human performance.

2 Background

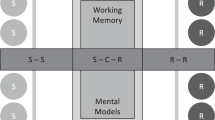

A subject doing assembly work is often subject to circumstances of increasing cognitive demands. A virtual-engineering approach is to assess the structural complexity of digitally engineered component-based industrial automation systems [6]. Product complexity and the manufacturing process by which a product is produced affect operational efficiency, which is to be considered by manufacturers seeking to understand the effect of expanding product lines on their production systems [7]. The downside from an ergonomic point of view is that the assembler must concentrate solely on the assembly process, i.e., how to assemble, and do not care about which parts to assemble which can eventually contribute to a high level of product quality [8]. Learning curves (LCs) are considered to be effective tools for measuring worker productivity and providing a statistical explanation of the learning process that occurs when the job is repeated. Using technology or other approaches to improve worker learning will reduce the negative impacts of large pools of employees and missing employees [9]. The translation and first assessment of the psychometric property (NASA-TLX), a multidimensional tool for calculating workload in general practice, is a widely used, subjective, multidimensional measuring method that scores perceived workload to evaluate the effectiveness of a task, plan, or team, or other performance aspects [10].

3 Experimentation

This section presents an experimental study showing the presentation of the data, the presentation of material, and the effects of using various varieties of pens with different parts. The purpose of the analysis is to analyze assembly task performance, primarily the number of assembled parts and the number of errors in each level combination. This segment describes an experimental study showing the presentation of data, the presentation of knowledge, and the effects of using various varieties of pens with different sections. In this study, there are six varieties of pens as shown in Fig. 1, with varying number of parts are to be assembled in eight different combinations of material and information presentation. Fifteen people volunteered for the trial, mostly engineering graduates, except a few from humanities background. The experiment is conducted at a laboratory premises where the entire setup is designed to identify the subject’s cognitive abilities. The subjects perform the task of constructing a pen within the time of ten minutes.

In addition to the subjects which conducted the assembly process, there are two researchers present. One manually controlled the assembly using a stopwatch, and the other disassembled the pieces of pen to measure the quality of the assembled pen. Table 1 shows the steps of the experiment, including the level of factors.

4 Results

The main aim of the experiment is to identify the number of pens that are correctly assembled and the quality of the assembled parts. The last scenario has the highest number of assembled pens which is due to the experience, the subjects have gained by assembling the pens from the first seven cases. The lowest assembled was in the first scenario as the subjects are not exposed to the assembling task and they only can use the previous knowledge about a pen to assemble.

As per Fig. 2 the number of errors is more in the scenario 7 as the individuals has photograph of the exploded view but as the parts look similar in some cases such as the refill, spring which is misplaced. There are certain parts which are exclusively for certain type of pens; they are inappropriately assembled even with the exploded views. The least number of errors happened in case 6, in which part numbers are given. It can be seen that the part number category has less errors than any other scenarios which suggests the important of giving part number variations for assembling the product.

4.1 Learning Effect Considering the Number of Pens Assembled

A learning curve is a graphical portrayal of how an improvement in learning results from greater experience. The idea of learning curves is translated into pen assembly task as a “difficulty curve”, which described how hard it was for the subject to assemble the pen in different scenarios. The subject become more proficient with the further tasks, gain better understanding of the pen parts, and the error factor is decreased. As with learning curves in industrial aspect, difficulty curves can have multitudes of shapes, and tasks may frequently provide various levels of difficulty that change the shape of this curve relative to subject and effectively find the best person for the task.

The subjects are divided into three clusters for easy identification of the best and worst assembler. From Fig. 3, it is evident that subject 5 is a good learner compared to others in the cluster. Subject 10 can also be considered as a better learner as the number of pens assembled could be higher. Subject 2 showed a better learning experience but in the seventh scenario, there is a decrease in the number of assembled pens.

From Fig. 4, subject 10 can be considered as the best learner and subject 7 as the worst. Subject 6, 9, and 8 showed an increased learning effect but the number of assembled pens was less comparatively. This is critical as it affects the whole amount required for production in a certain time and the error factor can also be considered.

From Fig. 5, subject 12 has the best learning curve and subject 14, the worst in terms of learning effect. Subject 15 and 13 had a decrease in the learning effect. Subject 11 had a gradual dip in the seventh scenario.

To summarize the results, it was considered that the end scenario must have a greater number of assembled pens without errors. According to this, subject 12 was the best learner and subjects 14 and 7 were the worst. The skill set of the workers can be identified and thus the allocation of a worker to a specific task according to his capabilities can be assigned.

4.2 NASA-TLX and Number of Pens Assembled

Therefore, study of the expected workload is also carried out using the workload evaluation tool NASA-TLX. In this analysis, after assembling pen in all scenarios, fifteen subjects are asked to rate their perceived workload on six different scales: mental, physical, temporal, performance, effort, and frustration. They set the scales from 0 to 100 and is depicted in Fig. 6. The factors are weighted in relation to each other to illustrate the most important aspects of the workload, where tension and mental workload are the primary focus; physical and performance are weighted as of lesser importance.

The NASA-TLX scores of various subjects are converted to various class intervals of four and is depicted in Table 2.

The comparison of these scores with the number of pens assembled correctly is to be considered so the rating of class intervals is considered as per Table 3.

The actual values of pens assembled can be compared with that of the NASA-TLX scores. The cognitive abilities will be different for different subjects and their rating on the different scenarios will be different from that of the experimental values.

The ratings of the scores give an idea about the difficulty level of the tasks and is given in Table 4. Out of the total ratings, the subjects have experienced a medium level of difficulty, considering all the scenarios. Only twenty percentage of subjects in various scenarios claimed that the tasks are easy. The easier ratings are obtained in scenario six and difficult in scenario one. The number of pens assembled are also rated according to the class intervals and they are listed in Table 5.

Subject 12 is the only person with a very good record of the number of pens assembled. Most of the subjects had done only a smaller number of assemblies in each scenario, which is considered as bad. This may be because, the quality of products assembled is the deciding factor in an assembly line. A good number of pens assembled is not observed in scenario six, as per the requirements or the highest value. The number of pens assembled in scenario 1 is bad but only five persons reported that scenario as difficult. In scenario 2, seven subjects rated the task as difficult and that is reflected in the number of pens correctly assembled. In scenario 6, two subjects genuinely rated as difficult but at the end there is no very good rating obtained. The learning effect for the final scenario must show a very good number of pens assembled, but only one subject could effectively achieve it and the rating was not given easy as per the learning experience.

5 Conclusion

This study provides an outline of the behavior of various subjects when they perform a specific assembly task for the first time and also how the productivity and quality of the assembled parts eventually increase. In response to manufacturers trying to understand the impact of increasing product lines on their production processes, the product complexity and the number of parts from which product is produced affect operating performance. The subjects show different trends of assembling products and even with the variety of products being increased, factor levels with proper instructions gained more quality and productivity in the assembly. The ability to think and differentiate the parts, learn with a particular phase, and recall the flaws happened concluded that using intermixed parts and grouped parts takes longer time and generates higher workload compared to separate parts in different boxes part numbered boxes. When using part numbered box and separated parts in different boxes, the task is made easier compared to intermixed parts and grouped parts. This is probably due to the difference in cognitive abilities of the subjects such as think, learn, remember, and pay attention. These skills can be further analyzed so that rotations in workstations among the subjects can be done according to their skills. One of the major cognitive ability of the subject must be their learning effect, which is also identified by giving various factor levels and the number of pens which each of them assembled had different trends.

The NASA-TLX values are not supporting the fact that part numbers with instructions are easier to do. The same is applicable for the number of pens assembled. This suggests that the subjective rating can be deviated from the exact experimental outputs. The errors made in assembly units are a huge loss to the manufacturing units, so assigning proper subjects in their order of their cognitive skills will be the best way to improve productivity especially in manual assembly lines. The assessment of cognitive skills can be verified using electroencephalogram (EEG) and galvanic skin response, but as the person is continuously moving from the position the signals are not accurate to support the assessment which is the major drawback of this experiment.

References

Burgess-Limerick R (2018) Participatory ergonomics: evidence and implementation lessons. Appl Ergon 68:289–293

Kadir BA, Broberg O, da Conceição CS (2019) Current research and future perspectives on human factors and ergonomics in industry 4.0. Comput Ind Eng 3:106004

Lowe BD, Dempsey PG, Jones EM (2019) Ergonomics assessment methods used by ergonomics professionals. Appl Ergon 81:102882

Zetterberg C, Heiden M, Lindberg P, Nylén P, Hemphälä H (2019) Reliability of a new risk assessment method for visual ergonomics. Int J Ind Ergon 72:71–79

Brolin A, Thorvald P, Case K (2017) Experimental study of cognitive aspects affecting human performance in manual assembly. Prod Manuf Res 5(1):141–163

Alkan B, Harrison R (2019) A virtual engineering-based approach to verify structural complexity of component-based automation systems in early design phase. J Manuf Syst 53:18–31

Trattner A, Hvam L, Forza C, Herbert-Hansen ZN (2019) Product complexity and operational performance: a systematic literature review. CIRP J Manuf Sci Technol 25:69–83

Gewohn M, Beyerer J, Usländer T, Sutschet G (2018) Smart information visualization for first-time quality within the automobile production assembly line. IFAC-PapersOnLine 51(11):423–428

Glock CH, Grosse EH, Jaber MY, Smunt TL (2019) Applications of learning curves in production and operations management: a systematic literature review. Comput Ind Eng 131:422–441

Flägel K, Galler B, Steinhäuser J, Götz K (2019) The “national aeronautics and space administration-task load index” (NASA-TLX)—an instrument for measuring consultation workload within general practice: evaluation of psychometric properties. Zeitschrift für Evidenz, Fortbildung und Qualität im Gesundheitswesen 147:90–96

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Giridhar, M.P., Panicker, V.V. (2021). Assessing Cognitive Behavior of Subjects Using Learning Effect and NASA-TLX in a Manual Pen Assembly. In: Pandey, C., Goyat, V., Goel, S. (eds) Advances in Materials and Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0673-1_33

Download citation

DOI: https://doi.org/10.1007/978-981-16-0673-1_33

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0672-4

Online ISBN: 978-981-16-0673-1

eBook Packages: EngineeringEngineering (R0)