Abstract

The conventional bricks are generally made up of clay as its principal constituent. The urbanization and industrialization lead to the use of conventional bricks at a very high rate. Moreover, the rapid increase in population and to meet its needs, new houses, and high-rise buildings are constructed in large numbers, which requires a large number of bricks for its construction. To decrease the extensive use of the clay and finding its substitute is the need of the hour. In the present study, the Fly Ash is used as the substitute of clay and fly ash bricks were made by using fly ash, sand, lime, and Plaster of Paris (POP) in different mix proportions. The fly ash brick specimens of size 230 × 110 × 70 mm were manufactured and various quality parameters like compressive strength at an age of 7 and 28 days, water absorption and dry density were tested. The economical mix design of the fly ash bricks for maximum compressive strength and its rate analysis was also done. It was observed from the results that the compressive strength decreases with increase in fly ash content and increases with an increase in sand and lime content in fly ash bricks. Water absorption value increases with an increase in fly ash content and decreases with increase sand and lime content in fly ash bricks.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A vast number of bricks are required for construction like new houses, elevated structures for expanding populace at a high rate. The urbanization prompts the utilization of regular bricks at a high rate (Akhtar et al. 2011). The ordinary bricks are for the most part comprised of mud as its standard constituent thus it is nearly fatigue. To conquer this issue some option is required. So to beat this issue or to lessen this issue up to some degree, fly powder can be used in set up of earth in assembling the bricks named fly ash bricks (Mishra 2015). This will prompt the reuse of fly ash cinder and spare the best layer of soil, which is extremely ripe utilized as dirt in customary bricks. Also, the cost of fly ash bricks will be less when contrasted with ordinary bricks (Samander et al. 2013). According to Government standards, we can utilize at least 25% of fly powder in bricks, where fly ash debris is being created (Naganathan et al. 2015).

Fly ash is a finely divided residue resulting from the combustion of powdered coal, transported by flue gases and collected by electrostatic precipitators (Gawatre and Vairagade 2014). It contains a small amount of unburnt carbon, which is acidic in nature. Its main constituents are silica, aluminum oxide, and ferrous oxide. Chemical composition of fly ash is shown in Table 1.

With the increase in the limit of warm power age in India the production of fly powder is all time high, which is roughly 50 million tons for every year. There are more than 70 warm power plants are in production and in future this number may increase to satisfy the requests of expanding populace (Banu et al. 2013).

To overcome this problem and to empower the usage of fly ash debris in 2003, the Government of India made it mandatory to utilize fly ash cinder with soil on weight to weight premise. It ought to be utilized for assembling of block tiles or squares inside a span of 100 km from coal-based warm power plants. From decades ago, endeavors are being made to discover a satisfactory technique for the transfer and appropriate use of fly fiery remains.

Endeavor has been made by assembling the fly ash bricks utilizing fly ash cinder as a rule constitute and blending with Coarse sand, Lime, and Plaster of Paris (POP) (Kumar and Rinku 2012).

2 Methodology

To accomplish the goal, with the assistance of writing audit and gathered distinctive fly ash brick tests in the wake of testing, we choose one proportion for fly ash debris, coarse sand, lime, and POP. Three classes of bricks were made. In the first class, fly ash variety was done and different parameters were kept consistent. In the second class, the coarse sand variety was done and different parameters were kept steady. Also in the third classification, hydrated lime was kept consistent and different parameters were kept steady.

Blend extents fly ash debris and all other crude materials were taken from assembling the unit. Each material in the required rate by weight as appeared in configuration blend were brought close to the blend. Initially the lime and sand were blended for 2–3 min. After that fly ash was blended in and required amount of water was included and blended for 2–3 min to acquired homogeneous blend and consistency in shading. The varying quantitites of fly ash, coarse sand and lime in the mixes are presented in Tables 2, 3 and 4 respectively.

3 Result and Discussions

Category 1 (Fly Ash Variation)

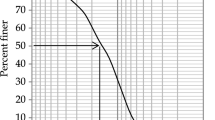

See Fig. 1.

Compressive Strength (N/mm2)

See Table 5.

Category 2 (Coarse Sand Variation)

It was observed from the conducted experiment, with an increase in the sand content in fly ash bricks the compressive strength increases. It was observed from the conducted experiments, with an increase in coarse sand content in fly ash bricks average water absorption value decreases and average dry density increases (Fig. 2 and Table 6).

Category 3 (Hydrated Lime Variation)

It was observed from the conducted experiments, with an increase in hydrated lime content in fly ash bricks average water absorption value decreases up to 25% and average dry density increases (Fig. 3 and Table 7).

4 Conclusion

-

1.

The compressive strength decreases with increase in fly ash content in fly ash bricks. The compressive strength varies from 8.69 to 15.81 N/mm2 and cost varies from Rs. 1.28 to Rs. 1.99 with a variation of fly ash from 40 to 70 kg keeping other parameters constant.

-

2.

The compressive strength increases with increase in coarse sand content in fly ash bricks. The compressive strength varies from 10.67 to 12.84 N/mm2 and cost varies from Rs. 1.47 to Rs. 2.03 with a variation of sand from 10 to 40 kg keeping other parameters constant.

-

3.

The compressive strength increases with increase in hydrated lime content in fly ash bricks optimum at 25%. The compressive strength varies from 8.43 to 13.04 N/mm2 and cost varies from Rs. 1.28 to Rs. 1.90 with a variation of lime from 10 to 30 kg keeping other parameters constant.

References

Akhtar JN, Alam J, Akhtar MN (2011) Bricks with total replacement of clay by fly ash mixed with different materials. Int J Eng Sci Technol (IJEST) 3(10):7338–7347

Banu T, Billah M, Gulshan F, Kurny ASW (2013) Experimental studies on fly ash-sand-lime bricks with gypsum addition. Am J Mater Eng Technol 1(3):35–40

Gawatre DW, Vairagade LN (2014) Strength characteristics of different types of bricks. Int J Sci Res (IJSR) 3(10):2247–2252

Kumar PA, Rinku P (2012) Comparative study of compressive strength of bricks made with various materials to clay bricks. Int J Sci Res Publ 2(7):7–10

Mishra V (2015) Evolution of properties of fly ash-lime bricks with soil. IJSTE—International J Sci Technol & Eng 1(9):12–18

Naganathan S, Yousef A, Mohamed O, Mustapha KN (2015) Performance of bricks made using fly ash and bottom ash. Constr Build Mater 96:576–580

Samander S, Dwivedi AK, Agarwal S (2013) Effect of silica fume on fly ash cement bricks—an experimental study. IOSR J Mech Civ Eng (IOSR-JMCE) 6(4):14–18

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, H., Singh, J., Kapoor, K. (2019). To Study the Strength Characteristics of Bricks Made with Fly Ash. In: Agnihotri, A., Reddy, K., Bansal, A. (eds) Sustainable Engineering. Lecture Notes in Civil Engineering, vol 30. Springer, Singapore. https://doi.org/10.1007/978-981-13-6717-5_37

Download citation

DOI: https://doi.org/10.1007/978-981-13-6717-5_37

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6716-8

Online ISBN: 978-981-13-6717-5

eBook Packages: EngineeringEngineering (R0)