Abstract

Free convection of an electrically conducting micropolar fluid past a permeable stretching surface is considered in the present analysis. The crux of the investigation is the study of velocity slip boundary condition that affects the flow behavior. In addition to that the temperature profile enhances with the inclusion of dissipative heat energy, thermal radiation and the heat generation/absorption parameter. Employing suitable similarity variables, the governing equations are transformed to nonlinear ODEs and numerical treatment such as fourth-order Runge-Kutta method in conjunction with shooting technique. Physical behavior of several contributing parameters for the flow phenomena, local skin-friction coefficient, the wall couple stress, and the local Nusselt number are presented via graphs and further described in the results and discussion section.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent days, a considerable interest among the researchers is found for the study of flow phenomena through a stretching sheet. The fact is the extensive application in both engineering and industries. As a pioneer work, Crane [1] presented his study for the laminar boundary flow of an incompressible, time-independent flow through a stretching surface. Further, Gupta and Gupta [2] extended the work of [1] for the influence of suction/injection in the boundary layer over a stretching surface. Vajravelu and Rollins [3] and Pavlov [4] have investigated the heat transfer properties in an electrically conducting fluid in conjunction with internal heat generation or absorption. Baag et al. [5] studied numerically by using the fourth-order Runge-Kutta method with shooting technique to compare their result with previous study. They confirmed the accuracy of their study. Ayano et al. [6] reported that the flow of micro-rotation components will be in opposite direction and one of these components is not rotating.

Das [7] investigated the chemical reaction and thermal radiation effect of MHD micropolar fluid by considering a rotating frame of reference. An analytical treatment by using least square method (LSM) has been carried out to investigate the effects of Reynolds number and Peclet number on a micropolar fluid flow by Fakour et al. [8]. Shamshuddin and Narayana [9] have considered an unsteady case of MHD micropolar fluid whose flow past an inclined plate with reference to a rotating system. They observed the regular behavior of micropolar fluid in their study. Ishak et al. [10] considered the MHD micropolar fluid flow in presence of magnetic field which is applied normal to the plate and thermal buouyancy in their study. They observed the dual behavior of solutions which exist for the assisting flow. Nazeer et al. [11] have considered a micropolar fluid in porous medium with uniform and non-uniform heated bottom wall. A study of micropolar fluid flow in porous medium over a stretchable disk by considering all the profiles like axial velocity, radial velocity, micro-rotation, temperature, and concentrations profiles have been carried out by Rauf et al. [12]. Sheikholeslami et al. [13] in their study of micropolar fluid used an analytical method (Homotopy Analysis Method) to investigate the behavior of Reynolds number and Pecelet number on all the used profiles. They observed the inter link of both these said numbers with Nusselt and Sherwood numbers.Viscous dissipation taken into consideration on the study of a MHD micropolar fluid flow is to investigate the behavior of translation velocity, micro-rotation, and temperature profiles. It has been observed that all these profiles showed the decreasing behavior for increasing values of viscous dissipation (see [14]). Srivastava [15] in his research paper considered the flow of MHD micropolar fluid in between two eccentrically rotating disks to study the effects of the micropolar parameter and Hartmann number on the velocity and micro-rotation profiles. Mishra et al. [16, 17] used the uniform magnetic field strengths along the flow direction to check the behavior of all the profiles considered in the work in presence of heat source and radiation parameter. Ashmawy [18] considered a convective micropolar fluid in between two vertical uniformly heated channels with velocity slip condition applied. Ferdows and Liu [19] used magnetic field and thermal buoyancy parameters in momentum equation, non-uniform heat source parameter in energy equation to investigate the behavior of magneto-micropolar fluid flow in a vertical plate.

In view of aforesaid discussion it is important to describe the physical significance of heat generation and absorption. Though it is difficult to model the exact internal heat generation or absorption, a mathematical model, following Foraboschi and Federico [20], can be expressed as \(S = \left\{ \begin{gathered} Q_{0} (T - T_{\infty } ),\,\,T \ge T_{\infty } \hfill \\ 0,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,T < T_{\infty } \hfill \\ \end{gathered} \right.\) which is valid for the state of some exothermic processes. We have extended the work of Mahmoud et al. [21] by incorporating thermal buoyancy parameter in momentum equation, thermal radiation, and viscous dissipation term in energy equation and also boundary condition of micropolar profile has been modified.

2 Mathematical Formulation

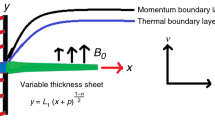

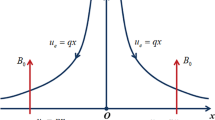

Two-dimensional free convective flow of an electrically conducting micropolar fluid past a porous stretching surface is considered in the present investigation. The plate is along the plane \(y = 0\), the flow takes place in the region \(y > 0\). Applied uniform magnetic field of strength \(B_{0}\) is imposed along the normal direction of the flow. Variable surface heat flux \(q_{s} (x) = bx^{m}\) (where b, m are constants) as well as the slip velocity boundary conditions are also assumed. Based upon the aforesaid assumptions the basic governing equations for the flow are

The boundary conditions are

Jena and Matkur [22] considered the case \((n = 0)\) of concentrated particle flows in which they observed that micro-elements close to the wall are unable to rotate. But Ahmadi [23] examined the case \((n = 1/2)\) of weak concentrations and indicates the vanishing of antisymmetric part where as the case for \((n = 1)\) turbulent boundary layer flows suggested by Peddieson [24]. The radiative heat flux term by using the Rosseland approximation [25] is given by

where \(\sigma^{*}\) Stefan–Boltzmann constant and \(k^{*}\) mean absorption coefficient. We have assumed that the temperature differences are very small within the fluid. We have expanded \(T^{4}\) by Taylor series expansion about \(T_{\infty }\) and neglecting higher order terms to express as a linear function. So \(q_{r}\) can be written as

Equation (4) takes the form:

3 Method of Solution

The equation of continuity (1) is satisfied by introducing the stream function \(\psi\) such that

and with the following dimensionless variables:

So the modified equations of the flow can be written as

The physical quantities of interest are the local skin-friction coefficient \(C_{fx}\), the dimensionless wall couple stress \(M_{x}\), and the local Nusselt number \(Nu_{x}\), which are defined as

where the local wall shear stress \(\tau_{W}\), the wall couple stress \(m_{w}\), and the heat transfer from the plate \(q_{w}\) are defined by

Using the similarity variables (10), we get

where \({\text{Re}}_{x} = \frac{{ax^{2} }}{\upsilon }\) is the local Reynolds number.

4 Results and Discussion

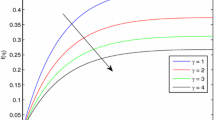

Free convection of an electrically conducting micropolar fluid past a stretching surface is considered in the current investigation. The characteristics of the energy equation are enhanced by incorporating the heat generation/absorption parameter as well as the viscous dissipation. In an addition, the slip boundary condition for the velocity is considered which affects the flow phenomena. The physical significance of the contributing parameters are obtained and presented via graphs. The rate coefficients for all the profiles are also displayed through graphs. The variation of several parameters on the profiles is presented in the corresponding figures. Figure 1 depicts the validation of the transverse velocity, longitudinal velocity, micro-rotation, and the temperature profiles in the absence of magnetic field, thermal buoyancy, and the thermal radiation. However, the result coincides with the work of Mahmoud et al. [21] showing the conformity of the convergence procedure of the current methodology. Figure 2 exhibits the behavior of the suction/injection parameter for various values of slip factor on the velocity distribution. The partial vacuum exerts upon a liquid is caused by the suction. Reduction in pressure is marked due to the removal of air from the space resulted to enter the fluid into the space. Therefore, the fluid exerts from the higher pressure region to lower pressure region. In comparison to suction and injection, it is seen that the suction lowers down the velocity profiles irrespective of the slip or no slip region. However, in case of no slip condition, the maximum velocity is rendered within the boundary layer and reduction in the profile is observed with increasing slip. Pick in the micro-rotation profiles is marked near the surface up to the region \(\eta \le 1\) and afterwards sudden fall is marked in Fig. 3. Moreover, suction produces higher pressure to reduce the profiles than that of injection. Similar observation is rendered in case of slip parameter as described in the Fig. 2. Figure 4 exhibits the distribution of temperature profiles for the variation of the suction/injection and slip parameters. It is observed that increasing slip enhances the fluid temperature in the entire region of the thermal boundary layer and injection also favorable to increase the temperature as well. The values of the material parameter (\(K\)) indicates the Newtonian and non-Newtonian characteristics of the fluid. \(K\) = 0 represents the Newtonian case and the \(K \ne 0\) shows the non-Newtonian nature. However, in the present case we have considered the non-Newtonian behavior of the fluid. Figure 5 illustrates the profiles of micro-rotation in conjunction with suction/injection. An increase in the material parameter enhances the micro-rotation profiles with pick near the surface and further it decelerates. The case of injection is also favorable to enhance it significantly. Figure 6 portrays the wall surface condition parameter (n) with suction/injection parameter on the micro-rotation distribution. The micro-rotation profile enhances rapidly near the surface with increasing the wall surface condition parameter. However, the injection is now favorable to enhance the profile for lower values of n but effect is reversed for higher values. Irrespective of values of suction/injection parameter, buoyancy parameter enriches the velocity profiles that exhibit in Fig. 7. The pressure difference results in a net upward force on the object. Figures 8 and 9 describe the impact of thermal radiation and heat source on the temperature profiles in conjunction with suction/injection parameter. Thermal radiation is one of the characteristics that depends on the various properties of the surface. Thermal enhancement occurs in the entire domain due to increase in the thermal radiation and heat source parameter. The coupling of temperature and velocity profile occurs due to the inclusion of coupling parameter, i.e., the Eckert number. Figure 10 describes the temperature distribution for the various values of Eckert number. From the mathematical definition, it is clear that increasing Eckert number enhances the fluid temperature. Finally, Figs. 11, 12, 13 display the computational results of shear stress, rate of heat transfer, and the couple stress for various values of suction/injection versus the slip parameter. The trend of the graph shows the decelerating effect, whereas increasing suction increases the rate coefficients with increasing slip.

5 Conclusive Remarks

Free convection of micropolar fluid in conjunction with slip parameter and the effect of heat source are exhibited in the present investigation. The behavior of characterizing parameter on the flow phenomena is displayed and discussed. However, the major contributions are laid down as

-

The validation of present result with earlier established result shows the conformity of the convergence procedure of the methodology employed.

-

Retardation in the velocity profiles is marked due to increase in suction regardless with the increase of slip parameter.

-

The rate coefficients enhance with increasing suction with respect to the slip parameter.

Abbreviations

- \(a,\,b\) :

-

Constants

- \(B_{0}\) :

-

External uniform magnetic field

- \(C_{fx}\) :

-

Local skin friction coefficient

- \(Cp\) :

-

Specific heat at constant pressure

- \(Ec\) :

-

Eckert number

- \(f\) :

-

Dimensionless stream function

- \(f_{w}\) :

-

Suction/injection parameter

- \(g\) :

-

Acceleration due to gravity

- \(G\) :

-

Micro-rotation parameter

- \(G_{1}\) :

-

Micro-rotation constant

- \(j\) :

-

Micro-inertia density

- \(k\) :

-

Thermal conductivity

- \(K\) :

-

Material parameter

- \(M\) :

-

Magnetic parameter

- \(m\) :

-

Heat flux exponent

- \(m_{w}\) :

-

Wall couple stress

- \(M_{x}\) :

-

Dimensionless wall couple stress

- \(N\) :

-

Micro-rotation/angular velocity

- \(n\) :

-

Micro-rotation boundary condition

- \(Nu_{x}\) :

-

Local Nusselt number

- \(\Pr\) :

-

Prandtl number

- \(Q_{0}\) :

-

Heat generation/absorption constant

- \(q_{r}\) :

-

Radiative heat flux

- \(q_{s}\) :

-

Variable surface heat flux

- \(q_{w}\) :

-

Heat transfer rate

- \(R\) :

-

Radiation absorption parameter

- \({\text{Re}}_{x}\) :

-

Reynold’s number

- \(S\) :

-

Heat generation/absorption parameter

- \(T\) :

-

Temperature of the fluid

- \(T_{\infty }\) :

-

Onset temperature

- \((u,v)\) :

-

Velocity components along x-, y-axes

- \(v_{w}\) :

-

Suction/injection velocity

- \((x,y)\) :

-

Horizontal and vertical co-ordinate axes

- \(\mu\) :

-

Dynamic viscosity

- \(\rho\) :

-

Fluid density

- \(\beta_{T}\) :

-

Coefficient of thermal expansion

- \(\sigma\) :

-

Electrical conductivity

- \(\gamma\) :

-

Spin gradient parameter

- \(\alpha\) :

-

Velocity slip parameter

- \(\alpha^{*}\) :

-

Velocity slip coefficient

- \(\omega\) :

-

Dimensionless micro-rotation velocity

- \(\eta\) :

-

Scaled boundary layer coordinate

- \(\theta\) :

-

Dimensionless temperature

- \(\lambda\) :

-

Thermal buoyancy parameter

- \(\tau_{w}\) :

-

Local wall shear stress

- \(\upsilon\) :

-

Kinematic viscosity

- \(\psi\) :

-

Stream function

References

L. Crane, Flow past a stretching plate. Z. Angew. Math. Phys. 21, 645–647 (1970)

P.S. Gupta, A.S. Gupta, Heat and mass transfer on a stretching sheet with suction or blowing. Can. J. Chem. Eng. 55, 744–746 (1977)

K. Vajravelu, D. Rollins, Heat transfer in electrically conducting fluid over a stretching sheet. Int. J. Non-Linear Mech. 27, 265–277 (1992)

K.B. Pavlov, Magnetohydrodynamic flow of an incompressible viscous fluid caused by deformation of a surface. Magn. Gidrodin. 4, 146–147 (1974)

S. Baag, S.R. Mishra, G.C. Dash, M.R. Acharya, Numerical investigation on MHD micropolar fluid flow toward a stagnation point on a vertical surface with heat source and chemical reaction. J. King Saud Univ. – Eng. Sci. 29, 75–83 (2017)

M.S. Ayano, S.T. Sikwila, S. Shateyi, MHD mixed convection micropolar fluid flow through a rectangular duct. Hindawi Mathematical Problems in Engineering, ID 9840862, 8 p (2018). https://doi.org/10.1155/2018/9840862

K. Das, Effect of chemical reaction and thermal radiation on heat and mass transfer flow of MHD micropolar fluid in a rotating frame of reference. Int. J. Heat Mass Transf. 54, 3505–3513 (2011)

M. Fakour, A. Vahabzadeha, D.D. Ganji, M. Hatami, Analytical study of micropolar fluid flow and heat transfer in a channel with permeable walls. J. Mol. Liq. 204, 198–204 (2015)

M.D. Shamshuddin1, P.V. SatyaNarayana, Primary and secondary flows on unsteady mhd free convective micropolar fluid flow past an inclined plate in a rotating system: a finite element analysis. FDMP14 (1), 57–86 (2018)

A. Ishak, R. Nazar, I. Pop, Magnetohydrodynamic (MHD) flow of a micropolar fluid towards a stagnation point on a vertical surface. Comput. Math. Appl. 56, 3188–3194 (2008)

M. Nazeer, N. Ali and T. Javed, Numerical simulation of MHD flow of micropolar fluid inside a porous inclined cavity with uniform/non-uniform heated bottom wall. Can. J. Phys. 1–37 (2017)

A. Rauf, M. Ashraf, K. Batool, M. Hussain, M.A. Meraj, MHD flow of a micropolar fluid over a stretchable disk in a porous medium with heat and mass transfer. AIP Adv. 5, 077156 (2015). https://doi.org/10.1063/1.4927501

M. Sheikholeslami, M. Hatami, D.D. Ganji, Micropolar fluid flow and heat transfer in a permeable channel using analytical method. J. Mol. Liq. 194, 30–36 (2014)

S.R. Sheri, Md Shamshuddin, Heat and mass transfer on MHD flow of micropolar fluid in the presence of viscous dissipation and chemical reaction. Proceedia Eng. 127, 885–892 (2015)

N. Srivastava, MHD flow of the micropolar fluid between eccentrically rotating disks. Hindawi Publishing Corporation International Scholarly Research Notices, 2014, ID 317075, 7 p (2014). https://doi.org/10.1155/2014/317075

S.R. Mishra, M.M. Hoque, B. Mohanty, N.N. Anika, Heat transfer effect on MHD flow of a micropolar fluid through porous medium with uniform heat source and radiation. (2018). https://doi.org/10.1515/nleng-2017-0126

S.R. Mishra, P.K. Pattnaik, G.C. Dash, Effect of heat source and double stratification on MHD free convection in a micropolar fluid. Alex. Eng. J. 54, 681–689 (2015)

E.A. Ashmawy, Fully developed natural convective micropolar fluid flow in a vertical channel with slip. J. Egypt. Math. Soc. 23, 563–567 (2015)

M. Ferdows, D. Liu, Natural convective flow of a magneto-micropolar fluid along a vertical plate. Propuls. Power Res. 7(1), 43–51 (2018)

F.P. Foraboschi, I.D. Federico, Heat transfer in a laminar flow of non- Newtonian heat generating fluids. Int. J. Heat Mass Transf. 7, 315–318 (1964)

M.A.A. Mahmoud, S.E. Waheed, MHD flow and heat transfer of a micropolar fluid over a stretching surface with heat generation (absorption) and slip velocity. J. Egypt. Math. Soc. 20, 20–27 (2012)

S.K. Jena, M.N. Mathur, Similarity solutions for laminar free convective flow of a thermomicropolar fluid past a nonisother-mal vertical plate. Int. J. Eng. Sci. 19, 1431–1439 (1981)

G. Ahmadi, Self-similar solution of incompressible micro-polar boundary layer flow over a semi-infinite plate. Int. J. Eng. Sci. 14, 639–646 (1976)

J. Peddieson, An application of the micropolar fluid model to the calculation of turbulent shear flow. Int. J. Eng. Sci. 10, 23–32 (1972)

M.Q. Brewster (Wiley, Inc., New York1992)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Pattnaik, P.K., Moapatra, D.K., Mishra, S.R. (2021). Influence of Velocity Slip on the MHD Flow of a Micropolar Fluid Over a Stretching Surface. In: Mishra, S.R., Dhamala, T.N., Makinde, O.D. (eds) Recent Trends in Applied Mathematics . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9817-3_21

Download citation

DOI: https://doi.org/10.1007/978-981-15-9817-3_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9816-6

Online ISBN: 978-981-15-9817-3

eBook Packages: EngineeringEngineering (R0)