Abstract

The feasibility of simultaneous nitrification denitrification and phosphate removal in a single-stage fixed-bed bioreactor was evaluated in this study. The bioreactor was packed with industrial wastes and agricultural wastes mixed in a definite proportion. A newly isolated simultaneous nitrifying and denitrifying bacterial strain was immobilized on the packed bed materials to facilitate nutrient removal. The bioreactor was fed with both real and synthetic wastewater under variable start-up and steady-state experimental conditions including hydraulic retention time (HRT), mode of aeration and nutrient loading rate and operated for 70 days continuously. In the steady-state condition ammonia, nitrate, and phosphate removal efficiencies of synthetic wastewater were 87.1–92.8%, 69.4–88.4%, and 88.4–100%, respectively, while the corresponding values of real domestic wastewater were 88.7–93.1%, 70.5–87.2%, and 84–89.4%, respectively. This work publicized the promising application prospect of the developed bioreactor in domestic wastewater treatment primarily focusing on nutrient removal.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Nutrient removal

- Domestic wastewater

- Industrial wastes

- Agricultural wastes

- Single-stage fixed-bed bioreactor

1 Introduction

Nitrogen and phosphorus, known as biostimulants, are essential for growth and development of life. However, sustained input of nutrients to aquatic environment leads to eutrophication. Eutrophication induced hazardous effects that are mostly accountable for the deterioration of water quality and eutrophication continues to rank at the top of the water quality hardships globally [1]. Consequently, treatment objective of most of the contemporary wastewater treatment plants have shifted from traditional sole carbon removal to simultaneous carbon and nutrient removal approach [2]. In recent years, to meet the more stringent effluent nutrient regulations, the treatment technologies have been improved and modified to get higher nutrient removal efficiencies. However, the processes are still facing many challenges from nutrient removal prospective. Therefore, there is a dire need to develop dependable domestic wastewater nutrient removal technologies that would be able to deal with the prevalent nutrient eradication issues.

Furthermore, achieving synergistic nitrogen and phosphorus in the single-stage bioreactor is highly desirous for minimization of substrate requirements and simplification of process configurations as compared to conventional bioreactors for nutrient removal. So, innovative wastewater treatment systems are essential for realizing the simultaneous nitrogen and phosphorus removal.

This study aimed at designing and developing a single unit packed bed bioreactor with immobilized specific microbial species to carry out simultaneous nitrification, denitrification, and phosphorus removal. The bioreactor was packed with industrial waste material (dolochar) as a potential reactive media for phosphate removal through physicochemical approach [3,4,5]. Likewise, a equivolume mixture of waste organic solid substances (WOSS) was used as another packing material for serving as carbon source to accelerate heterotrophic denitrification process [6, 7]. The packing materials were used as biofilm carriers for the immobilization of a microbial monoculture, Bacillus cereus GS-5 strain for enhanced simultaneous nutrient removal [8, 9]. The integration of biological as well as physicochemical approach for nutrient removal was attempted by selective use of microbial strain and packing materials. The nutrient removal performance was evaluated under different experimental conditions.

2 Materials and Methods

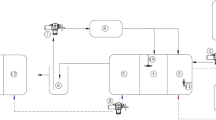

2.1 Bioreactor Configuration

Many small-scale bioreactors were configured using acrylic sheets. Figure 1 shows the actual image of the bioreactors with length, breadth, and height of 10, 10, and 30 cm, respectively. The adsorbent and carbon sources were packed inside the bioreactor in alternative manner and distributed in four to five layers. The media materials were bounded by glass wool covered holed acrylic plates in both the top and bottom side of the reactor to prevent media and biomass loss from the reactor. In addition, the arrangement was meant to facilitate equal distribution of influent across the packed bed. With the mentioned dimension and considering bed porosity of 72%, resultant working volume of the bioreactor was 1800 mL.

2.2 Microbe Immobilized Substrates

Bacillus cereus GS-5 strain was grown in a sterilized nutrient medium with composition of sodium acetate1.3 g, ammonium sulfate 0.472 g, basal medium 1.53 g, potassium nitrate 0.722 g, magnesium sulfate 0.2 g, calcium chloride 0.5 g, dipotassium hydrogen phosphate 0.113 g, and trace element solution 2 mL in 1 L of distilled water. The incubation conditions followed were 35 ºC temperatures, 7 pH, 125 rpm, and 36 h time period [10]. Fully grown cultures were centrifuged for 10 min at 7500 rpm and cells were collected as pellets after discarding supernatant. The cells were then washed repeatedly with 0.2% sterilized saline solution, and afterwards suspended in basal media added with essential microelements, carbon, and nitrogen sources for further use as an inoculum in the bioreactor.

500 g/L of dolochar and 100 g/L of WOSS were mixed with the nutrient medium in Erlenmeyer flasks and subjected for sterilization in autoclave at 121 °C, 15 psi for 20 min followed by addition of 10% v/v inoculum into the individual flasks. The incubation of the flasks was done under the experimental condition as mentioned above. To avoid nutrient shortage, 20% fresh media were added two times a week and to accelerate growth, proliferation, and biofilm formation 5% inoculum was added once in a week. The process continues for two weeks for biomass immobilization via microbial colonization on the carrier surface. Subsequently, the microbe immobilized carrier materials were taken out of the flasks and packed inside the bioreactor for further application.

2.3 Domestic Wastewater

Real domestic wastewater as well as synthetic solution emulating domestic wastewater condition was used in this work. In order to effectively control the experimental conditions and due to the unbalanced composition of actual wastewater, the synthetic wastewater was used. The same was prepared by dissolving (g/L) sodium acetate 1.4, ammonium sulfate 0.472, basal medium 1.53, potassium nitrate 0.722, magnesium sulfate 0.2, calcium chloride 0.5, dipotassium hydrogen phosphate 0.113, and 2 mL/L of trace element solution in tap water. The trace solution consisted of the following compounds (mg/L) 0.05 CuSO4·5H2O, 0.05 AlCl3·6H2O, 0.25 CoCl2·6H2O, 0.05 H3BO3, 0.5 FeSO4·7H2O, 0.01 Na2MoO4·2H2O, 0.5 MnCl2·4H2O, 0.05 ZnCl2, 0.15 CuCl2, 0.02 NiSO4·H2O, and 0.01 Na2SeO3. The pH was adjusted within 6–7 by adding base or acid as desired. The optimization of experimental parameters was performed with synthetic wastewater. After optimization, the real domestic wastewater was used to assess the nutrient removal performance efficiency of the bioreactor at the optimum conditions. The real domestic wastewater from the same source as reported in our earlier publication [8, 9] was collected and used in this study. The characteristics of both types of wastewater used in this work are shown in Table 1.

2.4 Analytical Techniques

NO3−-N, NO2−-N, and NH4+-N concentrations were measured by following the sodium salicylate, sulfanilic acid, and the Nessler method, respectively, colorimetrically in a UV/VIS spectrophotometer (Perkin-Elmer Lambd-25) [11]. Phosphate measurement was also done colorimetrically following vanadomolybdophosphoric acid method, the detail procedure of which was discussed elsewhere [3, 4]. The chemical oxygen demand (COD) concentration was determined by colorimetric method (5220-D) as per the procedure mentioned in the standard methods for the examination of water and wastewater [12]. All the samples were filtered through 0.45 µm membrane filter (PVDF, Whatman, UK) prior to analysis.

3 Results and Discussions

3.1 Preliminary Studies for Optimizing Factors

Based on the literature some of the key experimental parameters like DO and HRT that govern simultaneous nitrification–denitrification and denitrifying phosphate removal were selected and subsequently optimized in this work [13,14,15]. The bioreactor was packed with WOSS as the sole external carbon sources for the heterotrophic microbe to carry out the metabolic activities since the carbon source contained in the domestic wastewater was limited to meet the microbial requirement. The biodegradation and carbon release from WOSS is a complex process. So using WOSS as carbon source made it difficult to study the effect of C/N ratio as an experimental parameter and also the option of exploring the effects of different carbon sources got restricted. So, both these parameters were opted out for this study and every detail of WOSS as a carbon source has already been discussed in our earlier publications [6, 7]. The bioreactor was operated in the ambient room temperature since it was beyond the scope of the study to regulate the bioreactor temperature at 35 °C as optimized in the earlier study [8]. Nevertheless, the optimized pH (7.5) was maintained in this study by acid and base addition as desirous. For studying the effects of DO on performance efficiency, different modes of aeration were opted to imitate the optimized DO level. In addition, HRT as a key parameter for the bioreactor performance was optimized in this study.

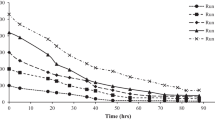

3.2 Nitrification and Physicochemical Ammonium Removal

Figure 2 demonstrates the ammonium removal efficiency and its concentration in the input and output of the bioreactor under different experimental conditions. After the start-up period, the ammonium input amplified progressively to examine its effect on the nitrogen elimination efficiency of the bioreactor. Real wastewater was fed to the bioreactor in the final phase of the operational period. Experimental conditions fixed during steady-state operation were 4 h HRT, 7.5 mL/min flow rate, and 2.65 ± 0.1 mg/L DO (achieved via dynamic aeration). As shown in Fig. 2, starting with 100 mg/L, the ammonium removal efficiency of 57.4% was reported on the day 1 of the operation. Till day 11, the trend of increasing ammonium removal continued with the last reported efficiency of 83% followed by three days of steady performance efficiency varying in 83–85% range and the average efficiency till day 14 was calculated to be nearly 70%. No appearance of nitrate till 8th day as evident from the figure indicated adsorptive ammonium removal during the mentioned period. Beyond first week of operation, commencement of ammonium removal via biological means was marked by progressive appearance of nitrate in increased concentrations in the reactor output confirming biofilm formation.

Starting with 30, 50, and 70 mg/L of ammonium in stage II, III, and IV of the bioreactor operation, the average output concentrations were below the allowable discharge limit with respective concentrations of 2.4, 4.3, and 5.8 mg/L [16]. The observation indicated that steady-state ammonium removal efficiency improved with increased input ammonium concentration, which was attributed to the resilience of mature biofilm to variation in influent ammonium loadings [14]. In the last phase of operation while dealing with real wastewater, in spite of variable inlet ammonium concentration in 49.62 to 60.46 mg/L range, the reactor exhibited efficient ammonium removal with average outlet concentration of 4.8 mg/L. The progressive accumulation of nitrate and nitrite to maximum concentrations of 9.8 and 3.1 mg/L, respectively, and subsequently decreasing to 1.02 and 0.59 mg/L in that order was witnessed from the figure. The synergistic ammonium removal and appearance of nitrate and nitrite, the intermediates of nitrification mechanism in the reactor effluent confirmed biological ammonium removal mediated by nitrification and denitrification. More precisely the mechanism is heterotrophic nitrification and aerobic denitrification as exhibited by the immobilized microbial strain Bacillus cereus GS-5, the same novel nutrient removal metabolic pathway was reported in our recent publications [8, 9].

3.3 Denitrification and Physicochemical Nitrate Removal

Figure 3 depicts the nitrate removal efficiency and its concentration in the input and output of the bioreactor under different experimental conditions. Similar experimental conditions and process flow as discussed in previous section were followed for nitrate removal. As shown in Fig. 3, starting with 100 mg/L, the nitrate removal efficiency of 45.2.4% was reported on the day 1 of the operation. Till day 7, the trend of increasing nitrate removal continued with 56.6% in 7th day followed by fast increase to 75.5% on 11th day afterwards three days of steady performance efficiency varying in 75.5–76.8% range and the average efficiency till day 14 was calculated to be nearly 60%. No appearance of nitrite till 7th day as evident from the figure indicated adsorptive nitrate removal during the mentioned period. Beyond first week of operation, commencement of nitrate removal via biological means was marked by progressive appearance of nitrite in increased concentrations in the reactor output along with enhanced nitrate removal beyond 15th day confirmed biofilm formation and stabilization.

Starting with 30, 50, and 70 mg/L of nitrate in II, III, and IV stage operation of the bioreactor, the average output concentrations were below the allowable discharge limit (10 mg/L) with respective concentrations of 6.6, 7.6, and 8.5 mg/L [16]. The observation indicated that steady-state nitrate removal efficiency improved with increased input nitrate concentration with passage of time, which was attributed to the resistance of mature biofilm to variation in influent nitrate loadings [14]. In the last phase of operation while dealing with real wastewater, in spite of variable inlet nitrate concentrations in 9.6–11.9 mg/L range, the reactor exhibited efficient ammonium removal with average outlet concentration of 2.3 mg/L. The progressive accumulation of nitrite, the denitrification intermediate to maximum concentration of 8.3 on 13th day and subsequently decreasing to below 1 mg/L beyond 31st day was witnessed from the figure. The momentary nitrite build-up signifying inadequate denitrification is attributed to the lag phase of the nitrite reductase prior to fully functioning and also due to competitive activity suppression by nitrate reductase [13]. The synergistic nitrate removal and appearance of nitrite, the intermediates of denitrification mechanism in the reactor effluent confirmed biological nitrate removal mediated by denitrification. More precisely, the mechanism is aerobic denitrification of nitrate to nitrogen gas under limited aeration condition through nitrite pathway as exhibited by the immobilized microbial strain Bacillus cereus GS-5 and the same novel nutrient removal metabolic pathway has already been reported in our earlier publications [8, 9].

3.4 Denitrifying and Physicochemical Phosphate Removal

Figure 4 displays the phosphate removal efficiency and its concentrations in the input and output of the bioreactor under different experimental conditions. Similar experimental conditions and process flows as discussed in previous section were followed for phosphate removal. As shown in Fig. 4, starting with 20 mg/L, the phosphate removal efficiency of 95. 4% was reported on the day 1 of the operation. The phosphate removal trend varied in the range of 95.7–100% till 41st day with reported average removal efficiency of 97.6%. After 42nd day steady performance efficiency with average removal efficiency of 90.4% was observed. Starting with 5 and 10 mg/L of phosphate in II and III stage operation of the bioreactor, there was no significant difference marked in the average removal efficiencies with the corresponding values of 99 and 97%. However, in phase IV by increasing the inlet phosphate concentration to 15 mg/L, the average removal efficiency reduced to 95%. In the last phase of operation, the reactor was supplied with real wastewater with variable inlet phosphate concentrations of 4.5–6 mg/L, the removal efficiency fluctuated in between 87.5 and 89.4% accordingly. During the entire operation period irrespective of the inlet phosphate concentration, the observed outlet concentrations were always below 1 mg/L, the allowable discharge limit for phosphate [16]. The highly efficient phosphate removal in the bioreactor was mainly attributed to the following three factors (i) adsorptive removal by activated carbon-based media material, dolochar, (ii) biological means via denitrifying phosphate removal as exhibited by the immobilized Bacillus cereus GS-5 strain, and, (iii) microbial assimilation as a nutrient for vital functions like metabolite synthesis, growth and proliferation [8, 17, 18]. Out of the above mentioned phosphate removal mechanisms, dolochar-based physicochemical approach contributed maximum phosphate removal with calculated contribution of more than 70%, whereas phosphate removal by biological means was approximately 26%.

4 Conclusions

In this study, the newly isolated microbial strain Bacillus cereus GS-5 immobilized laboratory scale single-stage fixed-bed bioreactors were developed for the realization of synergistic nitrogen and phosphorous removal. The bioreactors demonstrated outstanding simultaneous nutrient elimination efficiency from low, medium and high strength synthetic wastewater and from real domestic wastewater as well. The main mechanism of nitrogen removal, ammonium, and nitrate, in particular, was observed to be through heterotrophic nitrification and aerobic denitrification feature of the Bacillus cereus GS-5 strain, whereas phosphate was primarily removed by dolochar mediated physicochemical means. Only 26% of phosphate was removed by biological means through the denitrifying phosphate removal feature of the immobilized microbial biomass. Therefore, the fixed-bed bioreactor with advanced nutrient removal mechanisms can be recommended as an imperative alternative for nutrient confiscation from domestic wastewater.

References

Rout, P.R., Dash, R.R., Bhunia, P.: Development of an integrated system for the treatment of rural domestic wastewater: emphasis on nutrient removal. RSC Adv. 6(54), 49236–49249 (2016)

Guadie, A., Xia, S., Zhang, Z., Guo, W., Ngo, H.H., Hermanowicz, S.W.: Simultaneous removal of phosphorus and nitrogen from sewage using a novel combo system of fluidized bed reactor–membrane bioreactor (FBR-MBR). Bioresour. Technol. 149, 276–285 (2013)

Rout, P.R., Bhunia, P., Dash, R.R.: Effective utilization of a sponge iron industry by-product for phosphate removal from aqueous solution: a statistical and kinetic modelling approach. J. Taiwan Inst. Chem. Eng. 46, 98–108 (2015)

Rout, P.R., Dash, R.R., Bhunia, P.: Nutrient removal from binary aqueous phase by dolochar: highlighting optimization, single and binary adsorption isotherms and nutrient release. Process Saf. Environ. 100, 91–107 (2016)

Rout, P.R., Bhunia, P., Dash, R.R.: Evaluation of kinetic and statistical models for predicting breakthrough curves of phosphate removal using dolochar-packed columns. J. Water Process Eng. 17, 168–180 (2017)

Rout, P.R., Bhunia, P., Dash, R.R.: Assessing possible applications of waste organic solid substances as carbon sources and biofilm substrates for elimination of nitrate toxicity from wastewater. J. Hazard. Toxic. Radioact., 04016027 (2016)

Rout, P.R., Dash, R.R., Bhunia, P.: Effectiveness of aegle shell (AS) and groundnut shell (GS) as carbon sources for bio-denitrification of nitrate rich aqueous solution. Adv. Sci. Lett. 22(2), 354–358 (2016)

Rout, P.R., Bhunia, P., Dash, R.R.: Simultaneous removal of nitrogen and phosphorous from domestic wastewater using Bacillus cereus GS-5 strain exhibiting heterotrophic nitrification, aerobic denitrification and denitrifying phosphorous removal. Bioresour. Technol. 244, 484–495 (2017)

Rout, P.R., Dash, R.R., Bhunia, P., Rao, S.: Role of Bacillus cereus GS-5 strain on simultaneous nitrogen and phosphorous removal from domestic wastewater in an inventive single unit multi-layer packed bed bioreactor. Bioresour. Technol. 262, 251–260 (2018)

Sen, S.K., Raut, S., Satpathy, S., Rout, P.R., Bandyopadhyay, B., Mohapatra, P.K.D.: Characterizing novel thermophilic amylase producing bacteria from Taptapani Hot Spring, Odisha, India. Jundishapur J. Microbiol. 7(12), 1–7 (2014)

Bartošová, A., Michalíková, A., Sirotiak, M., Soldán, M.: Comparison of two spectrophotometric techniques for nutrients analyses in water samples. In: Research Papers Faculty of Materials Science and Technology Slovak University of Technology, vol. 20(32), pp. 8–19 (2012)

APHA.: Standard methods for the examination of water and wastewater. American Public Health Association, American Water Works Association, Water Environment Federation, Washington 17, 1.5–3.12 (2005)

Hu, Z., Zhang, J., Li, S., Wang, J., Zhang, T.: Effect of anoxic/aerobic phase fraction on N2O emission in a sequencing batch reactor under low temperature. Bioresour. Technol. 102(9), 5486–5491 (2011)

Li, W., Loyola-Licea, C., Crowley, D.E., Ahmad, Z.: Performance of a two-phase biotrickling filter packed with biochar chips for treatment of wastewater containing high nitrogen and phosphorus concentrations. Process. Saf. Environ. 102, 150–158 (2016)

Kong, Z., Feng, C., Chen, N., Tong, S., Zhang, B., Hao, C., Chen, K.: A soil infiltration system incorporated with sulfur-utilizing autotrophic denitrification (SISSAD) for domestic wastewater treatment. Bioresour. Technol. 159, 272–279 (2014)

Metcalf, E., Eddy, E.: Wastewater Engineering: Treatment and Reuse. McGrawHill, New York (2003)

Wen, X., Zhou, J., Li, Y., Qing, X., He, Q.: A novel process combining simultaneous partial nitrification, anammox and denitrification (SNAD) with denitrifying phosphorus removal (DPR) to treat sewage. Bioresour. Technol. 222, 309–316 (2016)

Zhou, Y., Ganda, L., Lim, M., Yuan, Z., Kjelleberg, S., Ng, W.J.: Free nitrous acid (FNA) inhibition on denitrifying poly-phosphate accumulating organisms (DPAOs). Appl. Microbiol. Biotechnol. 88(1), 359–369 (2010)

Acknowledgements

The authors are thankful to the Indian Institute of Technology Bhubaneswar, India for providing the resources and facilities to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rout, P.R., Dash, R.R., Bhunia, P. (2020). Insight into a Waste Material-Based Bioreactor for Nutrient Removal from Domestic Wastewater. In: Kalamdhad, A. (eds) Recent Developments in Waste Management . Lecture Notes in Civil Engineering, vol 57. Springer, Singapore. https://doi.org/10.1007/978-981-15-0990-2_32

Download citation

DOI: https://doi.org/10.1007/978-981-15-0990-2_32

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0989-6

Online ISBN: 978-981-15-0990-2

eBook Packages: EngineeringEngineering (R0)