Abstract

Here, we report an innovative electrospun composite nanofiber having a complex of Eu(TTA)3Phen doped in a matrix of polymer blends prepared by electrospinning for designing smart fabrics. Europium complex Eu(TTA)3Phen contains 2-thenoyltrifluoroacetone(TTA), 1,10-phenanthroline(Phen) and europium. It was synthesized by co-precipitation technique for the preparation of electrospun nanofibers of Eu(TTA)3Phen/polymer blends such as Eu(TTA)3Phen/PVDF-PMMA(Polyvinylidene fluoride-Polymethylmethacrylate) and Eu(TTA)3Phen/PVDF-PS(Polyvinylidene fluoride-Polystyrene. Nanofibers of Eu(TTA)3Phen/polymer blends were characterized by Scanning Electron Microscopy (SEM), Fourier Transform Infra Red (FTIR), X-ray diffraction (XRD) and Photoluminescence (Pl). Photoluminescence study of the nanofibers shows red emission which is allocated to the transitions between the first excited state (5D0) and the multiplet states (7F0-4). Due to the integration of Eu(TTA)3Phen complex into the polymer matrix and subsequent distortion of the symmetry around the Eu3+ ions by the chapping Polymer, the polarization of the Eu3+ ions was improved, which increased the probability for electronic dipole allowed transitions. The Judd-Ofelt theory was used to calculate intensity parameters from emission data of Eu(TTA)3Phen/polymers blends. As compared to PS and PMMA, presence of PVDF in both polymer blends generally increases the intensity of hypersensitive transition and perhaps is responsible for enhancement of photoluminescence properties. Electrospun nanofibers of Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA can be important candidate for designing photoluminescent smart fabrics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

There has been an increasing interest in use of europium complex with β-diketones due to their intense emission peaks in the visible and near infrared region when excited by ultraviolet radiation. These photoactive europium complexes are of both essential and technological interest due to their distinguishing luminescence properties such as extremely sharp emission bands, potential high internal quantum efficiency and long lifetime of emission. The trivalent europium ion (Eu3+) exposes strong and intense emission bands due to their f-f-electronics transition and broad range of luminescent lifetime, suitable for various applications, but they have low absorption coefficient, limiting the lighting output. However, these limitations can be improved by forming complexes of the rare-earth ions with organic ligands such as TTA and phen [1].

Chromophores of organic ligands used with europium shows strong absorption bands, so europium complex Eu(TTA)3Phen have ability to absorb much more light than the Eu3+ ions. These organic ligands used as an antenna effect in which it absorbs the excitation light and to shift the excitation energy to the higher energy levels of the Eu3+ ion, as of the emitting excited levels of Eu3+ ion can be populated [2, 3]. Organic ligand in complex such as Phen is a synergic shielding ligand which used to reduce the rate of non-radiative decays and strongly enhance the fluorescence intensity of the complex. Therefore, the key problem related to rare earth complex is to try to find a suitable matrix material to load them. Inorganic solid matrixes are promising host materials due to their good optical, thermal and chemical stability. In fact, many RE complexes have already been encapsulated in or adsorbed on host materials including silica, sol-gels and zeolite. A number of properties make polymers attractive hosts for rare-earth ions, including low cost, ease of fabrication on a wide range of substrates, low dispersion, and broad luminescence bands. Such europium complexes doped in polymers possess enhanced photoluminescence properties with this it shows improved thermal stability and mechanical flexibility [4]. The incorporation of europium complex into organic polymers presents an ideal and multipurpose approach to generate hybrid materials. It has been verified that the polymer-capped Eu(TTA)3Phen complexes possess improved photoluminescence properties and thermal stability, and are mechanically flexible. There is tremendous work going in textile for the fabrication of smart clothes with the use of nanofibers. Nanofibers of photoluminescent materials prepared by electrospinning method are in special demand. One-dimensional (1D) nanofibers are very interesting because of their surface properties, different from bulk materials. The photoactive Eu(TTA)3Phen complexes doped in polymer matrixes presents a class of new materials that shows the properties of both the europium complexes and the polymer matrix materials, useful in a wide range of new technologies. Nanofibers of Eu(TTA)3Phen complex cannot be directly obtained by electrospinning without the use of polymers. Polymer nanofibers do not emit light without lanthanide complexes mixed with polymers. Therefore, there is the need of composites of both categories to have fibers in nanoscale and light emission. Use of polymer not only as a carrier but it helps to enhance luminescent properties of material. The enhancement of luminescent efficiencies in Eu(TTA)3Phen/Polymer occurs as uniform distribution of the complex units along macromolecular chains of polymers. In present work PS, PMMA, PVDF with their blends are used as matrix material for observing the good coordination between Eu(TTA)3Phen complex and polymer so as to get enhanced luminescent fibers for fabric designing in the textile industries.

2 Experimental

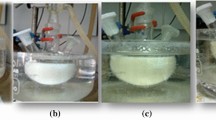

2.1 Preparation of Eu(TTA)3Phen Complex

Eu(TTA)3Phen complex powder was prepared by simple solution method [5]. TTA (6.63 mmol, 1.4725 g) and phen (2.21 mmol, 0.3979 g) were dissolved in 20 ml of ethanol in flask. This solution neutralized with NaOH solution to obtained pH = 7. In another flask europium chloride salt EuCl3 (2.21 mmol, 0.5708 g) was dissolved in 10 mL of double distilled water. Prepared solution was poured into the solution of TTA and phen. Finally, prepared solution was heated at 60 °C with continuous stirring for 1 h for obtaining homogenous solution. After 1 h precipitate of solution was formed and it was separated by using filter paper. The color of obtained compound was off-white which was then dried in oven at 80 °C for 2 h.

2.2 Preparation of Eu(TTA)3Phen/Polymer Blend Solutions

Preparation of electrospinning solution of Eu(TTA)3Phen/PVDF-PS composites, 1 g PVDF and 1 g PS were dissolved in 10 mL THF (tetrahydrofuran) solvent in one flask for obtained mass fraction of 20 wt%. Obtained mixture was magnetically stirred for 12 h till becoming uniform solution. Then 20% of Eu(TTA)3Phen was added to above uniform solution of polymer and again magnetically stirred for 12 h. Now solution is ready for electrospinning process for preparation of nanofibers. The same process was repeated for preparation of electrospinning solution of Eu(TTA)3Phen/PVDF-PMMA blend.

2.3 Preparation of Eu(TTA)3Phen/Polymer Blend Nanofibers

The prepared uniform electrospinning solution of Eu(TTA)3Phen/PVDF-PS blend was firstly filled into a 5 mL plastic syringe for preparation of nanofibers by electrospinning method. For the electrospinning process, prepared solution was fed to the tip using a syringe pump and adjust flow rate of 0.3 mL/h. A positive voltage of 25 kV was applied to the needle of the syringe that containing electrospinning solution. Metallic plate wrapped with aluminum foil and connected with grounded electrode. Distance between needle of the syringe and metallic plate must kept at a distance of 15 cm. The uniform electrospun nanofibers were collected on the conducting aluminum foil. After electrospinning process, collected membranes of nanofibers on aluminum foil were dried in a vacuum oven at 60 °C for 12 h so that to eliminate the residual organic solvent present with nanofibers. Same electrospinning method was repeated for another electrospinning solution of Eu(TTA)3Phen/PVDF-PMMA polymer blend.

3 Results and Discussion

3.1 Scanning Electron Microscopy

Surface morphological and structural properties of prepared nanofibers of different composites by electrospinning method can be studied by SEM (scanning electron microscopy). It examines the surface information of the materials and a detailed study of the morphological features like diameter of fibers, their length, and alignment etc. of all the samples had been carried. SEM study of synthesized nanofibers is important since they directly affect the photoluminescence emission intensity of the materials. As compare with nanofibers of pure polymer, diameter of Eu(TTA)3Phen/polymer blends are found to be smaller, this may be due to effect of increased conductivity of the electrospinning solution as addition of Eu(TTA)3Phen in pure polymer solutions. With addition of Eu(TTA)3Phen in pure polymer solutions, europium complex uniformly distributed along macromolecular chain of the polymers and it helps to increase conductivity of electrospinning solution which results to decrease diameter of nanofibers of Eu(TTA)3Phen/polymer blends. The presence of europium complex into the polymer matrix can efficiently recover the morphology of the electrospinning fibers. Such Eu(TTA)3Phen/Polymer blend nanofibers show more photoluminescence intensity as compared to nanofibers of pure Eu(TTA)3Phen complex, Increased in intensity of Eu(TTA)3Phen/Polymer blend nanofibers which may be due to their large surface area and small diameter as they show high aspect ratio that confirmed from their SEM images.

SEM images of Eu(TTA)3Phen/PVDF-PS blend electrospun nanofibers shows diameters in the range of 300 to 700 nm and Eu(TTA)3Phen/PVDF-PMMA blend electrospun nanofibers shows diameters in the range of 100 to 500 nm as respectively shown in Fig. 9.1a, b. Obtained nanofibers of Eu(TTA)3Phen/polymer blends are aligned in random orientation on the collector, which was occurred by the bending instability of the spinning jet and stationary collector [6, 7].

3.2 FTIR Spectroscopy

FTIR spectra of Eu(TTA)3Phen/PVDF-PS blend and Eu(TTA)3Phen/PVDF-PMMA blend nanofibers are shown in Fig. 9.2. In the spectrum of Eu(TTA)3Phen/PVDF-PS blend there are presence of bands of PS and PVDF with europium complex. FTIR spectra shows bands of PS which are shifted from its original position to slightly higher frequencies at 756, 1450, 1492 and 1602 cm−1, shows the vibrations of the benzenoid ring in PS and one extra broad band appeared at 3400 cm−1 arises by the vibration of hydroxyl groups of PS [8]. FTIR spectra shows the bands of stretching vibration of the C=O group at 1185 cm−1 which are characteristic peak of PVDF, which shows a little shift to the higher frequencies as compared with pure PVDF spectra. These shifting of bands for PS and PVDF in Eu(TTA)3Phen/polymers blends occur due to coordination of europium complex with PS and PVDF polymer matrix [9]. The vibration peaks of Eu(TTA)3Phen complex also get shifted to higher frequencies due to the surrounding polymer matrix. In FTIR spectrum of Eu(TTA)3Phen/PVDF-PMMA polymer blends, there are presence of characteristic bands of PMMA and PVDF at 1724 cm−1 and 1185 cm−1 respectively, at higher frequency region with some bands of Eu(TTA)3Phen complex [10]. These shifting of bands from its positions, show that the europium complexes are effectively incorporated into polymer blend matrix.

3.3 X-Ray Diffraction

Figure 9.3 shows X-ray diffraction patterns of Eu(TTA)3Phen/PVDF-PS blend and Eu(TTA)3Phen/PVDF-PMMA blend nanofibers. In XRD pattern of Eu(TTA)3Phen/Polymer blends, there are diffraction peaks of PMMA, PVDF and PS exist. Diffraction peaks shows the maximum sharp peak intensity for polymer/polymer blends as europium complex Eu(TTA)/phen doped in polymer blend matrix which results a maximum degree of crystallinity due to increasing degree of ordering of atoms at polymer blend, means that the crystal structure remained constant [11]. X-ray diffraction patterns also shows a sharp peak of europium complex in Eu(TTA)3Phen/polymer blend, it represented that chemical bonding exist between polymers and europium complex. There are small corresponding diffraction peaks at 2θ = 15°–58° of europium observed. Presence of all these peaks of europium complex in XRD pattern of Eu(TTA)3Phen/Polymer blends, indicates the development of a solid solution of Eu(TTA)3Phen in polymer blend matrix.

3.4 Photoluminescence

The emission spectra of europium complex Eu(TTA)3Phen, Eu(TTA)3Phen/PVDF-PS blend and Eu(TTA)3Phen/PVDF-PMMA blend electrospun nanofibers are shown in Fig. 9.4. Under excitation at 354 nm, emission spectrum of Eu(TTA)3Phen was extended from 550 to 655 nm [12]. The emission spectrum shows four emission peaks at 579, 592, 612, 642, 654 nm, for the transitions 5D0 → 7F0,5D0 → 7F1, 5D0 → 7F2, 5D0 → 7F3, 5D0 → 7F4 respectively. These transitions can be characteristically the f–f transitions of Eu3+ ions in the europium complex. The transition 5D0 → 7F1 is a magnetic dipole transition, it allowed by the Laporte selection rule. The intensity of 5D0 → 7F1 transition are very weak as it is unaffected by the influence of surrounding material environment. The lower transitions 5D0 → 7F0 and 7F3 are forbidden transitions and its intensities not change with external change in surrounding materials. The transition 5D0 → 7F2 called as hypersensitive transition and its emission intensity strongly influenced by surrounding polymer matrix as well as local symmetry of the europium ions of the complex and nature of ligands. The emission spectra of Eu(TTA)3Phen/PVDF-PS blend and Eu(TTA)3Phen/PVDF-PMMA blend electrospun nanofibers shows much stronger intensity of hypersensitive transition 5D0 → 7F2 than hypersensitive transition of Eu(TTA)3Phen complex, indicates that Eu3+ ion is in a single site without a center of inversion and presence of surrounding polymer matrix region around the europium complex which influenced the chemical environment around the Eu3+ ions due to this, higher probability for the electronic dipole allowed transitions which leads to increased hypersensitive transition rate and varies its intensity [13,14,15,16,17,18,19]. Hypersensitive transition are intraconfigurational electric dipole transitions which are initially forbidden by the Laporte selection rule but when a europium ions of europium complex conjugated to a chemical complex of Eu(TTA)3Phen, the Eu3+ ion commencing is in a coordinating environment and the forbidden transitions changes into partly allowed.

As compare with hypersensitive intensity of Eu(TTA)3Phen complex, intensity of Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA blends are much high, due to the presence of PVDF in both polymer blends. Increased in intensity of Eu(TTA)3Phen/Polymer blend nanofibers which may be due to their large surface area and small diameter as they show high aspect ratio that confirmed from their SEM images study. The enhancement of luminescent efficiencies in Eu(TTA)3Phen/Polymer blend occurs as there uniform distribution of the complex units along macromolecular chains of polymer matrix.

The CIE (Commission Internationale de l’ Eclairage) color model is used to study emission intensity in terms of intensity of color emitted during transitions. This study used coordinates system. The coordinates of the Eu(TTA)3Phen complex, Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA nanofibers were obtained by color calculator software of CIE using PL emission data of each sample. The CIE coordinates calculated for Eu(TTA)3Phen complex shows red emission in visible region with coordinates x = 0.61, y = 0.32 shown in Fig. 9.5a.

Figure 9.5b, c show CIE calculated coordinates for Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA, respectively. For Eu(TTA)3Phen/PVDF-PS CIE coordinates are x = 0.64, y = 0.33 and for Eu(TTA)3Phen/PVDF-PMMA CIE coordinates are x = 0.64, y = 0.34. As addition of polymers PS and PVDF into pure Eu(TTA)3Phen complex, CIE results shows slightly change in coordinates with position of color in CIE graph. CIE coordinates for Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA deviated from its original position as in europium complex and it shows good red color saturation. The calculated CIE shows good color saturation for red emission. As europium complex is integrated with polymers matrix, the emission intensity of hypersensitive transitions increased and the CIE color coordinates for its moves towards pure or deep saturated red emission region. The CIE calculated color coordinates for europium complex showed red color region and for europium complex incorporated polymer matrix showed deep saturated red emission region.

4 Conclusion

Eu(TTA)3Phen/PVDF-PS blend and Eu(TTA)3Phen/PVDF-PS blend nanofibers with diameters in nano range were prepared by electrospinning process. Due to the addition of Eu(TTA)3Phen complex into the polymer matrix and successive distortion of the symmetry around the Eu3+ ions by the chapping Polymer, the polarization of the Eu3+ ions was improved, which increased the probability for electronic dipole allowed transitions. As increased in electronic dipole allowed transitions there were increased in intensity of hypersensitive transition. Addition of Eu(TTA)3Phen complex in polymers generally enhances the luminescent intensity as compared to pure europium complex Eu(TTA)3Phen. Polymers like PS, PMMA and PVDF generally increases the luminescent intensity of the 5D0 → 7F2 hypersensitive transition of Eu3+ ions. As compare with hypersensitive intensity of Eu(TTA)3Phen complex, intensity of Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA blends are much high, due to the presence of PVDF in both polymer blends. Nanofibers of Eu(TTA)3Phen/polymer blends shows large surface area and small diameter as they represents high aspect ratio that confirmed from their SEM images. As Eu(TTA)3Phen/PVDF-PS and Eu(TTA)3Phen/PVDF-PMMA blend nanfibers shows good morphology and excellent luminescent property, it could be applied for the designing of photoluminescent smart fabric.

References

X. Cui, H. Ming, T. Zhang, W. Feng, Electrospinning preparation and photoluminescence properties of erbium complex doped composite fibers. Spectrochim. Acta Part A 79, 1998–2002 (2011)

B. Rajamouli, C.S. Dwaraka Viswanath, S. Giri, C.K. Jayasankar, V. Sivakumar, Carbazole functionalized new bipolar ligand for monochromatic red light-emitting europium(III) Complex: combined experimental and theoretical study. New J. Chem. 41, 3112–3123 (2017)

J. Feng, H. Zhang, Hybrid materials based on lanthanide organic complexes: a review. J. Chem. Soc. Rev. 42, 387–410 (2013)

K. Binnemans, P. Lenaerts, K. Driesen, C. Gorller-Walrand, A luminescent tris(2-thenoyltrifluoroacetonato) europium(III) complex covalently linked to a 1,10-phenanthrolinefunctionalised sol–gel glass. J. Mater. Chem. 14, 191–219 (2004)

L.R. Melby, N.J. Rose, E. Abrmson, J.C. Caris, Synthesis and fluorescence of some trivalent lanthanide complexes. J. Am. Chem. Soc. 86, 5117–5128 (1964)

C. Chang, C. Huang, Y. Chang, C. Kuo, Enhancement of light scattering and photoluminescence in electrospun polymer nanofibers. J. Opt. Express A. 18, 174–189 (2010)

X. Zhang, S. Wen, S. Hu, Q. Chen, H. Fong, L. Zhang, L. Liu, Luminescence properties of Eu(III) complex/polyvinylpyrrolidone electrospun composite nanofibers. J. Phys. Chem. C 114, 3898–3903 (2010)

Y. Hongquan, L. Tao, C. Baojiu, W. Yanbo, L. Yue, Preparation of aligned Eu(DBM)3phen/PS fibers by electrospinning and their luminescence properties. J. Colloid Interface Sci. 8, 23–56 (2013)

N. Betz, L. Moel, E. Balanzat, J.M. Ramillon, J. Lamotte, FTIR study of PVDF irradiated by means of swift heavy ions. Polym. Sci. Part. J Polym. Phys. 32, 1493–1502 (1994)

J. Kai, C. Maria, C. Felinto, A. Luiz, O. Nunes, L. Oscar, Intermolecular energy transfer and photostability of luminescence-tuneable multicolour pmma films doped with lanthanide β-diketonate complexes, supplementary material (ESI) for journal of materials chemistry. J. Roy. Soc. Chem. 5, 123–156 (2011)

Y. Li, C. Zhang, D. Yu, X. Wang, Tailoring spatial distribution of Eu(TTA)3phen within electrospun polyacrylonitrile nanofibers for high fluorescence efficiency. J. RSC Adv. 87, 548–568 (2016)

Z. Xiaoping, W. Shipeng, H. Shui, Z. Liqun, L. Li, Electrospinning preparation and luminescence properties of Eu(TTA)3phen/polystyrene composite nanofibers. J. Rare Earths 28, 332–337 (2010)

A. Sharma, D. Singh, I. Singh, Synthesis and characterization of optical properties of europium (III) complex with 4,4,4-trifluoro-1-phenyl-1,3-butanedione and 1,10 Phenanthroline. Proc. of ASID New Delhi 5, 862–945 (2006)

L.V. Rosa, A. Paula, A. Marques, T.S. Tanaka, V. Motta, A. Varela, R. Leite, Europium(III) concentration effect on the spectroscopic and photoluminescent properties of BaMoO4:Eu. J. Fluoresce. 19, 495–500 (2009)

A. Zhang, N. Sun, L. Liping, Y. Yamin, Z. Xijin, J. Husheng, L. Xuguang, X. Bingshe, Tunable white light emission of Eu, Tb, Zn-containing copolymers by RAFT polymerization. J. Mater. Chem. C. 3, 9933–9941 (2015)

D. Chitnis, N. Thejo Kalyani, S.J. Dhoble, Structural and optical investigation of novel europium hybrid organic complex for OLEDs and solid state lighting. J. Mater. Phys. Chem. 5, 1–10 (2017)

H. Shao, Q. Ma, X. Dong, W. Yu, M. Yang, Y. Yang, J. Wang, G. Liu, Electrospun flexible coaxial nanoribbons endowed with tuned and simultaneous fluorescent color-electricity-magnetism trifunctionality. Art. Sci. Rep. 8, 10452–10486 (2015)

S. Corneliu, S. Stan, P. Horlescu, M. Popa, A. Coroabab, L. Laura, E. Ursub, Photoluminescent polymer composites with R, G, B emission and their potential applications in LCD displays. New J. Chem. 40, 6505–6512 (2016)

S.L. Sonawane, S.K. Asha, Blue, green, and orange-red emission from polystyrene microbeads for solid-state white-light and multicolor emission. J. Phys. Chem. B. 118, 9467–9475 (2014)

Acknowledgements

The Department of Science and Technology (DST, New Delhi, India) supports this work under DST-FIST Program, Grant No. SR/FST/PSI-178/2012(C).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Dandekar, M.P., Itankar, S.G., Nandanwar, D.V., Kondawar, S.B. (2020). Electrospun Eu(TTA)3Phen/Polymer Blend Nanofibers for Photoluminescent Smart Fabrics. In: Murakami, RI., Koinkar, P., Fujii, T., Kim, TG., Abdullah, H. (eds) NAC 2019. Springer Proceedings in Physics, vol 242. Springer, Singapore. https://doi.org/10.1007/978-981-15-2294-9_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-2294-9_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-2293-2

Online ISBN: 978-981-15-2294-9

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)