Abstract

Lignocellulosic biomass has become popular as an untapped source for biofuel production which plays a dual role, i.e., sustainable development and renewable energy production. Biofuels are the alternatives to fossil fuel which are cheap and environmental friendly and also have the capability to reduce energy crisis along with waste management. But, there are some hurdles in direct conversion of lignocellulosic biomass (composed of cellulose, hemicellulose, and lignin mainly) to biofuels (i.e., biohydrogen, biogas, bioethanol, biobutanol, etc.). The main problem occurs during the renovation of the lignocellulosic substrate to biofuel with due to the composite nature of lignin. Lignin also prohibits cellulose and hemicellulose to expose to digestion easily by microbial activity. Pretreatment of lignocellulosic biomass is a pre-requisite to alter the compositional and the structural obstruction of the biomass resulting in an enhanced yield of biofuel. This chapter provides an overview of various lignocellulosic biomass resources along with biofuel production technologies with special reference to physico-chemical and biological technologies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

There are various challenges in the present world like climate change, depletion of resources, and increase in demand for fuel, etc. for which we humans are fighting. A robust increase in industrialization leads to an increase in demand for fuels which provides benefits to some countries that are capable to fluctuate the price of fuels. As these issues grow over the years, research has also been increased to find some alternative sources of fuel (Aftab et al. 2019). These alternative sources usage can help in controlling the environmental pollution and have the potential to fulfill the global energy demand to some extent.

While finding the alternative solution, biomass-derived energy sources came out as boon to the world. These biomass-derived fuels have the potential to replace conventional energy sources and are also non-polluting and environmentally benign (Mahapatra and Kumar 2017). This book chapter thus designed to have some in-depth knowledge about the biomass-derived fuels, their advantages, and different ways through which yield can be enhanced.

7.1.1 History and Progression of Biofuel Production

For a very long time period, we (humans) depended on fossils to meet our energy demands. Plant biomass was the first source of fuel utilized by human beings. With increase demand of industrialization, fertile lands and biomass were destroyed. The negative impact of traditional fuels on circumstances and increase demand lead researchers to shift their focus towards biomass again. Fuels generated from this biomass were then classified into first, second, third, and fourth generation which will be discussed later in this chapter. A huge variety of biomass has been utilized and explored till now for biofuel production. Currently biomass fulfills more than 10% global energy demands which make it a viable source of fuel for the present and future generations (Miao and Wu 2004; Saidur et al. 2011; Heidenreich and Foscolo 2015; Sikarwar et al. 2017).

7.1.2 Current Scenario

Increase in population resulted in the increased demand for food and fuel both. Lignocellulosic waste generated during the production of crops can act as a good energy source which also leads to the sustainable development of the society. The present era has lots of technologies that can help in extracting the energy from the lignocellulosic biomass and the continuous development also helps in finding the more suitable way to increase the yield of biofuels (Mari 2016). Various modifications have been done in different countries to increase the utilization of the biomass-derived fuels. As there are many pros of biomass-derived fuels, there are also some negative aspects which have to solve like pilot-scale modifications, higher yield, storage, transport, and the modifications which have to be done to utilize these fuels in efficient manner. Apart from all these technological issues, awareness regarding biofuels is also very important. In the present conditions, there are various pretreatment methods that are being explored to increase the yield of biofuels like physical, chemical, physico-chemical, biological, etc. (Kumari and Singh 2018) which will be discussed in detail further.

7.1.3 Different Types of Biofuels

Now-a-days there are several types of biofuel that can be extracted from lignocellulosic biomass such as hydrogen, methane, ethanol, etc. (Mahapatra and Kumar 2017). These renewable energy sources have greater potential in comparison to the conventional fuels in relations to energy security, financial issues, and ecological stability (Demirbas 2009; Nigam and Singh 2011; Zabed et al. 2016; Zabed et al. 2019). Some of these fuels are:

7.1.3.1 Bioethanol

At present time bioethanol is majorly produced from corn and sugarcane at the industrial level and can be blended with gasoline in specific proportions (RFA 2015). A huge variety of waste can be exploited to produce bioethanol, e.g., citrus peels, leaves, straw, corn stock, sugarcane bagasse, etc. (Kumari and Singh 2018). Fermentation of molasses and starch for bioethanol production is emerging out as a mature technology and different cellulolytic clostridia can be used for this fermentation process. (Antoni et al. 2007).

7.1.3.2 Biobutanol

Biobutanol is considered as an excellent fuel as it can be used directly in engines without modifying them. Production of biobutanol is mainly done by solventogenic Clostridium sp. bacteria during the fermentation process which help in the breakdown of the complex sugars like pentose, hexose (Mahapatra and Kumar 2017). Fermentation pathway used for the production of biobutanol is termed as the ABE pathway (Kumar and Gayen 2011). There are various feedstocks which can be utilized for the production of biobutanol like sugarcane juice, Napier grass, corn stover, willow biomass, rice straw, etc. (Cheng et al. 2012, Ranjan et al. 2013, Guo-Chao et al. 2016, Chi-Ruei et al. 2017, Jianzhi et al. 2017). There are various kinds of usage of biobutanol like in cosmetics, drugs, antibiotics, hormones, etc. (Cheng et al. 2012).

7.1.3.3 Biomethane

Biomethane is another viable fuel that can be formed from biomass through anaerobic digestion (AD). Production of biomethane is considered as the simplest and favorable method due to less capital investment and economic benefits (Rao et al. 2010; Chandra et al. 2012). Basically biomethane can be produced through two methodologies, i.e., chemical and biological, out of which biological process operates at a slower rate (Michailos et al. 2020). In agricultural driven countries there is a huge feedstock which can be utilized for the biomethane production like sugarcane, food waste, petha wastewater, etc. (Bansal et al. 2012; Kumar and Lin 2013; Bruno et al. 2016).

7.1.3.4 Biohydrogen

Hydrogen is regarded as the most excellent fuel due to its clean, non-polluting nature and high calorific value. All these properties make hydrogen as a future fuel drawing more and more attention (Valdez-Vazquez et al. 2005). Numerous methods have been used for the production of hydrogen-like steam remodeling, hydrocarbon’s partial oxidation, coal gasification, photolysis of H2O, biological method, etc. In comparison to the other methods, the biological hydrogen production method is an energy extensive process that can be performed using various feedstocks both solid and liquid-like food waste, petha wastewater, rice straw, vegetable waste, etc. (Singhal and Singh 2014; Kumari and Singh 2018).

7.1.4 Advantages of Biofuels

Till now we have an outlook of biofuel, its types and capabilities in the present time. Worldwide researchers are focused to develop some efficient technology and method for the production of biofuels which can meet global energy demands (Zabed et al. 2019). Some of the advantages of biofuels are listed below:

-

Reduced the use of fossil fuels

-

Higher reliability and renewability

-

Reduced air pollution and landfill sites

-

Waste stabilization

-

Reduced Greenhouse gases

-

Carbon sequestration

-

Sustainability

-

Employment generation and rural development

-

New industrial development, etc.

7.1.5 Environmental Challenges and Remediation

Global, economic and social changes are mainly related to the energy potential of a country. Presently, petroleum and coal are used to fulfill 80% of the energy demands worldwide which is expected to grow by 37% till 2040 (Joshi et al. 2017; Kour et al. 2019). A large number of methods are available and can be expended for the production of biofuels (Tomes et al. 2010). Plant biomass, agricultural wastes, food waste, etc. has the potential and are being studied over the years for the production of biofuels. There are various advantages of biofuels but still some challenges have to be faced to make biofuels worldwide acceptable in an efficient manner (Dragone et al. 2010; Rodionova et al. 2017).

Presently, the challenges some of which have to be confronted for mercantile extraction of biofuel to meet the global energy demands are (Scott et al. 2010; Nigam and Singh 2011; Wang et al. 2018):

-

Enzyme production

-

Technology development and cost

-

Pretreatment methods for enhanced yield of biofuels

-

Storage and transport facilities

-

Food-fuel competition, etc.

To overcome most of these challenges, various biofuel production technologies have developed and some are under the developing stage. For the production of second-, third-, and fourth-generation biofuels by pretreatment of lignocellulosic biomass and technologies utilized is discussed in the following sections.

7.2 Biofuel Production Technologies

A number of biofuel production technologies are used in the last decades for biofuel generation. Generally, biofuels are derived from a large variety of biomass, microorganisms, and different plants or animal wastes (Mari 2016). Biofuels are classified into four main categories according to the feedstock used and the production technology applied for the production process. Figure 7.1 represents the four categories of biofuels (Kumari and Singh 2018).

Classification of biofuels. Source: Kumari and Singh 2018

7.2.1 First-Generation Biofuel Production

Production of “first-generation” biofuels takes place by utilization of agricultural food crops like wheat, rice, maize, sugarcane, barley, soybean oil, sugar beet, sunflower seed, palm oil, cellulose, etc. But, utilization of these food crops is not advantageous as it can result in problems like food scarcity in developing countries like India which is already facing food supply problems due to the enhancement of the human population (Naik et al. 2010). Some of technologies provide a limited yield of specific biofuel and also negatively impact the food security (Mari 2016). The rise in food prices is an undesirable effect of first-generation biofuel production. These biofuels also have some negative impression on surroundings and carbon balance which confines the intensification of first generation biofuel production (Laursen 2006). Thus there is an urgent need to develop an advanced technology for biofuel production which could be capable to produce biofuels from non-food renewable sources of biomass. This necessity attracted researchers to switch to produce second and third generation biofuels.

7.2.2 Second-Generation Biofuel Production

“second generation” biofuels are derived from the agricultural biomass (also called lignocellulosic biomass) rather than food crops by use of advanced technologies. The main objective of second-generation biofuel production is to sustainably produce a higher amount of biofuels from non-food parts of crops, agricultural residues, municipal solid wastes, and industrial wastes (Antizar-Ladislao and Turrion-Gomez 2008). Production of these biofuels is also environmental friendly because these are carbon deficient or carbon neutral and hence do not contribute to CO2 concentrations like fossil fuels. Production of second generation biofuels is expensive as these are produced from cheap, abundant, and easily available non-food biomass (Naik et al. 2010). second generation fuels have the potential to demote net carbon discharge, upsurge energy proficiency, and undermine the drawbacks of first generation biofuels (Antizar-Ladislao and Turrion-Gomez 2008). These fuels can be obtained by AD and fermentation after the pretreatment of lignocellulosic biomass (Kumari and Singh 2020a).

7.2.3 Third-Generation Biofuel Production

Production of “third generation” biofuels is now under massive research to develop a cost-effective method to upgrade the metabolic production of biofuels from algal biomass. The separation process in bio-oil production of third-generation biofuels to eliminate non-fuel part to lower the production cost is in practice correspondingly (Mari 2016). Hence specific extraction of biofuels like biodiesel, ethanol, and biogas from algal biomass is of great interest to enhance biofuel production from renewable sources that would able to compete with fossil fuels in the future (Panbdey et al. 2014). This expertise is still not commercial and sustainable due to low Photon to fuel transition proficiency of biodiesel production. Recent improvements in metabolically engineered algal biomass to enhance lipid production without cooperating progress can be considered likely an imperative breakthrough regarding the ecological production of biodiesel (Trentacoste et al. 2013). The combined production of algal biofuel and high-value chemicals, using wastewater (and or seawater) as cultivation modes along with the elaboration of supplementary economical bio-reactors are some expertise, which will force to produce algal biofuel more advantageous in the immediate future. It is the matter of immediate concern to modify a genetically engineered cost-efficient algal biofuel to restrain the problem of agronomy, harvesting, and handling (Medipally et al. 2015).

7.2.4 Fourth-Generation Biofuel Production

Production of “fourth-generation” biofuels takes place by the use of photosynthetic biology of algae and cyanobacteria (Scaife et al. 2015) being a juvenile but highly progressing field for renewable energy production. Production of first-, second-, and third-generation biofuels is dependent whichever upon biomass or organic wastes those are the result of former time photosynthesis of plants (different from contemporary resources). Even though these fuels are very useful but their production is often limited to the productivity and availability of the consequent raw material which bounds their global applications. Conversely production of fourth-generation biofuels would be centered on widely available, cheap, and principally everlasting raw materials (Mari 2016). Photosynthetic or photocatalytic water splitting into its elements through sunlight can be fitted a huge supplier of global scale fuel production. This can be achieved either by unnatural photosynthesis (Inganäs and Sundström 2016) or and through uninterrupted solar biofuel fabrication expertise. Not only the hydrogen generation (Sharma et al. 2019) but also the manufacture of carbon deficient fuels is promising via simultaneous boosted preoccupation of atmospheric carbon dioxide and inventive strategy of artificial metabolic routes to produce biofuels. Hence fourth-generation biofuels can be produced by designer photosynthetic bacteria, electro-biofuels, or specifically couturier synthetic organelles designed to produce highly esteemed products (Mari 2016).

7.3 Lignocellulosic Biomass Resources

Mainly two types of biomass resources are available in the world which can be obtained from the agriculture sector, aquatic plants, forest, and industries as depicted in Fig. 7.2. Plants, trees, grasses, forests, agricultural crop residues, and municipal solid wastes are the versatile renewable sources of biofuel production for a long time because these are everlasting and renew through the photosynthesis process by use of environmental CO2, water, and sunlight. Due to the presence of their constituents (namely cellulose, hemicellulose, and lignin) these are called lignocellulosic biomass. Primary metabolites like carbohydrates and lignin are present in abundance in lignocellulosic biomass as compared to secondary metabolites (i.e., gum, resins, rubber, waxes, alkaloids, tannins, etc.) being lower amounts present (Clark 2007; Naik et al. 2010). These low volume secondary metabolites are applied to produce prominent chemicals (i.e., medicines, cosmetics, food flavors, etc.) using assimilated techniques. Whereas the lignocellulosic portion of plant biomass can be exploited for a large variety of biofuel production (i.e., biogas, biohydrogen, bioethanol, biomethanol, biodiesel, etc.) after suitable pretreatment of biomass (Yadav and Vivekanand 2020; Kumari and Singh 2018).

Schematic representations of various kinds of biomass resources. Source: Naik et al. 2010

7.3.1 Agricultural Crops and Their Waste by-Products

The agriculture sector produces two types of crops mainly; food crops and grasses. Food crops include wheat, maize, rice, sugarcane, sugar beet, sweet sorghum, vegetables, fruits, oilseed rape, etc. and grasses include switch grass, rye, alfalfa, Miscanthus, etc. But the use of these crops for biofuel production creates conflict between food and energy (Fenning et al. 2008) so crop residues are the best alternatives of food crops that can be used for biofuel production. Rice straw, wheat straw, barley straw, corn cobs, corn stover, citrus waste, switch grass, etc. are the good option of agro-industrial wastes (Jeihanipour and Bashiri 2015). Production of lignocellulosic ethanol and the use of rice straw for this purpose is now in demand because other agricultural residues (i.e., wheat straw, barley straw, and corn stalks) are used as cattle fodder. But high silica content makes rice straw unfit to use as cattle feed and confirms its high availability for biofuel production (Kumari and Singh 2020a, 2020b; Singh and Kumar 2019; Hans et al. 2019).

7.3.2 Municipal Solid Waste (MSW)

MSW comprises residues from household and industry (i.e., fruits and vegetable rinds, food waste, rotten fruits and vegetables, fruit pulp from juice industries, paper waste, kitchen waste, etc.) which is a virtuous raw material for biofuel production. A variety of MSW had been recycled for biogas production (Bolzonella et al. 2019; Kader et al. 2015; Bansal et al. 2013), biohythane (Gottardo et al. 2017; Yeshanew et al. 2016; Giuliano et al. 2014), biohydrogen (Singh et al. 2017; Ghimire et al. 2015; Singhal and Singh 2014; Bansal et al. 2012; Elsayed et al. 2011), bioethanol (Kumari et al. 2018), volatile fatty acids (Kumari and Singh 2020a) and other high-value commodities. The great advantage of MSW is its biodegradability (about 65%) which eases its utilization to produce biogas and bioethanol (Li et al. 2007). The use of biodegradable MSW is more suitable if it treated on site for waste to energy purpose because this practice will reduce the extra load of landfills (McIvor and Evans 2008). The government of India has encouraged people to segregation of biodegradable and non-biodegradable fraction of their household waste and door to door collection of both kinds of waste is also managed separately for proper utilization of biodegradable fraction by energy as well as manure production plants. For this purpose, “Swachh Bharat Abhiyan” campaign was launched in India on October 2, 2014, on the occasion of the birthday of Mahatma Gandhi.

7.3.3 Wood and its Wastes

Wood residues like sawdust and wood chips are another option of lignocellulosic biomass which can be obtained from a number of trees (e.g., eucalyptus, poplar, Salix, bamboo, pine, willow, etc.) (Salehian et al. 2013; Tomé and Verwijst 1996) and provide hypothetically high calorific values than agronomic wastes for biofuel production. A large advantage of cultivating these woody plants is growth in the marginal of agronomic land without compete with food harvests for space (Fenning et al. 2008). Pine forests in India (Uttarakhand) produce around 20.58 lakhs tones biomass per year on dry basis (e.g., pine needles, bark, etc.) (Bisht et al. 2014) which can be a good option for biofuel production prior suitable pretreatment. The use of poplar leaves was found effective after acid and alkaline enzymatic pretreatment for biohydrogen production (Cui et al. 2010). Currently, just a minor fraction of liquid fuels is derived from forests which can be enhanced by the development of a viable and economic technique for liquid biofuel production from woods for widespread use in the transportation segment.

7.3.4 Algal Biomass

The use of algal biomass for biotechnological biodiesel production is a new emerging field of research (Kim et al. 2013). Bioenergy production using algal biomass (microalgae and macroalgae both) attracted investors for funding projects to produce biofuels using this sustainable biomass even the cultivation of some species of algae is also in practice to achieve good biofuel yields. Biofuels derived from algal stuff are generally called third- and fourth-generation biofuels (Fig. 7.1). Cultivation of these algae can be done in natural ponds, man-made ponds, or in photo-bioreactors. Thousands of algal species are available with varying sizes from microscopic to about 60 meter long. In sympathetic environments, algal commodity grows very swiftly and attains its total mass with 50% oil (Algae base 2020). Various microalgal (Feng et al. 2019; Fabiana et al. 2016; Costa et al. 2015) and macroalgal biomass (Montingelli et al. 2016; Xue et al. 2016; Yann et al. 2015) were consumed to produce biohydrogen, biogas, and other biofuels. Application of a synergistic approach for sustainable production of third- and fourth-generation biodiesel from algal biomass can reduce the cost of biofuel (Raslavičius et al. 2014).

7.3.5 Food Processing Wastes

A large variety of food processing wastes has been utilized for the production of various kinds of biofuels. Being produced from different industries, these wastes can also be called the industrial wastes and includes; palm oil mill effluent (Seengenyoung et al. 2018, Mamimin et al. 2015), dairy wastewater (Kumari et al. 2018), sugarcane bagasse (Bruno et al. 2016), wastewater from pulp and paper industry (Antizar-Ladislao and Turrion-Gomez 2008), olive mill wastewater (Anish et al. 2016), de-oiled jatropha waste (Kumar and Lin 2013), wastewater sludge (Guo et al. 2008), rambutan fruit waste (Kandari and Gupta 2012), used cooking oil, etc. are used for the production of biofuels. These food processing wastes were used solely or with some other lignocellulosic biomass for ethanol and biogas production (Kumari and Singh 2020a; Kumari et al. 2018). Besides from these wastes, various industrial wastewater forms are also rich source of organic substrates and energy can be recovered from these wastewaters in the form of biofuels and electricity (Kumari and Singh 2019; Singhal and Singh 2015).

7.3.6 Garden Waste

Tree pruning, leaves, stem, grasses, bark, nutshells, etc. are some types of garden wastes and can be utilized for producing biofuels after collection at the time of seasonal or manual cutting and shaping of garden plants and hedges. This is also a kind of lignocellulose rich biomass but cannot be used without prior pretreatment for biofuel extraction. Agricultural residues contribute only 5% of lignocellulosic biomass production (similar to landfill gases) followed by MSW (24%) and woods and wood residues (65%) (Deshmukh et al. 2008).

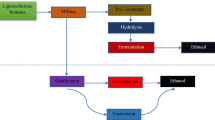

7.4 Advanced Pretreatment Technologies and Their Effects

Pretreatment is a process of converting complex lignocellulosic biomass into its simple components (cellulose, hemicellulose, and lignin). Removal of lignin, hemicellulose preservation with enhancement in the porosity of the material is the main objective of the pretreatment process. An effectively economic pretreatment should reduce the crystallinity of cellulose with improvement in released sugar and produce the least amount of inhibitors (Chiaramonti et al. 2012). For this purpose, a number of pretreatment technologies (namely, physical, chemical, physico-chemical, biological, and combined) are available, shown in Fig. 7.3.

7.4.1 Chemical Pretreatment

Figure 7.3 shows various types of chemical pretreatment methods of lignocellulosic biomass for enhanced biofuel production. Different kind of lignocellulosic biomass was pretreated chemically for the production of biofuels. Olive mill residue was pretreated with alkaline H2O2 for biomethane production (Siciliano et al. 2016). Free nitrous acid was used by Xue et al. (2016) for the pretreatment of algal biomass for methane production. Ghimire et al. (2015) used Sodium 2–bromoethane sulfonic acid for pretreatment of potato and pumpkin waste for biohydrogen production. NaOH was used for alkaline pretreatment of Teff straw (Akiber et al. 2015), pine wood (Salehian et al. 2013), rice straw (Chandra et al. 2012), and poplar leaves (Cui et al. 2010). Alkaline petha wastewater and acidic dairy wastewater pretreatment were applied for pretreating rice straw for bioethanol and methane production (Kumari and Singh 2020a, Kumari et al. 2018). Olive mill wastewater and olive pomace were pretreated with H2SO4, NaOH, and CaCO3 for bioethanol production (Sen et al. 2016). Gamba grass (Bagudo et al. 2014), willow biomass (Han et al. 2013), and rice straw (Ranjan et al. 2013) were pretreated with H2SO4 for ethanol and biobutanol production, respectively. Corn stover was pretreated with deep eutectic solvents for biobutanol production (Guo-Chao et al. 2016).

7.4.1.1 Effect of Chemical Pretreatment Methods

The higher concentration of acid in acid pretreatment produces many inhibitors which inhibits the growth of microbes and reduces biofuel production (Taherzadeh and Karimi 2008). Strong oxidizing agents like H2O2 oxidizes lignin to produce inhibitors (soluble aromatic compounds), more than 4% H2O2 inhibits the anaerobic digestion (AD) process (Song et al. 2012). Alkaline pretreatment also inhibits AD particularly methanogenesis (Chandra et al. 2012). Ozonolysis is an expensive technique and utilization of large amount of ozone limits its extensive use (Appels et al. 2012). Ionic liquid pretreatment is a new technique for the pretreatment of lignocellulosic biomass but the high cost is major drawback of this technique due to the use of expensive solvents (Kumari and Singh 2018). In organosolv pretreatment organic solvents (ethanol, methanol, acetone, ethyl glycol, etc.) with acid and alkalis as catalysts are used as de-lignifying agents (Guo-Chao et al. 2016).

7.4.2 Physical Pretreatment

These pretreatments include milling, grinding, freezing, pyrolysis, and biomass irradiation with various rays (Fig. 7.3). Many of these pretreatment technologies were used on a large variety of biomass by various researchers for biofuel production. Microalgal biomass was pretreated by beating, ball milling, and microwave (MW) for biomethane production (Montingelli et al. 2016). Milling was applied to a large variety of biomass (e.g., Sawdust, Japanese cedar, rice bran, rice straw, and husk) for enhanced biomethanol production (Hitoshi et al. 2005). MW irradiation was applied to wastewater sludge (Guo et al. 2008), mixed microbial culture (Singhal and Singh 2014), and microalgal biomass (Feng et al. 2019) for biohythane, biohydrogen, and biomethane production, respectively. Wheat straw was MW irradiates at 150 °C for enhancement in methane yield (28%) than untreated straw (Jackowiak et al. 2011). Extrusion of cassava was done for the maximum conversion of starch to ethanol (Chang and El-Dash 2003). Catalytic pyrolysis was applied by Bu et al. (2016) for biofuel and other chemical production.

7.4.2.1 Effects of Physical Pretreatment Methods

Size reduction enhanced biofuel production but De la Rubia et al. (2011) found that milling should be done in such a way so that it will not negatively affect the biofuel production process because excessive milling may result in reduced biofuel yield with extreme amount of inhibitory products (volatile fatty acids). A great advantage of milling is that fermentative inhibitors like furfural and hydroxymethyl furfural are not produced in milling (Ramos 2003). According to Gabhane et al. (2011) MW pretreatment collapses the cellulosic component of biomass as a result of dielectric polarization by molecular conflict. Li et al. (2012) reported that MW irradiation of Pennisetum hybrid at 260 °C adversely affected methane production. Extrusion is thermo-physical pretreatment which is more advantageous because fiber shortening occurs due to disruption of biomass by application of shear forces (Senturk-Ozer et al. 2011). Freezing is an eco-friendly but comparatively expensive pretreatment technique because of applying less amount of harmful chemicals but less research has been done. Pyrolysis is done at more than 300 °C for the disintegration of biomass cellulose into gases (CO and H2) and char which is finally converted into glucose for the biofuel production process.

7.4.3 Physico-Chemical Pretreatment

Various physico-chemical pretreatment methods are also listed in Fig. 7.3 which was used for the lignocellulosic biomass pretreatment. Use of ultrasonication was done to pretreat rice straw (Kumari and Singh 2020a; Kumari et al. 2018) and food wastes (Elsayed et al. 2011) for methane, ethanol, and biohydrogen production. Coconut husk and cactus (Fabiana et al. 2016), sugarcane bagasse were auto-hydrolyzed (Bruno et al. 2016), beach-macro-algae was pretreated with thermo-acidic (Yann et al. 2015; Akiber et al. 2015), Miscanthus lutarioriparius was treated with a steam explosion (Ivo et al. 2016). Household food wastes were pretreated with ammonia for biohythane production (Gottardo et al. 2017). Microalgae were pretreated with chemical assisted ultrasonication for biomethane production (Caporgno et al. 2016).

7.4.3.1 Effect of Physico-Chemical Pretreatment Methods

These pretreatment methods are more advantageous over solely physical and chemical pretreatment methods because most of the methods are cost-effective. Ammonia fiber explosion does not necessitate reduced grain size and the formation of inhibitors does not take place (Kumar et al. 2009). Ultrasonication can able to disrupt the cell wall configuration via cavitation with intensification in specific surface areas and also reduce the degree of polymerization with an increase in biomass solubility (Sen et al. 2016). Autohydrolysis is more beneficial because it disrupts biomass to makes it more operative without the use of any chemical for the enzymatic attack but low saccharification rate and production of inhibitory products is a major drawback (Taherzadeh and Karimi 2008). Liquid hot water pretreatment does not demand any exclusive and expensive corrosive-opposing objects for biofuel producing reactor setup (Laser et al. 2002). CO2 explosion is more effective but costly as compared to lower inhibition formation (Sindhu et al. 2016).

7.4.4 Biological Pretreatment

These methods are extra eco-friendly than other methods for lignin removal which are namely fungal, microbial consortium, and enzymatic. MSW was pretreated biologically for biohydrogen and methane production (Bolzonella et al. 2019). Lignocellulosic biomass was pretreated biologically with Curvularia lunata (Yadav and Vivekanand 2020) for methane production, microalgae (Fabiana et al. 2016), poplar leaves (Cui et al. 2010), and rice straw (Sen et al. 2016) were enzymatically pretreated for biohydrogen production. Cassia fistula L. fruit pulp was pretreated with Rhodosporidium kratochvilovae (Alok et al. 2015) for biodiesel production. Sugarcane bagasse was pretreated with by Thermoascus aurantiacus for biobutanol production (Zong-Wen et al. 2016). Microalgae were enzymatically pretreated with cellulase and enzyme mixture for biomethane production (Fabiana et al. 2016). Pretreatment of corn stover via co-culture of two fungi (Clostridium cellulolyticum and Citrobacter amalonaticus) was used for biohydrogen production (Shou-Chi et al. 2018).

7.4.4.1 Effect of Biological Pretreatment Methods

A wide variety of white rot-fungi have been used for biological pretreatment, among which Phanerochaete chrysosporium has highest proficiency in lignin disruption (Sindhu et al. 2016). In case of pure fungal strains, sterilization of lignocellulosic biomass is required to avoid the contamination of fungi to escape the reduced biofuel yields which is not pre-requisite for most of the microbial consortium pretreatment. Nowadays, lignocellulosic biomass pretreatment in assistance with genetically modified fungal or microbial species have gained more attention because of high biofuel yield as compared to natural species. Microbial consortium pretreatment was found to be best in all three biological pretreatments because less care is required for maintaining the mixed microbial source to prevent from being contaminated which also resulted in reduced pretreatment cost. But biological pretreatment is not as much effective as chemical pretreatment due to long retention time, high microbial selectivity, and being overpriced, and further research is required (Kumari and Singh 2018).

Apart from the above pretreatment methods, a long list of research is additionally available for the application of combined pretreatment technologies for enhancement of biofuel yields. Combined pretreatments have many advantages over single pretreatments (e.g., more lignin removal and high cellulose solubility). Singhal and Singh (2015) applied combined heat with acid and alkali on petha wastewater for biohydrogen generation. Rice straw was pretreated with ultrasonic-assisted alkaline petha wastewater and acidic dairy wastewater for bioethanol and methane production (Kumari and Singh 2020a, Kumari et al. 2018). Ivo et al. (2016) applied a steam explosion with NaOH and size reduction and Montingelli et al. (2016) used beating and ball milling with MW for enhanced biomethane production.

7.5 Future Research Directions

There is a great scope in biofuel production as these are capable of eliminating various problems such as fuel security, depletion of resources, environmental challenges, etc. Apart from this biofuel production can also led to the waste minimization which will reduce the load on landfill sites (McIvor and Evans 2008). A lot of research has been done and it is still going further to find out the suitable method which can enhance the production. There are various methods of biofuel production which have been explored at the lab scale but the main challenge is to imply that at large pilot scale. There is no doubt in accepting that biofuel has the potential to fulfill the world energy demand and future research will be focused on the applications of the technology at pilot scale. After the implementation of biofuel technology, there will be various effects which have to be monitored. Lignocellulosic biomass will play an effective role in biofuel production as the amount of this biomass will increase with enhanced energy demand as the population increases.

Pretreatment methods are also explored which are less energy intensive, chemical free, and result in better yield production. Coupling of various pretreatment methods can also affect the yield either in positive or negative manner (Kumari and Singh 2018). Treatment of mixed lignocellulosic waste can also be carried out such that there should be some symbiotic relationship between the two biomass and help in the degradation of each other. This can reduce the pretreatment cost and make the process more viable (Kumari and Singh 2020b) which can be easily adapted anywhere. Climatic conditions also affect the efficiency of bacterial degradation which reduced biofuel production for some favorable time period during the year. This problem should also be focused so that the continuous production of biofuel can be done at a pilot scale.

Future research should explore some easy growing enzymes which can be adapted by a farmer so that they can treat their agricultural waste and energy produced from this can be utilized. Technology should be made adaptive to use biofuels for transportation and conversion of it into electricity which can help in reducing the loads on conventional fossil fuels.

7.6 Conclusion

Keeping the present situation of fulfilling energy demand in mind, the production of biofuels from cheap and alternative biomass sources has been highly encouraged in the last decades. The complexity of lignocellulosic biomass restricts to utilize the biomass resources directly for energy generation. Pretreatment is the pre-requisite to produce biofuels from lignocellulosic biomass. A large variety of pretreatment processes are available but most of these processes are chemical based and harmful to environment. To find a cheap, energy-efficient and eco-friendly (green) pretreatment process is a challenge that would be able to reduce or totally remove the hurdles of available pretreatment technologies. Two or more pretreatment processes when applied in combination can solve some part of the problem but still further research is required to tackle the rest. Utmost all combinations of pretreatments utilize high energy for further energy generation in the form of biofuels which enhances the cost of the pretreatment process. This energy consumption should be balanced in such a way so that biorefineries become a profitable sector for the developers and workers of this field.

Abbreviations

- AD:

-

Anaerobic Digestion

- MSW:

-

Municipal Solid Waste

- MW:

-

Microwave

References

Aftab MN, Iqbal I, Riaz F et al (2019) Different pretreatment methods of lignocellulosic biomass for use in biofuel production. In: Biomass for Bioenergy-Recent Trends and Future Challenges. IntechOpen, London

Akiber C, Hairong Y, Dexun Z et al (2015) Bio-methane production and physicochemical characterization of anaerobically digested Teff (Eragrostis tef) straw pretreated by sodium hydroxide. Bioresour Technol 181:214–219

Algae Base (2020). Available from: http://www.algaebase.org. Accessed 05 June 2020

Alok P, Dev KS, Neha A et al (2015) Biodiesel production from non-edible lignocellulosic biomass of Cassia fistula L. fruit pulp using oleaginous yeast Rhodosporidium kratochvilovae HIMPA1. Bioresour Technol 197:91–98

Anish G, Fabio S, Luigi F et al (2016) Effects of operational parameters on dark fermentative hydrogen production from biodegradable complex waste biomass. Waste Manag 50:55–64. https://doi.org/10.1016/j.wasman.2016.01.044

Antizar-Ladislao B, Turrion-Gomez JL (2008) Review: second-generation biofuels and local bioenergy systems. Biofuels Bioprod Bioref 2:455. https://doi.org/10.1002/bbb.97

Antoni D, Zverlov VV, Schwarz WH (2007) Biofuels from microbes. Appl Microbiol Biotechnol 77(1):23–35

Appels L, Impe JV, Dewil R (2012) Oxidizing agents and organic solvents as pretreatment for anaerobic digestion. In: Mudhoo A (ed) Biogas production: pretreatment methods in anaerobic digestion. Wiley, Hoboken, pp 199–214

Bagudo BU, Dangoggo SM, Usman J (2014) Bioethanol production potential of Andropogon gayanus. Ann Biol Res 5(1):106–111

Bansal SK, Singhal Y, Singh R (2012) Biohydrogen production by anaerobic treatment from kitchen waste using mixed culture. J Hum Welf Ecol 5(4):457–459

Bansal SK, Sreekrishnan TR, Singh R (2013) Effect of heat pretreated consortia on fermentative biohydrogen production from vegetable waste. Natl Acad Sci Lett 36(2):125–131

Bisht AS, Singh S, Kumar M (2014) Pine needles a source of energy for Himalayan region. Int J Sci Technol Res 3(12):161–164

Bolzonella D, Mıcoluccı F, Battısta F et al (2019) Producing Biohythane from urban organic wastes. Waste and Biomass Valorization 11:2367. https://doi.org/10.1007/s12649-018-00569-7

Bruno ELB, Diego RSL, Oscar FHA et al (2016) Optimization of sugarcane bagasse autohydrolysis for methane production from hemicellulose hydrolyzates in a biorefinery concept. Bioresour Technol 200:137–146

Bu Q, Morgan JHM, Liang J et al (2016) Chapter two – catalytic microwave pyrolysis of lignocellulosic biomass for fuels and chemicals. Adv Bioenergy 1:69–123. https://doi.org/10.1016/bs.aibe.2016.09.002

Caporgno MP, Olkiewicz M, Pruvost J et al (2016) A novel pre-treatment for the methane production from microalgae by using N-methyl morpholine-N-oxide (NMMO). Bioresour Technol 201:370–373

Chandra R, Takeuchi H, Hasegawa T (2012) Hydrothermal pretreatment of rice straw biomass: a potential and promising method for enhanced methane production. Appl Energy 94:129–140

Chang YK, El-Dash AA (2003) Extrusion-cooking of cassava starch as a pretreatment for its simultaneous saccharification and fermentation for ethanol production. Acta Aliment 32:219–235

Chaudhary L, Pradhan P, Soni N et al. (2014) Algae as a feedstock for bioethanol production: new entrance in biofuel world. Int J ChemTech Res 6(2):1381–1389

Cheng CL, Che PY, Chen BY et al (2012) Bio-butanol production from agricultural waste by an acclimated mixed bacterial microflora. Appl Energy 100:3–9

Chiaramonti D, Prussi M, Ferrero S et al (2012) Review of pretreatment processes for lignocellulosic ethanol production, and development of an innovative method. Biomass Bioenergy 46:25–35

Chi-Ruei H, Yu-Yuan K, Si-Yu L (2017) Lignocellulosic butanol production from Napier grass using semi-simultaneous saccharification fermentation. Bioresour Technol 231:101–108

Clark JH (2007) Green chemistry for the second generation biorefinery-sustainable chemical manufacturing based on biomass. J Chem Technol Biotechnol 82:603–609

Costa JC, Oliveira JV, Pereira MA et al (2015) Biohythane production from marine macroalgae Sargassum sp. coupling dark fermentation and anaerobic digestion. Bioresour Technol 190:251–256

Cui M, Yuan Z, Zhi X et al (2010) Biohydrogen production from poplar leaves pretreated by different methods using anaerobic mixed bacteria. Int J Hydrog Energy 35(9):4041–4047

De la Rubia MA, Fernandez-Cegri V, Raposo F et al (2011) Influence of particle size and chemical composition on the performance and kinetics of anaerobic digestion process of sunflower oil cake in batch mode. Biochem Eng J 58–59:162–167

Demirbas A (2009) Political, economic and environmental impacts of biofuels: a review. Appl Energy 86:S108–S117

Deshmukh SS, Jinturkar AM, Gawande JS (2008) Comparative experimental study of single basin and stepped type solar still. J Energy Educ Sci Technol 20:79–85

Dragone G, Fernandes BD, Vicente AA et al (2010) Third generation biofuels from microalgae. Curr Res Technol Edu Top Appl Microbiol Microb Biotechnol 2:1355–1366

Elsayed E, Hisham H, George N (2011) Ultrasonication for biohydrogen production from food waste. Int J Hydrog Energy 36(4):2896–2803

Fabiana P, Andrea HD, Paqui B et al (2016) Improving biogas production from microalgae by enzymatic pretreatment. Bioresour Technol 199:347–351

Feng RZ, Zaidi AA, Zhang K et al (2019) Optimisation of microwave pretreatment for biogas enhancement through anaerobic digestion of microalgal biomass. Periodica Polytechnica Chem Eng 63(1):65–72

Fenning TM, Walter C, Gartland KMA (2008) Forest biotech and climate change. Nat Biotechnol 26:615–617

Gabhane J, William SPMP, Vaidya AN et al (2011) Influence of heating source on the efficacy of lignocellulosic pretreatment—a cellulosic ethanol perspective. Biomass Bioenergy 35:96–102

Ghimire A, Valentino S, Frunzo L et al (2015) Biohydrogen production from food waste by coupling semi-continuous dark-photofermentation and residue post-treatment to anaerobic digestion: a synergy for energy recovery. Int J Hydrog Energy 40:16045–16055

Giuliano A, Zanetti L, Micolucci F et al (2014) Thermophilic two-phase anaerobic digestion of source-sorted organic fraction of municipal solid waste for bio-hythane production: effect of recirculation sludge on process stability and microbiology over a long-term pilot-scale experience. Water Sci Technol 69(11):2200–2209

Gottardo M, Micolucci F, Bolzonella D et al (2017) Pilot scale fermentation coupled with anaerobic digestion of food waste - effect of dynamic digestate recirculation. Renew Energy 114:455–463

Guo L, Li XM, Bo XYQ et al (2008) Impacts of sterilization, microwave and ultrasonication pretreatment on hydrogen producing using waste sludge. Bioresour Technol 99:3651–3658

Guo-Chao X, Ji-Cai D, Rui-Zhi H et al (2016) Enhancing cellulose accessibility of corn Stover by deep eutectic solvent pretreatment for butanol fermentation. Bioresour Technol 203:364–369

Han SH, Cho DH, Kim YH et al (2013) Bio-butanol production from 2-year-old willow biomass by acid hydrolysis and acetone–butanol–ethanol fermentation. Energy 61:13–17

Hans M, Kumar S, Chandel AK et al (2019) A review on bioprocessing of paddy straw to ethanol using simultaneous saccharification and fermentation. Process Biochem 85:125–134. https://doi.org/10.1016/j.procbio.2019.06.019

Heidenreich S, Foscolo PU (2015) New concepts in biomass gasification. Prog Energy Comb Sci 46:72–95

Hitoshi N, Toshirou H, Toshimitsu I et al (2005) Bio-methanol production and CO2 emission reduction from forage grasses, trees, and crop residues. In: Originally presented at the third USDA symposium on greenhouse gases & carbon sequestration in agriculture and forestry. Baltimore, USA

Inganäs O, Sundström V (2016) Solar energy for electricity and fuels. Ambio. https://doi.org/10.1007/s13280-015-0729-6

Ivo AN, Chao L, Bing W et al (2016) Physico-chemical pretreatments for improved methane potential of Miscanthus lutarioriparius. Fuel 166:29–35

Jackowiak D, Bassard D, Pauss A et al (2011) Optimisation of a microwave pretreatment of wheat straw for methane production. Bioresour Technol 102:6750–6756

Jeihanipour A, Bashiri R (2015) Perspectives of biofuels from wastes: a review. Institute of Chemical Technology and Polymer Chemistry, Department of Chemistry and Biosciences, Karlsruhe Institute of Technology (KIT), Karlsruhe

Jianzhi Z, Le Y, Meng L et al (2017) N-butanol production from sucrose and sugarcane juice by engineered Clostridium tyro butyricum over expressing sucrose catabolism genes and adhE2. Bioresour Technol 233:51–57

Joshi G, Pandey JK, Rana S et al (2017) Challenges and opportunities for the application of biofuel. Renew Sust Energ Rev 79:850–866

Kader F, Baky AH, Khan MNH et al (2015) Production of biogas by anaerobic digestion of food waste and process simulation. Am J Mech Eng 3(3):79–83

Kandari V, Gupta S (2012) Bioconversion of vegetable and fruit peel wastes in viable product. J Microbiol Biotechnol Res 2(2):308–312

Kim J, Yoo G, Lee H et al (2013) Methods of downstream processing for the production of biodiesel from microalgae. Biotech Adv 31:862–876

Kour D, Rana KL, Yadav N et al (2019) Technologies for biofuel production: current development, challenges, and future prospects. In: Prospects of renewable bioprocessing in future energy systems. Springer, Cham, pp 1–50

Kumar G, Lin CY (2013) Bioconversion of de-oiled Jatropha waste (DJW) to hydrogen and methane gas by anaerobic fermentation: influence of substrate concentration, temperature and pH. Int J Hydrog Energy 38:63–72

Kumar M, Gayen K (2011) Developments in biobutanol production: new insights. Appl Energy 88(6):1999–2012

Kumar P, Barrett DM, Delwiche MJ et al (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Kumari D, Chahar P, Singh R (2018) Effect of ultrasonication on biogas and ethanol production from rice straw pretreated with petha waste water and dairy waste water. Int J Curr Eng Sci Res (IJCESR) 5(1):65–73

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renew Sust Energ Rev 90:877–891

Kumari D, Singh R (2019) Recent advances in bioremediation of wastewater for sustainable energy products. In: Rathoure AK (ed) Zero Waste: Management Practices for Sustainability. E-Publishing. CRC Press, Taylor & Francis Group, Boca Raton, ISBN 978-0-367-18039-3, pp 247–276

Kumari D, Singh R (2020a) Ultrasonic assisted petha waste water pretreatment of rice straw for optimum production of methane and ethanol using mixed microbial culture. Renew Energy 145:682–690

Kumari D, Singh R (2020b) Coupled green pretreatment of petha wastewater and rice straw. Environ Sustain Indicat 5:100013. https://doi.org/10.1016/j.indic.2019.100013

Laser M, Schulman D, Allen SG et al (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for conversion to ethanol. Bioresour Technol 81:33–44

Laursen W (2006) Students take a green initiative. Chem Eng 774:32–34

Li A, Antizar-Ladislao B, Khraisheh M (2007) Bioconversion of municipal solid waste to glucose for bio-ethanol production. Bioprocess Biosyst Eng 30:189–196

Li L, Kong X, Yang F et al (2012) Biogas production potential and kinetics of microwave and conventional thermal pretreatment of grass. Appl Biochem Biotechnol 166:1183–1191

Mahapatra MK, Kumar A (2017) A short review on biobutanol, a second generation biofuel production from lignocellulosic biomass. J Clean Energy Technol 5(1):27–30

Mamimin C, Singkhala A, Kongjan P et al (2015) Two-stage thermophilic fermentation and mesophilic methanogen process for biohythane production from palm oil mill effluent. Int J Hydrog Energy 40(19):6319–6328

Mari AE (2016) From first generation biofuels to advanced solar biofuels 45. Springer, Amsterdam, pp 24–31

McIvor A, Evans L (2008) A sustainable biofuelled future? Cleantech 1:5–9

Medipally SR, Yusoff FD, Banerjee S et al (2015) Microalgae as sustainable renewable energy feedstock for biofuel production. BioMed Res Int. https://doi.org/10.1155/2015/519513

Miao X, Wu Q (2004) High yield bio-oil production from fast pyrolysis by metabolic controlling of Chlorella protothecoides. J Biotechnol 110(1):85–93

Michailos S, Walker M, Moody A et al (2020) Biomethane production using an integrated anaerobic digestion, gasification and CO2 biomethanation process in a real waste water treatment plant: a techno-economic assessment. Energy Conver Manag 209:112663

Montingelli ME, Benyounis KY, Stokes JAG (2016) Pretreatment of macroalgal biomass for biogas production. Energy Conver Manag 108:202–209

Naik SN, Vaibhav VG, Prasant KR et al (2010) Production of first and second generation biofuels: a comprehensive review. Renew Sust Energ Rev 14:578–597

Nigam PS, Singh A (2011) Production of liquid biofuels from renewable resources. Prog Energy Comb Sci 37(1):52–68

Panbdey A, Lee DJ, Chisti Y et al (2014) Biofuels from algae. Elsevier, Amsterdam

Ramos LP (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nova 26:863–871

Ranjan A, Khanna S, Moholkar V (2013) Feasibility of rice straw as alternate substrate for biobutanol production. Appl Energy 103:32–38

Rao PV, Baral SS, Dey R et al (2010) Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew Sust Energ Rev 14(7):2086–2094

Raslavičius L, Semenov VG, Chernova N et al (2014) Producing transportation fuels from algae: in search of synergy. Renew Sust Energ Rev 40:133–142

RFA (2015) Pocket guide to ethanol 2015. www.EthanolRFA.org

Rodionova M, Poudyal R, Tiwari I et al (2017) Biofuel production: challenges and opportunities. Int J Hydrog Energy 42:8450–8461

Saidur R, Abdelaziz EA, Demirbas A et al (2011) A review on biomass as a fuel for boilers. Renew Sust Energ Rev 15(5):2262–2289

Salehian P, Karimi K, Zilouei H et al (2013) Improvement of biogas production from pine wood by alkali pretreatment. Fuel 106:484–489

Scaife MA, Nguyen GTDT, Rico J et al (2015) Establishing Chlamydomonas reinhardtii as an industrial biotechnology host. Plant J 82:32–546

Scott SA, Davey MP, Dennis JS et al (2010) Biodiesel from algae: challenges and prospects. Curr Opin Biotechnol 21:277–286

Seengenyoung J, Mamimin C, Prasertsan P et al (2018) Pilot-scale of biohythane production from palm oil mill effluent by two-stage thermophilic anaerobic fermentation. Int J Hydrog Energy:1–9. https://doi.org/10.1016/j.ijhydene.2018.08.021

Sen B, Chou YP, Wu SY et al (2016) Pretreatment conditions of rice straw for simultaneous hydrogen and ethanol fermentation by mixed culture. Int J Hydrog Energy 41(7):4421–4428

Senturk-Ozer S, Gevgilili H, Kalyon DM (2011) Biomass pretreatment strategies via control of rheological behaviour of biomass suspensions and reactive twin screw extrusion processing. Bioresour Technol 102(19):9068–9075

Sharma S, Pai MR, Kaur G et al (2019) Efficient hydrogen generation on CuO core/AgTiO2 shell nano-hetero-structures by photocatalytic splitting of water. Renew Energy 136:1202–1216

Shou-Chi Z, Qi-Heng L, Yuan L et al (2018) Enhanced biohydrogen production from corn Stover by the combination of Clostridium cellulolyticum and hydrogen fermentation bacteria. [Article in press]. J Biosci Bioeng. https://doi.org/10.1016/j.jbiosc.2016.03.014

Siciliano A, Stillitano MA, De Rosa S (2016) Biogas production from wet olive mill wastes pretreated with hydrogen peroxide in alkaline conditions. Renew Energy 85:903–916

Sikarwar VS, Zhao M, Fennell PS et al (2017) Progress in biofuel production from gasification. Prog Energy Comb Sci 61:189–248

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass – an overview. Bioresour Technol 199:76–82

Singh M, Kumari D, Chahar P et al (2017) Effect of different microbial culture on biohydrogen production from Benincasa hispida waste. In: Humanitarian Technology Conference (R10-HTC), 21st-23rd December, 2016 IEEE Region 10, DEI, Dayalbagh, Agra. Institute of Electrical and Electronics Engineers. IEEE Xplore, Piscataway

Singh R, Kumar S (2019) A review on biomethane potential of paddy straw and diverse prospects to enhance its biodigestibility. J Clean Prod 217:295–307

Singhal Y, Singh R (2014) Effect of microwave pretreatment of mixed culture on biohydrogen production from waste of sweet produced from Benincasa hispida. Int J Hydrog Energy 39(14):7534–7540

Singhal Y, Singh R (2015) Energy recovery from petha industrial wastewater by anaerobic digestion. Int J Sci Eng 2(3):146–151

Song ZL, Yang GH, Guo Y et al (2012) Comparison of two chemical pretreatments of rice straw for biogas production by anaerobic digestion. Bioresources 7:3223–3236

Taherzadeh MJ, Karimi K (2008) Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci 9:1621–1651

Tomé M, Verwijst T (1996) Modelling competition in short rotation forests. Biomass Bioenergy 11:177–187

Tomes D, Lakshmanan P, Songstad D (2010) Biofuels: global impact on renewable energy, production agriculture, and technological advancements. Springer Science & Business Media, New York

Trentacoste EM, Shrestha RP, Smith SR et al (2013) Metabolic engineering of lipid catabolism increases microalgal lipid accumulation without compromising growth. Proc Natl Acad Sci U.S.A 110:19748–19753

Valdez-Vazquez I, Sparling R, Risbey D et al (2005) Hydrogen generation via anaerobic fermentation of paper mill wastes. Bioresour Technol 96(17):1907–1911

Wang S, Sun X, Yuan Q (2018) Strategies for enhancingmicrobial tolerance to inhibitors for biofuel production: a review. Bioresour Technol 258:302–309

Xue B, Paul AL, Paul DJ et al (2016) Enhanced methane production from algal digestion using free nitrous acid pre-treatment. Renew Energy 88:383–390

Yadav M, Vivekanand V (2020) Biological treatment of lignocellulosic biomass by Curvularia lunata for biogas production. Bioresour Technol 306:123151

Yann NB, Laurenz T, Roland B (2015) Thermo-acidic pretreatment of beach macroalgae from Rügen to optimize bio-methane production-double benefit with simultaneous bioenergy production and improvement of local beach and waste management. Mar Drugs 13(9):5681–5705

Yeshanew MM, Frunzo L, Pirozzi F et al (2016) Production of biohythane from food waste via an integrated system of continuously stirred tank and anaerobic fixed bed reactors. Bioresour Technol 220:312–322

Zabed H, Faruq G, Boyce AN et al (2016) Evaluation of high sugar containing corn genotypes as viable feedstocks for decreasing enzyme consumption during dry-grind ethanol production. J Taiwan Inst Chem Eng 58:467–475

Zabed HM, Akter S, Yun J et al (2019) Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew Sust Energ Rev 105:105–128

Zong-Wen P, Wei L, Hui Z et al (2016) Butanol production employing fed-batch fermentation by Clostridium acetobutylicum GX01 using alkali-pretreated sugarcane bagasse hydrolysed by enzymes from Thermoascus aurantiacus QS 7-2-4. Bioresour Technol 212:82–91

Acknowledgment

The authors want to acknowledge the Director of D.E.I., Dayalbagh, Agra, HOD of Chemistry department, and parents for providing support and encouragement to carry out this study in the critical pandemic situation.

Competing Interests

All the authors declare that they have no competing interests.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kumari, D., Jain, Y. (2020). Enhanced Biofuel Production from Lignocellulosic Biomass: An Overview of Advanced Physico-Chemical and Biological Technologies. In: Verma, P. (eds) Biorefineries: A Step Towards Renewable and Clean Energy. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-15-9593-6_7

Download citation

DOI: https://doi.org/10.1007/978-981-15-9593-6_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9592-9

Online ISBN: 978-981-15-9593-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)